Vacuum coating apparatus, method and product with laser pattern formed on substrate surface

A substrate surface, vacuum coating technology, applied in the direction of vacuum evaporation coating, the process for producing decorative surface effects, layered products, etc., can solve the problems of difficult recovery of metal components, high manufacturing cost, and lack of metal components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

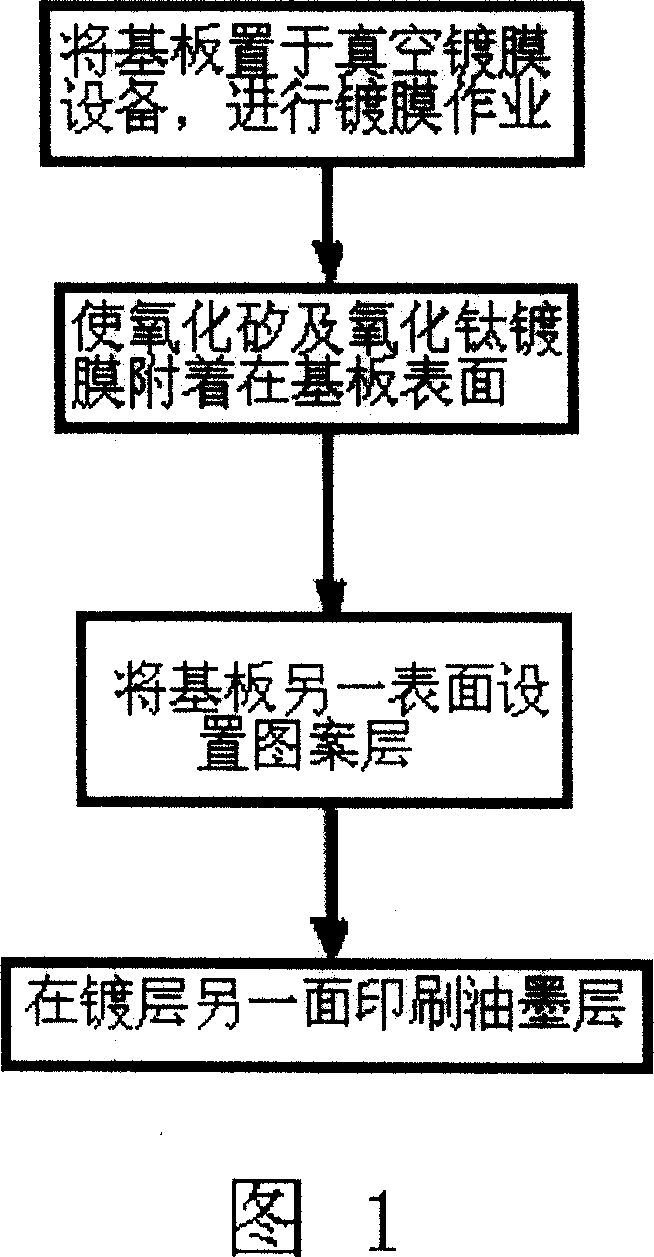

[0045] In order to be able to further have a deeper, clear and detailed understanding and understanding of the structure, use and characteristics of the present invention, preferred embodiments are now cited, and detailed descriptions are as follows in conjunction with the accompanying drawings:

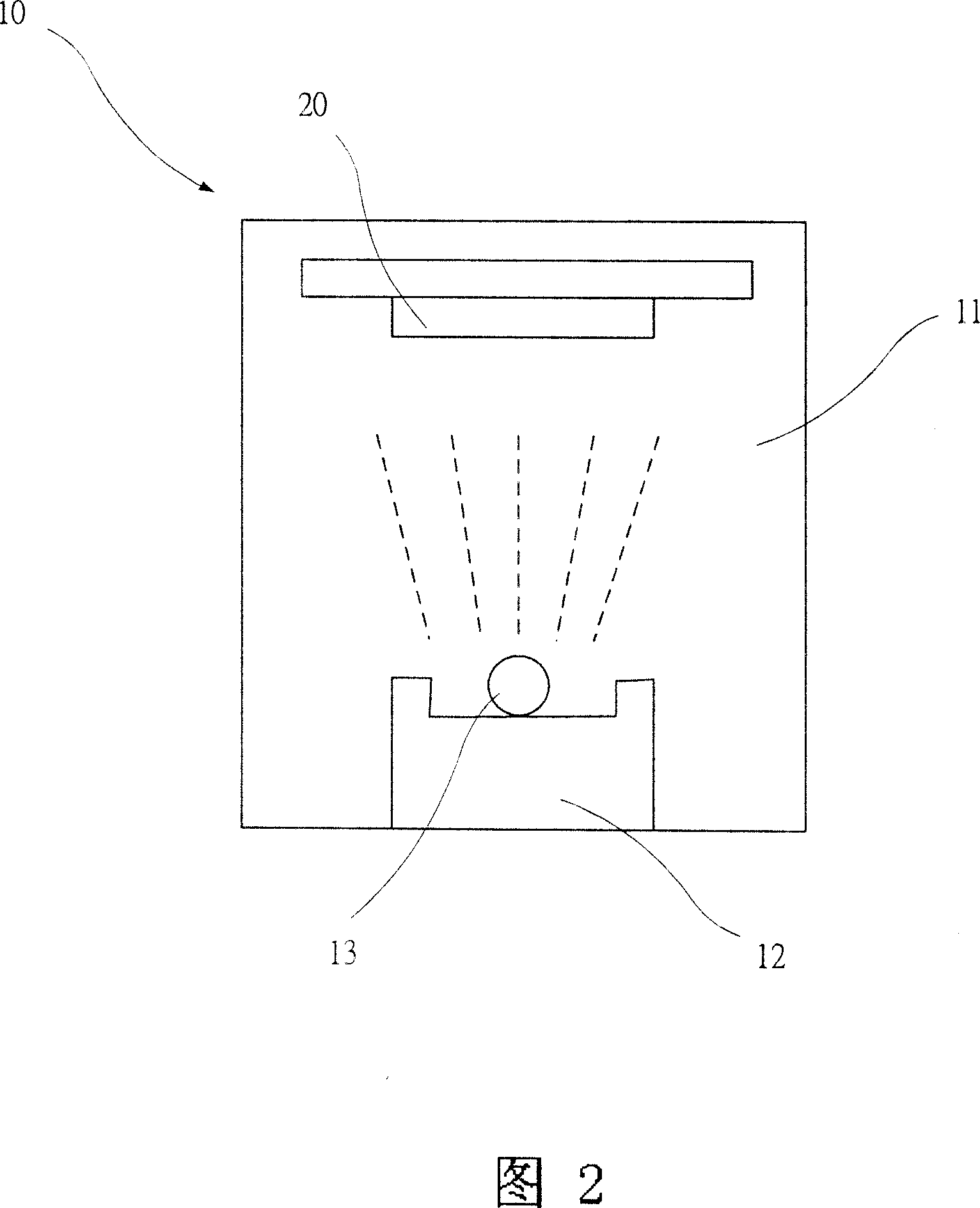

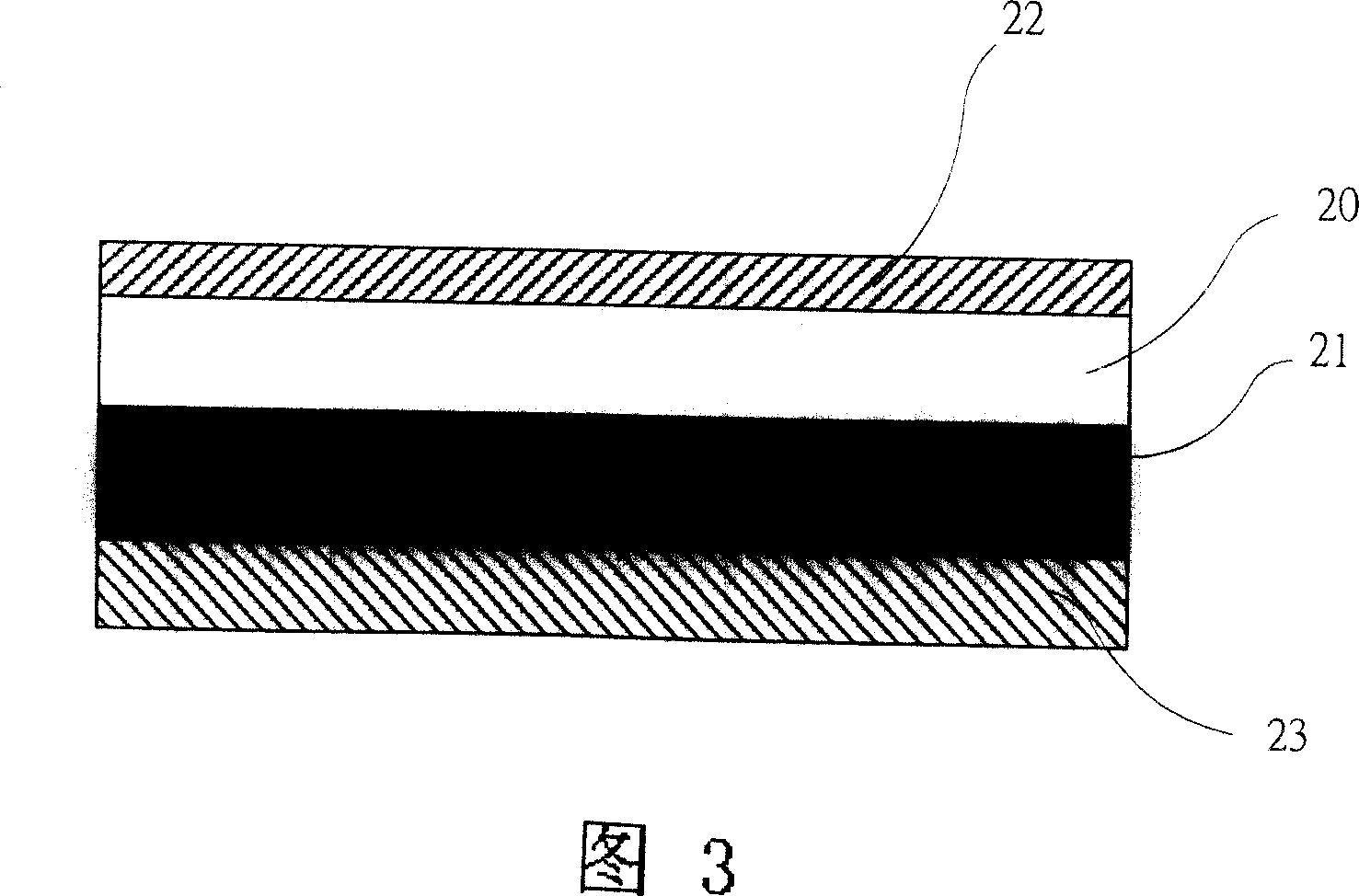

[0046] In a preferred embodiment, the material of the substrate is polycarbonate, and the substrate is clamped in the fixture of the vacuum evaporation equipment, and the coating layer is sequentially laid on the surface of the substrate by ion coating, and the silicon oxide and titanium oxide are vapor-deposited on the surface of the substrate, and the thickness and layer order of silicon oxide and titanium oxide are adjusted. Through the combination of silicon oxide and titanium oxide, different light and shadow effects can be presented.

[0047] In an ideal embodiment, the base material is made of acrylic material, and silicon oxide and titanium oxide are deposited on the surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com