Efficient flotation method for pegmatite type spodumene

A technology of spodumene and pegmatite, which is applied in the field of high-efficiency flotation of pegmatite spodumene, which can solve the problems of many times of selection, severe weathering of raw ore, and recovery rate difficult to exceed 80%, achieving low consumption , The effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

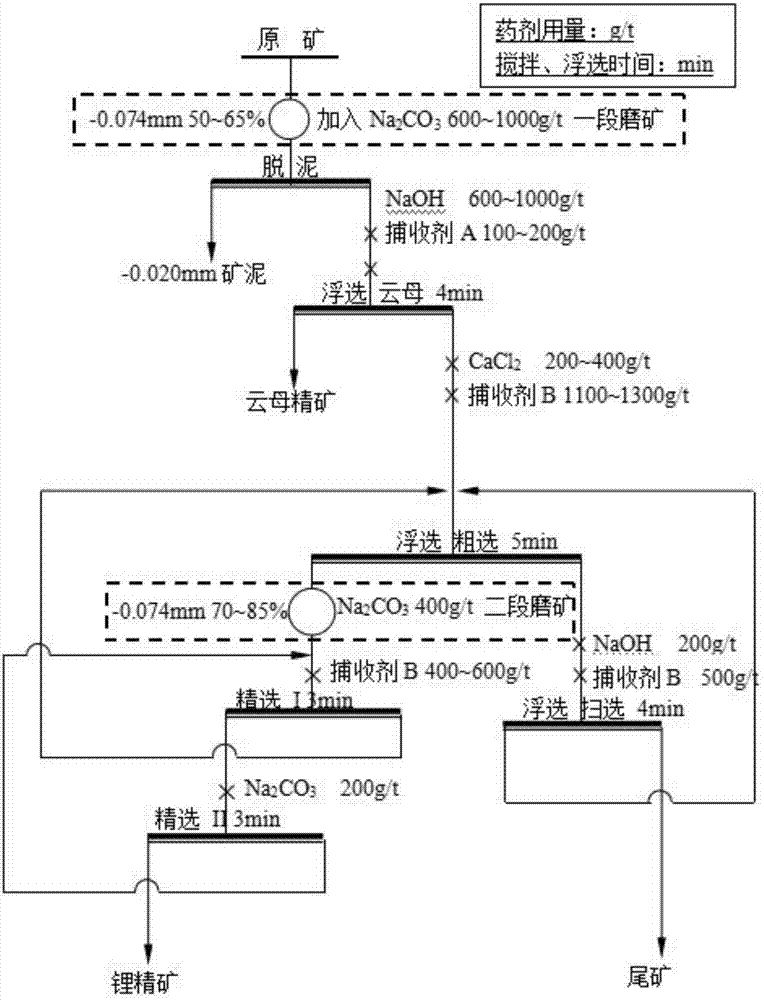

[0039] (1) Grind the pegmatite-type spodumene raw ore to a fineness of -0.074mm and account for 65%, and add Na during grinding 2 CO 3 , Na 2 CO 3 The additive amount is 800g / ton raw ore, after which desliming is carried out to discard the ore slime, and the desliming particle size is -0.02mm;

[0040] (2) add NaOH to step (1) gain, after stirring, add collector A and carry out flotation; Described collector A is made up of dodecylamine and naphthenic acid soap by mass ratio 1:2.5; In every ton of step (1) gained, the addition amount of NaOH is 800g, and the addition amount of collector A is 150g; Gained mica concentrate is separated after flotation;

[0041] (3) first add CaCl to the result of step (2) 2 , and fully stirred, then add collector B and carry out flotation roughing to obtain rough concentrate of lithium; the collector B is composed of dodecylamine and oxidized paraffin wax soap in a mass ratio of 1:12; (2) The resultant, CaCl 2 and the addition of collector...

Embodiment 2

[0050] (1) Grind the pegmatite-type spodumene ore until the fineness of -0.074mm accounts for 50%, and add Na during grinding 2 CO 3 , Na 2 CO 3 The additive amount is 800g / ton raw ore, after which desliming is carried out to discard the ore slime, and the desliming particle size is -0.02mm;

[0051] (2) add NaOH to step (1) gain, after stirring, add collector A and carry out flotation; Described collector A is made up of dodecylamine and naphthenic acid soap by mass ratio 1:2.5; In every ton of step (1) gained, the addition amount of NaOH is 600g, and the addition amount of collector A is 100g; Gained mica concentrate is separated after flotation;

[0052] (3) first add CaCl to the result of step (2) 2 , and fully stirred, then add collector B and carry out flotation roughing to obtain rough concentrate of lithium; the collector B is composed of dodecylamine and oxidized paraffin wax soap in a mass ratio of 1:12; (2) The resultant, CaCl 2 and the addition amount of coll...

Embodiment 3

[0061] (1) Grind the pegmatite-type spodumene ore until the fineness of -0.074mm accounts for 60%, and add Na during grinding 2 CO 3 , Na 2 CO 3 The additive amount is 700g / ton raw ore, after which desliming is carried out to discard the ore slime, and the desliming particle size is -0.02mm;

[0062] (2) add NaOH to step (1) gain, after stirring, add collector A and carry out flotation; Described collector A is made up of dodecylamine and naphthenic acid soap by mass ratio 1:2.5; In every ton of step (1) gained, the addition amount of NaOH is 1000g, and the addition amount of collector A is 200g; Gained mica concentrate is separated after flotation;

[0063] (3) first add CaCl to the result of step (2) 2 , and fully stirred, then add collector B and carry out flotation roughing to obtain rough concentrate of lithium; the collector B is composed of dodecylamine and oxidized paraffin wax soap in a mass ratio of 1:12; (2) The resultant, CaCl 2 and the addition of collector ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com