Fluoride elastic double-wall heat-shrinkable sleeve and preparation method thereof

A heat-shrinkable sleeve and elastic technology, applied in the direction of insulators, electrical components, circuits, etc., can solve problems affecting equipment operation, difficult sealing protection, poor wear resistance, etc., to increase the scope of application, improve elasticity, and wear resistance excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

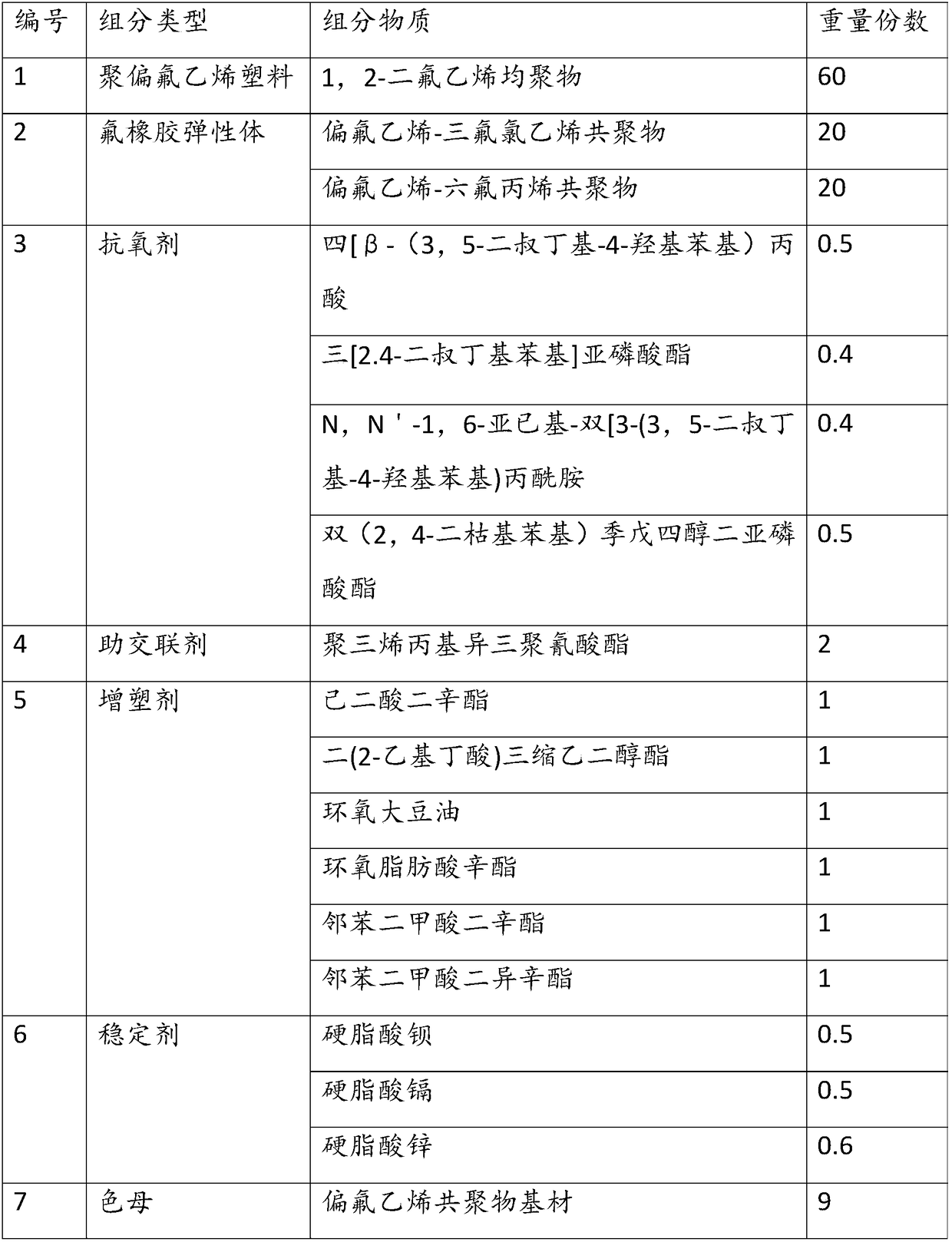

[0039] Raw materials of the fluoride elastic double-wall heat-shrinkable sleeve (by weight):

[0040] (1) Skin raw material components: 60 parts of 1,2-difluoroethylene homopolymer; 40 parts of blends of vinylidene fluoride-chlorotrifluoroethylene copolymer and vinylidene fluoride-hexafluoropropylene copolymer ;Tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid, tris[2.4-di-tert-butylphenyl]phosphite, N,N'-1,6-hexylene Base-bis[3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionamide, bis(2,4-dicumylphenyl)pentaerythritol diphosphite four kinds of blends 1.8 parts ; 2 parts of polytriallyl isocyanurate; dioctyl adipate, bis(2-ethylbutyrate) triethylene glycol ester, epoxy soybean oil, epoxy fatty acid octyl ester, ortho 6 parts of blends of dioctyl phthalate and diisooctyl phthalate; 1.6 parts of blends of barium stearate, cadmium stearate, and zinc stearate; vinylidene fluoride There are 9 parts of copolymer base material, and the proportion of vinylidene fluoride copoly...

Embodiment 2

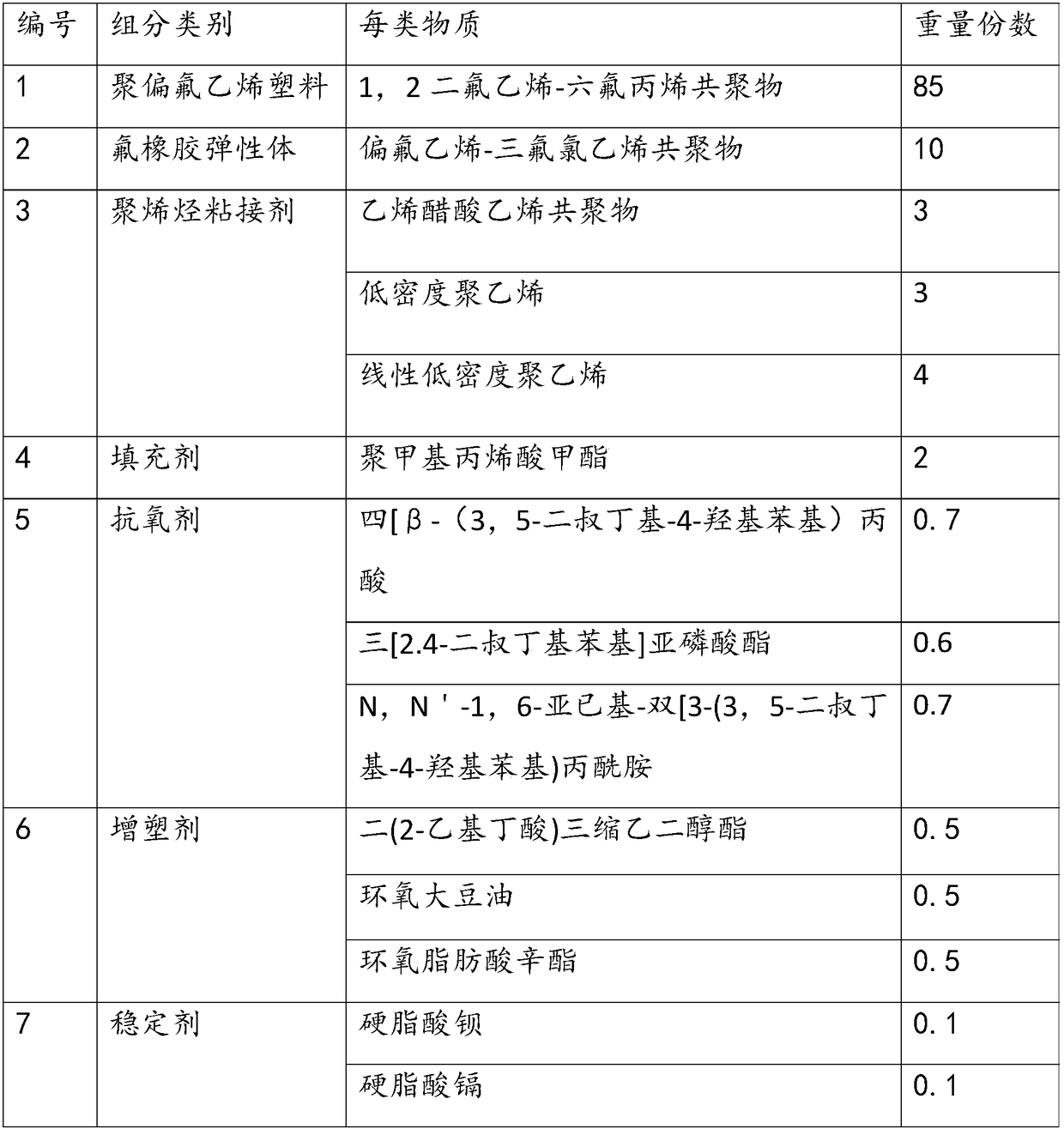

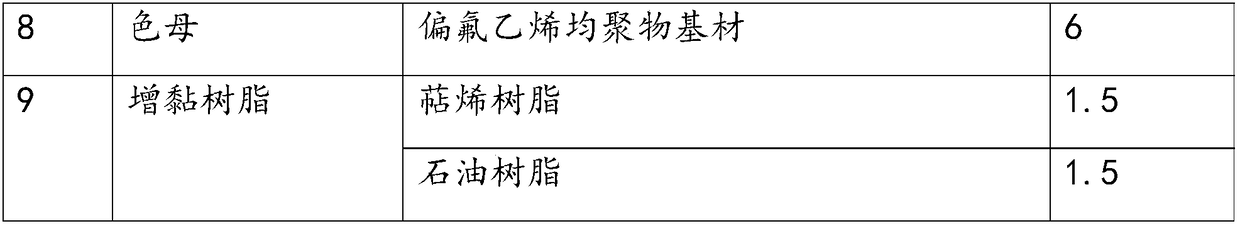

[0054] Raw materials of the fluoride elastic double-wall heat-shrinkable sleeve (by weight):

[0055] (1), outer skin raw material components: 98 parts of blends of 1,2-difluoroethylene homopolymer and 1,2 difluoroethylene-hexafluoropropylene copolymer; vinylidene fluoride-tetrafluoroethylene-hexafluoroethylene 5 parts of fluoropropylene terpolymer; tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid, tris[2.4-di-tert-butylphenyl]phosphite, N,N '-1,6-hexylidene-bis[3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionamide, bis(2,4-dicumylphenyl)pentaerythritol diphosphite , β-(3,5-di-tert-butyl-4-hydroxyphenyl) octadecyl propionate, bis(2,4-di-tert-butylphenyl) pentaerythritol diphosphate, bis(octadecyl base) 2.5 parts of a blend of seven kinds of pentaerythritol diphosphite; three kinds of triallyl cyanurate, triallyl isocyanurate, and polytriallyl isocyanurate 4 parts of blends; 1 part of blends of dioctyl phthalate, diisooctyl phthalate, and diisodecyl phthalate; barium ...

Embodiment 3

[0070] Raw materials of the fluoride elastic double-wall heat-shrinkable sleeve (by weight):

[0071] (1), outer skin raw material components: 74 parts of 1,2 difluoroethylene-hexafluoropropylene copolymer; vinylidene fluoride-chlorotrifluoroethylene copolymer, vinylidene fluoride-hexafluoropropylene copolymer, vinylidene fluoride-four 25 parts of blends of three kinds of vinyl fluoride-hexafluoropropylene terpolymer; 0.2 parts of β-(3,5-di-tert-butyl-4-hydroxyphenyl) octadecyl propionate; 6 parts of a blend of triallyl phthalate and triallyl isocyanurate; dioctyl phthalate, diisooctyl phthalate, diisodecyl phthalate , dioctyl adipate, bis(2-ethylbutyrate) triethylene glycol ester, epoxidized soybean oil, 4 parts of a blend of seven kinds of epoxy fatty acid octyl ester; barium stearate, monoalkane 0.2 parts of two kinds of blends based on tin; 5 parts of vinylidene fluoride homopolymer substrate, and the proportion of vinylidene fluoride homopolymer substrate gradually incre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com