Fully automatic jproduction line for building block of heat retaining building mould for polyphenylene concrete

A technology of polystyrene concrete and thermal insulation moulding, applied in unloading devices, ceramic molding machines, manufacturing tools, etc., to achieve the effects of ensuring molding cycle and finished product quality, compact and practical layout, and small input-output ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

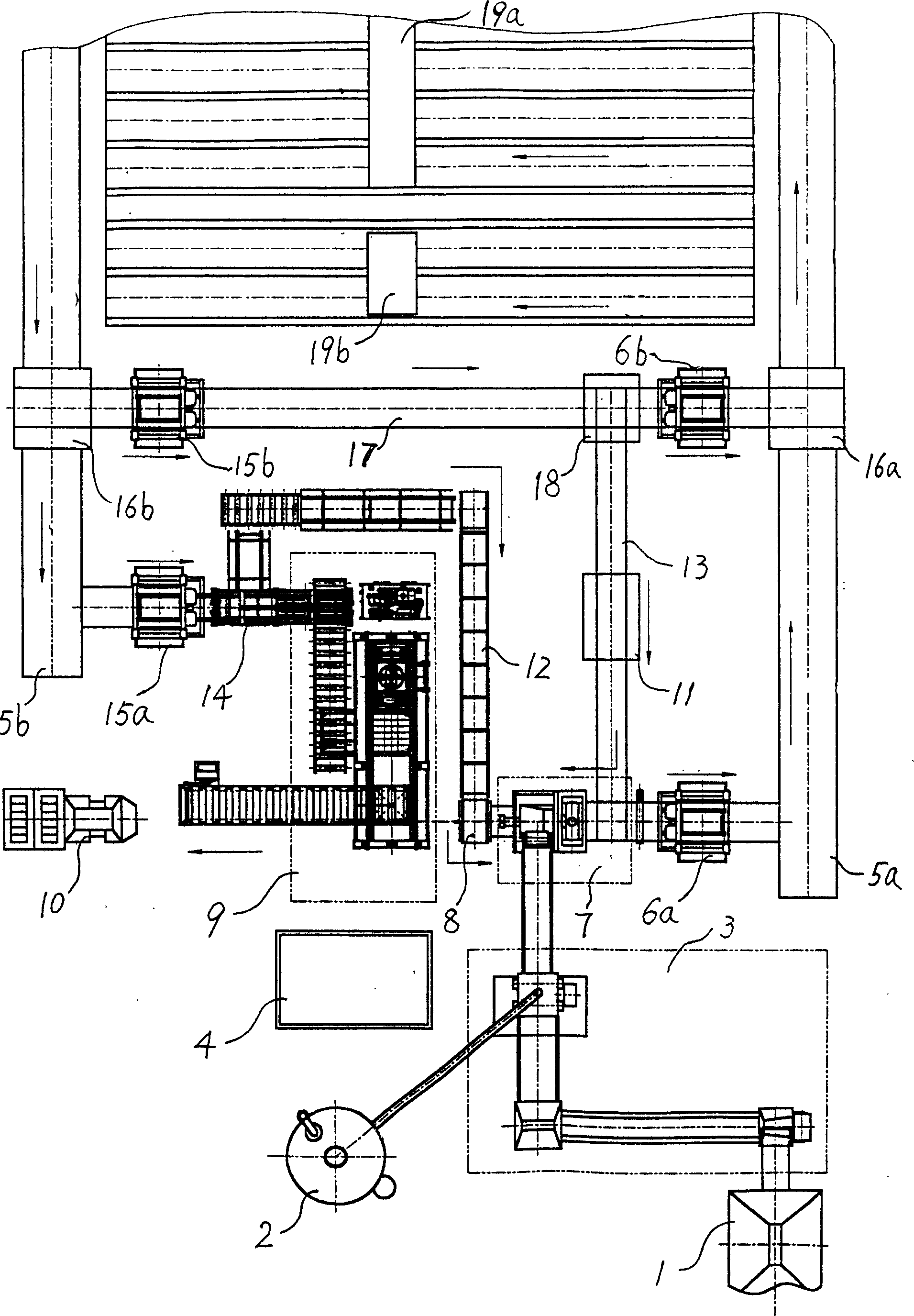

[0010] As shown in the figure, the full-automatic production line of polyphenylene concrete thermal insulation building blocks according to the present invention consists of a batching mixer 3, a forming host 7, a plate supply machine 8, a program-controlled transfer kiln car 16, a kiln car transfer track 5, and a curing kiln 19 , material transfer table 17, demoulding machine 18, mold pushing machine 11, plate separator 14, palletizing system 9, plate lifting machine 6, plate descending machine 15 and control system 4, etc. The curing kiln 19 includes a block curing kiln 19a and a molded block pre-curing kiln 19b which are respectively composed of a plurality of parallel kilns. The transfer track 5b is formed, and the material transfer platform 17 is connected between the two transfer tracks 5a, 5b. The demoulding machine 18 is located on the material conveying table 17, and the mold case recovery conveying table 13 leading to the mold inlet end of the molding host 7 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com