Superhigh load scissor-type lifting platform

A lifting platform, super large technology, applied in the direction of lifting frame, lifting device, etc., can solve the problems that cannot meet the work requirements of super large load, limited arm bearing capacity, unfavorable manual operation, etc., achieve large elasticity and strength, improve stability, Good load drift effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

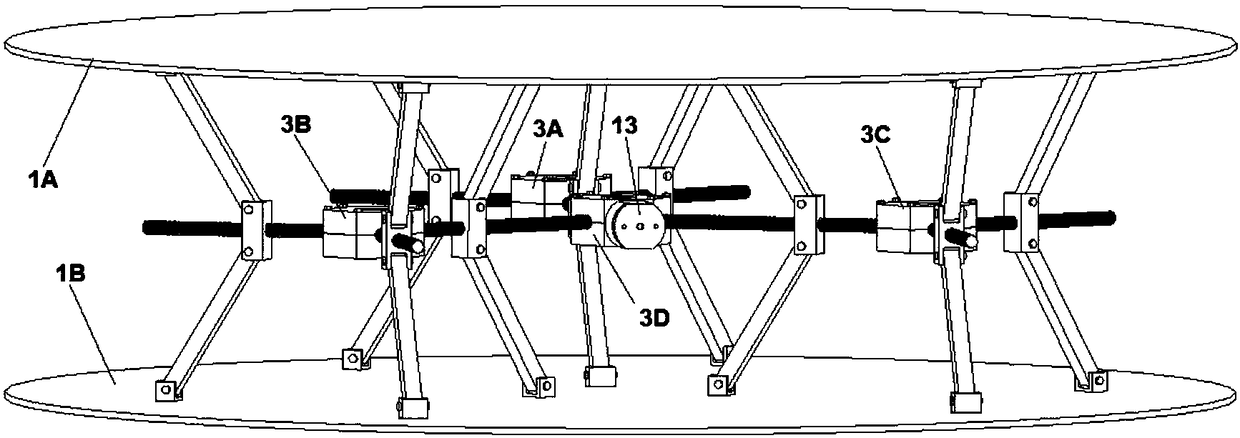

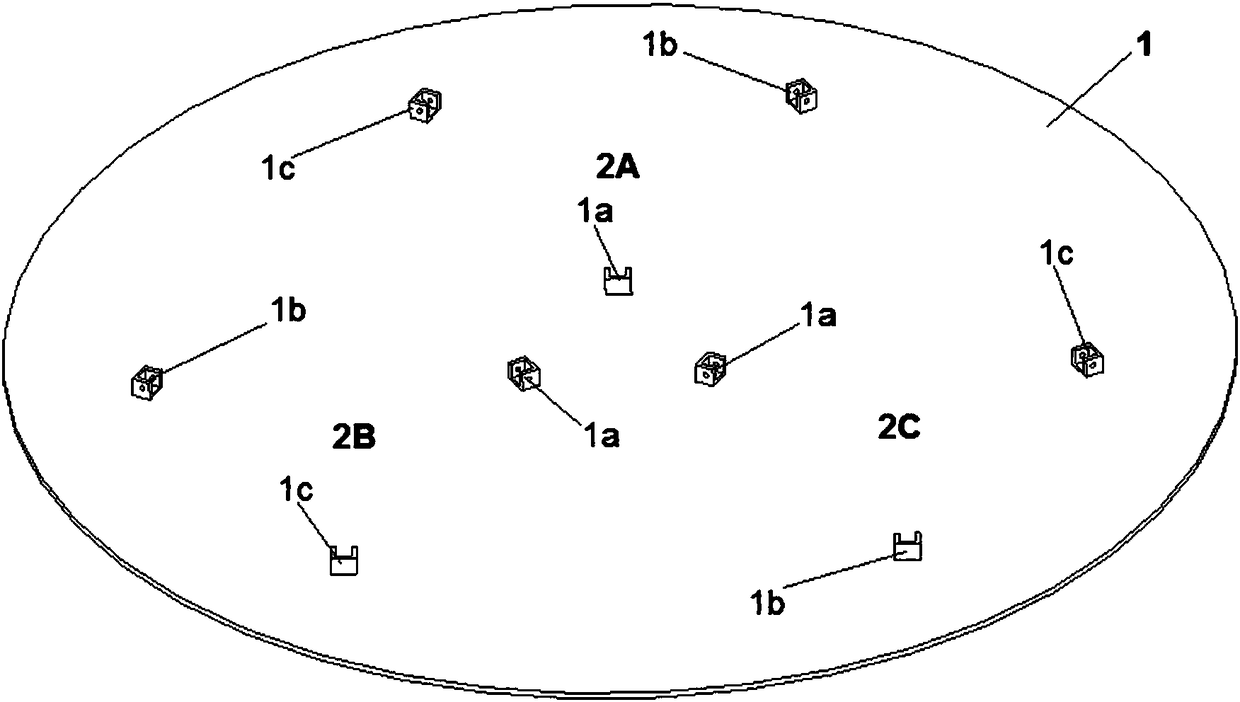

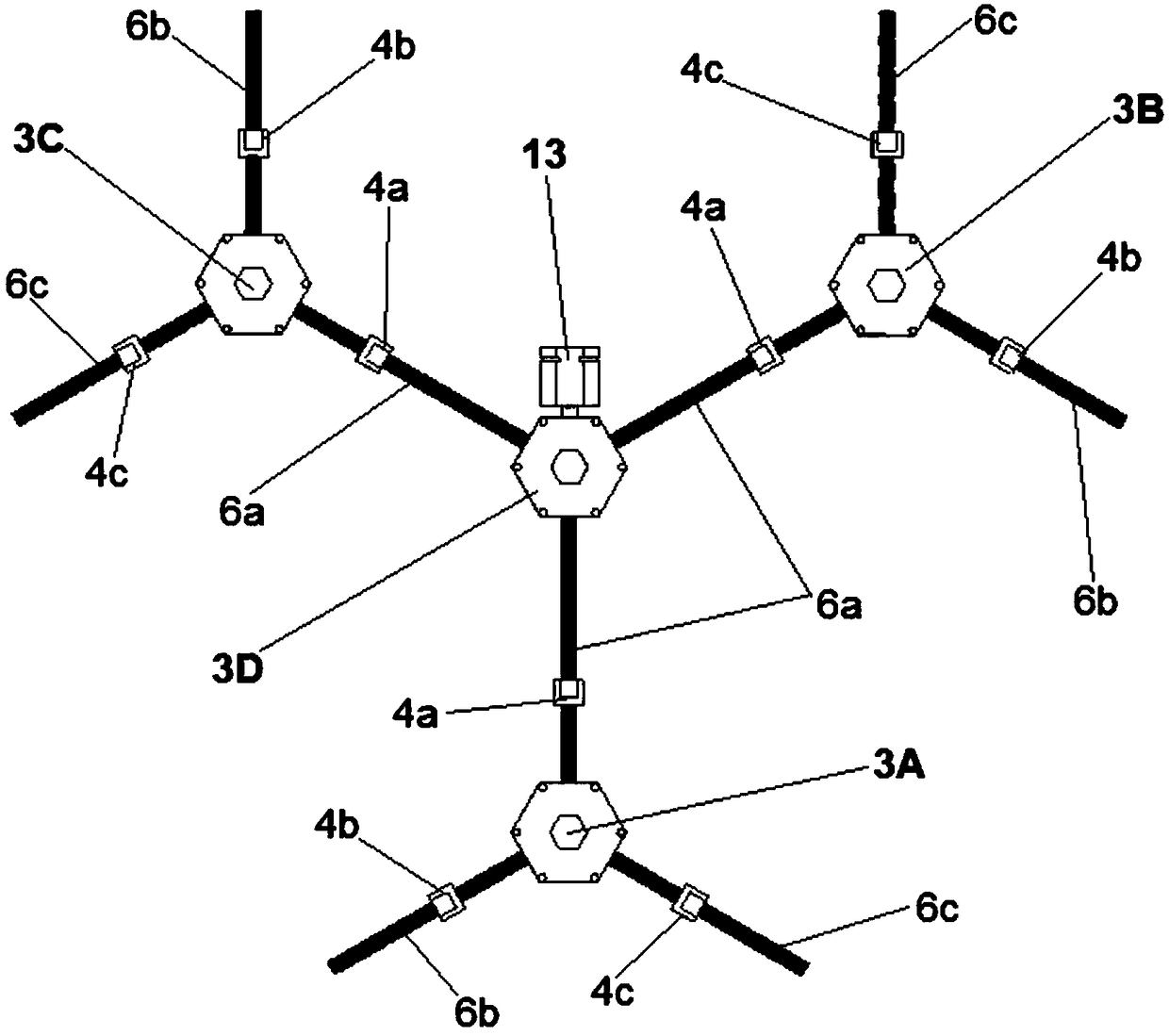

[0058] The super-large load scissor lift platform proposed by the present invention includes a top plate and a bottom plate supported by three three-arm support units. The top and bottom plates have the same size and shape. Designed with a spiral pattern on the outer surface of the top and bottom plates to increase traction and friction with ground and lifting surfaces. For the shape of the top and bottom plates, several designs such as round, triangular and star are possible.

[0059] Both the top plate and the bottom plate have three sets of hinged contact points for connecting the flat plate and the arm, and each set of hinged contact points is used for connecting the corresponding three-arm support unit with the plate. Each three-arm support unit has three corresponding arms, and each arm is composed of two upper and lower links. The upper arm link connects the top plate to the upper groove of the elbow bracket, and the lower arm link connects the elbow bracket The lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com