Ultralight paper clay and preparation method thereof

A technology of paper clay and bonding materials, which is applied in the field of ultra-light paper clay and its preparation, which can solve the problems of sticky hands, heavy products, sticky plasticine, etc., and achieve improved strength and elasticity, improved softness, and is not easy to break Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

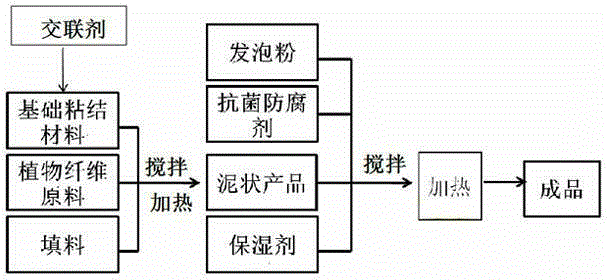

[0045] A preparation method of ultra-light paper clay, comprising the following steps:

[0046]1) Boil water and viscous material according to (5-10): 1 mass ratio to form basic cohesive material, and take 20-75 parts by mass;

[0047] 2) Select the filler, and crush the filler into particles of suitable size, and take 10-70 parts by mass;

[0048] 3) The plant fiber is subjected to beating or refining treatment until the plant fiber becomes soft and cut and divided;

[0049] 4) After the cross-linking agent is completely dissolved, add it to step 1) and stir evenly;

[0050] 5) Add the crushed filler in step 2) and the treated plant fiber in step 3) to step 1), mix well and heat to form a mud-like product; the mixing process and heating in step 5) are at the same time To carry out, the heating temperature is 60-100°C, so as to keep the bonding material in an easy-to-flow state, reduce the stirring resistance, and avoid the phenomenon of uneven stirring.

[0051] 6) Add 0.8...

Embodiment 1

[0056] 1) Boil water and viscous material according to the mass ratio of 5:1 to form the basic bonding material, and take 20 parts by mass; the boiling time is 0.5 hours, and the boiling temperature is 60°C.

[0057] 2) Select the filler and crush the filler, wherein the particle size of the crushed particles is 10 mesh, and take 70 parts by mass;

[0058] 3) The plant fibers are beaten or refined until the plant fibers become soft and cut and divided into filaments to make them better mixed and improve the cracking of the product; the mass fraction of water in the plant fibers is 40% .

[0059] 4) After the cross-linking agent is completely dissolved, add it to step 1) and stir evenly;

[0060] 5) Take 1 portion of the crushed filler in step 2) and the treated plant fiber in step 3) and add it to step 1), and mix well to form a mud-like product; the mixing process in step 5) It needs to be completed in a heated state, and the heating temperature is 60°C, so as to keep the b...

Embodiment 2

[0065] 1) Boil water and viscous material according to the mass ratio of 8:1 to form the basic bonding material, and take 40 parts by mass; the boiling time is 2 hours, and the boiling temperature is 80°C.

[0066] 2) Select the filler and crush the filler, wherein the particle size of the crushed particles is 500 mesh, and take 35 parts by mass;

[0067] 3) The plant fibers are subjected to beating or refining treatment until the plant fibers become soft and cut and divided into filaments to make them better mixed and improve the cracking of the product; the water content in the plant fibers is 70%.

[0068] 4) After the cross-linking agent is completely dissolved, add it to step 1) and stir evenly;

[0069] 5) Add 9 parts of the crushed filler in step 2) and the treated plant fiber in step 3) to step 1), and mix well to form a muddy product; the mixing process in step 5) It needs to be completed in a heated state, and the heating temperature is 80°C, so as to keep the bondi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com