Magnetoelectricity type passive velocity transducer and manufacturing technology thereof

A speed sensor, magnetoelectric technology, applied in the field of magnetoelectric passive speed sensor and its manufacturing process, can solve the problems of no temperature resistance, small induced voltage, low sensitivity, etc., to improve high temperature resistance and reduce work The effect of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with accompanying drawing:

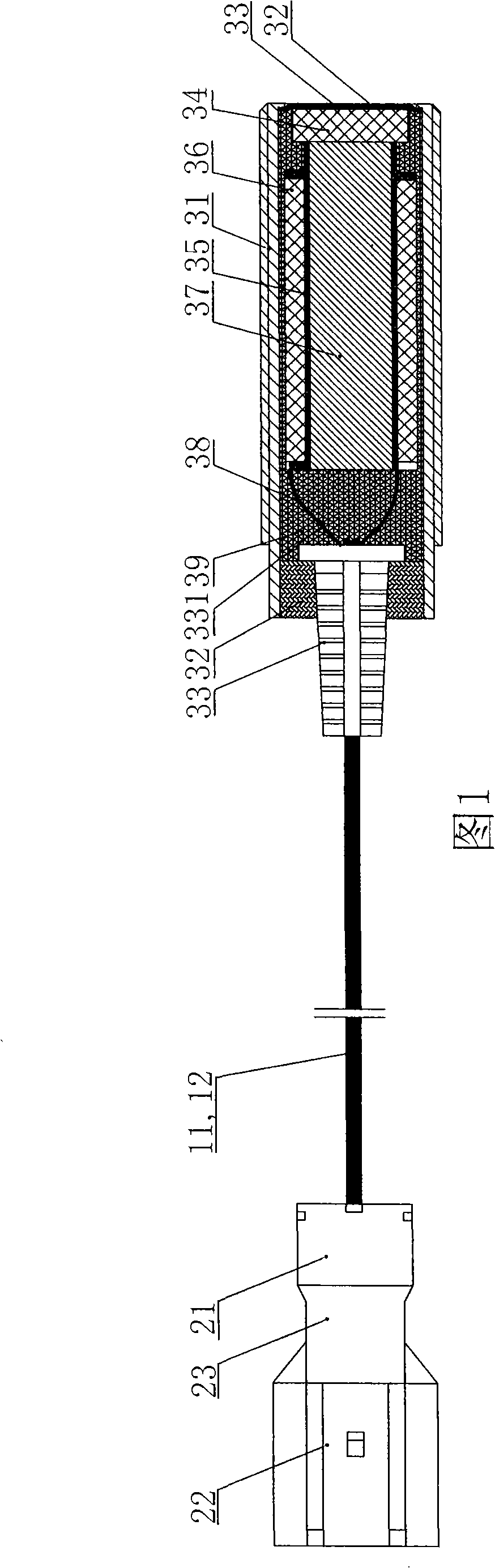

[0032] Please refer to FIG. 1 , the magnetoelectric passive speed sensor is composed of a connector 2 and a speed sensor 3 fixed at both ends of an insulated wire 12 in a heat-shrinkable sleeve 11 .

[0033] Described speed sensor 3 is made of shell 31, shell 31 head by the cable buckle 30 of plug 32 encapsulation, shell 31 afterbody by the plug 32 of electronic silica gel encapsulation, mica sheet 33 and magnet 34, the coil that magnet 34 other end is provided with Skeleton 35, the combined coil 36 wound on the bobbin 35 by the enameled wire, the iron core 37 placed in the center of the bobbin 35, the electrical connection between the head of the iron core 37 and the double insulated wire 331 drawn from the wire buckle 30 is made by thermal shrinkage. The insulated lead wire 38 set in the bushing and the two-component silica gel 39 that is integrally potted in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com