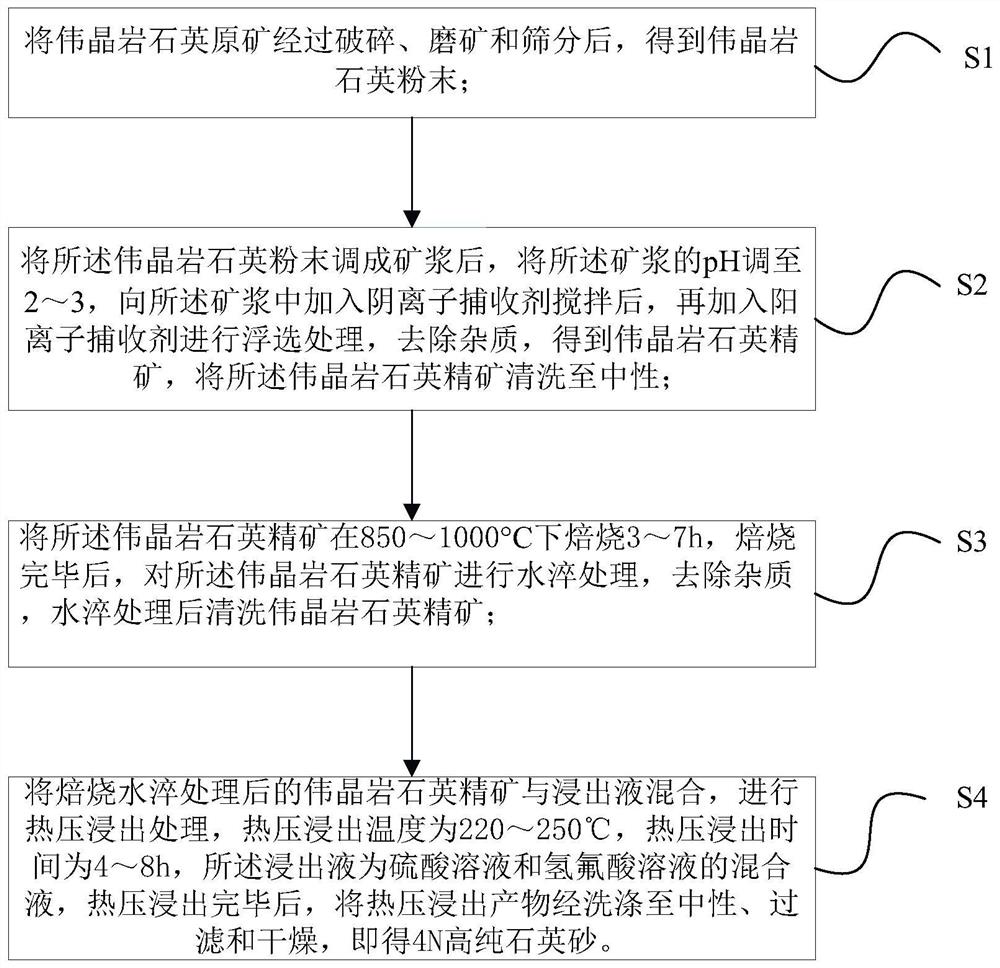

Method for preparing 4N high-purity quartz sand by taking pegmatite quartz as raw material

A technology of high-purity quartz sand and pegmatite, which is applied in chemical instruments and methods, wet separation, silicon dioxide, etc., can solve the problems of complex preparation process and insufficient purity of high-purity quartz sand, and promote the flotation of ore pulp. , The process is simple, the effect of increasing the contact surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1 of the present invention provides a method for preparing 4N high-purity quartz sand from pegmatite quartz in a certain place in Inner Mongolia. The method includes the following steps:

[0039] (1) Crushing, grinding, and screening: Use a jaw crusher to crush the pegmatite quartz raw ore, then use a ball mill to grind the ore, and finally use a vibrating screen to sieve the material to 50-140 mesh to obtain pegmatite quartz powder ;

[0040] (2) Flotation treatment: add ultra-pure water to the pegmatite quartz powder to adjust the slurry to 10wt%, and then add a mass fraction of 10% H 2 SO 4 solution to adjust the pH of the pulp to 2, add 300g.t -1 Sodium dodecylsulfonate, stirred for 5min, then added 600g.t -1 Dodecylamine is carried out flotation, open inflation valve, after stirring for 30s, scrape foam until no foam is produced, remove silicate gangue minerals such as feldspar, mica in pegmatite quartz powder, obtain pegmatite quartz concentrate, An...

Embodiment 2

[0045] Embodiment 2 of the present invention provides a method for preparing 4N high-purity quartz sand from pegmatite quartz in a certain place in Inner Mongolia. The method includes the following steps:

[0046] (1) Crushing, grinding, and screening: Use a jaw crusher to crush the pegmatite quartz raw ore, then use a ball mill to grind the ore, and finally use a vibrating screen to sieve the material to 50-140 mesh to obtain pegmatite quartz powder ;

[0047] (2) Flotation treatment: add ultrapure water to the pegmatite quartz powder to adjust the slurry to 20wt%, and then add a mass fraction of 10% H 2 SO 4 solution to adjust the pH of the pulp to 2.5, add 300g.t -1 Sodium dodecylsulfonate, stirred for 5min, then added 600g.t -1 Dodecylamine is carried out flotation, open inflation valve, after stirring for 30s, scrape foam until no foam is produced, remove silicate gangue minerals such as feldspar, mica in pegmatite quartz powder, obtain pegmatite quartz concentrate, A...

Embodiment 3

[0052] Embodiment 3 of the present invention provides a method for preparing 4N high-purity quartz sand from pegmatite quartz in a certain place in Inner Mongolia. The method includes the following steps:

[0053] (1) Crushing, grinding, and screening: Use a jaw crusher to crush the pegmatite quartz raw ore, then use a ball mill to grind the ore, and finally use a vibrating screen to sieve the material to 50-140 mesh to obtain pegmatite quartz powder ;

[0054] (2) Flotation treatment: add ultrapure water to the pegmatite quartz powder to adjust the slurry to 25wt%, and then add a mass fraction of 10% H 2 SO 4 solution to adjust the pH of the pulp to 3, add 400g.t -1 Sodium dodecylsulfonate, stirred for 5min, then added 700g.t -1 Dodecylamine is carried out flotation, open inflation valve, after stirring for 30s, scrape foam until no foam is produced, remove silicate gangue minerals such as feldspar, mica in pegmatite quartz powder, obtain pegmatite quartz concentrate, And...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com