Beneficiation method for pegmatite type spodumene

A beneficiation method and spodumene technology, applied in chemical instruments and methods, flotation, wet separation, etc., can solve the problems of low spodumene concentrate grade and high beneficiation cost, and improve selectivity and collection capacity. , the effect of reducing the amount of raw ore and reducing the consumption of pharmaceuticals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

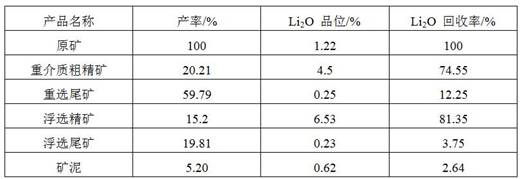

Embodiment 1

[0031] Embodiment 1, a kind of beneficiation method for pegmatite type spodumene, its steps are as follows:

[0032] (1) Crushing, screening and grading: Spodumene ore is crushed to a suitable size through crushing and screening, and then divided into coarse and fine particles through grading. , Desliming operation;

[0033] (2) Dense medium pre-selection: the coarse-grained materials after ore washing and desliming are fed into the heavy medium sorting operation, and the dense medium concentrate and heavy medium tailings are sorted out;

[0034] (3) Grinding and flotation: the fine-grained minerals and the slime produced by the desliming operation are fed into the classification operation to remove part of the fine ore slime; the dense medium coarse concentrate is separated from the underflow of the desliming operation Grinding and flotation operations are carried out to finally obtain spodumene concentrate.

[0035] In the dense medium pre-selection operation, the dense me...

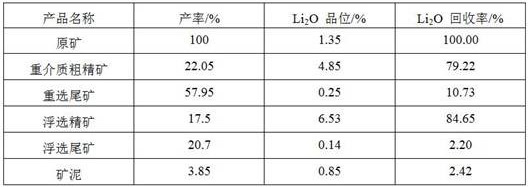

Embodiment 2

[0048] Embodiment 2, a kind of beneficiation method for pegmatite type spodumene, its steps are as follows:

[0049] (1) Crushing, screening and grading: Spodumene ore is crushed to a suitable particle size through crushing and screening, and then divided into coarse and fine particle sizes through grading operations, and the grading particle size is controlled at 4mm;

[0050] (2) Heavy medium pre-selection: the coarse-grained materials of the classification operation are first sent to the cylindrical washing machine for scrubbing, and the scrubbed pulp is sent to a stage of desliming operation. The deslimed particle size is controlled at 0.75mm, and the deslimed The underflow is fed into the dense medium separation operation, and the dense medium concentrate and heavy medium tailings are separated out. The heavy medium concentrate and tailings are fed into the next process after the desliming operation, and the overflow and screening of the first stage of desliming operation ...

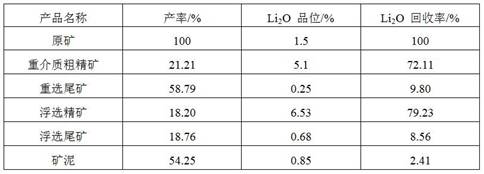

Embodiment 3

[0057] Embodiment 3, a kind of beneficiation method for pegmatite type spodumene, its steps are as follows:

[0058] (1) Crushing, screening and grading: Spodumene ore is crushed to a suitable particle size through crushing and screening, and then divided into coarse and fine particle sizes through grading operations, and the grading particle size is controlled at 3mm;

[0059] (2) Heavy medium pre-selection: the coarse-grained materials of the classification operation are first sent to the cylindrical washing machine for scrubbing, and the scrubbed pulp is sent to a stage of desliming operation. The deslimed particle size is controlled at 0.75mm, and the deslimed The underflow is fed into the dense medium separation operation, and the dense medium concentrate and heavy medium tailings are separated out. The heavy medium concentrate and tailings are fed into the next process after the desliming operation, and the overflow and screening of the first stage of desliming operation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com