Synthesis method for urease inhibitor and application of urease inhibitor

The technology of a urease inhibitor and a synthesis method, which is applied in the synthesis field of urease inhibitors, can solve the problems of low utilization rate, difficult use, thermal instability and the like, and achieves the effects of good finished product quality, short processing flow and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

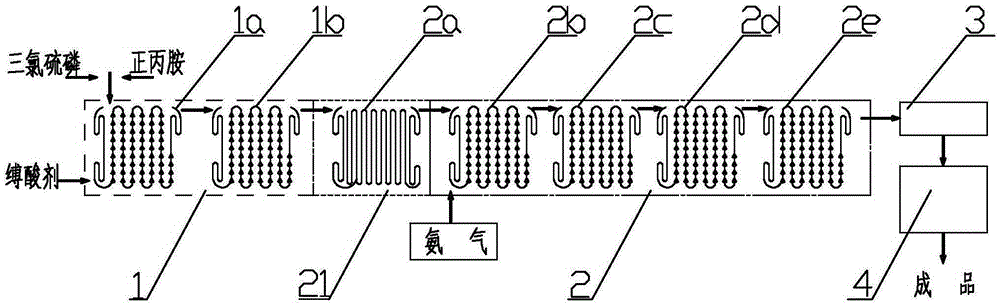

[0031] Embodiment 1-6: the impact of main raw material addition amount on yield

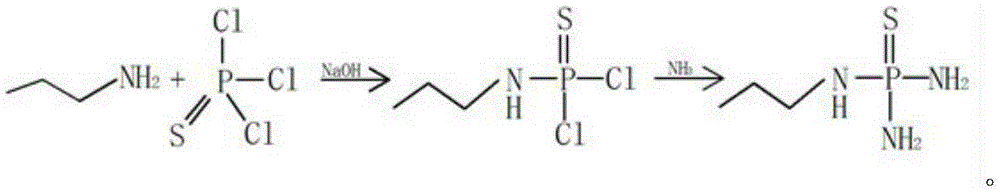

[0032] The raw materials are mainly n-propylamine and trichlorophosphoric acid. In this embodiment, the addition ratio is mainly reflected by n-propylamine. The addition amount of each component (trichlorophosphoric acid: n-propylamine: NaOH is the molar ratio) and its influence on the yield and purity are shown in Table 1.

[0033] Table 1 The impact of different addition ratios on the yield

[0034]

[0035]n-Propylamine and parathion trichloride participate in the reaction, fixed at a certain temperature, under the conditions of 20 seconds of reaction time, when n-propylamine is a small amount, the content of impurity thiophosphoric triamide in the product rises, and the yield decreases; when n-propylamine is excessive , the impurity di-n-propylthiophosphoric triamide amount rises in the product, and the product yield declines; as can be seen from Table 1, when n-propylamine: phosphorus tr...

Embodiment 7-9

[0036] Embodiment 7-9: the influence of reaction atmosphere pressure on yield

[0037] In the reaction process, pressure, as the driving force of material transportation, will directly affect the transfer of materials and the reaction time. n-Propylamine and phosphorous trichloride participate in the reaction, at a fixed feed ratio and kept at a certain temperature, the impact of reaction atmosphere pressure on the yield is shown in Table 2 (trichlorophosphoric acid: n-propylamine: NaOH is the molar ratio, and the pressure unit is MPa).

[0038] The impact of different reaction pressures on the yield in table 2

[0039]

[0040] In this application, the pressure of the reaction atmosphere is the internal pressure of the microchannel. When the back pressure valve of the microchannel reactor is controlled to 0-0.5MPa, the time for materials to pass through the reactor normally is 10-15s for one module and 20-30s for two modules. Shown in conjunction with table 2, because wh...

Embodiment 10-15

[0040] In this application, the pressure of the reaction atmosphere is the internal pressure of the microchannel. When the back pressure valve of the microchannel reactor is controlled to 0-0.5MPa, the time for materials to pass through the reactor normally is 10-15s for one module and 20-30s for two modules. Shown in conjunction with table 2, because when passing through a module, residence time 10-15s, reaction does not reach completely, so yield is low; When passing through two modules, residence time reaches 20-30s, yield can have larger Improve; when the control back pressure valve is 0MPa, the time for the material to pass through one module in the microchannel is 10s, and the time for passing through two modules is 20s. At this time, the material can completely react, and the product yield can reach 89%; When the number of modules increases the reaction time, because there is almost no back-mixing phenomenon in the channel, increasing the residence time has almost no eff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com