Cumene hydroperoxide normal-pressure tubular reactor and production technology

A cumene hydrogen peroxide, tubular reactor technology, which is applied in the preparation of peroxy compounds, chemical instruments and methods, organic chemistry, etc., can solve the problem that the safety needs to be further improved, the air residence time is short, and the CHP is unstable. problem, to achieve the effect of simple structure, low cost and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

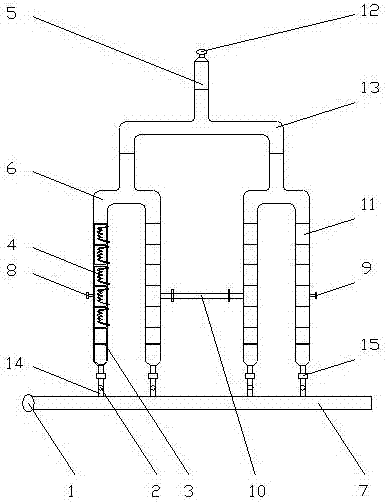

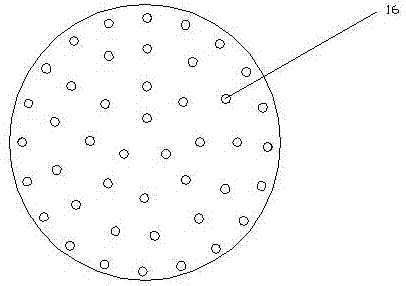

[0025] The cumene hydrogen peroxide atmospheric pressure tubular reactor of the present invention comprises a reactor 11, a spiral tube heat exchanger 4, a condenser 5, and connecting pipelines. Said reactor 11, spiral tube heat exchanger 4, and condenser 5 are connected through connecting pipelines. There are five reactors 11, which are connected to each other by flanges to form a reactor group, and one end of the formed reactor group is connected to the reactor connecting pipe 6 through a flange. The other end of the reactor connecting pipe 6 is connected with the condenser connecting pipe 13 through a flange. The condenser connecting pipe 13 is connected with the condenser 5, and the top of the condenser 5 is equipped with a reaction gas outlet 12 for removing the acid gas generated by the oxidation reaction. The pipeline at the other end of the reactor group is equipped with an air distributor 3, and the air distributor 3 is evenly formed with air distribution holes 16. ...

Embodiment 2

[0028] The reactor 11 of the cumene hydrogen peroxide atmospheric tubular reactor of the present invention is 6, and the reactor group is 8, and the remaining parts and the connection mode of the cumene hydrogen peroxide atmospheric tubular reactor and implementation Example 1 is the same.

[0029] The production process of the cumene hydrogen peroxide atmospheric pressure tubular reactor of the present invention is in the reactor 11, the heat exchange medium is heated by the spiral tube heat exchanger 4, the temperature is controlled at 70°C, and the reaction materials are fully mixed with the air , Carry out oxidation reaction under normal pressure, all the other processes are identical with embodiment 1.

Embodiment 3

[0031] The reactor 11 of the cumene hydrogen peroxide atmospheric pressure tubular reactor of the present invention is 7, and the reactor group is 12, and the remaining parts of the cumene hydrogen peroxide atmospheric pressure tubular reactor and the connection method and implementation Example 1 is the same.

[0032] The production process of the cumene hydrogen peroxide atmospheric pressure tubular reactor of the present invention is in the reactor 11, the heat exchange medium is heated by the spiral tube heat exchanger 4, the temperature is controlled at 90 ° C, and the reaction materials are fully mixed with the air , Carry out oxidation reaction under normal pressure, all the other processes are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com