Three-dimensional manufacturing apparatus, three-dimensional manufactured object producing method, and container for three-dimensional manufacturing apparatus

A technology of three-dimensional manufacturing and manufacturing methods, which is applied in the direction of manufacturing auxiliary devices, processing and manufacturing, manufacturing tools, etc., and can solve problems such as time-consuming and small conductance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

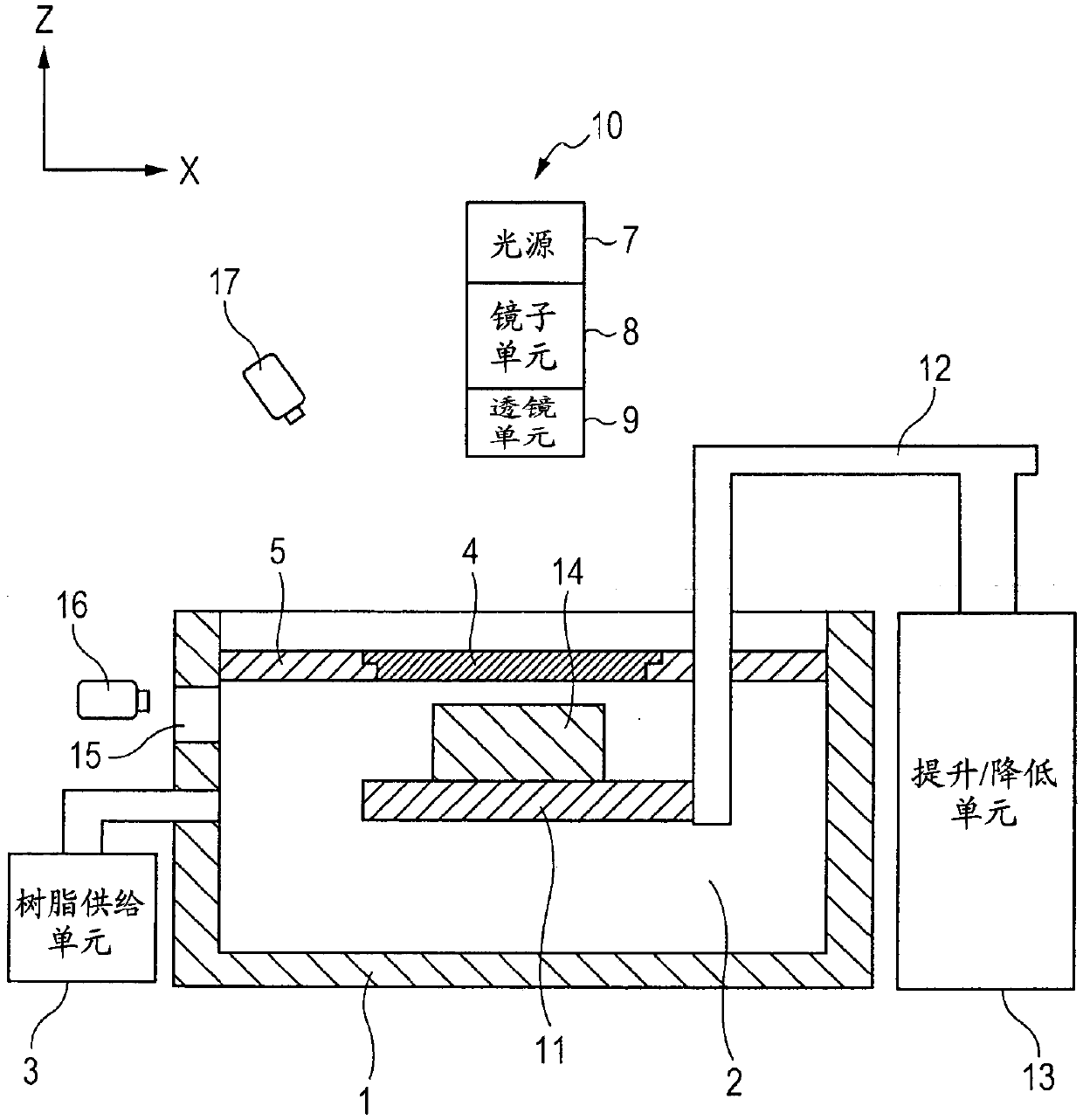

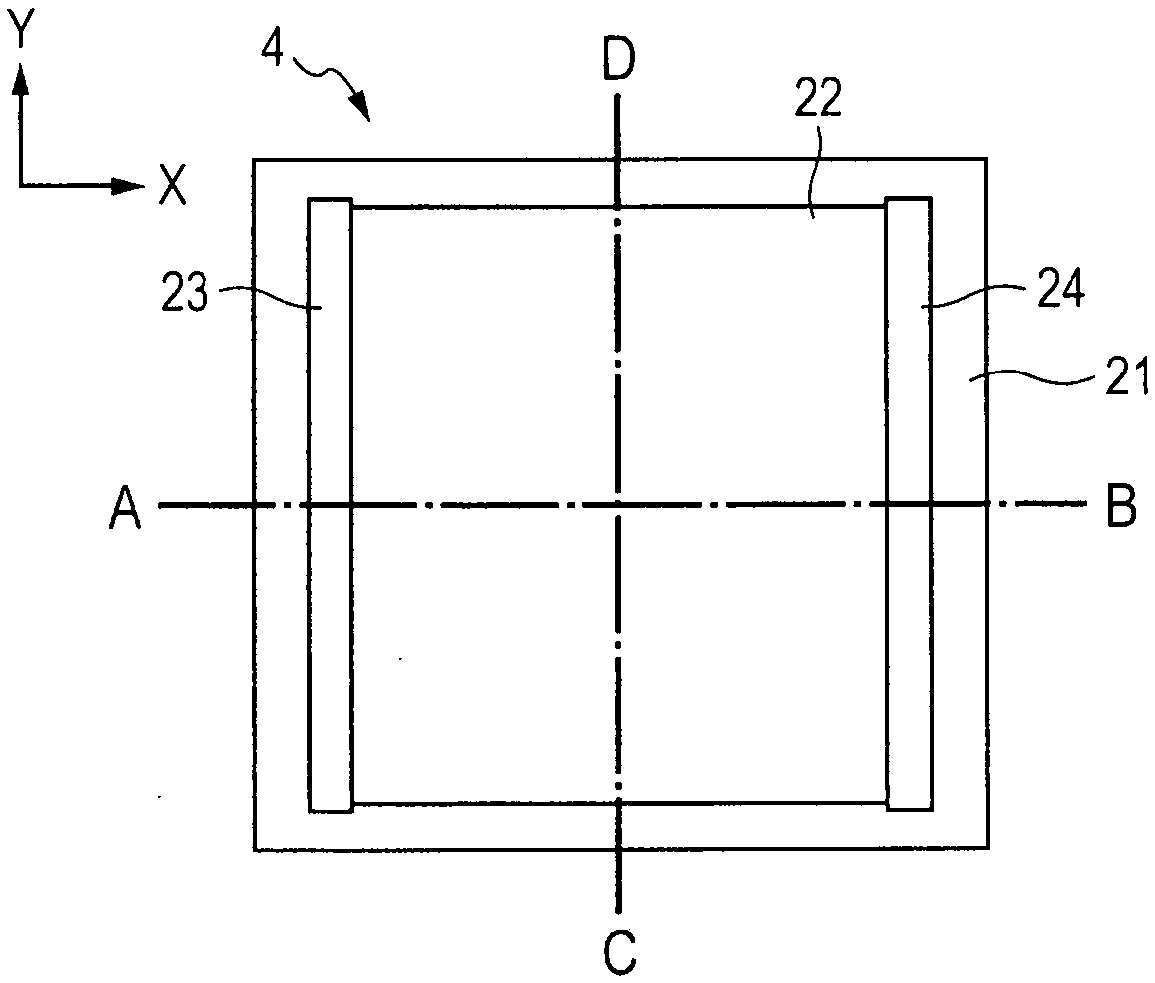

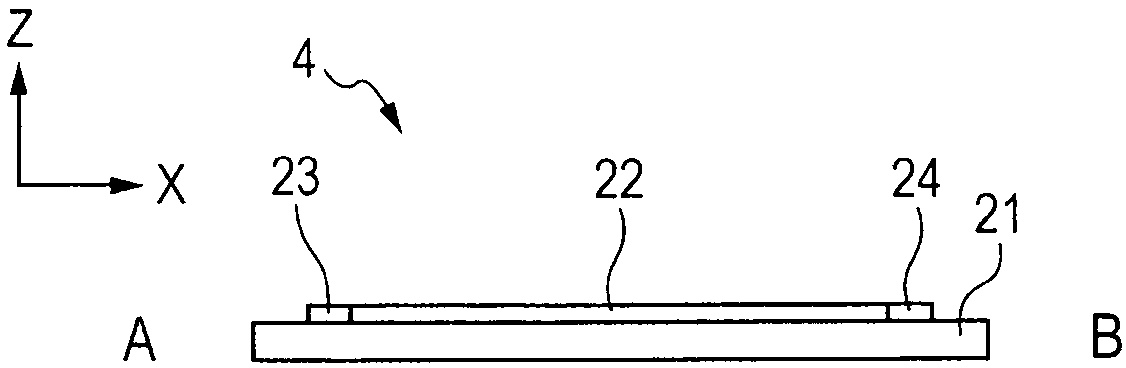

[0051] figure 1 is a schematic sectional view for describing the composition of the three-dimensional manufacturing apparatus according to the first embodiment of the present invention.

[0052] (device configuration)

[0053] exist figure 1 , shows a container 1, a liquid photocurable resin 2, a resin supply unit 3, a light transmission part 4, a light shielding part 5, a light source 7, a mirror unit 8, a lens unit 9, a light source unit 10, a base 11, a lift / lowering arm 12 , lifting / lowering unit 13 , three-dimensionally fabricated object 14 , observation section 15 , infrared thermal viewer 16 and infrared thermometer 17 .

[0054] The container 1 which is a container for holding the liquid photo-curable resin 2 is formed of a material that blocks light of a wavelength region in which the liquid photo-curable resin is cured or hardened.

[0055] The resin supply unit 3 includes a tank for storing a liquid photocurable resin and a pump, and supplies the liquid photocur...

no. 2 example

[0144] Figures 9A-9C is a schematic cross-sectional view for describing the composition of a three-dimensional manufacturing apparatus according to a second embodiment of the present invention.

[0145] The device of the first embodiment heats the light-transmitting portion by a transparent heater that generates heat by energization. However, the device of the second embodiment is different from the device of the first embodiment in that the light-transmitting portion is heated by the infrared heating device.

[0146] (device configuration)

[0147] exist Figures 9A-9C , shows a container 1, a liquid photocurable resin 2, a resin supply unit 3, a light source 7, a mirror unit 8, a lens unit 9, a light source unit 10, a base 11, a lifting / lowering arm 12, a lifting / lowering unit 13, Three-dimensionally fabricated object 14 , viewing portion 15 and infrared thermal viewer 16 .

[0148] Due to the above constituent elements and reference figure 1 The constituent elements o...

no. 3 example

[0180] Figure 9B is a schematic cross-sectional view of an apparatus for describing the composition of a three-dimensional manufacturing apparatus according to a third embodiment of the present invention.

[0181] As with the device of the second embodiment, in the device of the third embodiment, the light-transmitting portion is heated by an infrared heating device. However, the light-transmitting portion of the device in the third embodiment is different from the device in the second embodiment in that the light-transmitting portion transmits gas such as oxygen that prevents curing of the photocurable resin.

[0182] (device configuration)

[0183] exist Figure 9B , shows a container 1, a liquid photocurable resin 2, a resin supply unit 3, a light source 7, a mirror unit 8, a lens unit 9, a light source unit 10, a base 11, a lifting / lowering arm 12, a lifting / lowering unit 13, Three-dimensionally fabricated object 14 , viewing portion 15 , infrared thermal viewer 16 , i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com