Nano-silver dispersion liquid and preparation method of nano-silver dispersion liquid as well as preparation method of nano-silver antibacterial coating

A nano-silver and dispersion technology, which is applied in coating, metal material coating process, liquid chemical plating, etc., can solve the problems of no affinity, lower silver concentration, single stable nano-dispersion, etc., to achieve improved hydrophilicity or Effects of hydrophobicity, reduction of raw material cost, and enhancement of hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

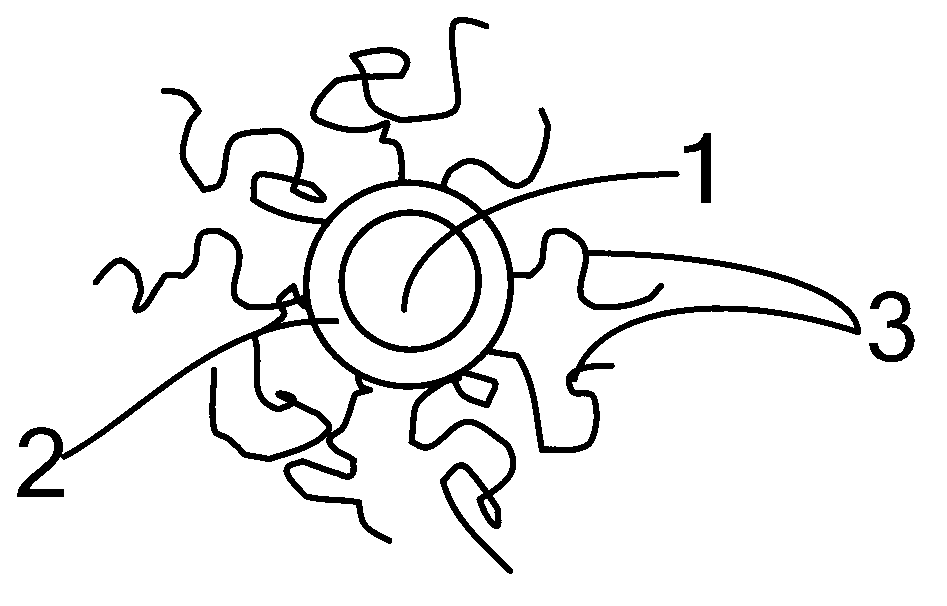

Image

Examples

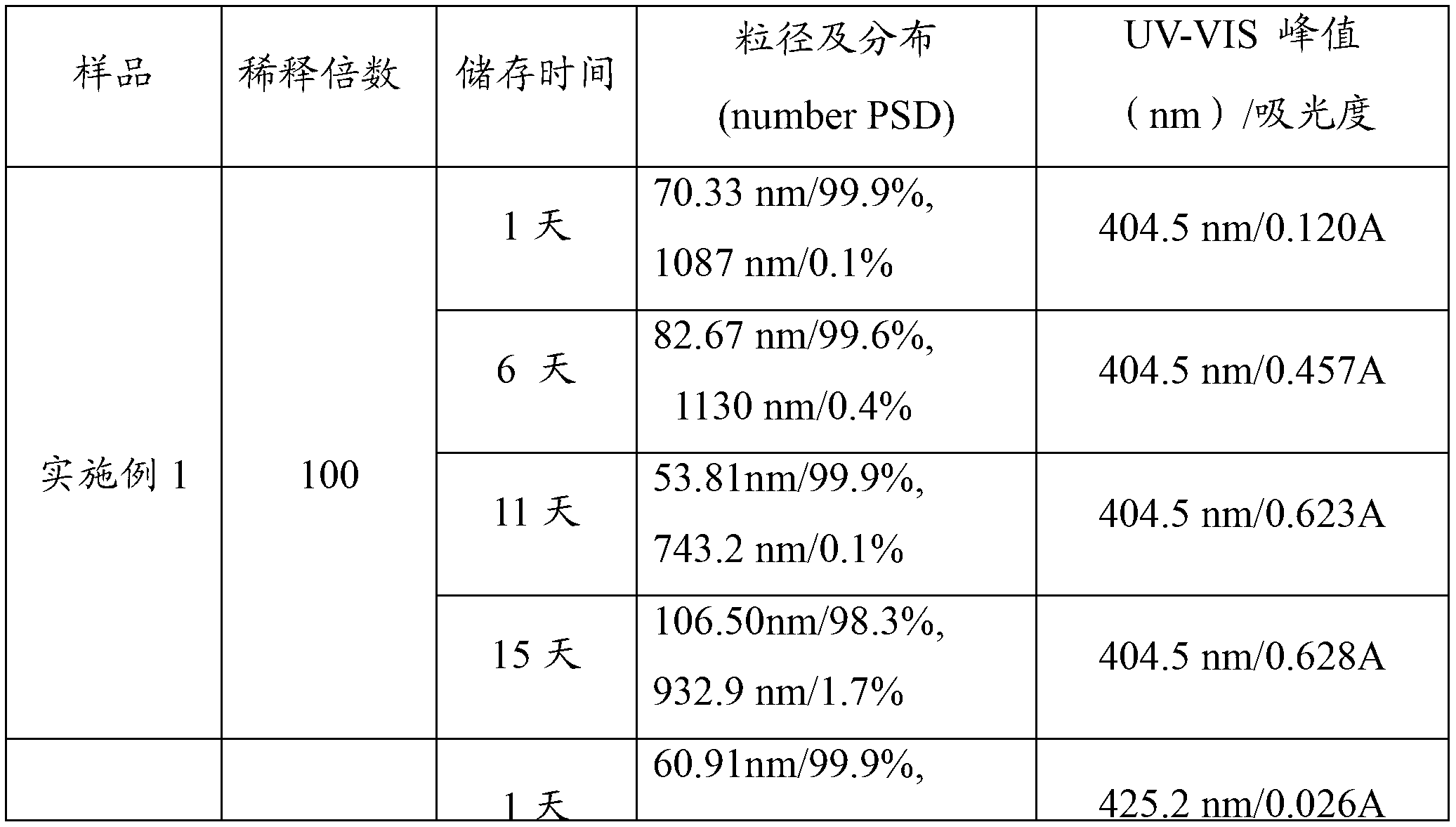

Embodiment 1

[0064] A preparation method of nano-silver dispersion liquid, comprising the following steps:

[0065] (1) Mix 1.185 grams of hydroxyethyl cellulose aqueous solution with a mass concentration of 3% and 19 grams of distilled water evenly, and then add 0.095 grams of dispersant (brand: BYK380N, first diluted into an aqueous solution with a mass concentration of 50%);

[0066] (2) Add 1 gram of silver nitrate to the above solution, and stir until the solid silver nitrate is completely dissolved to obtain a silver nitrate solution;

[0067] (3) Add 0.489 g of distilled water dropwise to 1.621 g of aminopropyltrimethoxysilane under stirring to obtain a total of 2.11 g of hydrolyzate;

[0068] (4) Under high-speed stirring, add 2.11 g of the aminopropyltrimethoxysilane hydrolyzate obtained above to the silver nitrate solution dropwise, and continue stirring for 3 minutes after the addition is completed;

[0069] (5) Under stirring, add 1.591 grams of glucose solution with a mass co...

Embodiment 2

[0072] A preparation method of nano-silver dispersion liquid, comprising the following steps:

[0073] (1) Mix 1.0 g of hydroxyethyl cellulose aqueous solution with a mass concentration of 3% and 19.998 g of distilled water evenly, then add 0.08 g of dispersant (brand: BYK380N, first dilute into an aqueous solution with a mass concentration of 50%);

[0074] (2) Add 0.002 g of silver nitrate to the above solution, and stir until the solid silver nitrate is completely dissolved to obtain a silver nitrate solution;

[0075] (3) Add 0.489 g of distilled water dropwise to 1.621 g of aminopropyltrimethoxysilane under stirring to obtain a total of 2.11 g of hydrolyzate;

[0076] (4) Under high-speed stirring, add 0.004 g of the aminopropyltrimethoxysilane hydrolyzate obtained above to the silver nitrate solution dropwise, and continue stirring for 3 minutes after the addition is completed;

[0077] (5) Under stirring, add 0.013 g of glucose solution with a mass concentration of 10%...

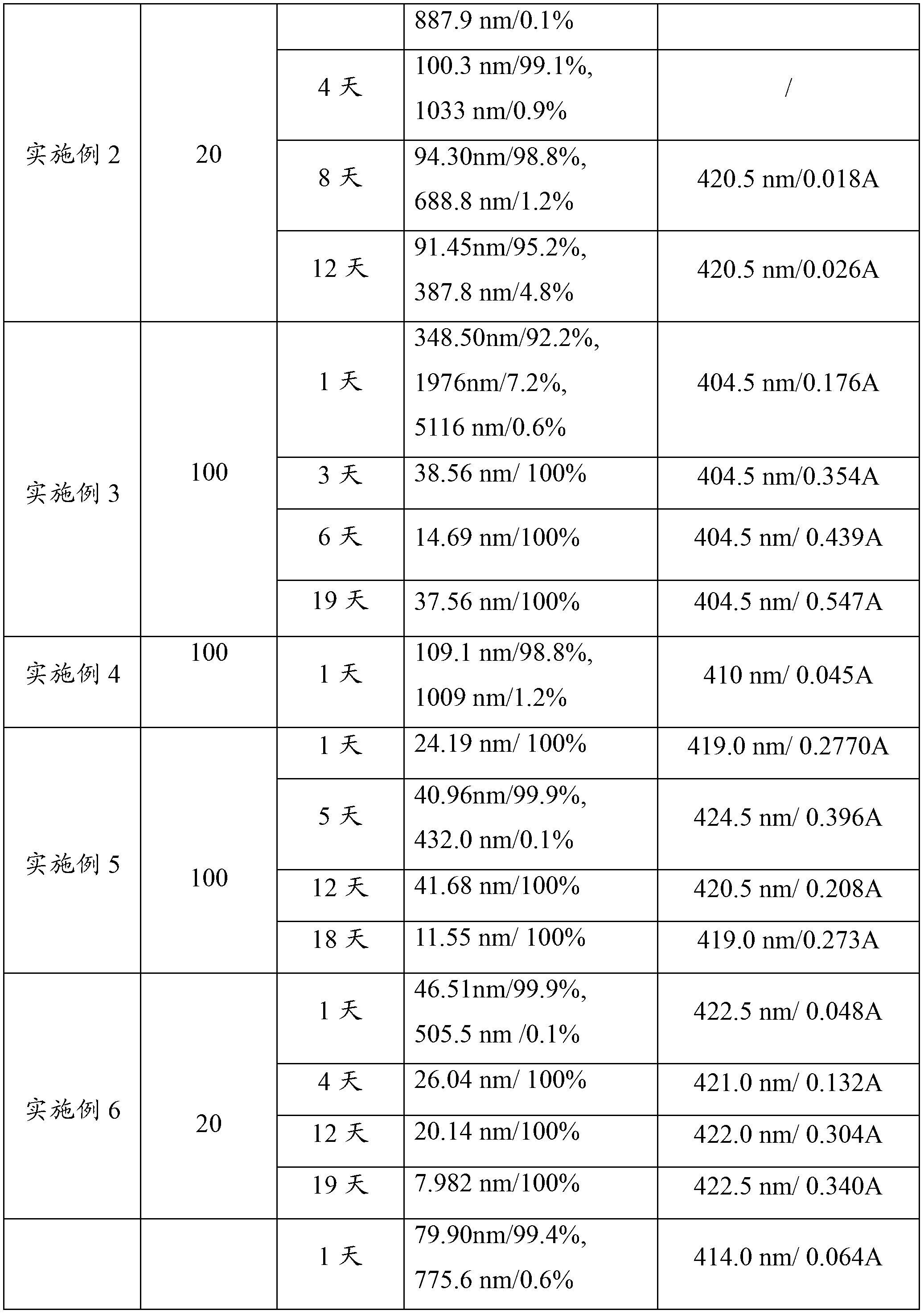

Embodiment 3

[0080] A preparation method of nano-silver dispersion liquid, comprising the following steps:

[0081] (1) Mix 1.185 grams of hydroxyethyl cellulose aqueous solution with a mass concentration of 3% and 19 grams of distilled water evenly, then add 0.095 grams of dispersant (brand: BYK380N, first dilute into an aqueous solution with a mass concentration of 50%);

[0082] (2) Add 1 gram of silver nitrate to the above solution, and stir until the solid silver nitrate is completely dissolved to obtain a silver nitrate solution;

[0083] (3) Add 0.02 g of nano-silica particles (brand name: DegussaA200) to the obtained silver nitrate solution, and disperse the mixed solution by ultrasonic waves for 30 minutes until all nano-silica particles are evenly dispersed in the solution. At this time, The appearance of the solution is translucent liquid;

[0084] (4) Add 0.489 g of distilled water dropwise to 1.621 g of aminopropyltrimethoxysilane under stirring to obtain a total of 2.11 g of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com