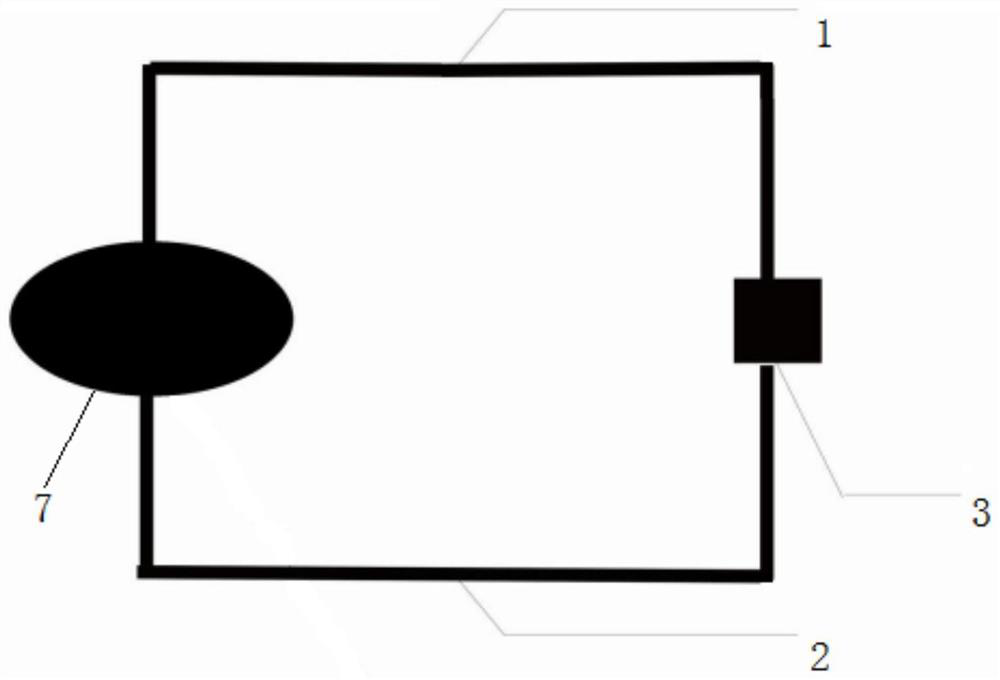

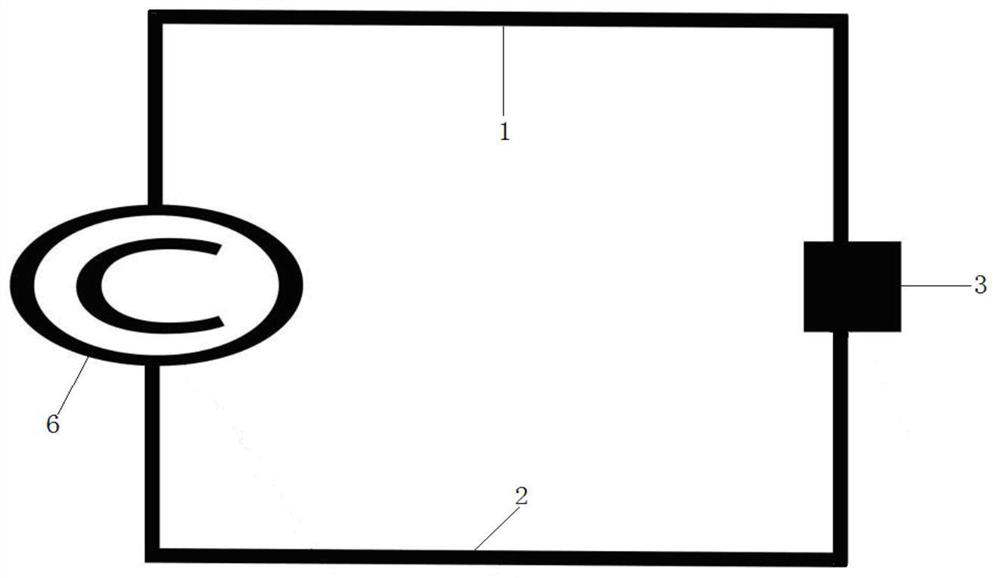

Anti-counterfeit label

An anti-counterfeiting label and label technology, applied in instruments, inks, household appliances, etc., can solve the problems of visual impact, label color change, etc., and achieve the effects of good thixotropy, fast heating rate, and high heating efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

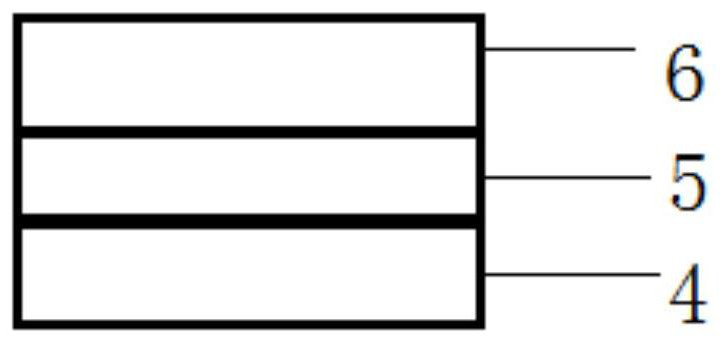

[0044] The preparation method of the low-voltage heating ink specifically comprises the following steps:

[0045] (1) Weigh the components of the low-voltage heating ink in parts by mass, put the water-based acrylic resin, rosin resin, pH regulator and deionized water in a stirring tank and stir for 5 to 10 minutes. After mixing evenly, add Carbon black, graphite, carbon nanotube dispersion and xanthan gum, stir evenly, finally add dispersant and defoamer, stir evenly to form primary heating ink;

[0046] (2) After mixing the primary heating ink and ball milling beads according to the mass ratio of 3:1, put it in an electric mixer and stir for 1 to 3 hours, then take it out and filter it, and finally put the primary heating ink in a sand mill and grind it until the particle size is below 5 μm , Obtain low voltage heating ink.

[0047] In the preparation process of the low-voltage heating ink, xanthan gum can form a stable three-dimensional network structure with conductive fi...

Embodiment 1

[0049] Weigh respectively 7% water-based acrylic resin, 7% rosin resin, 6% graphite, 10% carbon black, 35% carbon nanotube dispersion, 0.5% formamide, 0.5% ethanolamine, 5% DisponerW-518 water-based wetting and dispersing agent, 0.3% xanthan gum, 0.5% TEGO Foamex 805 water-based defoamer and 28.2% deionized water.

[0050] Put 7% water-based acrylic resin, 7% rosin resin, 0.5% formamide, 0.5% ethanolamine and 28.2% deionized water in a stirring tank and stir for 5-10 minutes. After mixing evenly, add 10% charcoal in sequence Black, 6% graphite, 35% carbon nanotube dispersion and 0.3% xanthan gum, stir evenly, finally add 5% Disponer W-518 water-based wetting and dispersing agent and 0.5% TEGO Foamex 805 water-based Defoamer, stir evenly to form primary heating ink; mix the primary heating ink and ball milling beads according to the mass ratio of 3:1, mix and disperse in an electric mixer for 2 hours, take out and filter, and finally put the primary heating ink in a sand mill ...

Embodiment 2

[0062] Weigh 7% of water-based acrylic resin, 7% of rosin resin, 5% of graphite, 10% of carbon black, 35% of carbon nanotube dispersion, 1% of ethanolamine, and 5% of Disponer W in parts by mass - 920 type aqueous wetting and dispersing agent, 0.3% of xanthan gum, 0.5% of Defom W-0506 type aqueous defoamer and 29.2% of deionized water.

[0063] Put 7% water-based acrylic resin, 7% rosin resin, 1% ethanolamine and 29.2% deionized water in a stirring tank and stir for 5-10 minutes. After mixing evenly, add 10% carbon black, 5% Graphite, 35% carbon nanotube dispersion and 0.3% xanthan gum, stir evenly, finally add 5% DisponerW-920 water-based wetting and dispersing agent and 0.5% DefomW-0506 water-based defoamer, stir evenly Form the primary heating ink; mix the primary heating ink and ball milling beads according to the mass ratio of 3:1, mix and disperse in an electric mixer for 2.5 hours, take out and filter, and finally put the primary heating ink in a sand mill to grind to a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com