Ultralow-temperature high-vacuum atomic force microscope system

An atomic force microscope and high vacuum technology, used in scanning probe microscopy, discharge tubes, instruments, etc., can solve problems such as inability to achieve sample testing, achieve convenient maintenance and replacement, ensure independence, and reduce external noise. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

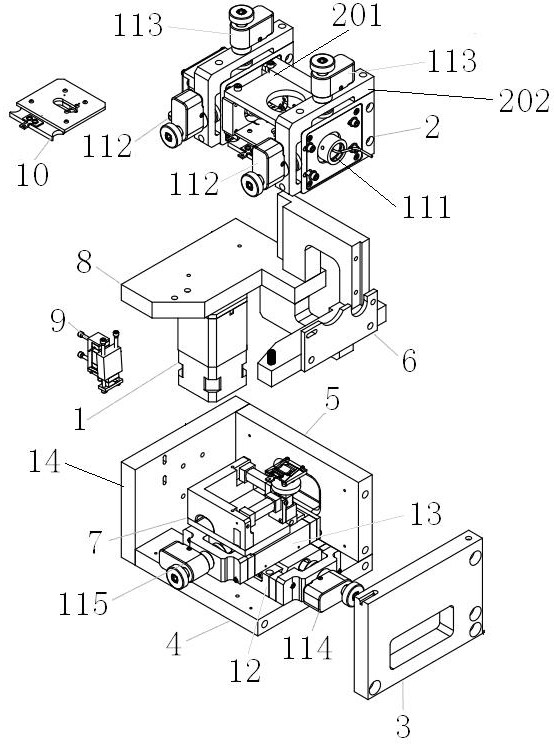

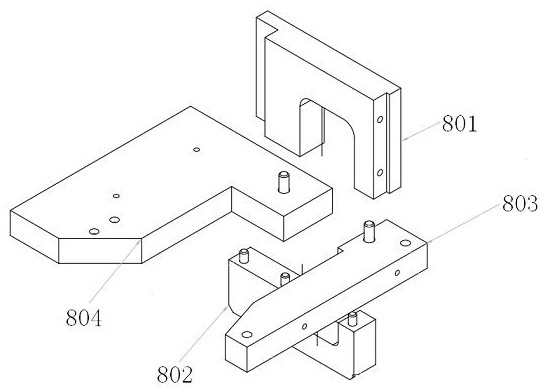

[0032] Such as Figure 1~7 As shown, an ultra-low temperature high vacuum atomic force microscope system includes an integrated fiber optic optical lever system 2, a Z-axis lifting platform 8, and a support with a built-in X-axis moving stage 12, a Y-axis moving stage 13, and a 15-micron scanner 7. seat.

[0033] A vacuum low-temperature linear motion motor 1 is provided between the support and the Z-axis lifting platform 8; a light lever support frame 6 is provided on one side of the Z-axis lifting platform 8, and a Z-axis vacuum low-temperature motor movement limiter 9 is provided on the other side , the bottom is connected with the support; the optical lever support frame 6 is connected with the integrated optical fiber optical lever system 2; the X-axis mobile platform 12 is provided with a Y-axis mobile platform 13, and the Y-axis mobile platform 13 is provided with a 15 micron scanner 7.

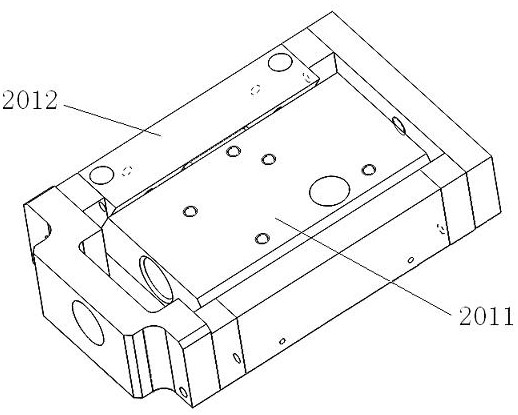

[0034]Wherein: the integrated optical fiber optic lever system 2 includes a mobi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com