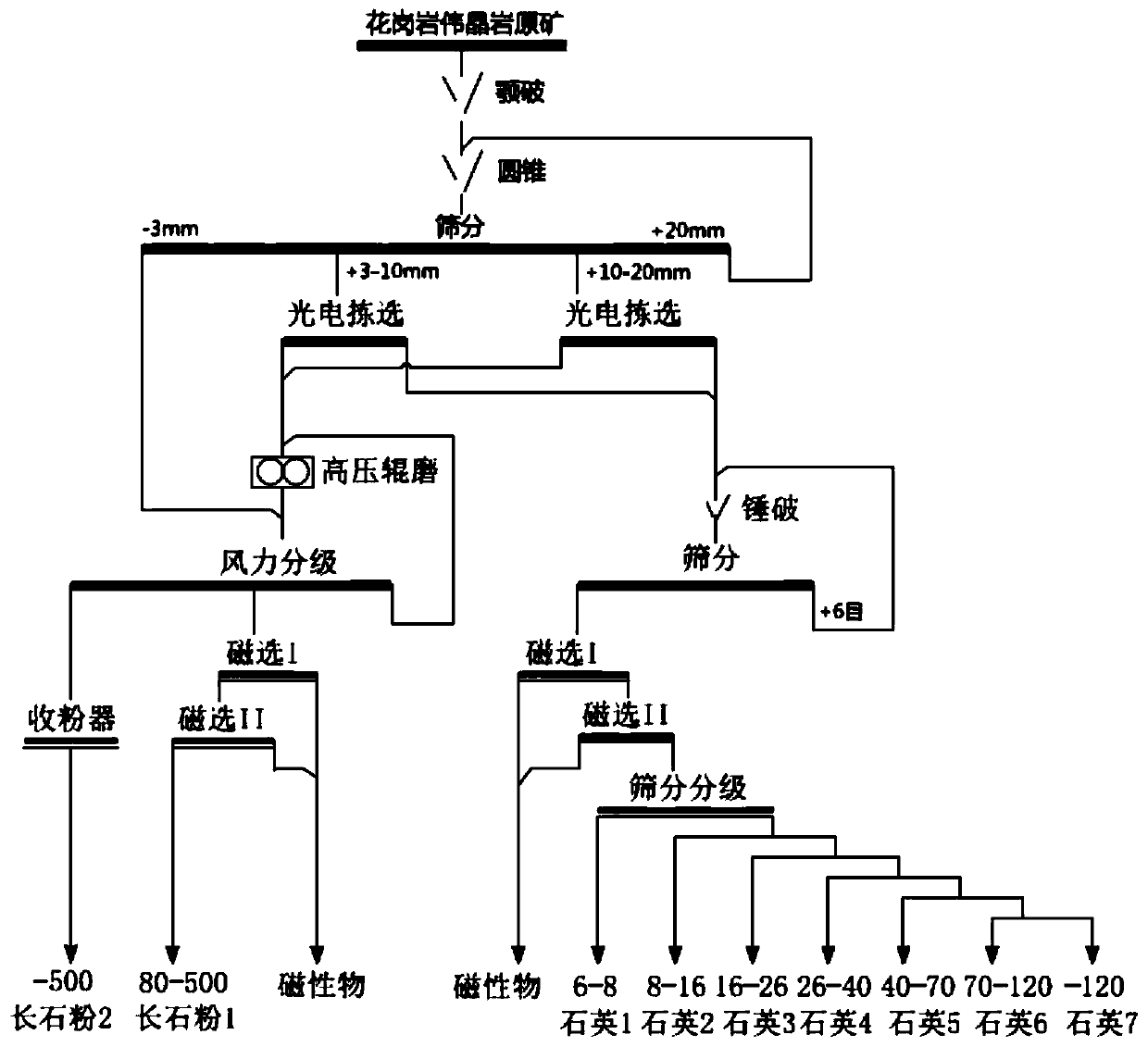

Method for coarse grain separation and dry-type powdering of granite pegmatite

A technology of dry pulverization and pegmatite, applied in the direction of solid separation, etc., can solve the problems of difficulty in realizing industrial scale production, secondary pollution of materials, and large energy consumption, so as to avoid drying energy consumption, large processing capacity, The effect of reducing energy costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The test sample is a grano-pegmatite-type feldspar quartz ore in Luoyang, Henan Province, the raw ore grade is k 2 O>7%, Fe 2 o 3<0.13%, using the technological process of the present invention to carry out intelligent photoelectric sorting-high-pressure roller final grinding for purification, sorting and powder making. The intelligent photoelectric sorting control sets the sorting target to hit white, the sensitivity value is 80, the spot value is 20, and the sorting high-pressure air pressure is 0.8MPa. High-pressure roller mill: When the high-pressure roller mill is working, the pressure between the rollers is 4-5MPa, the roller speed is 1.6m / min, and the roll gap is 5-20mm. The fineness of the granular material can be dynamically adjusted and optimized by adjusting the air volume of the classifier and the rotor speed. After the closed-circuit balance between the high-pressure roller mill and the V-type classifier, the cycle load is 150-280%. Feldspar powder 1 wit...

Embodiment 2

[0040] The test sample is a granite pegmatite mine in Turpan, Xinjiang, the raw ore grade is k 2 O>9%, Fe 2 o 3 <0.13%, intelligent photoelectric sorting feeding particle size 2-18mm. The technological process of the present invention is used for testing, and the intelligent photoelectric sorting control sets the sorting target as whitening, the sensitivity value is 55, the spot value is 10, and the sorting high-pressure air pressure is 0.8 MPa. When the high-pressure roller mill is working, the pressure between the rollers is 4-5MPa, the roller speed is 1.6m / min, and the roller gap is 8-20mm. After the closed-circuit balance between the high-pressure roller mill and the V-type classifier, the cycle load is 150-280%. The magnetic field strength of magnetic separation I is 5000-6000kA / m, and the magnetic field strength of magnetic separation II is 7000-10000, which mainly removes magnetic impurities and magnetic minerals during processing. The quartz particles are classifie...

Embodiment 2

[0041] Table 2 Example 2 Granite pegmatite coarse-grained separation index

[0042] sample K 2 O / %

Na 2 O / %

Fe 2 o 3 / %

Al 2 o 3 / %

SiO 2 / %

Yield / % Raw ore 9.78 0.42 0.07 11.51 76.35 100.00 Feldspar 13.37 0.58 0.09 15.64 67.83 73.14 quartz / / 0.002 0.25 99.56 26.86

[0043] It can be seen from Table 2 that after intelligent photoelectric sorting of quartz particles, the yield of feldspar concentrate obtained is 73.14%, and k 2 O content increased from 9.78% of the original ore to 13.37%, k 2 O+Na 2 O is 13.95%, Fe 2 o 3 Content 0.09%. High-pressure roller mill and V-type powder selection closed-circuit pulverization system, feldspar powder-0.180mm products account for 85%, the product is fired at 1200 degrees to a whiteness of 64, and the energy consumption cost of pulverization is 8KWh / t, which is 38% lower than the traditional ball mill pulverization process .

[0044] Intelligent sort...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com