Connect method of heat-shrinkable sleeve

A heat-shrinkable sleeve and connection method technology, which is applied to tubular items, household appliances, other household appliances, etc., can solve the problems of high air leakage rate, fire hazard in lighter sintering method, and cut fingers, etc., and achieve sealing performance. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

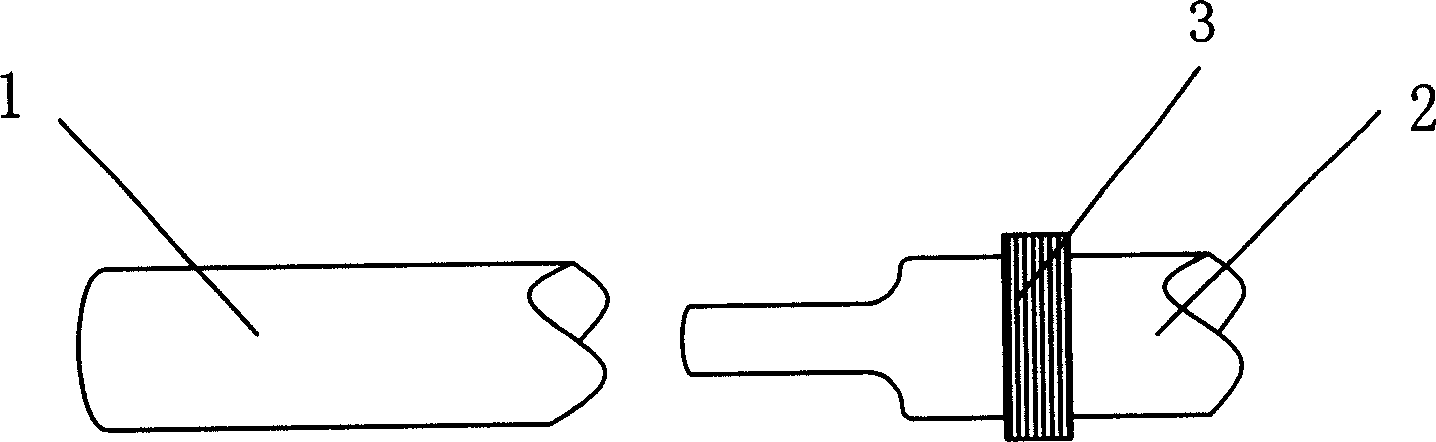

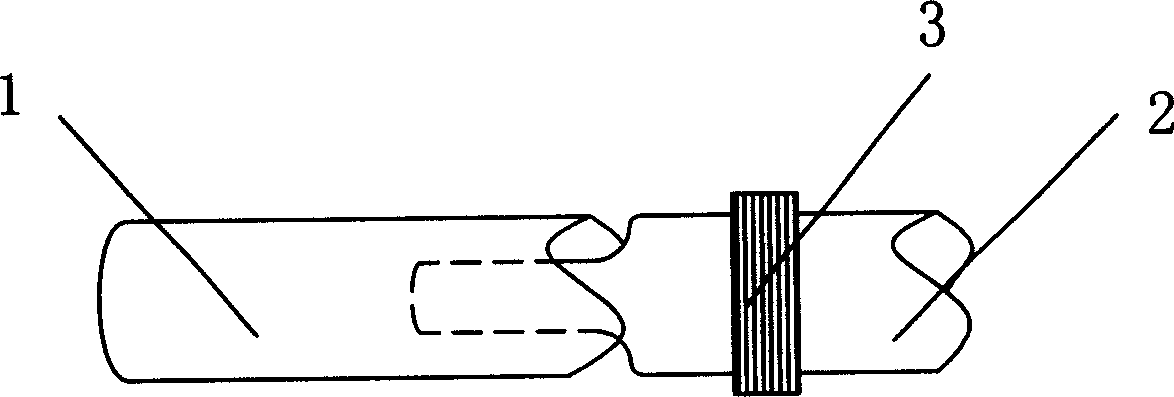

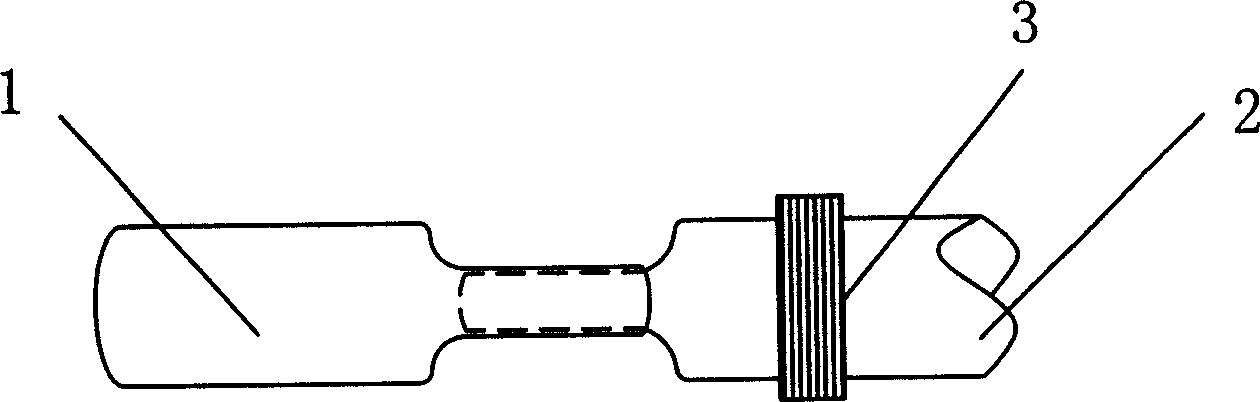

[0016] see Figure 1 to Figure 4 A method for connecting heat-shrinkable sleeves of the present invention is to connect and seal at least two sections of sleeves to form an overall airtight heat-shrinkable sleeve, that is, the heat-shrinkable sleeve has at least two sections of sleeves , and the outermost ends of the two outermost sections of the heat-shrinkable sleeve are sealed ends, and the method includes a connecting step and a sealing step. This connection step is to connect two adjacent sections of casing, and define the two sections of casing as the first casing 1 and the second casing 2 respectively. One and the two ends of the second casing 1, 2, aim the butt end of the first casing 1 at the heat source and heat for a few seconds to pre-shrink. At this time, the diameter of the butt end of the first casing 1 becomes smaller, and then the end Dock and insert into the butt end of the second casing 2, and then align the butt joints of the first and second sleeve 1, 2 wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com