Method for manufacturing composite plate with lateral round end arc wrap angle ranged from 90 degrees to 180 degrees and products thereof

A manufacturing method and composite board technology, which is applied in the direction of flat products, manufacturing tools, and the joining of wooden veneers, can solve the problems of appearance influence, lower product yield, increase labor and material consumption, etc., and achieve smooth and smooth surface. The effect of convenient subsequent processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] From the description of the accompanying drawings and technical solutions given above, the inventive content of the present invention can already be understood. The present invention will be further described below through the description of specific embodiments in conjunction with the accompanying drawings.

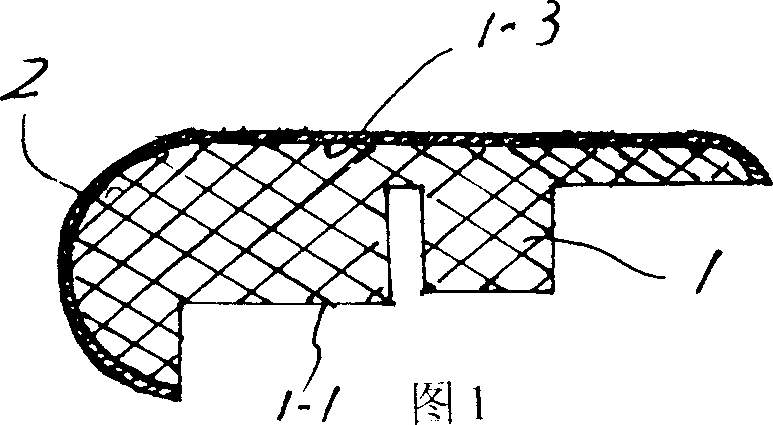

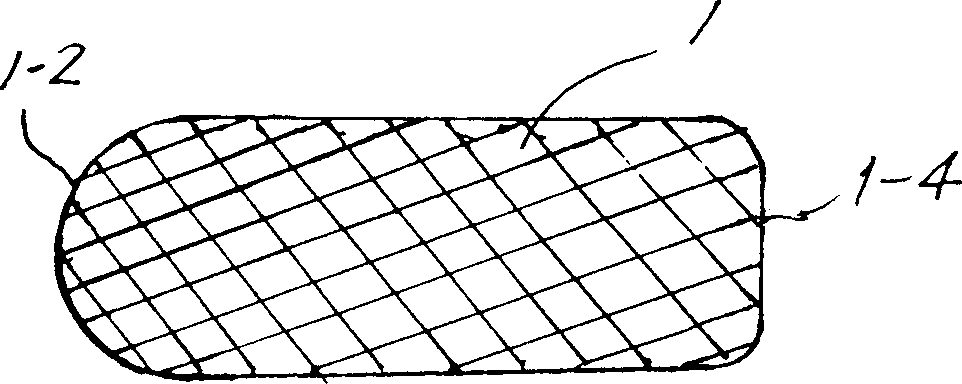

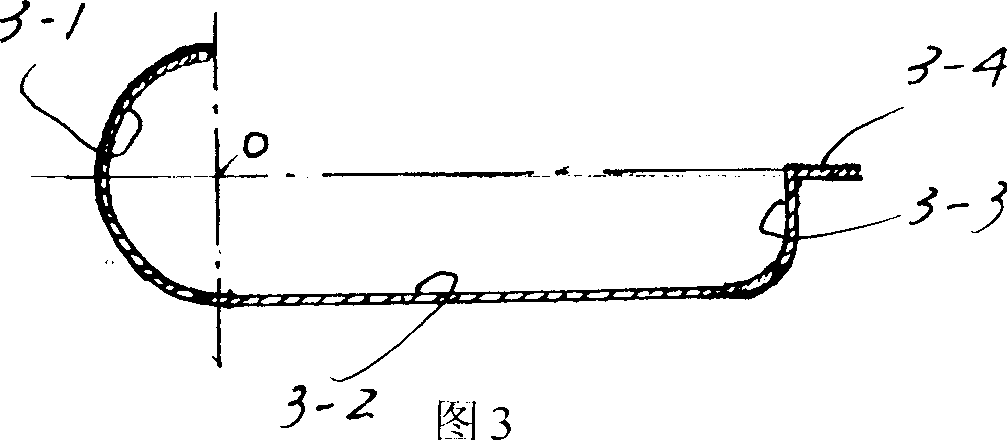

[0031] One of the specific embodiments is shown in Figures 1, 2, 3, 4, and 5. A method for manufacturing a composite board with a circular arc wrapping angle of 180° on one side. The density board 1 is used as a blank, and the usual half-pair composite mold 4 is used to wrap the veneer paper 2 and heat in turn according to the blank 1. Compression molding is carried out in two steps, while its

[0032] In blank 1 wrapping veneer paper step, be that veneer paper 2 is wrapped on blank 1, then the blank 1 of wrapping veneer paper 2 is filled into cover mold 3 (as attached Figure 4 shown). The blank 1 has a length of 2000 mm.

[0033] In the thermocompression for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com