Green process for producing vinyl beta-ionol

A technology of ionol and green technology, applied in the field of green technology, can solve the problems of high production equipment requirements, THF recovery and treatment, THF loss, etc., to improve the conversion rate of raw materials, ensure the safety and stability of the reaction, and reduce the reaction time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

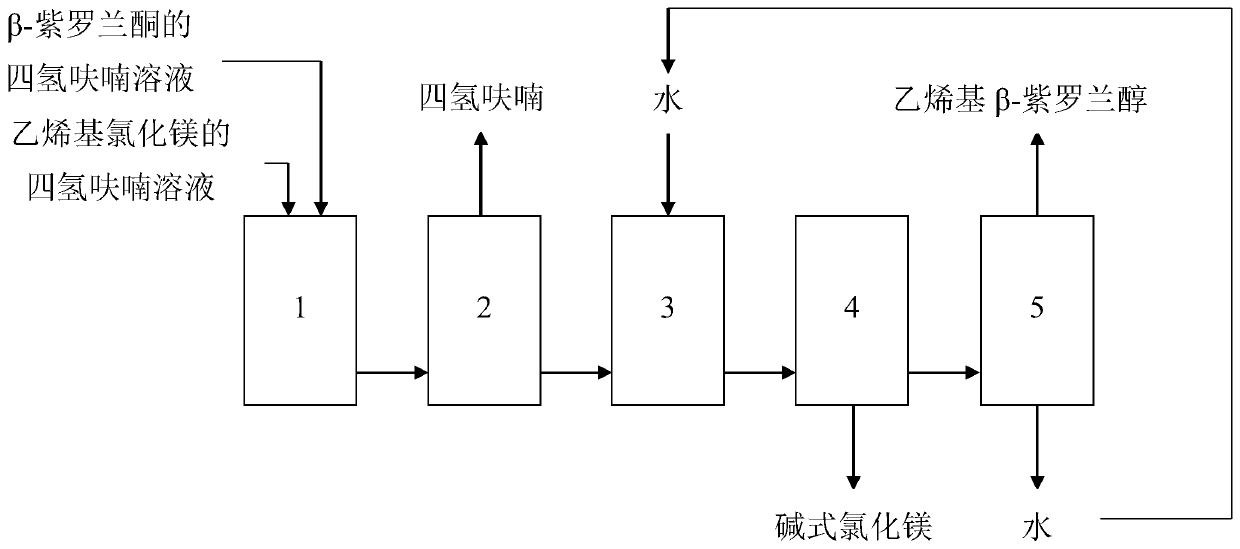

[0042] Pump anhydrous tetrahydrofuran into microchannel reactor 1, discharge the air in the microchannel, set the reaction temperature to 0°C, and continuously pump 2.0mol / L β-ionone tetrahydrofuran solution and 2.0mol / L ethylene Magnesium chloride tetrahydrofuran solution, the pump flow rate is 0.5L / h. Collect the reaction solution flowing out and recover anhydrous tetrahydrofuran through vacuum distiller 2 at room temperature and vacuum distillation. The pressure in the vacuum distillation is -0.098Mpa, and the substrate is slowly added to the hydrolysis reactor 3 filled with 200ml of ice water and stirred for hydrolysis. React until no solid precipitates out, filter through the filter 4 to remove the basic magnesium chloride solid, pass the filtrate into the liquid separator 5, let the filtrate stand for layers, and separate the upper oil phase to obtain the product vinyl β-ionol , the lower water phase returns to pass in the hydrolysis reactor 3 and continues to be used fo...

Embodiment 2

[0044] Pump anhydrous tetrahydrofuran into microchannel reactor 1, discharge the air in the microchannel, set the reaction temperature to 10°C, and continuously pump 1.6mol / L β-ionone tetrahydrofuran solution and 1.6mol / L ethylene Magnesium chloride tetrahydrofuran solution, the pump flow rate is 1.0L / h. Collect the reaction solution flowing out and recover anhydrous tetrahydrofuran through vacuum distiller 2 at room temperature and vacuum distillation. The pressure in the vacuum distillation is -0.091Mpa, and the substrate is slowly added to the hydrolysis reactor 3 filled with 400ml ice water and stirred for hydrolysis. React until no solid precipitates out, filter through the filter 4 to remove the basic magnesium chloride solid, pass the filtrate into the liquid separator 5, let the filtrate stand for layers, and separate the upper oil phase to obtain the product vinyl β-ionol , the lower water phase returns to pass in the hydrolysis reactor 3 and continues to be used for ...

Embodiment 3

[0046]Pump anhydrous tetrahydrofuran into microchannel reactor 1, discharge the air in the microchannel, set the reaction temperature at 5°C, and continuously pump 1.0mol / L β-ionone tetrahydrofuran solution and 1.0mol / L ethylene Magnesium chloride tetrahydrofuran solution, the pump flow rate is 2.0L / h. Collect the reaction liquid flowing out and recover anhydrous tetrahydrofuran through vacuum distiller 2 at room temperature and vacuum distillation. The pressure in the vacuum distillation is -0.08Mpa, and the substrate is slowly added to the hydrolysis reactor 3 containing 500ml of 15°C water and stirred. Hydrolyze until no solid precipitates out, filter through the filter 4 to remove the basic magnesium chloride solid, pass the filtrate into the liquid separator 5, let the filtrate stand for layers, and separate the upper oil phase to obtain the product vinyl β-violet Alcohol, the lower floor water phase returns to pass in the hydrolysis reactor 3 and continues to be used for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com