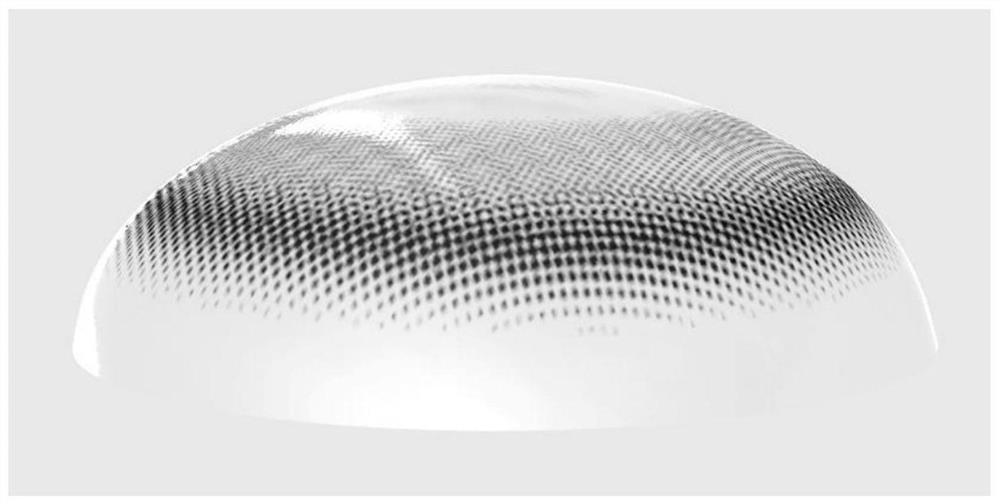

Blazed 5D colorful cosmetic contact lens and preparation method thereof

A bright and light-changing technology, applied in the field of cosmetic contact lenses, can solve problems such as lack of transparency, metallic flicker, and single color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

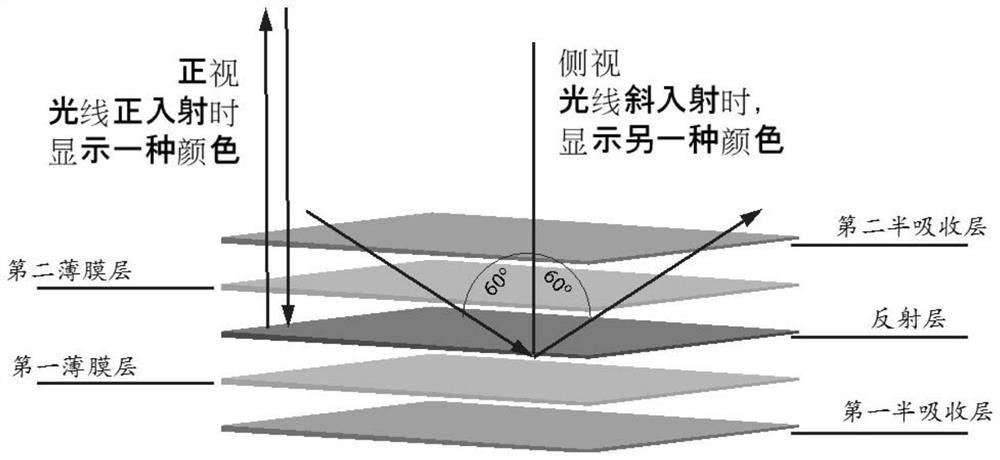

[0049] The preparation raw material of the reflective layer is photochromic ink.

[0050] In the present invention, taking the center of the spherical surface as the center, the distribution density of the convex dots preferably increases in the direction of outward extension; the increasing trend is preferably a regular increase or an irregular increase; The law of the regular increase is not limited in any way. In the present invention, the size of each of the raised dots is preferably the same or different.

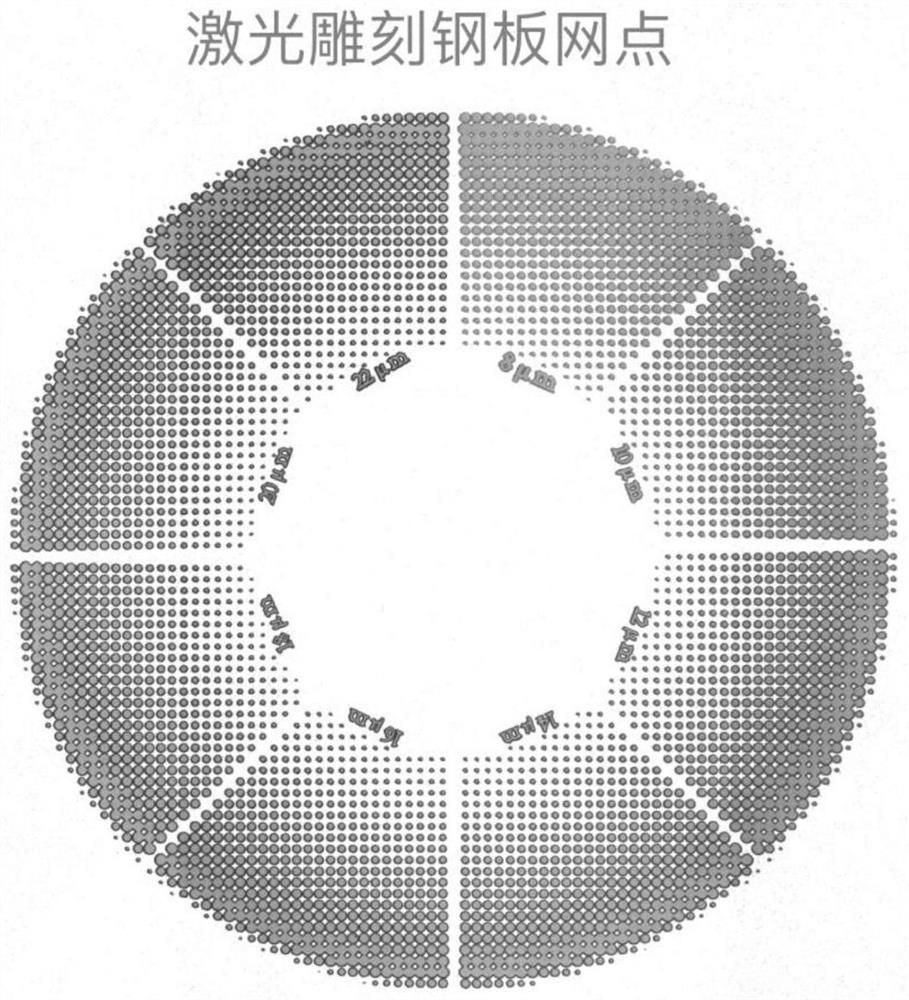

[0051] In the present invention, the diameter of the raised dots is preferably 0.02 to 1.5 mm, more preferably 0.08 to 1.0 mm, and most preferably 0.2 to 0.6 mm; the angle between two adjacent raised dots is preferably 30° to 180° °, more preferably 40°-130°, most preferably 60°-100°; the height of the raised dots is preferably 8-22 μm, more preferably 10-20 μm, and most preferably 13-16 μm. In the present invention, the raised dots preferably have a "U"-shaped struc...

Embodiment 1

[0092] Using laser engraving method, the steel plate is laser engraved to obtain the pattern mold of Guangyao 5D colorful color contact lens, and then the carrier plastic mold of Guangyao 5D colorful color contact lens is obtained through color contact printing technology; the shape of the carrier plastic mold is similar to the eyeball surface. match, the carrier plastic mold is centered on the center of the spherical surface, along the line of defense extending outward, including a central spherical area, an annular spherical area and an edge spherical area; the surface of the annular spherical area is provided with concave mesh points ( The structure of the concave mesh point is as follows image 3 As shown in the figure, the diameter of the dots is [0.02mm~1.5mm], and the layout gradually increases in the form of dots, and the connection layout between dots presents various angles [30°~180°]. The purpose of designing the distribution of dots of different sizes : make differ...

Embodiment 2

[0100] Referring to Embodiment 1, the only difference is that the structure of the concave mesh points is as follows: image 3 shown;

[0101] Using laser engraving method, the steel plate is laser engraved to obtain the pattern mold of Guangyao 5D colorful contact lenses, and then the carrier plastic mold of Guangyao 5D colorful contact lenses is obtained through color contact printing technology; the shape of the carrier plastic mold is similar to the eyeball surface. match, the carrier plastic mold is centered on the center of the spherical surface, along the line of defense extending outward, including a central spherical area, an annular spherical area and an edge spherical area; the surface of the annular spherical area is provided with concave mesh points ( The structure of the concave mesh point is as follows image 3 As shown in the figure, the diameter of the dots is [0.02mm~1.5mm], and the layout gradually increases in the form of dots, and the connection layout be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com