Spindle sleeve

a spindle and sleeve technology, applied in the field of spindle sleeves, can solve the problems of large replacement costs, relatively heavy and costly spindle parts, and the inability to fully meet the needs of use, and achieve the effect of light weight and durabl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

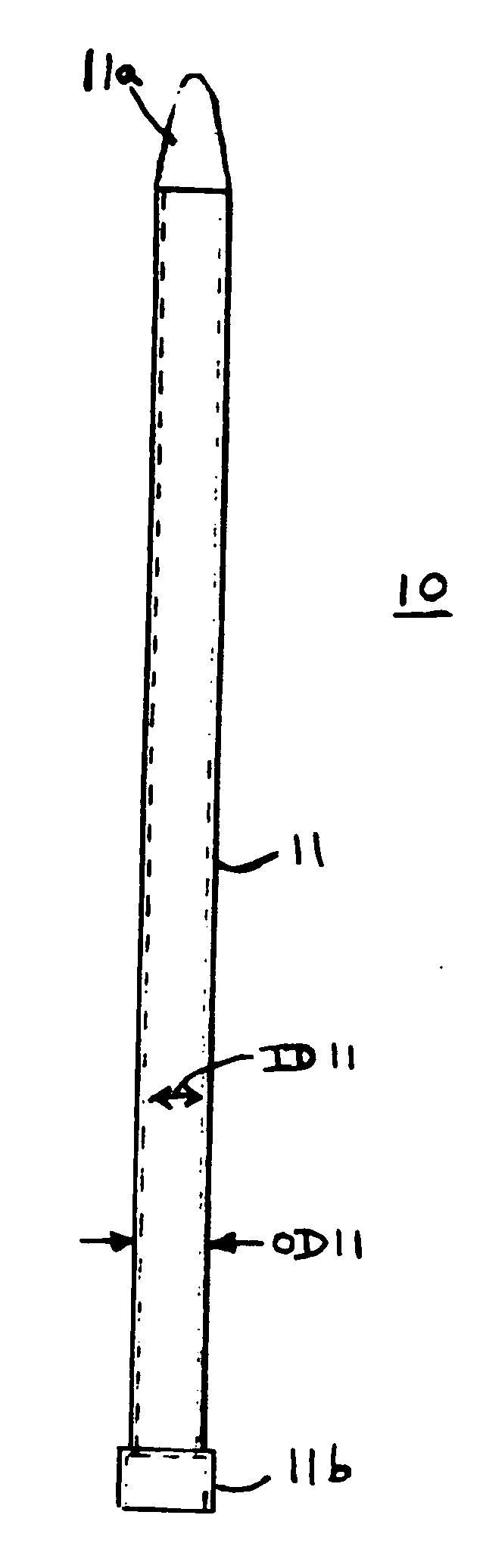

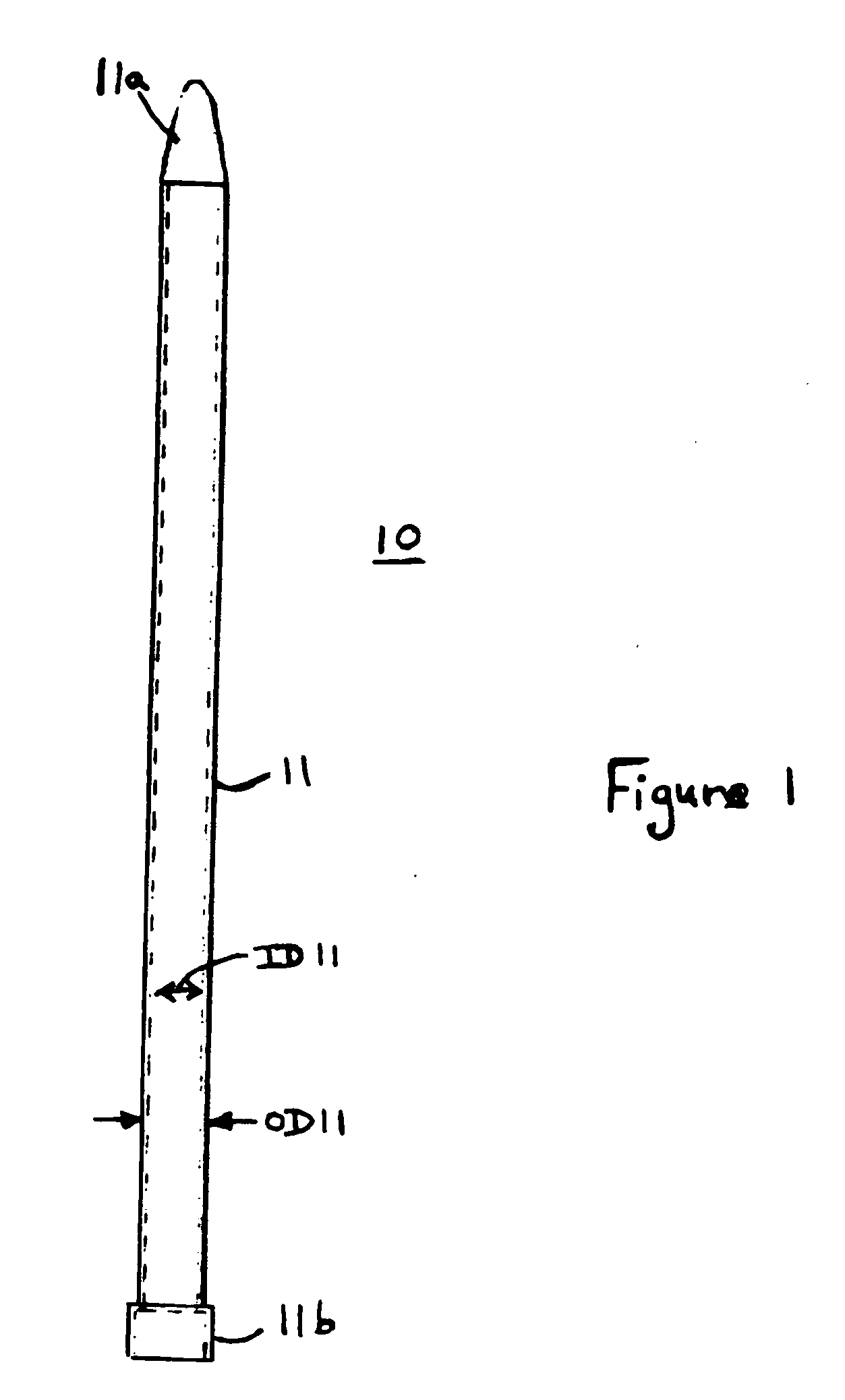

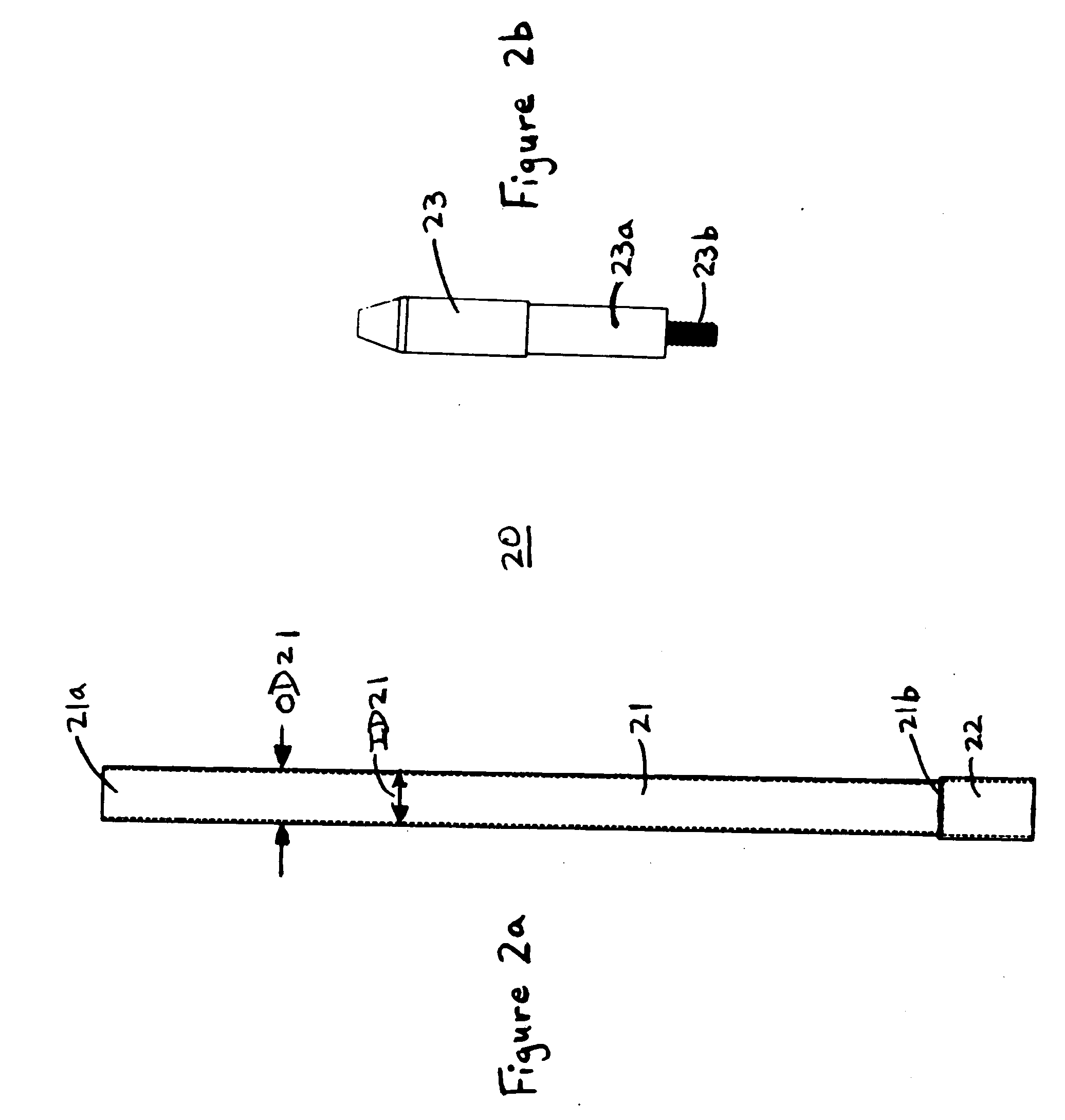

[0020] This disclosure provides tools such as a spindle sleeve or sleeve-like device configured to slip over a spindle for stacking a plurality of manufactured articles (for example, flat discs or cards, such as optical discs), in order to facilitate transport of the plurality of discs.

[0021] For example, in the manufacturing of optical discs, as discussed infra, discs are stacked on spindles at various stages of a manufacturing line. Conventional manufacturing systems use metal spindles which can manually be removed from the line. However, the metal spindles are rather costly, and therefore it is desirable to maintain a minimum number of spindles for use in the manufacturing system. For similar reasons, it is desirable to avoid using the spindles as transport devices.

[0022] Use of spindle sleeves or sleeve-like devices which slide over the spindles, as provided by this disclosure, allows the spindles to remain in place in the manufacturing system while allowing the spindle sleeve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com