Continuous high-strength fiber resin-based compound core for overhead conductor and preparation method thereof

A high-strength fiber and overhead wire technology, which is applied in the direction of cable/conductor manufacturing, conductors, insulated conductors, etc., can solve problems such as low damage tolerance, inconvenient production and laying-out construction, and performance degradation of composite cores, so as to improve the safety of use , Conducive to the popularization and application and the effect of reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

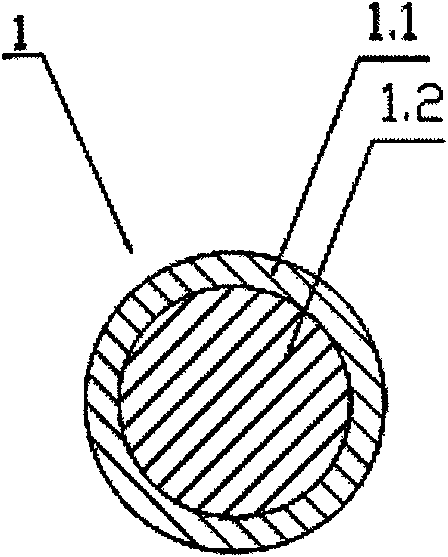

[0032] Embodiment 1: see figure 1 , a single composite core 1 for stranding, which is composed of T700 carbon fiber with a volume fraction of 75V / V% and epoxy resin of 25V / V% cured to form an inner core 1.2 with a diameter of Φ2mm, and an outer layer composed of glass fiber textile tape and G40122 epoxy flexible resin cured Layer 1.1, concentrically compounded to obtain a composite core with a diameter of 2.5 mm. Among them, the glass transition temperature of the inner and outer layer resin is 185°C, and the curing time is 2.5 minutes. According to the prior art, it is impregnated and pultruded to form a composite core, and the semi-cured (soft state with hard rubber) composite core is obtained by pultruding at 120°C for 1 minute.

Embodiment 2

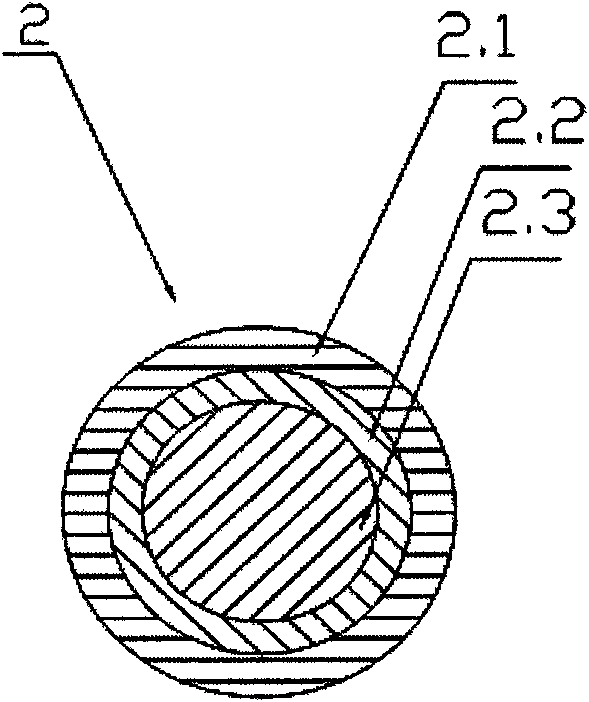

[0033] Example 2: see figure 2 , as in Example 1, the single composite core 2 is composed of three concentric composite layers, in which the outer two layers 2.1 and 2.2 are made of flexible resin, such as PLM-3203. The single composite core is pultruded into a semi-cured state.

Embodiment 3

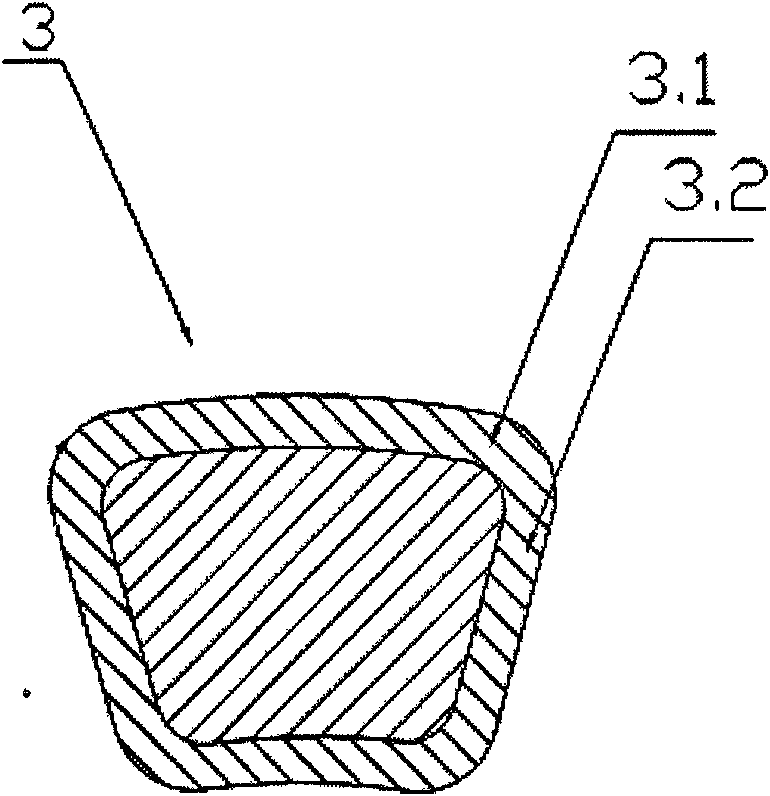

[0034] Embodiment 3: see image 3 , as in Example 1, the cross-section of the single composite core 3 is tile-shaped, wherein the core is made of carbon fibers cured by thermosetting epoxy resin, the outer layer 3.1 and the sub-outer layer 3.2 are longitudinally wrapped by alkali-free glass fibers, and the flexible resin is cured. The single composite core is pultruded into a semi-cured state.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer layer thickness | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com