Preparation method of pegmatite porous glass ceramics

A technology of porous glass-ceramic and a manufacturing method, which is applied in the field of porous glass-ceramic and can solve the problems of insufficient attention to thermal insulation materials and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

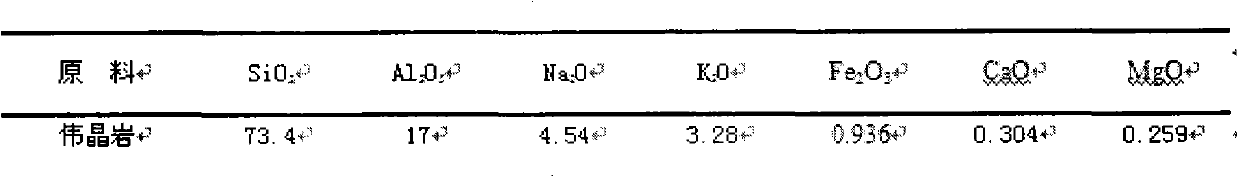

[0016] Recipe: the pegmatite used is a kind of ore in Benxi City, Liaoning Province, and its chemical composition is obtained by quantitative analysis of the X-ray fluorescence spectrometer (SRS-3400 type) produced by German Bruker Company, and its composition is shown in Table 1,

[0017] Table 1. Pegmatite chemical composition (wt%)

[0018]

[0019] 1. The raw materials are called according to the mass percentage, and the components are designed as follows: 29% pegmatite, 29.2% silica, 26.2% calcite, 9.7% borax, 3.3% zinc oxide, 1.4% sodium nitrate, 1.1% soda ash, put the raw materials into the mixing Mix in feeder for 1 hour;

[0020] 2. Pour the mixture into the crucible furnace to melt the base glass at 4°C / min to 1450°C and keep it warm for 3 hours;

[0021] 3. Pour the melted and clarified glass liquid into 20°C water to quench and quench it to make glass particles;

[0022] 4. Put the pegmatite glass particles into a drying furnace at 100°C for drying, put the dr...

Embodiment 2

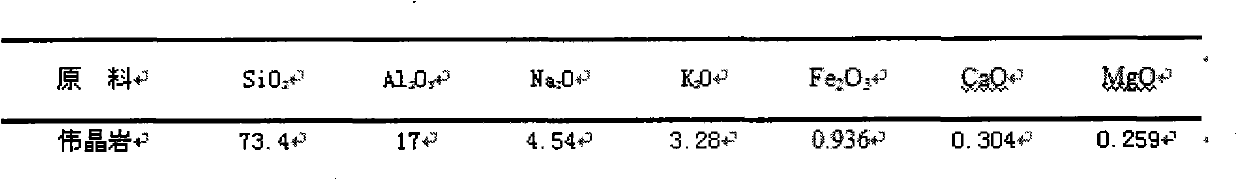

[0028] Recipe: the pegmatite used is a kind of ore in Benxi City, Liaoning Province, and its chemical composition is obtained by quantitative analysis of the X-ray fluorescence spectrometer (SRS-3400 type) produced by German Bruker Company, and its composition is shown in Table 2,

[0029] Table 2. Pegmatite chemical composition (wt%)

[0030]

[0031] 1. The raw materials are weighed according to the mass percentage. The components are designed as follows: 54.3% pegmatite, 7.2% silica, 26.7% calcite, 6.7% borax, 3.4% zinc oxide, and 1.7% sodium nitrate. Mix for 1 hour;

[0032] 2. Pour the mixture into the crucible furnace to melt the base glass at 4°C / min to 1450°C and keep it warm for 3 hours;

[0033] 3. Pour the melted and clarified glass liquid into 20°C water to quench and quench it to make glass particles;

[0034] 4. Put the pegmatite glass particles into a drying furnace at 100°C for drying, put the dried glass frit into a ball mill to grind, and pass the crushe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

| Pore size distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com