Selective flotation collector for spodumene and application thereof

A spodumene, selective technology, applied in selective deposition, solid separation, etc., can solve the problems of weak collection ability, inconvenient preparation and addition of pharmaceutical agents, and weak foaming ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0014] The collector of selective flotation spodumene is made of industrial fatty acid, hydroxylamine compound and inorganic base through saponification reaction in proportions of 65%, 15% and 20% by mass respectively. Industrial fatty acid has -COOH pole The non-polar group contains 9 carbons, the hydroxylamine compound has -N-OH polar group, the non-polar group is a hydrocarbon chain, and the inorganic base is sodium carbonate, which realizes the industrial fatty acid and hydroxylamine complete saponification of the compound.

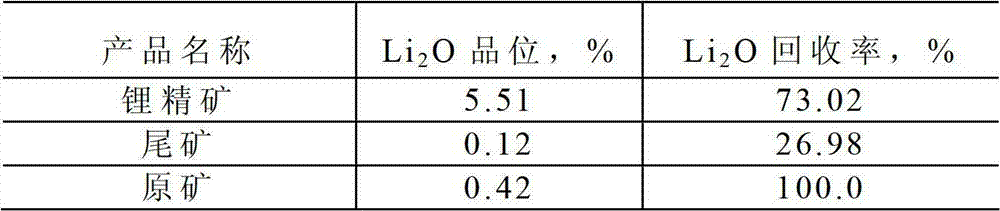

[0015] The low-grade spodumene tailings of Xinjiang Keketuohai Rare Metal Company contain 0.42%Li 2 O, add 200g / t of the collector of the present invention, use it at a pulp temperature of 10°C, and obtain the separation results in Table 1 after flotation separation.

[0016] Table 1 Spodumene flotation index 1

[0017]

Embodiment 2

[0019] The collector of selective flotation spodumene is made of industrial fatty acid, hydroxylamine compound and inorganic base through saponification reaction according to the mass ratio of 85%, 5% and 10% respectively. The industrial fatty acid has -COOH pole Sexual groups, non-polar groups contain 10 carbons, and hydroxylamine compounds have The polar group, the non-polar group are hydrocarbon chains, and the inorganic base is sodium hydroxide, which realizes the complete saponification of industrial fatty acids and hydroxylamine compounds.

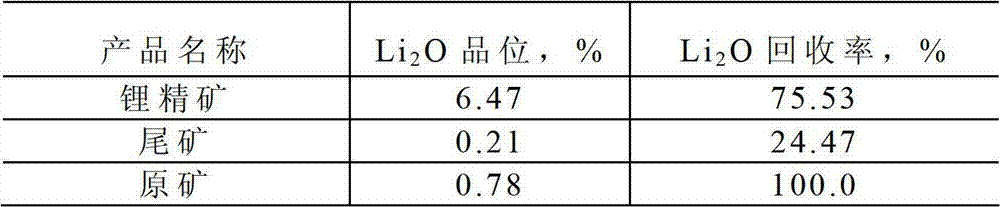

[0020] A medium-grade lithium ore in a place in Jiangxi contains 0.78% Li 2 O, add 500g / t of the collector of the present invention, use it at a slurry temperature of 20°C, and obtain the separation results in Table 2 after separation by flotation.

[0021] Table 2 Spodumene flotation index 2

[0022]

Embodiment 3

[0024] The collector for selective flotation of spodumene is made of industrial fatty acid, hydroxylamine compound and inorganic base through saponification reaction in proportions of 75%, 10% and 15% by mass respectively. Industrial fatty acid has -COOH pole The non-polar group contains 20 carbons. Hydroxylamine compounds have The polar group, the non-polar group are benzene rings, and the inorganic base is sodium hydroxide, which realizes the complete saponification of industrial fatty acids and hydroxylamine compounds.

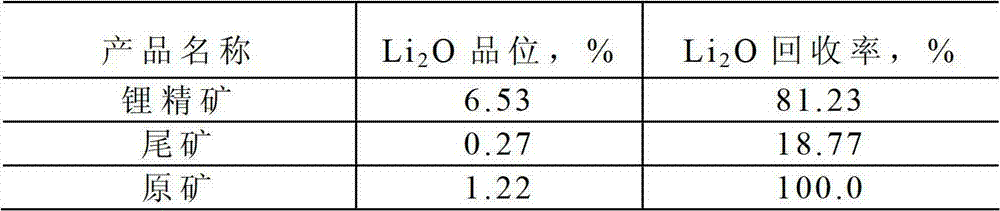

[0025] A medium-to-high-grade lithium ore in a place in Sichuan contains 1.22% Li 2 O, add 600g / t of the collector of the present invention, use it at a slurry temperature of 25°C, and obtain the separation results in Table 3 after separation by flotation.

[0026] Table 3 Spodumene flotation index 3

[0027]

[0028] The test indexes in Table 1 to Table 3 show that adopting the collector of the present invention to separate spodumene by flotation ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com