High performance golf ball having a reduced distance

a golf ball and high-performance technology, applied in the field of golf balls, can solve the problems of low ball performance, low ball performance, range balls, etc., and achieve the effect of reducing overall distance and high-performance trajectory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

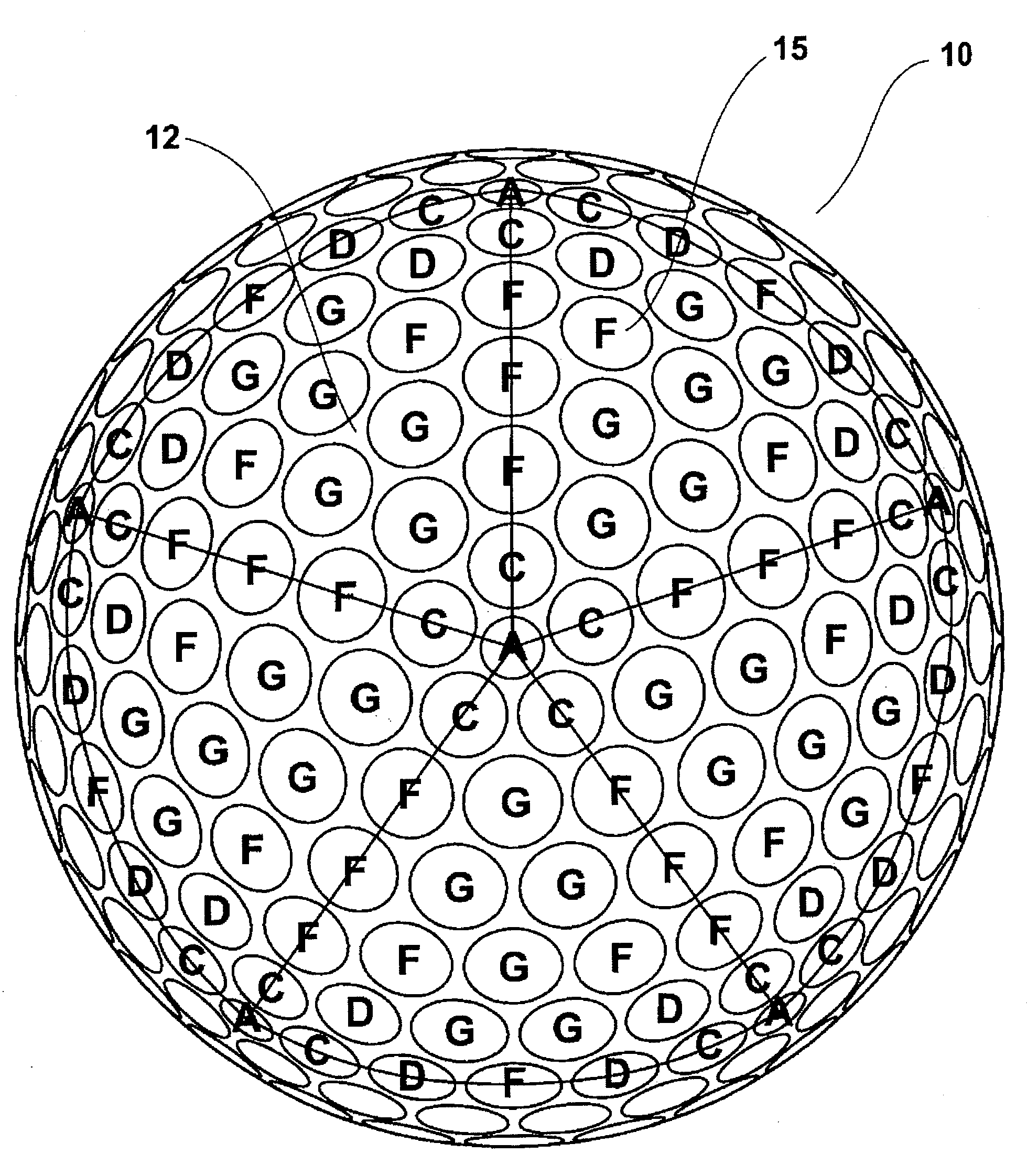

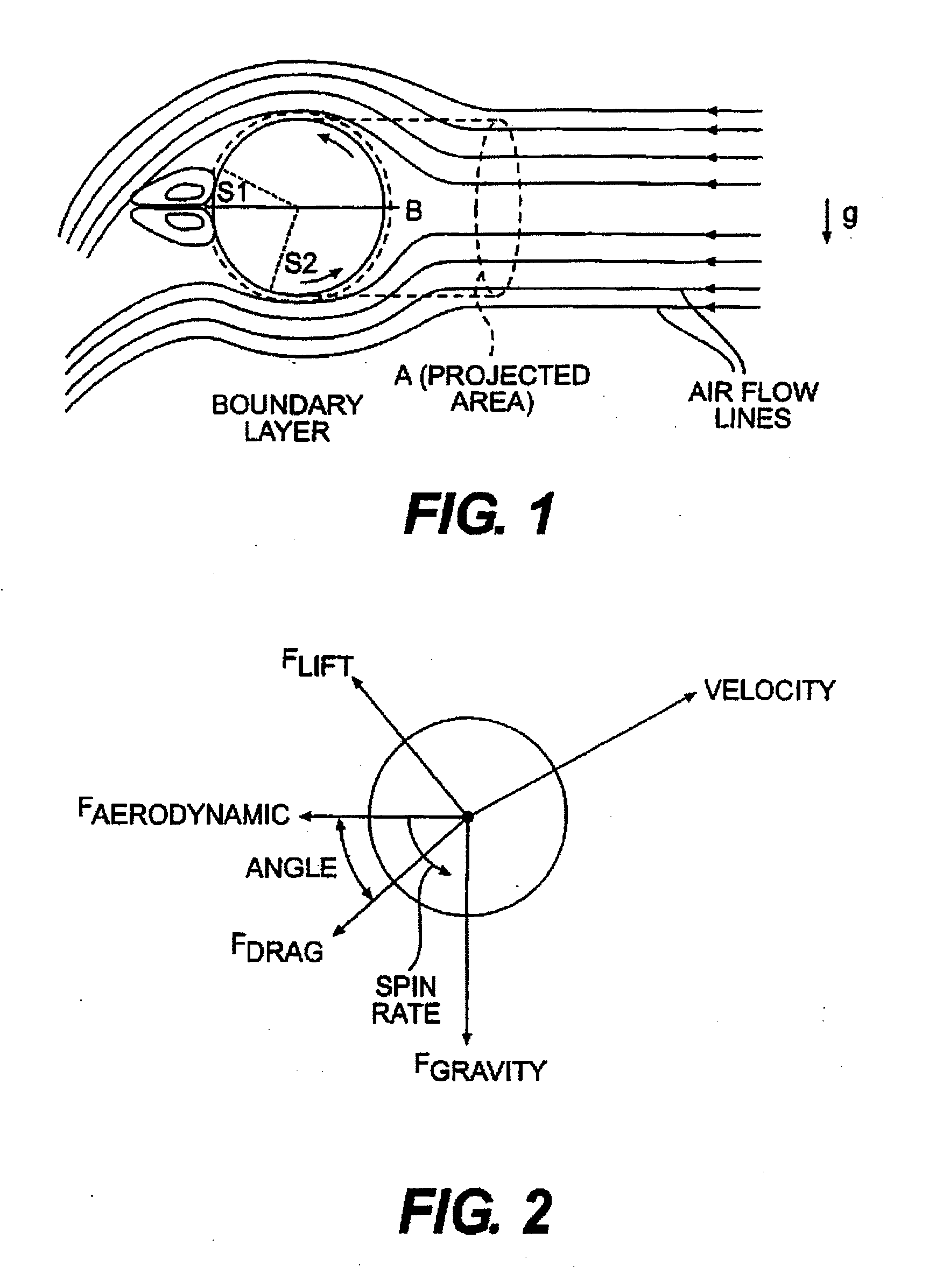

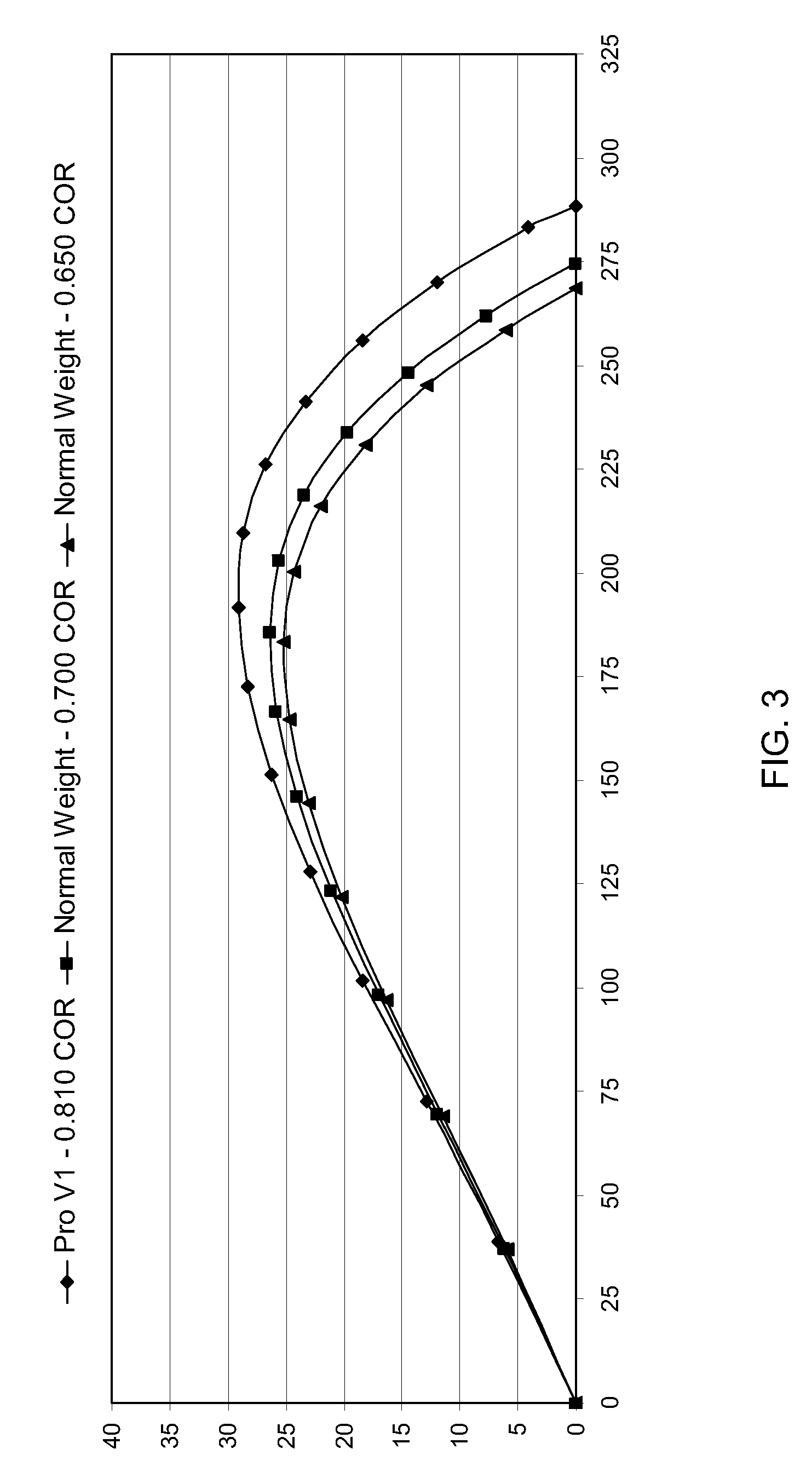

[0024]The distance that a golf ball will travel upon impact by a golf club is a function of the coefficient of restitution (CoR), the weight, and the aerodynamic characteristics of the ball, which among other things are affected by one or more factors, such as the size, dimple coverage, dimple size and dimple shape. An embodiment of the present invention provides for a golf ball having a combination of low CoR core and cover materials coupled with a less efficient aerodynamic dimple pattern that achieves a reduction in carry and overall distance of at least 5 yards versus a conventional golf ball, while still providing the look, sound, feel and trajectory shape of a conventional golf ball. In various embodiments of the present invention, a high performance golf ball having a reduced distance is achieved via a combination of increased coefficient of drag, increased coefficient of lift, reduced weight, increased size, reduced compression, and / or decreased CoR. Specific embodiments of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com