Polycarbonate high polymer material and preparation method thereof

A polymer material, polycarbonate technology, applied in the field of polycarbonate polymer materials and its preparation, can solve the problems of tensile strength and elongation at break, etc., to achieve the effect of improving elasticity and strength, and expanding the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

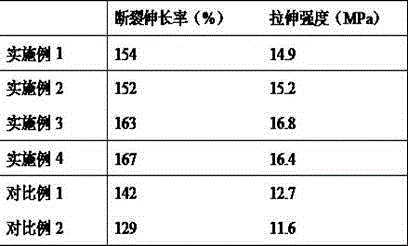

Examples

Embodiment 1

[0033] (1) Take 30 parts of polycarbonate, 5 parts of polyethylene terephthalate, 7 parts of cyclomethicone, 4 parts of polyvinyl alcohol phosphate, and 3 parts of tetrabutyl titanate by weight. 10 parts of polyethylene, 5 parts of polychlorotrifluoroethylene, 5 parts of glass fiber, and 3 parts of silicon dioxide, mix the above ingredients, adjust the temperature to 60 ° C, and stir for 2 hours;

[0034] (2) After cooling, melt and extrude the mixture. The extrusion method is twin-screw extruder extrusion. The temperature in the zone is 200°C, and the temperature in the third zone is 230°C. After extrusion, it is pelletized by a pelletizer to prepare polycarbonate polymer materials.

Embodiment 2

[0036] (1) Take 14 parts of polycarbonate, 10 parts of polyethylene terephthalate, 3 parts of cyclomethicone, 10 parts of polyvinyl alcohol phosphate, and 9 parts of tetrabutyl titanate by weight. , 4 parts of polyethylene, 12 parts of polychlorotrifluoroethylene, 2 parts of glass fiber, and 7 parts of silicon dioxide, mix the above ingredients, adjust the temperature to 70 ° C, and stir for 1 hour;

[0037] (2) After cooling, melt and extrude the mixture. The extrusion method is twin-screw extruder extrusion. The temperature in the zone is 210°C, and the temperature in the third zone is 220°C. After extrusion, it is pelletized with a pelletizer to prepare polycarbonate polymer materials.

Embodiment 3

[0039] (1) Take 26 parts of polycarbonate, 6 parts of polyethylene terephthalate, 6 parts of cyclomethicone, 9 parts of polyvinyl alcohol phosphate, and 8 parts of tetrabutyl titanate by weight. , 5 parts of polyethylene, 10 parts of polychlorotrifluoroethylene, 4 parts of glass fiber, and 4 parts of silicon dioxide, mix the above ingredients, adjust the temperature to 60 ° C, and stir for 2 hours;

[0040] (2) After cooling, melt and extrude the mixture. The extrusion method is twin-screw extruder extrusion. The temperature in the zone is 200°C, and the temperature in the third zone is 230°C. After extrusion, it is pelletized by a pelletizer to prepare polycarbonate polymer materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com