Continuous ultralow temperature reaction device

A chemical reaction, ultra-low temperature technology, applied in the field of continuous ultra-low temperature reaction devices, can solve the problems of reduced yield of target products, high labor costs, low production efficiency, etc., to avoid the aggravation of side reactions, high work efficiency, increase Effect of reactive contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

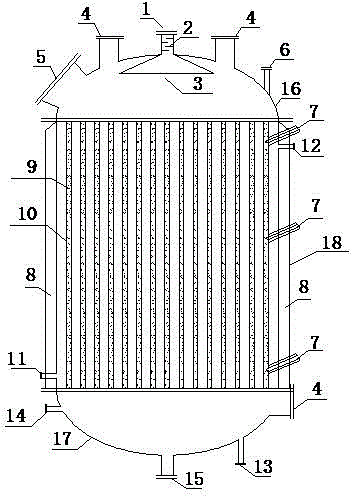

[0013] The reaction device of the present invention comprises an upper head 16 , a lower head 17 and a kettle body 18 . Its characteristics are: the upper head 16 is provided with a sight glass port 4, a manhole port 5, an inert gas inlet 6 and a feed port 1, a static tray 2 is installed in the feed port 1 pipeline, and the end of the feed port 1 pipe is A cloth distributor 3 is connected. Different liquid raw materials enter the pipeline through the feed inlet 1, are mixed on the static tray 2 in the pipeline of the feed inlet 1, and are continuously transported into the reactor after passing through the distributor 3. The kettle body 18 is composed of a series of tubes 10, an outer jacket 8, and a thermometer 7. The series of tubes 10 are vertically arranged in parallel and are equal to the length of the kettle body 18. The round holes distributed on the top are correspondingly connected, and the lower nozzle is connected correspondingly with the round holes on the bottom p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com