Patents

Literature

33 results about "Fixed bed bioreactor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

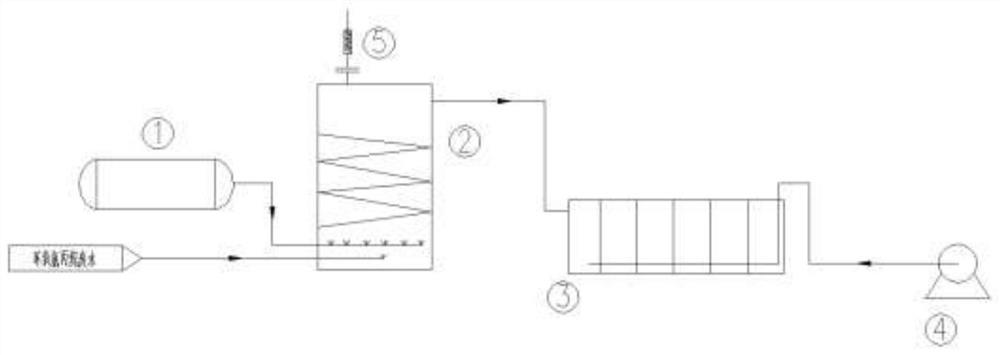

Dissimilatory sulfate reduction as a process to promote denitrification in marine recirculating aquaculture systems

InactiveUS7462284B2Promote autotrophic denitrificationPromote dissimilatory sulfate reductionWater treatment parameter controlWater contaminantsHigh concentrationSludge

Owner:UNIV OF MARYLAND BALTIMORE COUNTY

Dissimilatory sulfate reduction as a process to promote denitrification in marine recirculating aquaculture systems

InactiveUS20070163952A1Promote dissimilatory sulfate reductionReduce water exchangeWater treatment parameter controlWater contaminantsHigh concentrationSludge

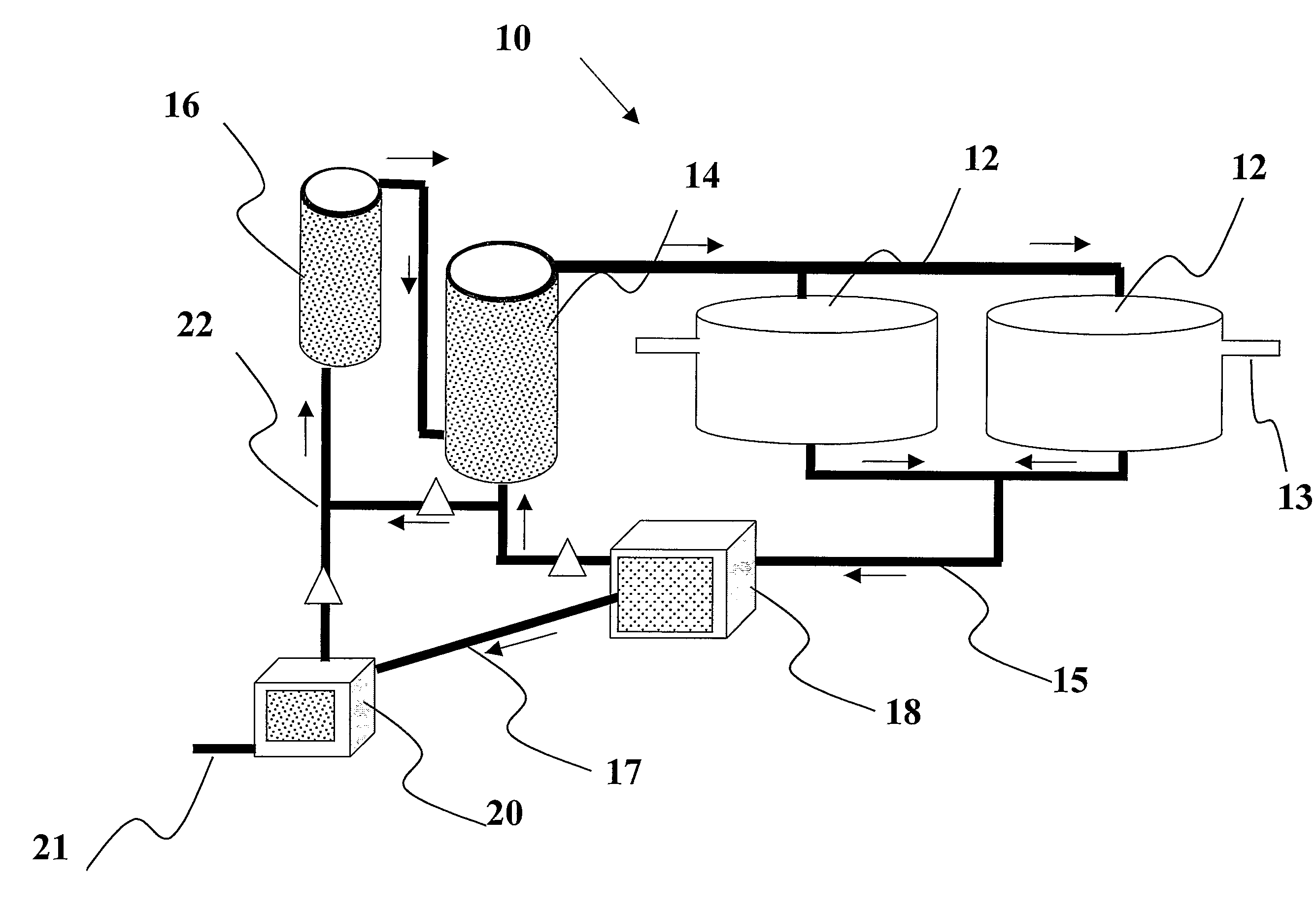

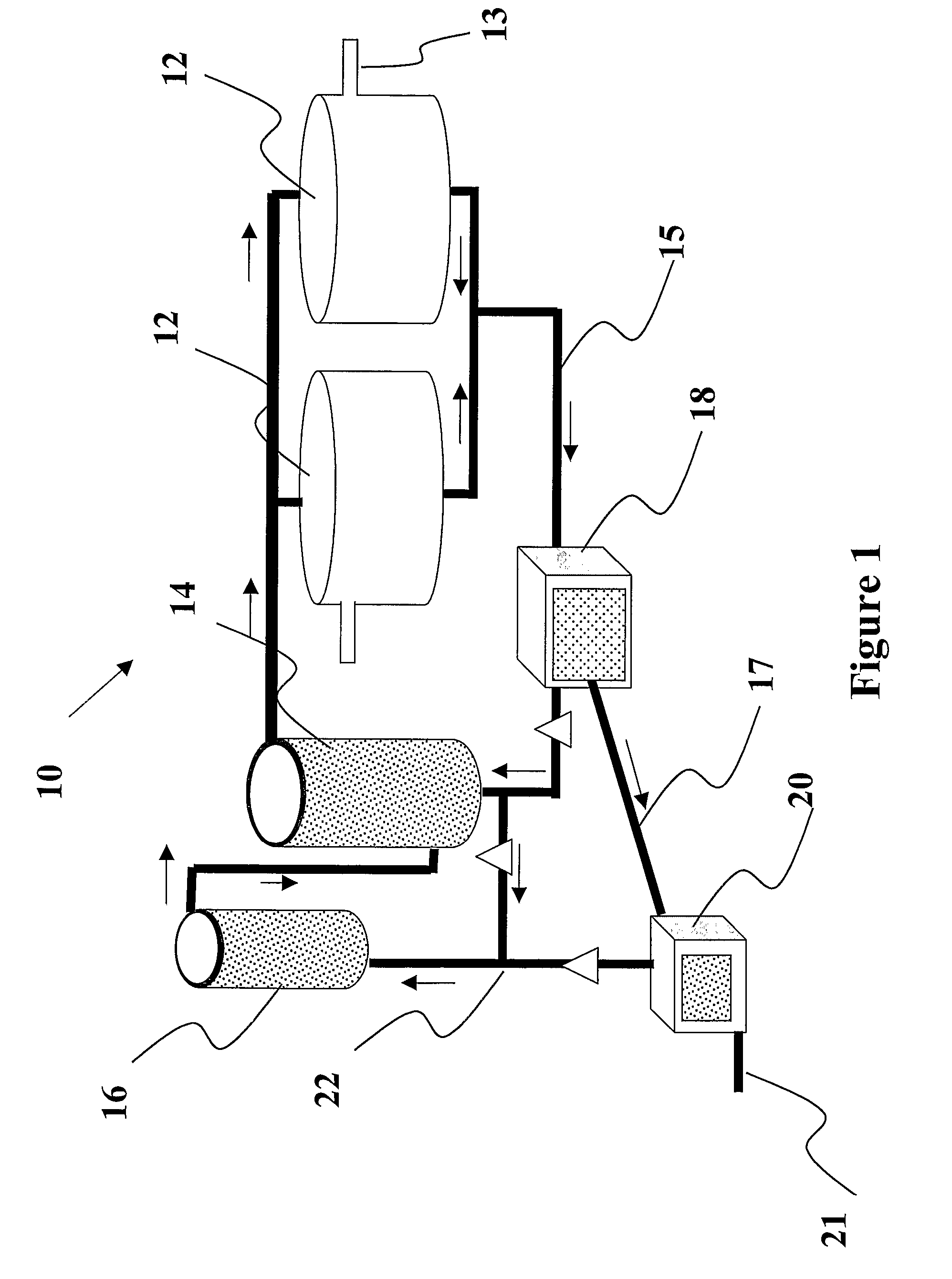

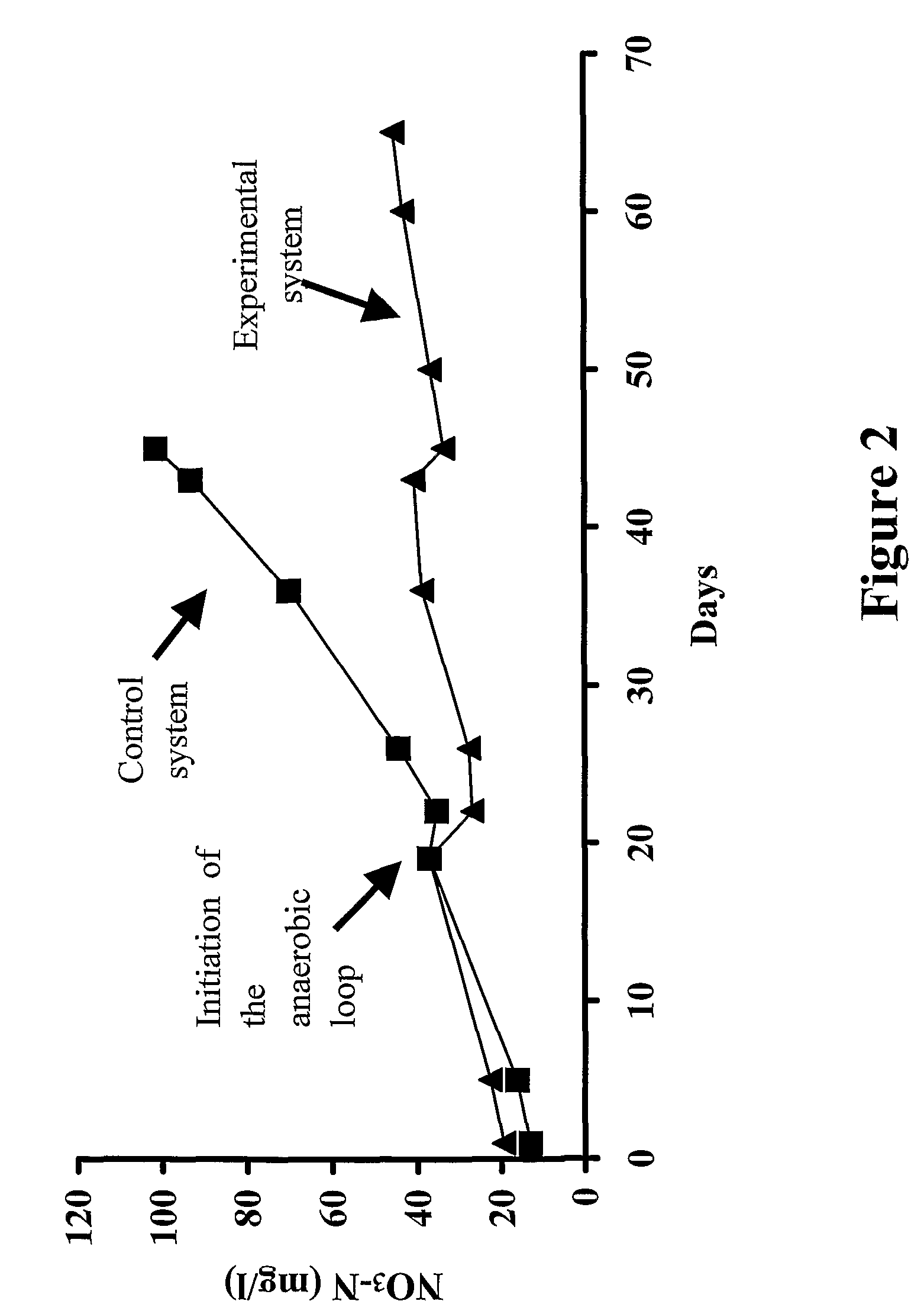

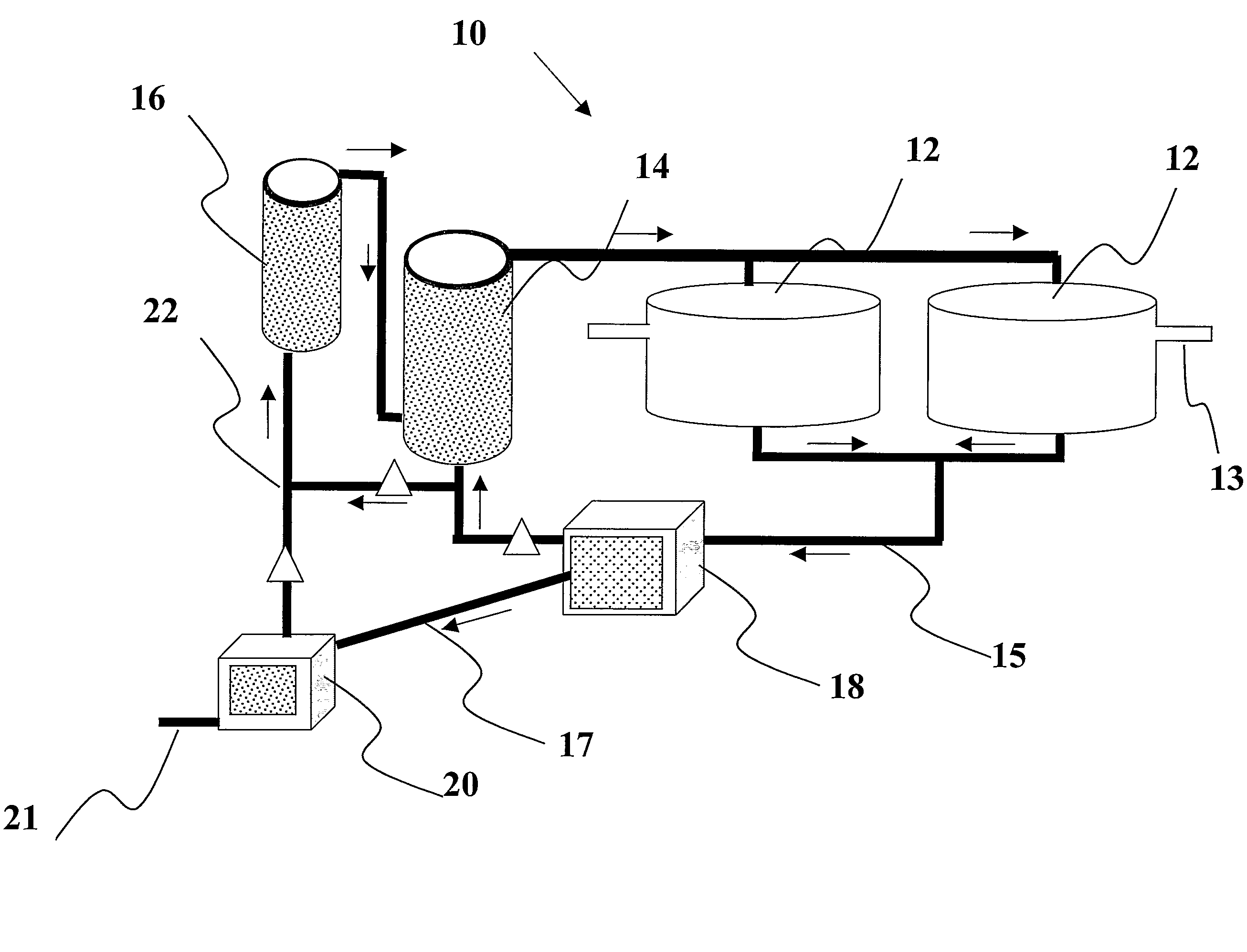

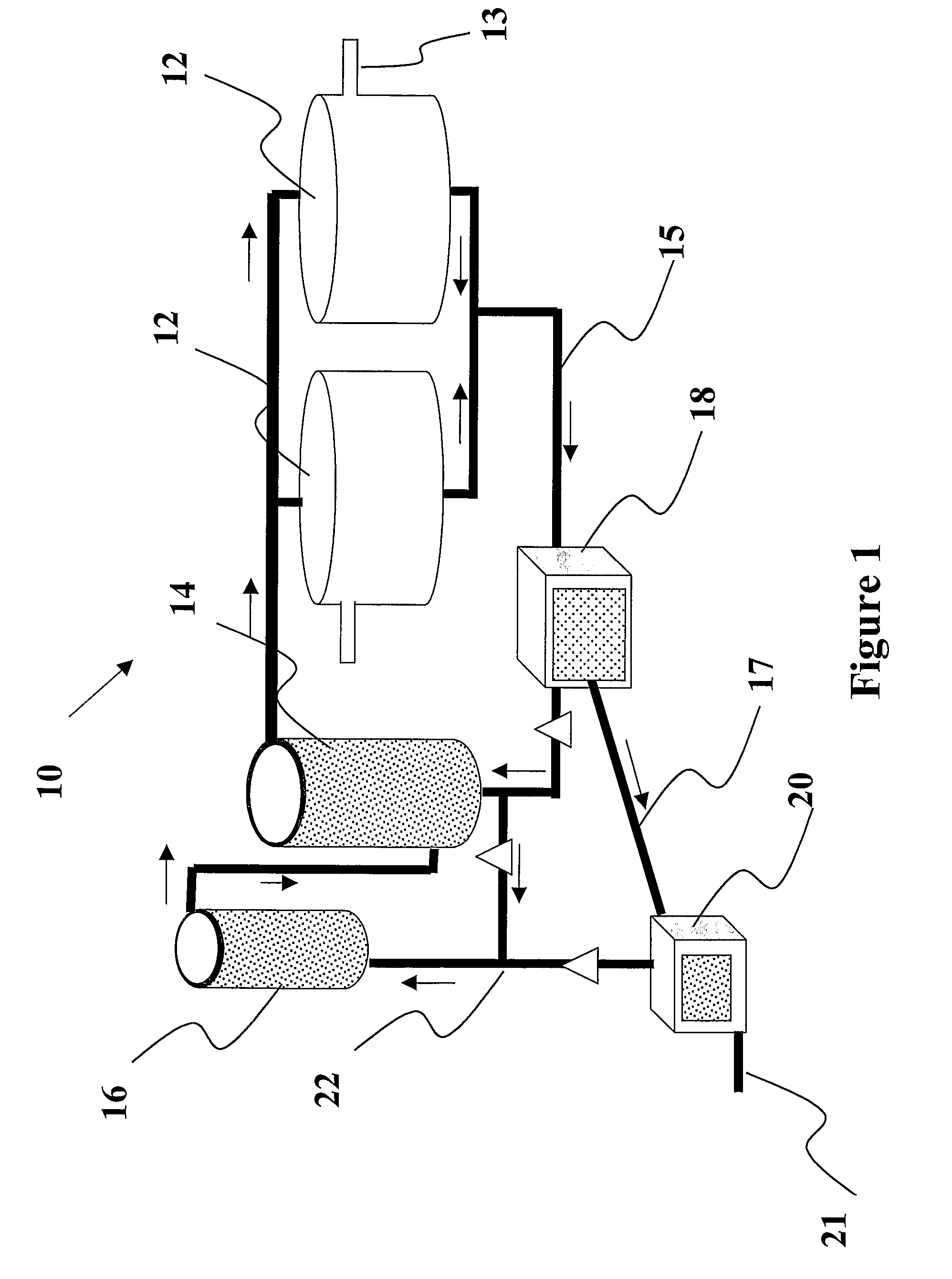

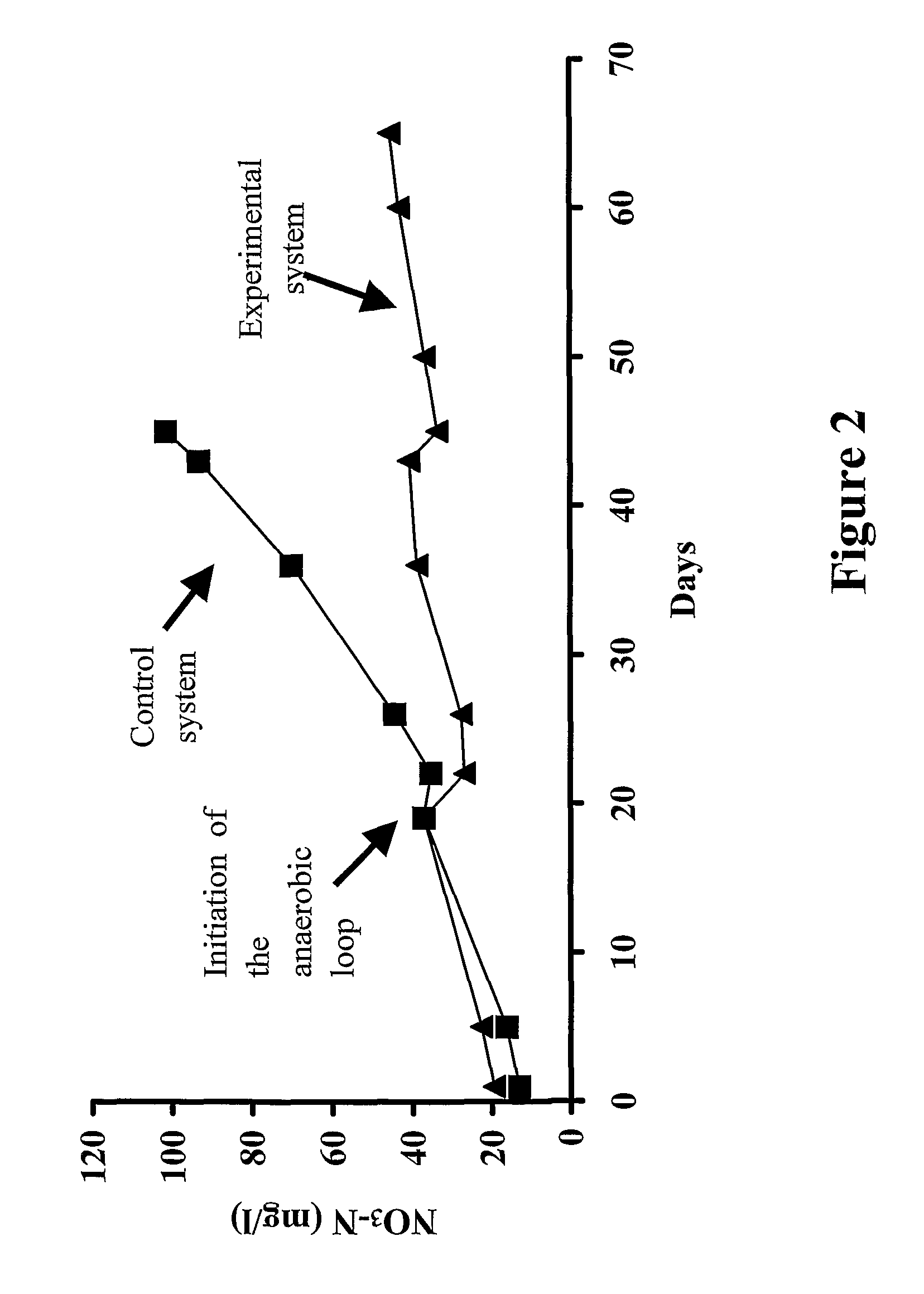

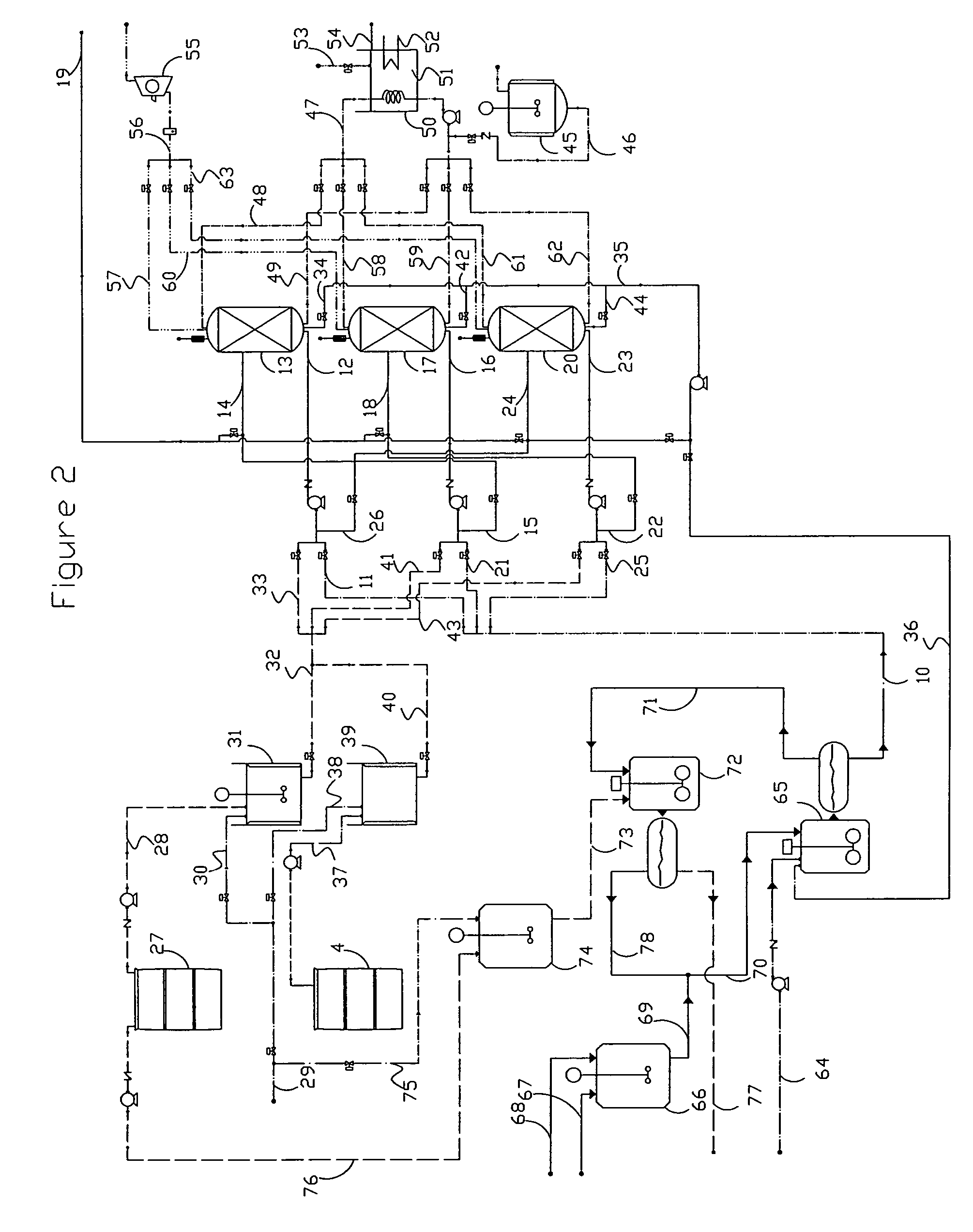

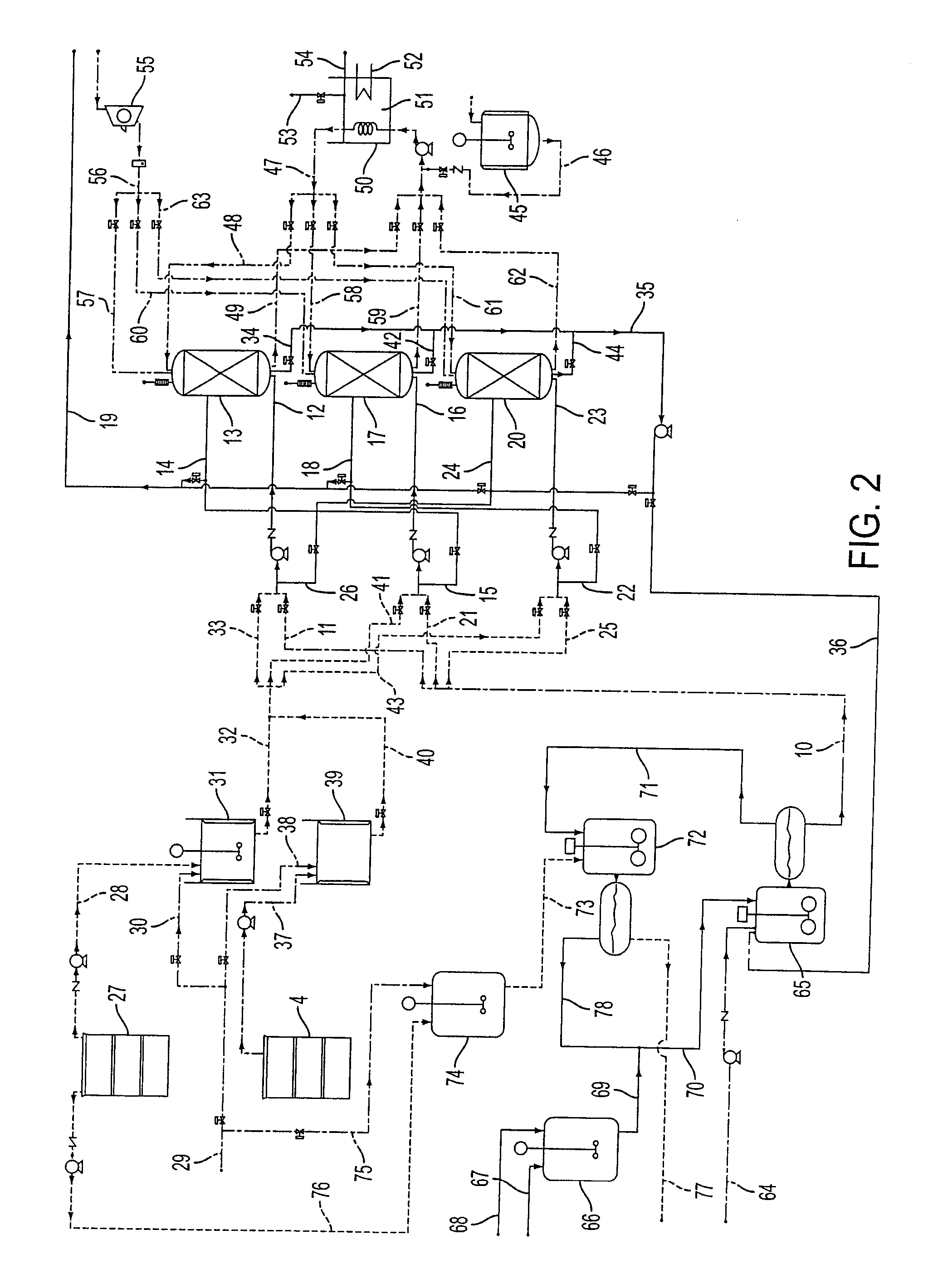

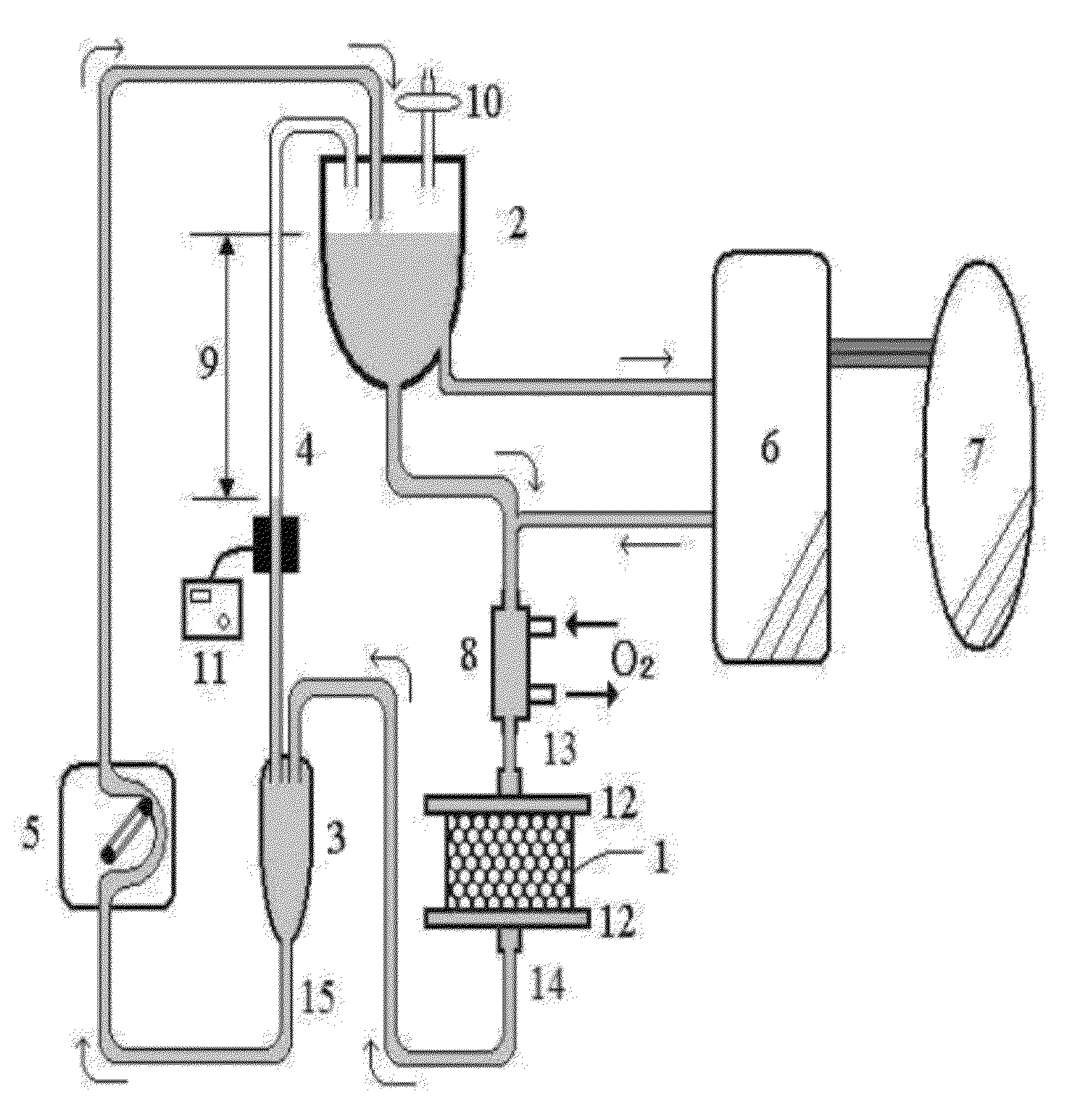

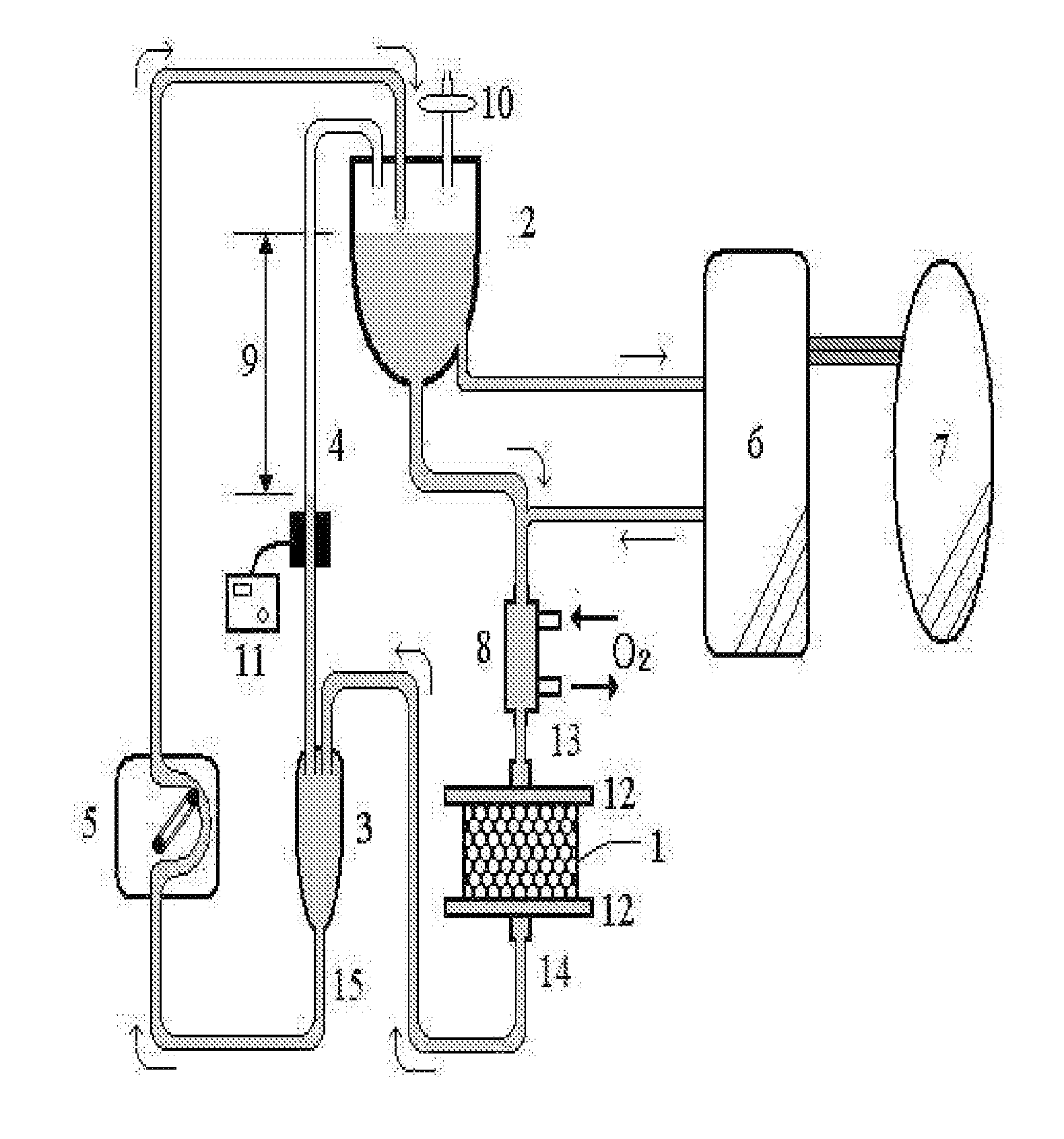

The present invention relates to a novel approach for nitrate removal from a marine recirculating system (10) wherein high concentrations of sulfate found in seawater is used in combination with sludge (20) collected from fish growing tanks (12) to promote dissimilatory sulfate reduction to hydrogen sulfide. The sulfide is used as an electron source to promote autotrophic denitrification in an up-flow fix bed bioreactor (16), followed by nitrification in a nitrification unit (14). By utilizing the symbiotic relationship between the sulfate-reducing and sulfide-oxidizing bacterial community, nitrate accumulation is controlled in the recirculating water of the system thereby reducing water exchange in the marine recirculating system.

Owner:UNIV OF MARYLAND BALTIMORE COUNTY

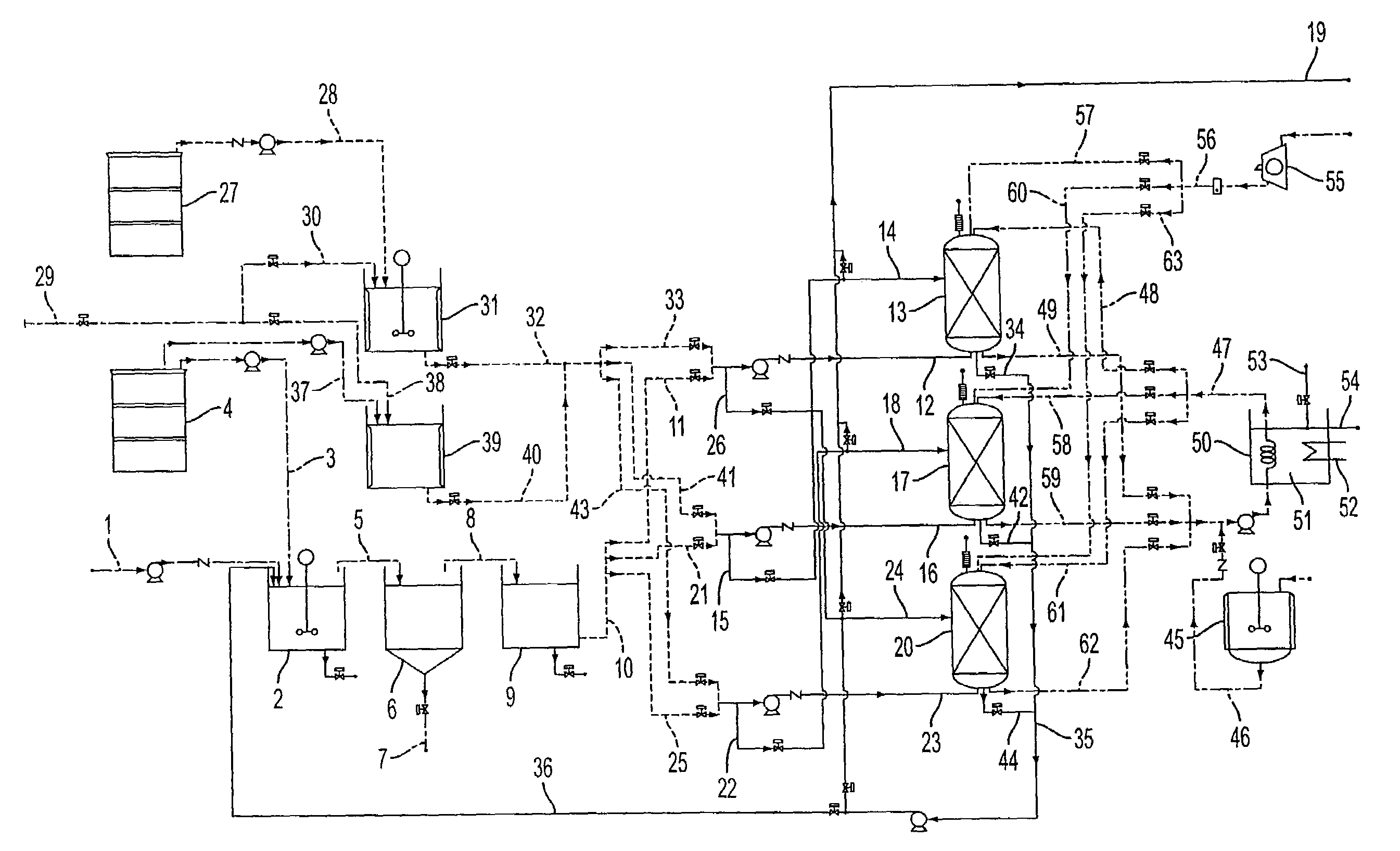

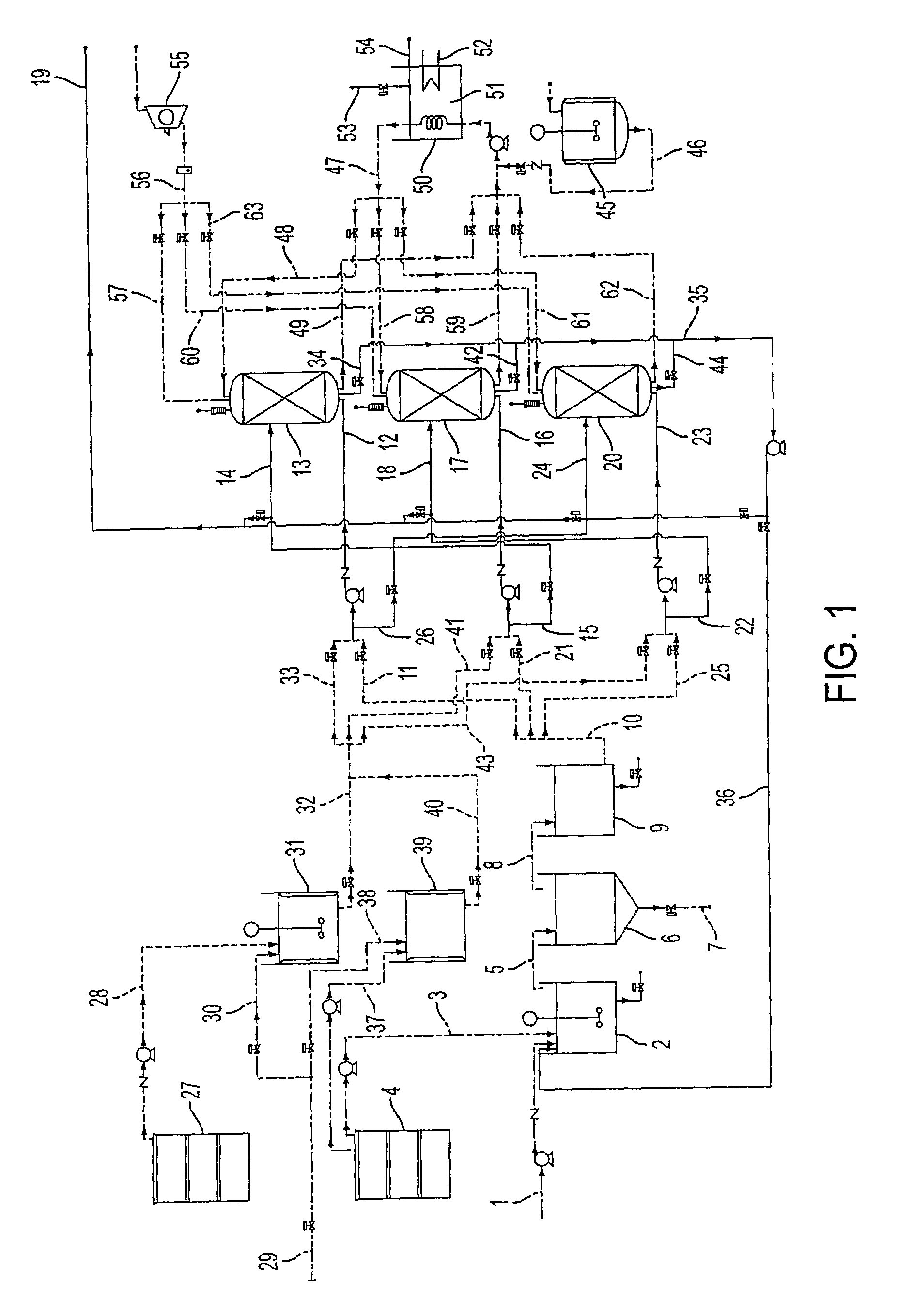

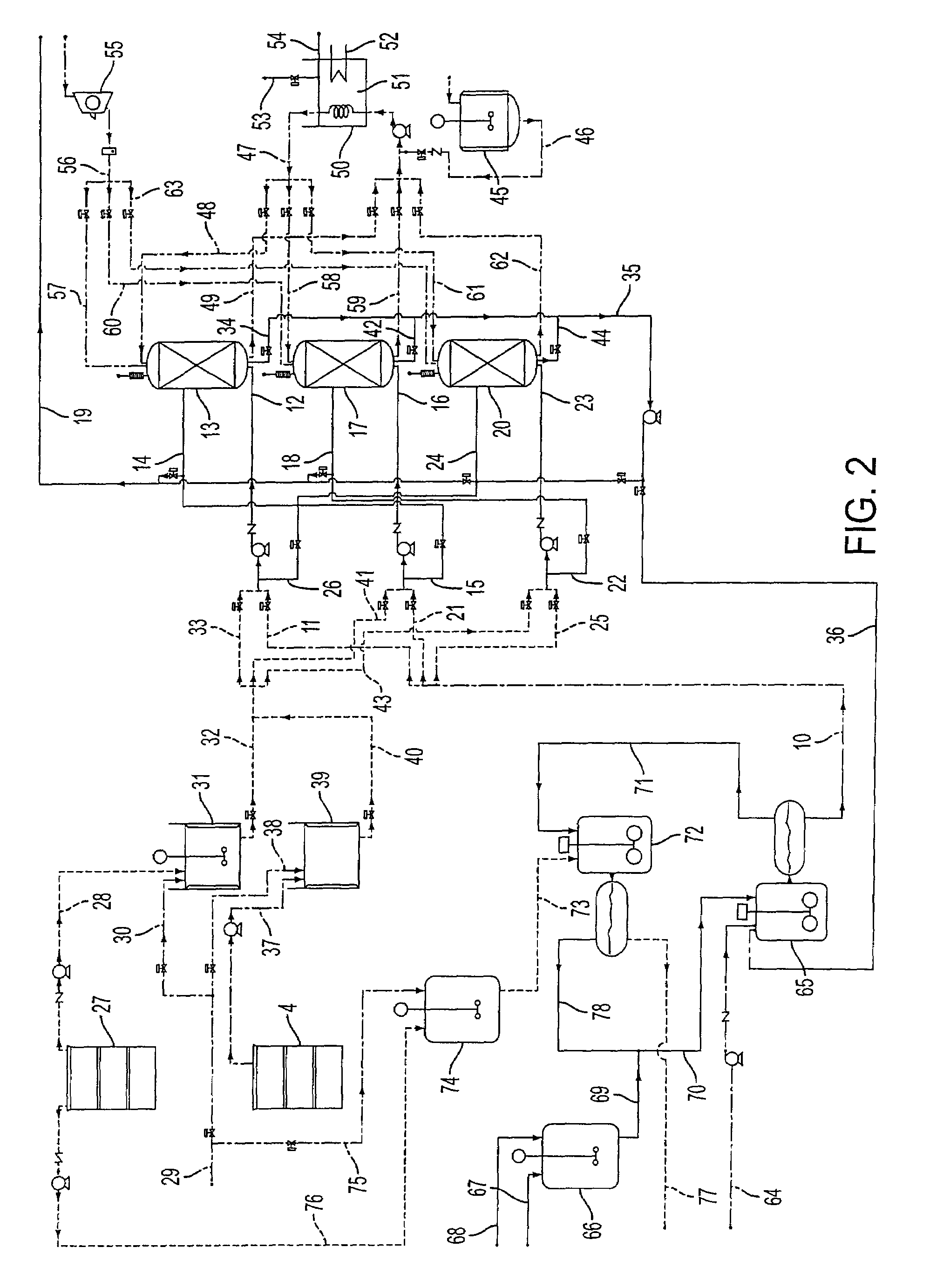

Process for the removal of metals by biosorption from mining or industrial effluents

InactiveUS7326344B2Increase capacityWaste water treatment from quariesTreatment using aerobic processesSolventTreated water

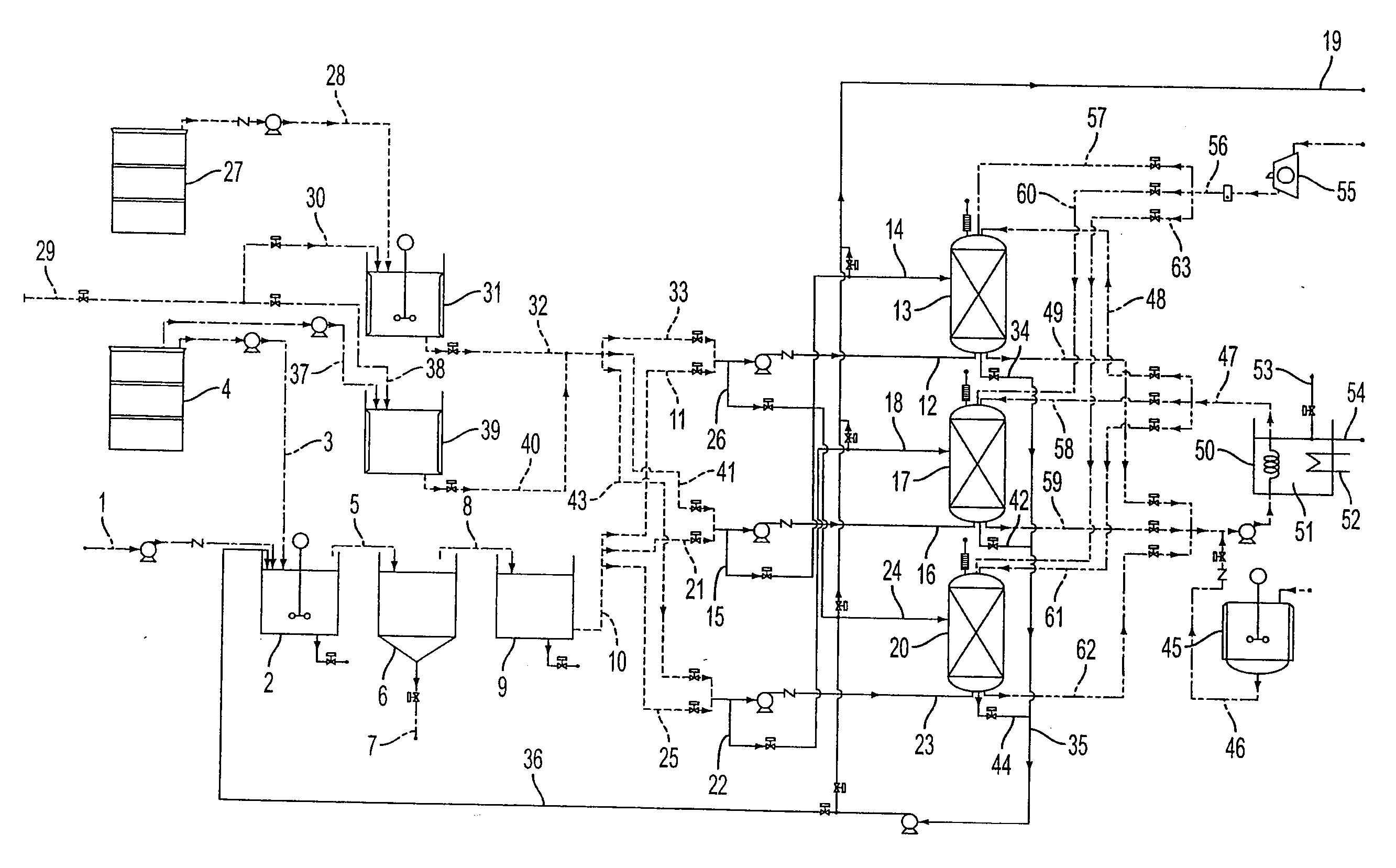

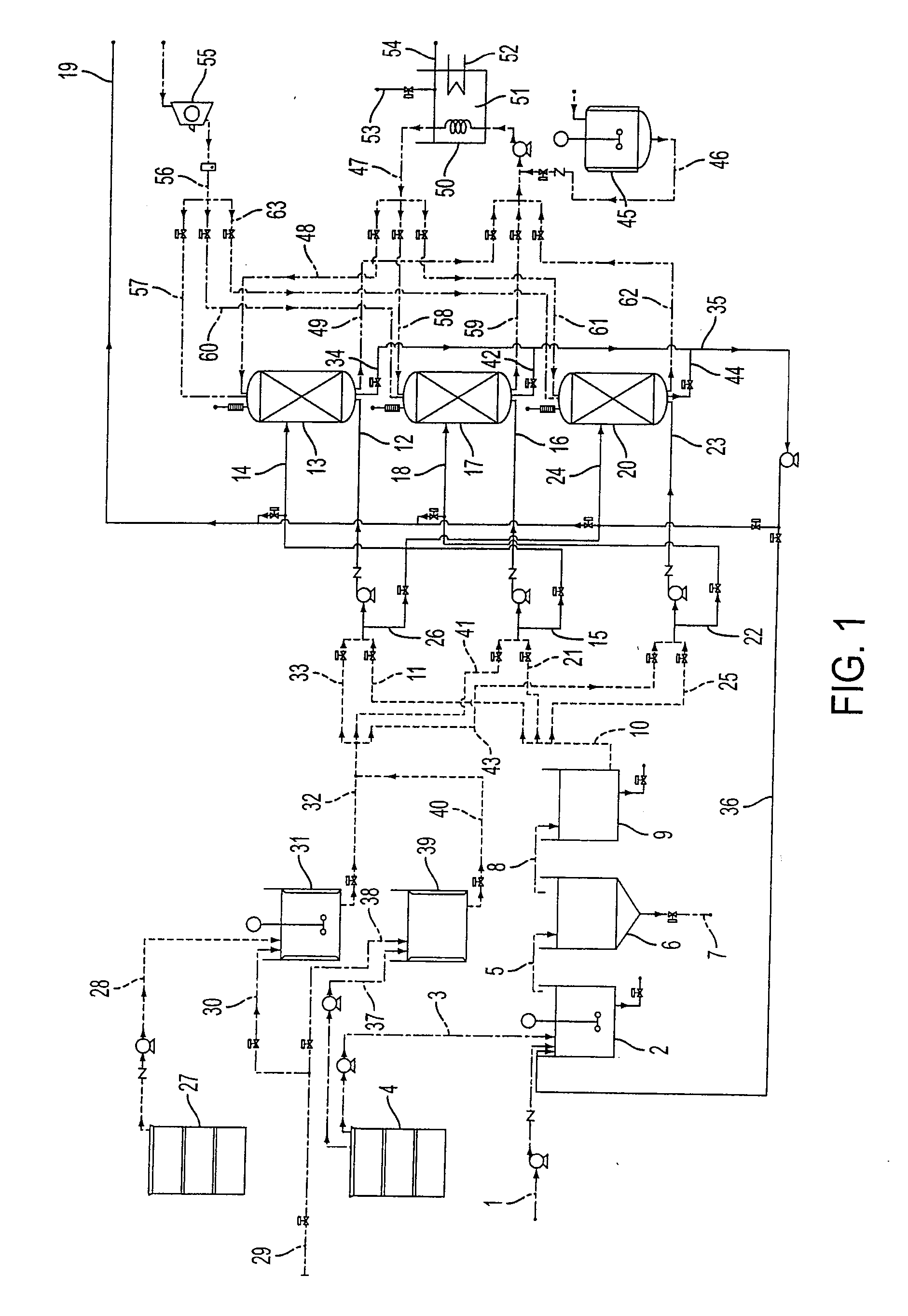

A method and a plant to remove metals by biosorption from mining or industrial effluents comprising: (a) subject the effluent to at least one first stage of pre-treatment, selecting among: precipitation by pH rising, solvent extraction or solvent extraction on emulsified membranes in order to reduce its load of metals to a concentration level that allows it to be treated by the next stage of biosorption, and (b) subject the liquid that has been previously in the stage of pre-treatment to a second stage of continuous metals removal by biosorption. To perform the continuous metals removal by biosorption is supplied a group of reactors, constituted for at least one, or at least two or at least three fixed bed bioreactors, which packing material has been colonized with a biofilm formed by a bacterial culture or a mixture of microorganisms with the capacity of binding metals by biosorption; pre-treated water is led to the group of bioreactors, the treated effluent comes from this last one and is led to the discharge of the plant.

Owner:UNIVERSITY OF CHILE +1

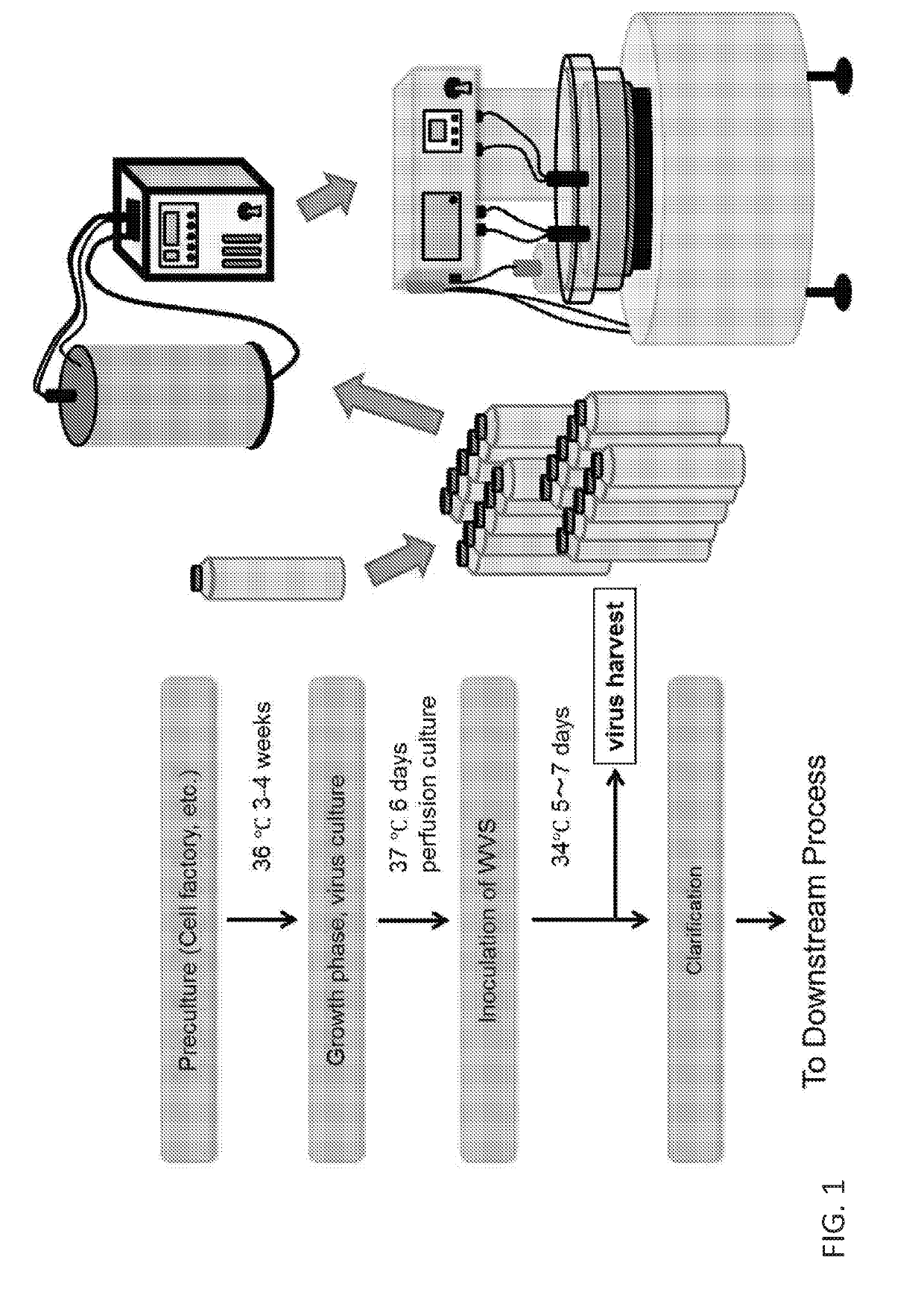

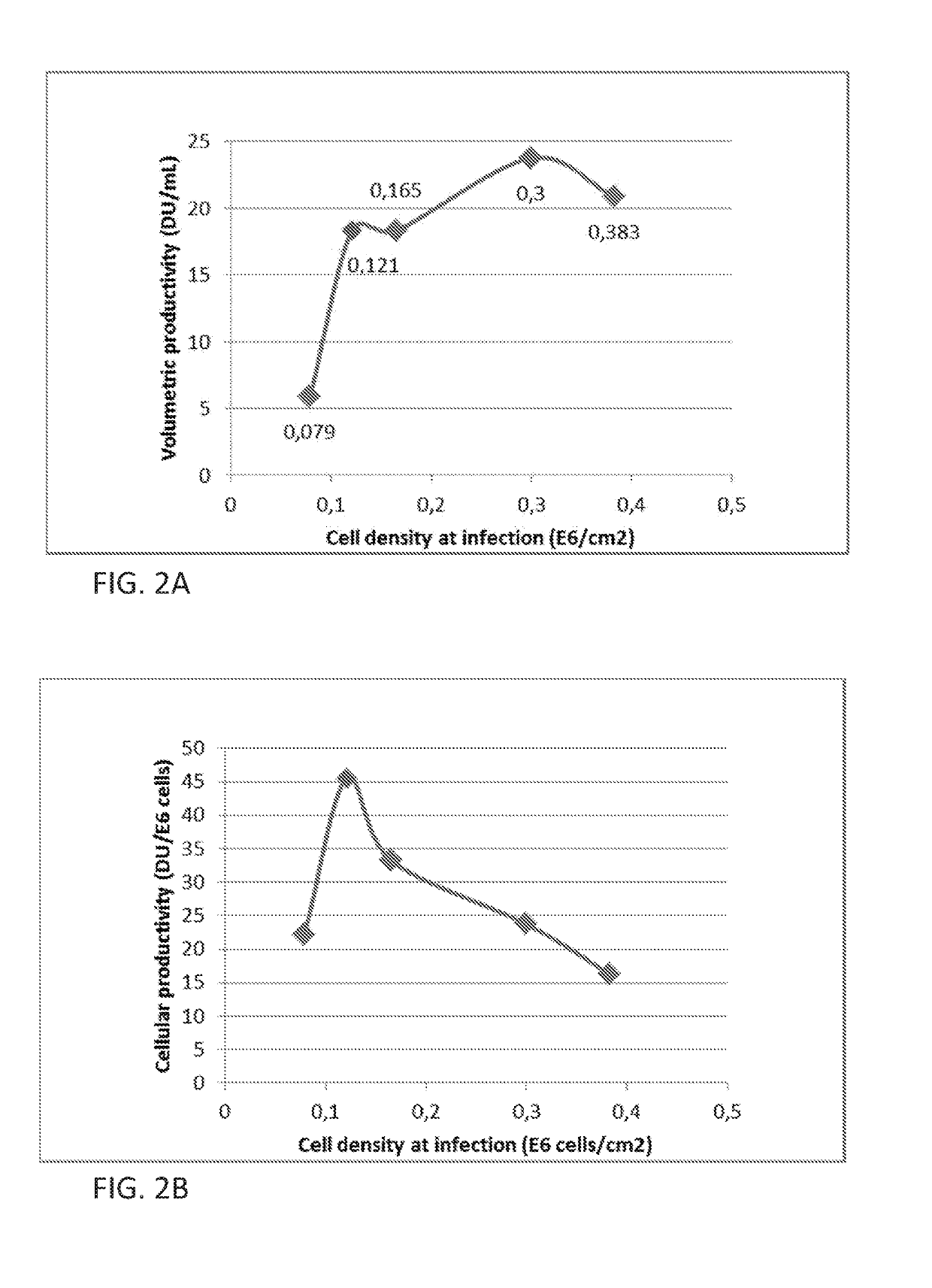

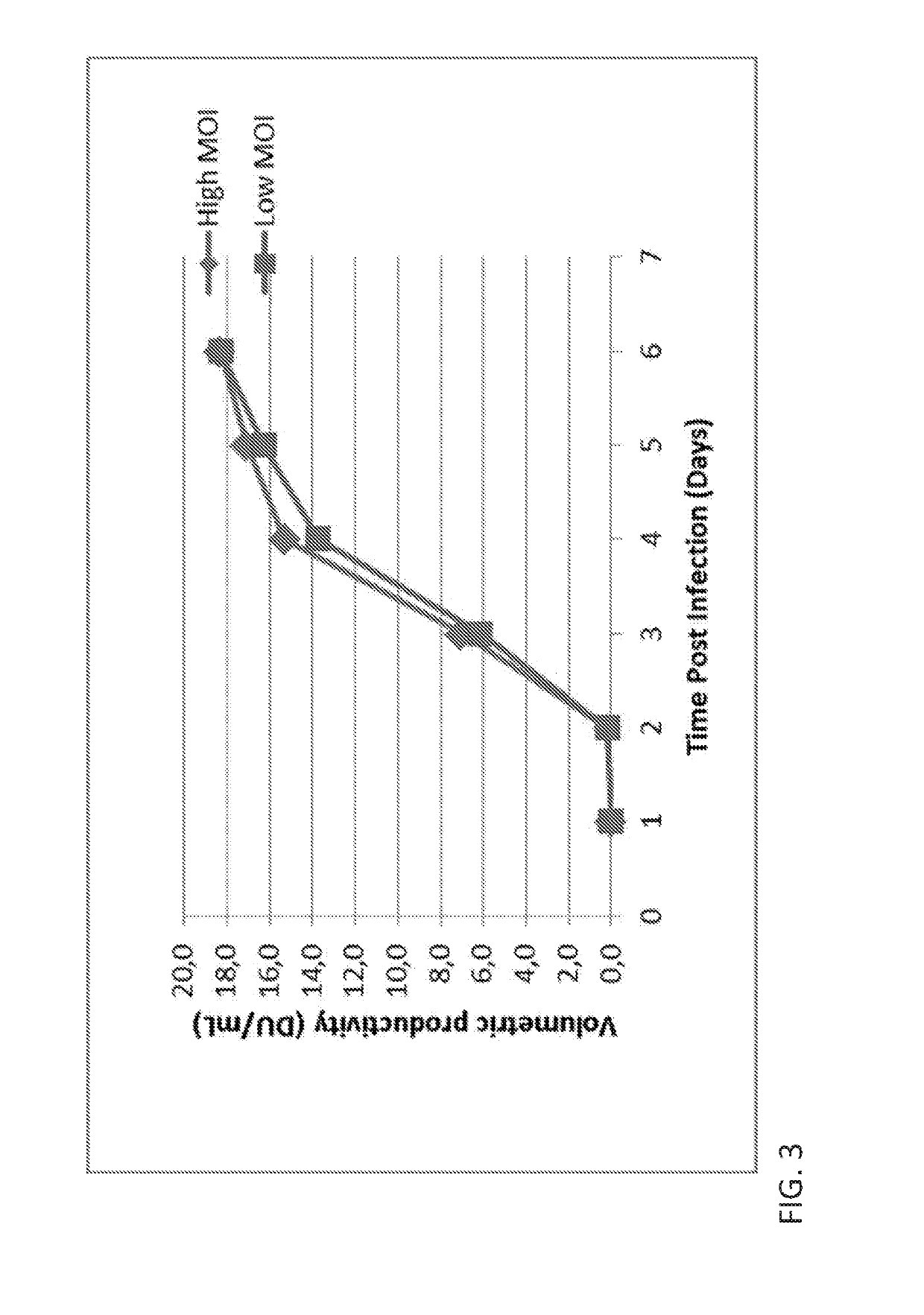

Methods for producing virus for vaccine production

InactiveUS20190194628A1Reducing per-dose costCost-effectiveSsRNA viruses positive-senseViral antigen ingredientsCulture cellVaccine Production

The present disclosure relates to methods of producing Enterovirus C, e.g., for poliomyelitis vaccine production. In some embodiments, the methods include adding polysorbate to the cell culture medium during or prior to inoculation with the virus and / or culturing cells in a fixed bed bioreactor. Further provided herein is an Enterovirus C produced by the methods of production disclosed herein, as well as compositions, immunogenic compositions, and vaccines related thereto.

Owner:TAKEDA PHARMA CO LTD +1

Methods for producing virus for vaccine production

InactiveUS20180195048A1Enhanced viral productionImprove cost efficiencySsRNA viruses positive-senseViral antigen ingredientsCulture cellVaccine Production

The present disclosure relates to methods of producing Enterovirus A, e.g., for vaccine production, that include culturing cells in a fixed bed bioreactor. Further provided herein is an Enterovirus A produced by the methods of production disclosed herein, as well as compositions, immunogenic compositions, and vaccines related thereto.

Owner:TAKEDA VACCINES INC

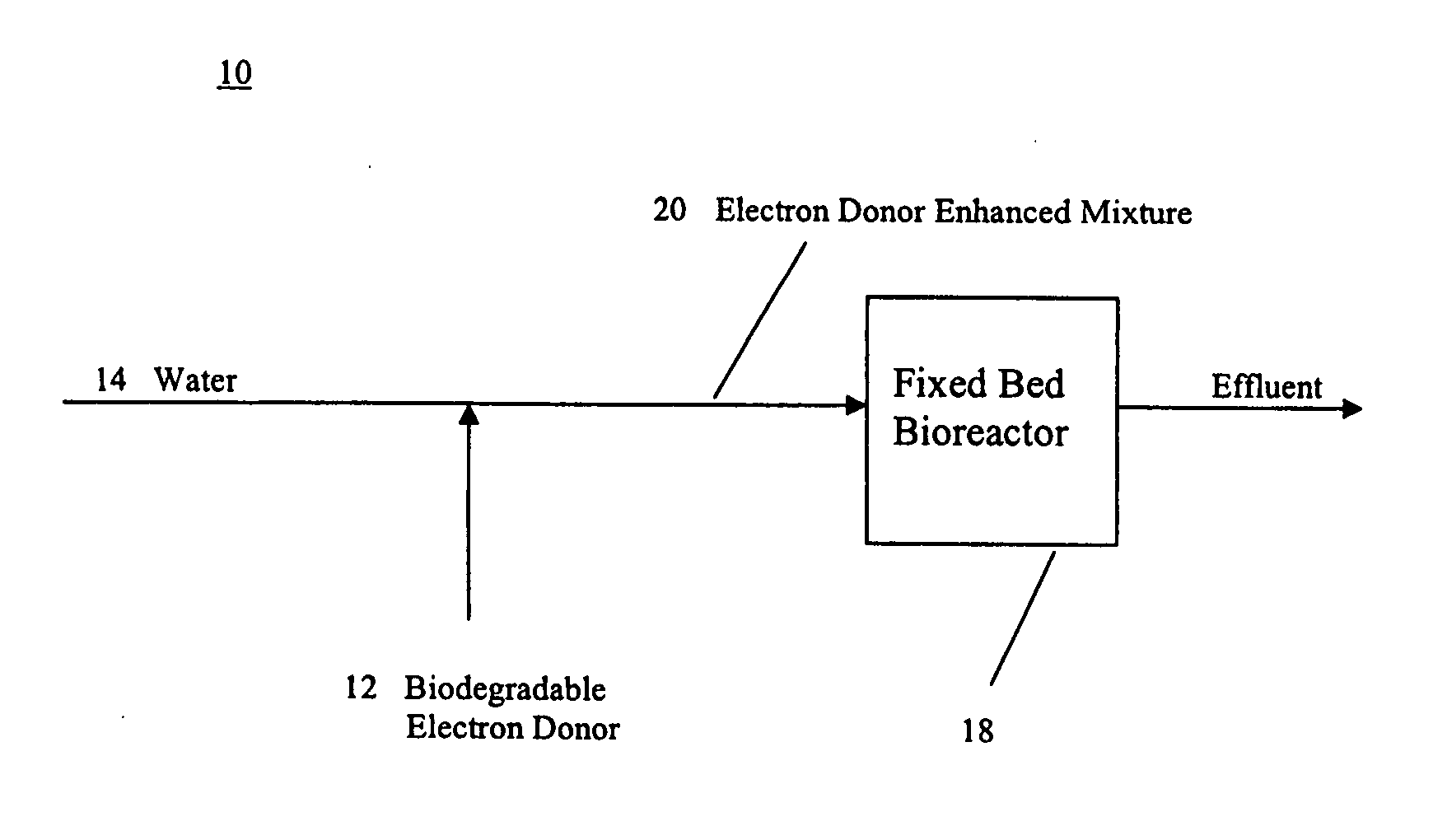

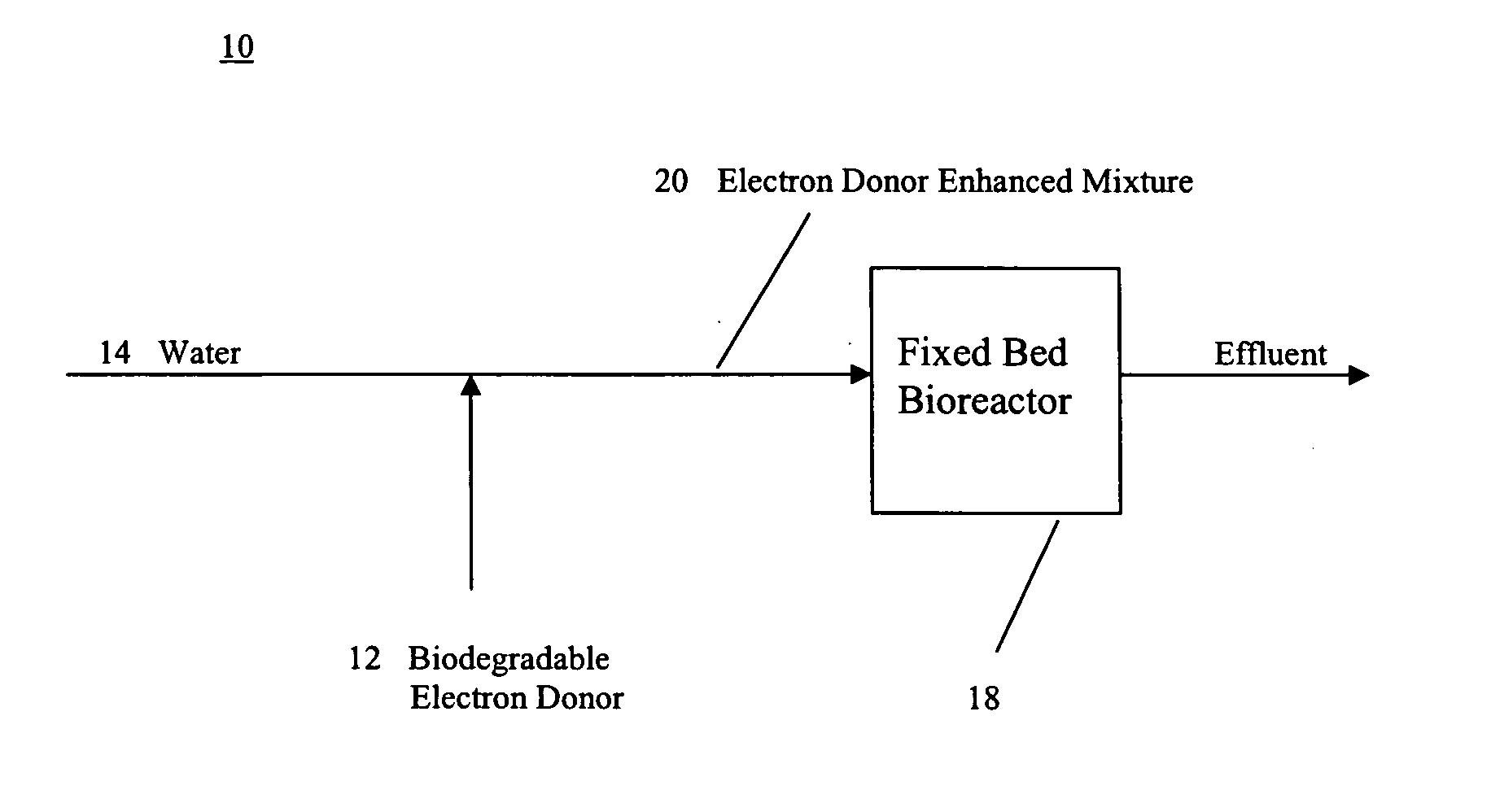

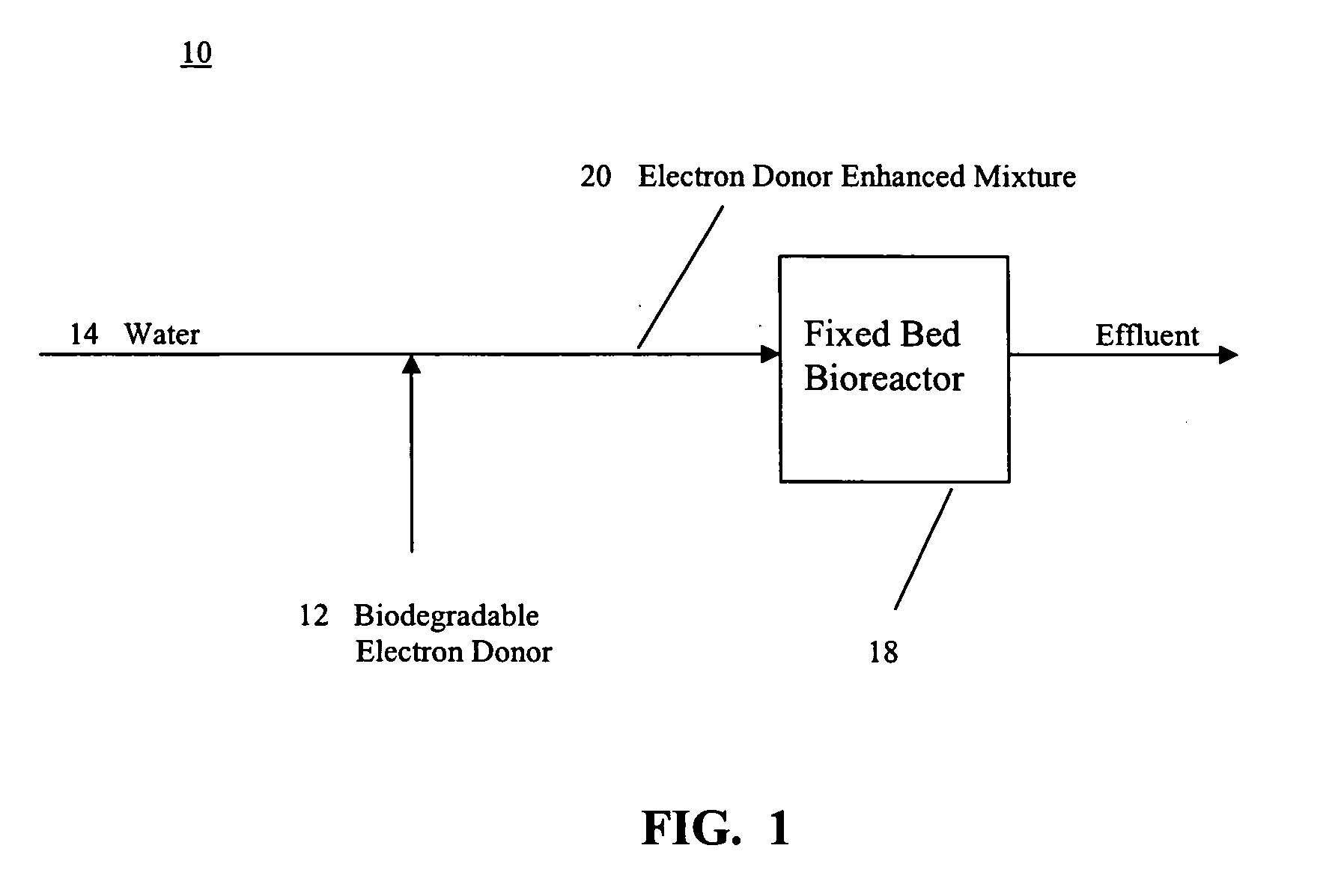

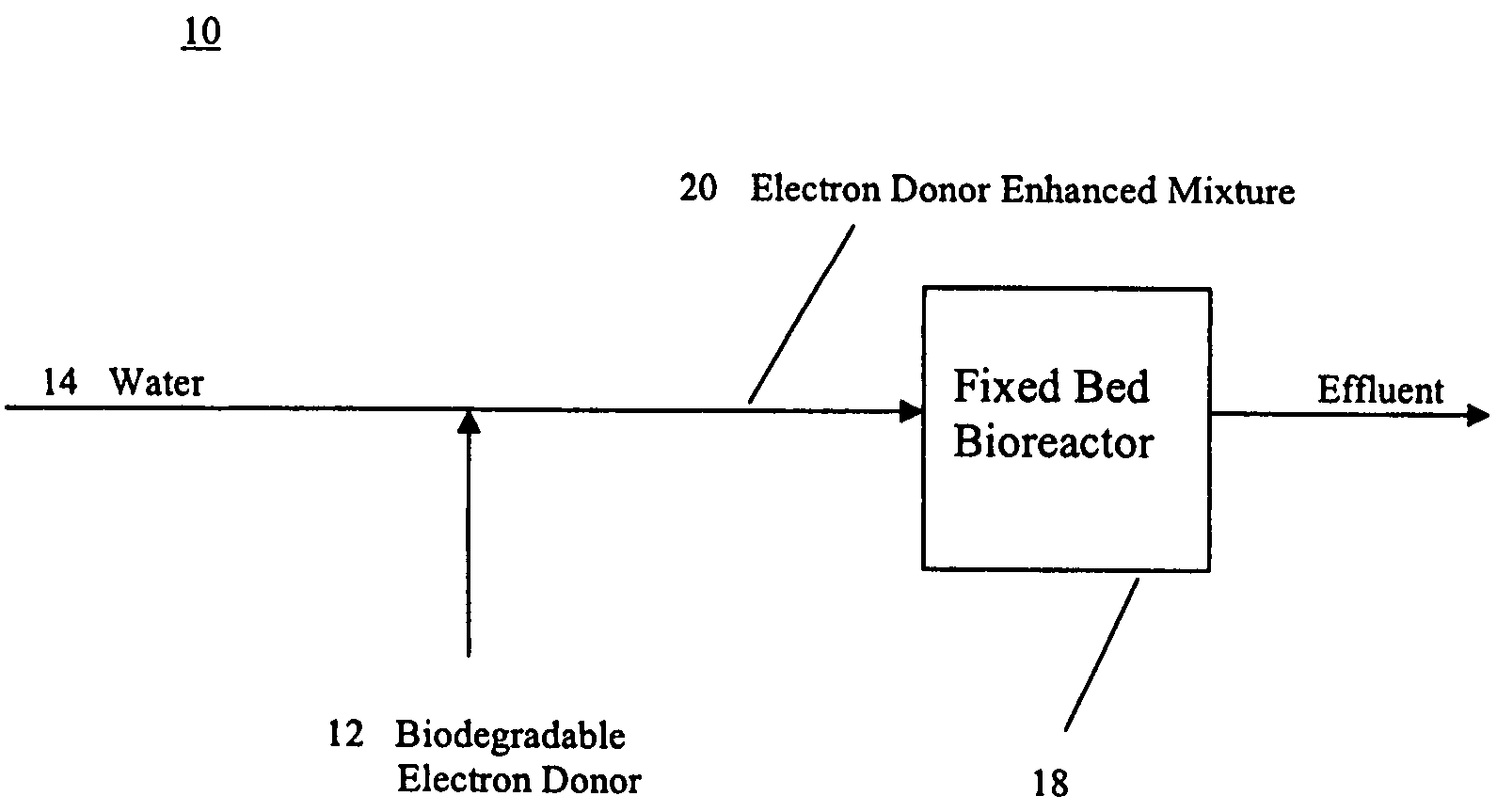

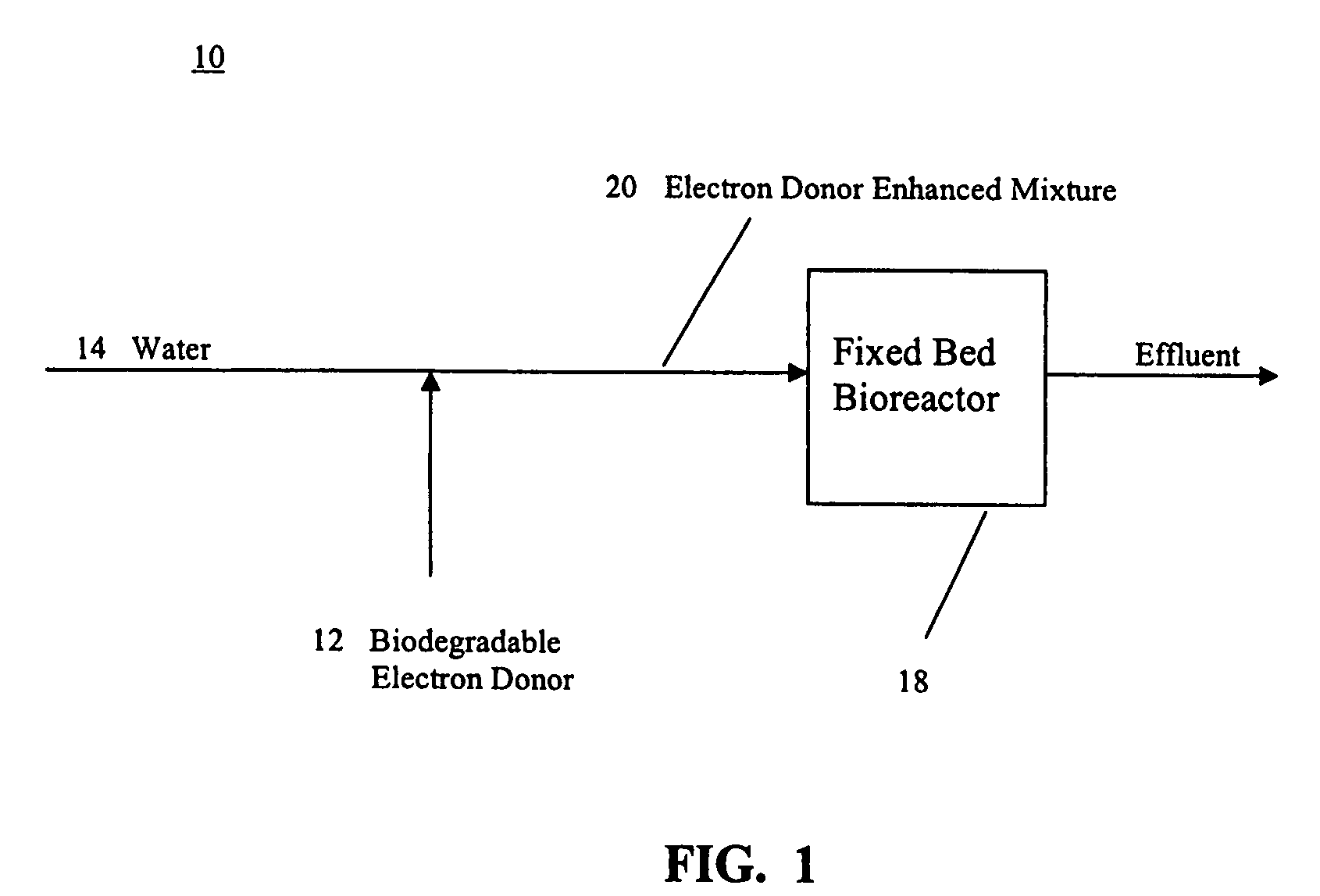

Process for treatment of organic contaminated water

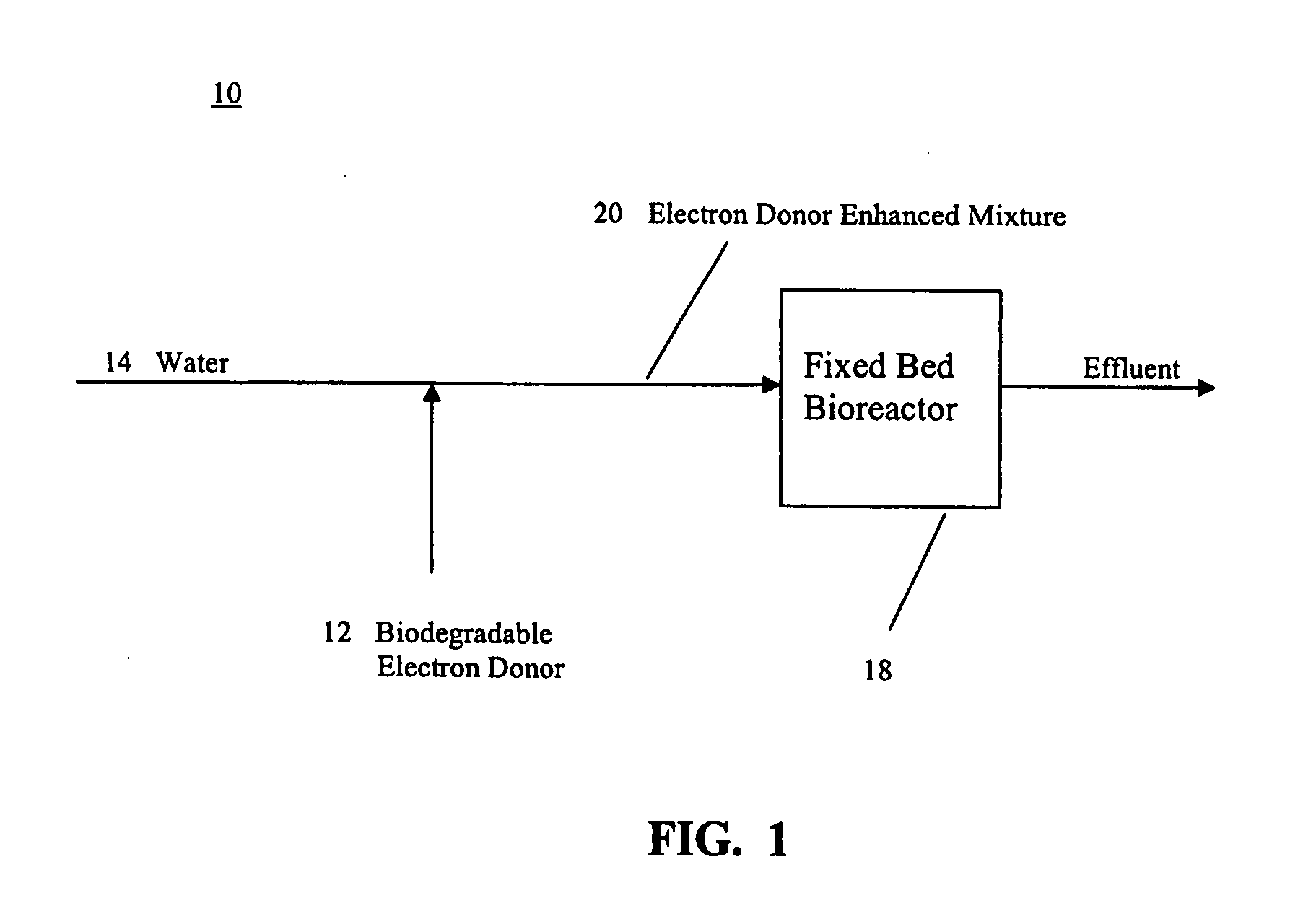

InactiveUS20070193950A1Water treatment parameter controlTreatment using aerobic processesMetaboliteElectron donor

The present invention may be used in methods for treatment of drinking water contaminated with algal metabolites. An inflow of water in a drinking water treatment facility may have multiple types of algal metabolites wherein each algal metabolites has a concentration of less than 20 μg / l. The water may contain indigenous bacteria that may serve as a bioreactor inoculum. The water may be dosed with a biodegradable electron donor at a concentration of less than 7 mg / l to form water, electron donor solution. The water, electron donor solution may be processed through a fixed-bed bioreactor for an empty bed bioreactor contact time of less than 30 minutes. An effluent of the fixed-bed bioreactor may have an algal metabolite concentration for each algal metabolite of less than 10 ng / l.

Owner:SEMOTO

Plant for the removal of metals by biosorption from mining or industrial effluents

InactiveUS7479220B2Increase capacityWaste water treatment from quariesTreatment using aerobic processesSolventTreated water

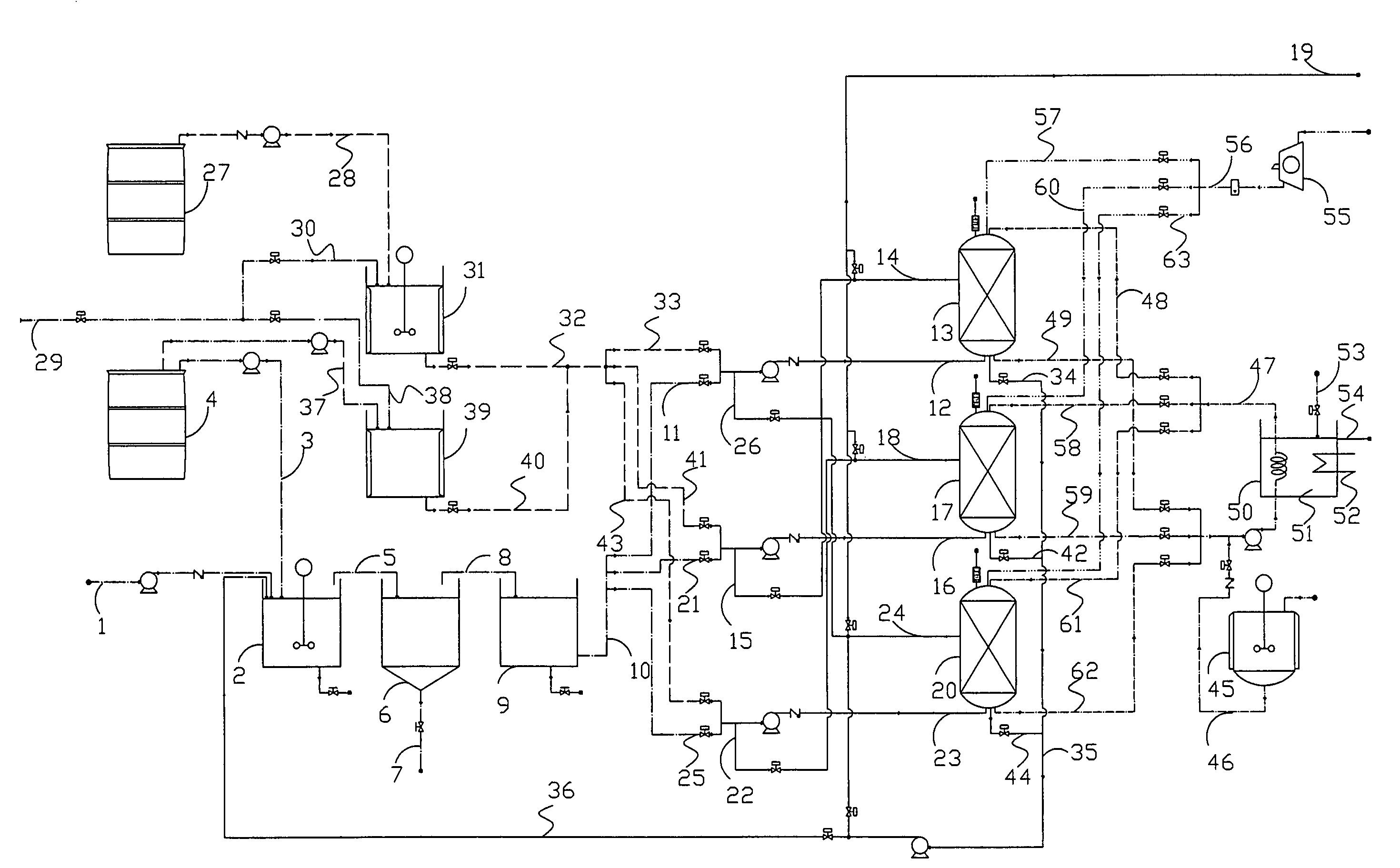

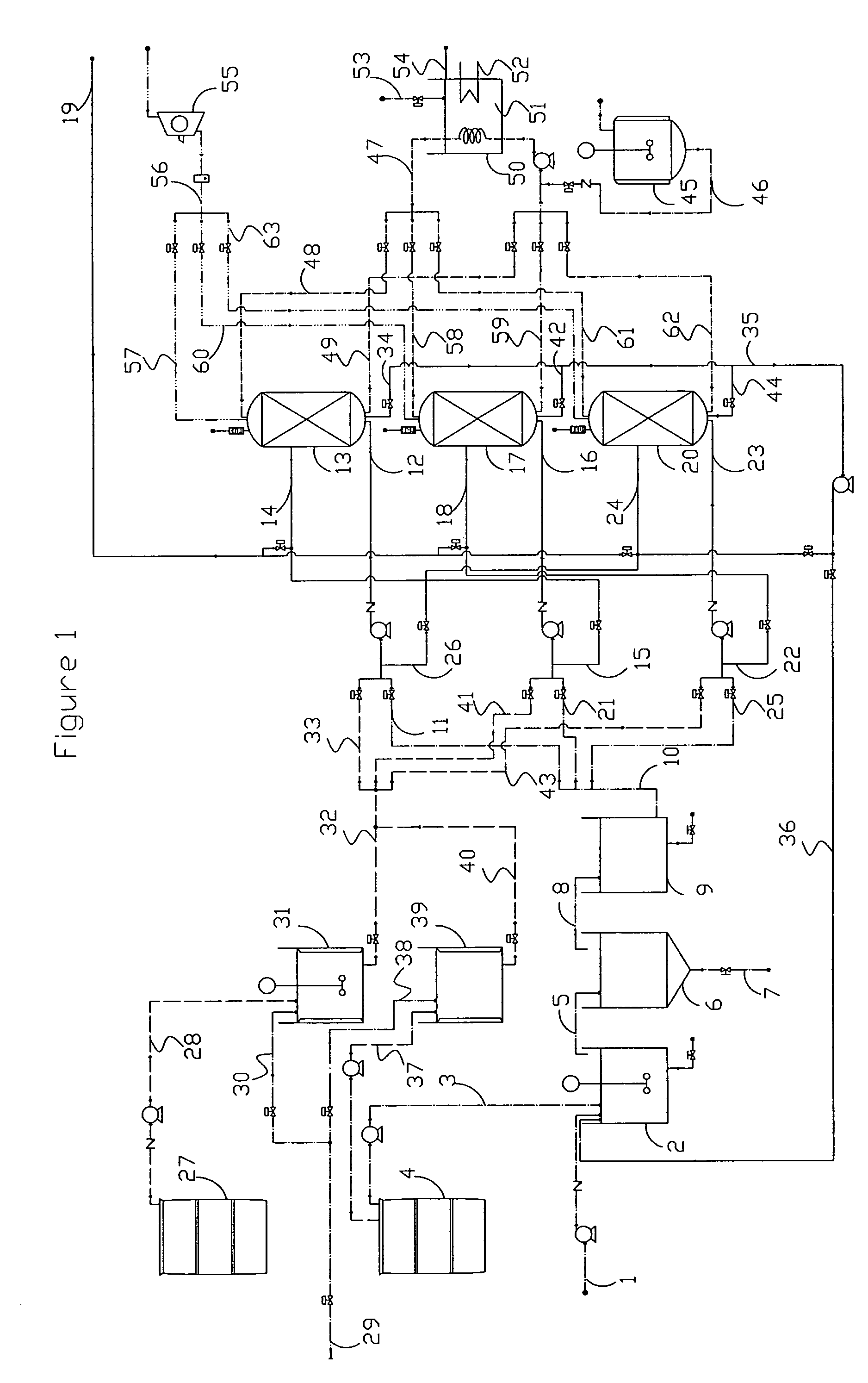

A method and a plant to remove metals by biosorption from mining or industrial effluents comprising: (a) subject the effluent to at least one first stage of pre-treatment, selecting among: precipitation by pH rising, solvent extraction or solvent extraction on emulsified membranes in order to reduce its load of metals to a concentration level that allows it to be treated by the next stage of biosorption, and (b) subject the liquid that has been previously in the stage of pre-treatment to a second stage of continuous metals removal by biosorption. To perform the continuous metals removal by biosorption is supplied a group of reactors, constituted for at least one, or at least two or at least three fixed bed bioreactors, which packing material has been colonized with a biofilm formed by a bacterial culture or a mixture of microorganisms with the capacity of binding metals by biosorption; pre-treated water is led to the group of bioreactors, the treated effluent comes from this last one and is led to the discharge of the plant.

Owner:UNIVERSITY OF CHILE +1

Process And Plant For The Removal Of Metals By Biosorption From Mining Or Industrial Effluents

InactiveUS20080142422A1Adequate aerationWaste water treatment from quariesTreatment using aerobic processesSolventTreated water

A method and a plant to remove metals by biosorption from mining or industrial effluents comprising: (a) subject the effluent to at least one first stage of pre-treatment, selecting among: precipitation by pH rising, solvent extraction or solvent extraction on emulsified membranes in order to reduce its load of metals to a concentration level that allows it to be treated by the next stage of biosorption, and (b) subject the liquid that has been previously in the stage of pre-treatment to a second stage of continuous metals removal by biosorption. To perform the continuous metals removal by biosorption is supplied a group of reactors, constituted for at least one, or at least two or at least three fixed bed bioreactors, which packing material has been colonized with a biofilm formed by a bacterial culture or a mixture of microorganisms with the capacity of binding metals by biosorption; pre-treated water is led to the group of bioreactors, the treated effluent comes from this last one and is led to the discharge of the plant.

Owner:UNIVERSITY OF CHILE +1

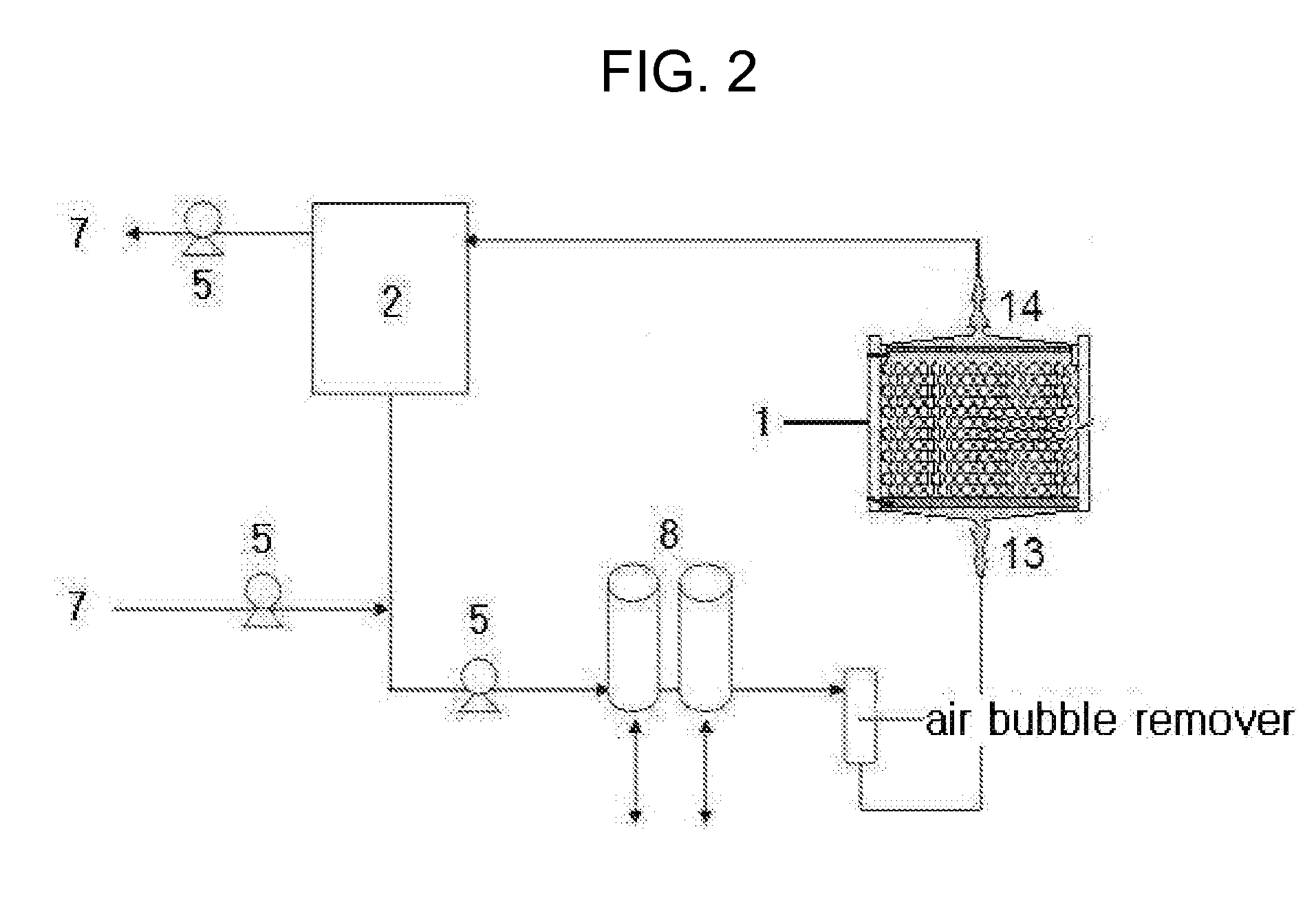

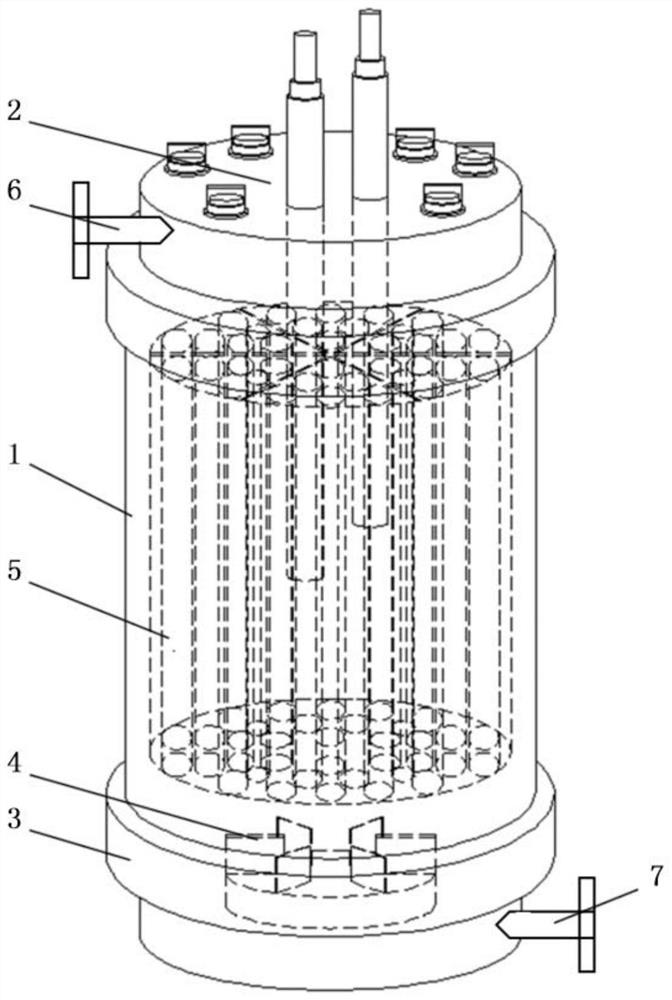

Shell-and-tube fixed bioreactor

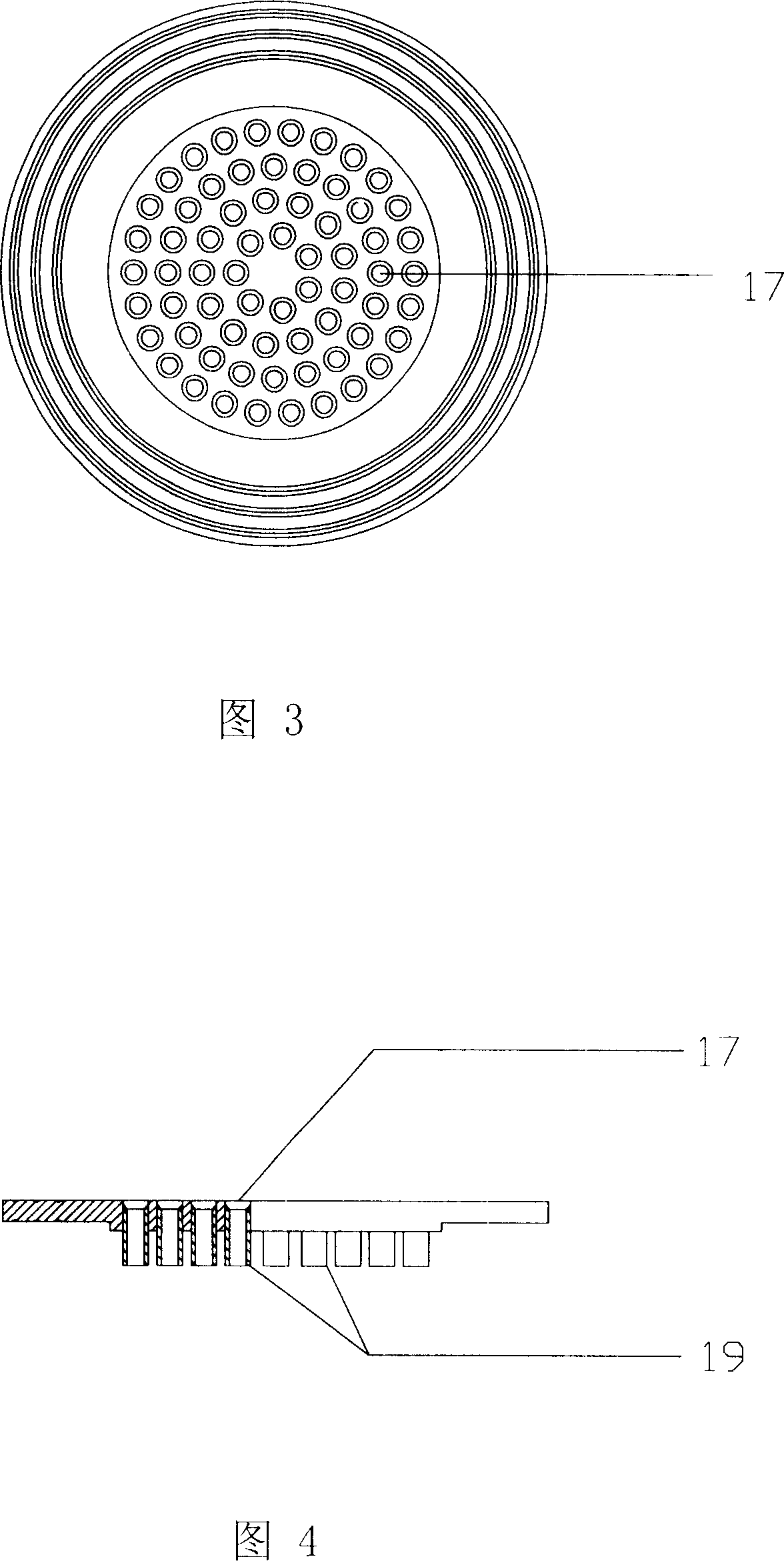

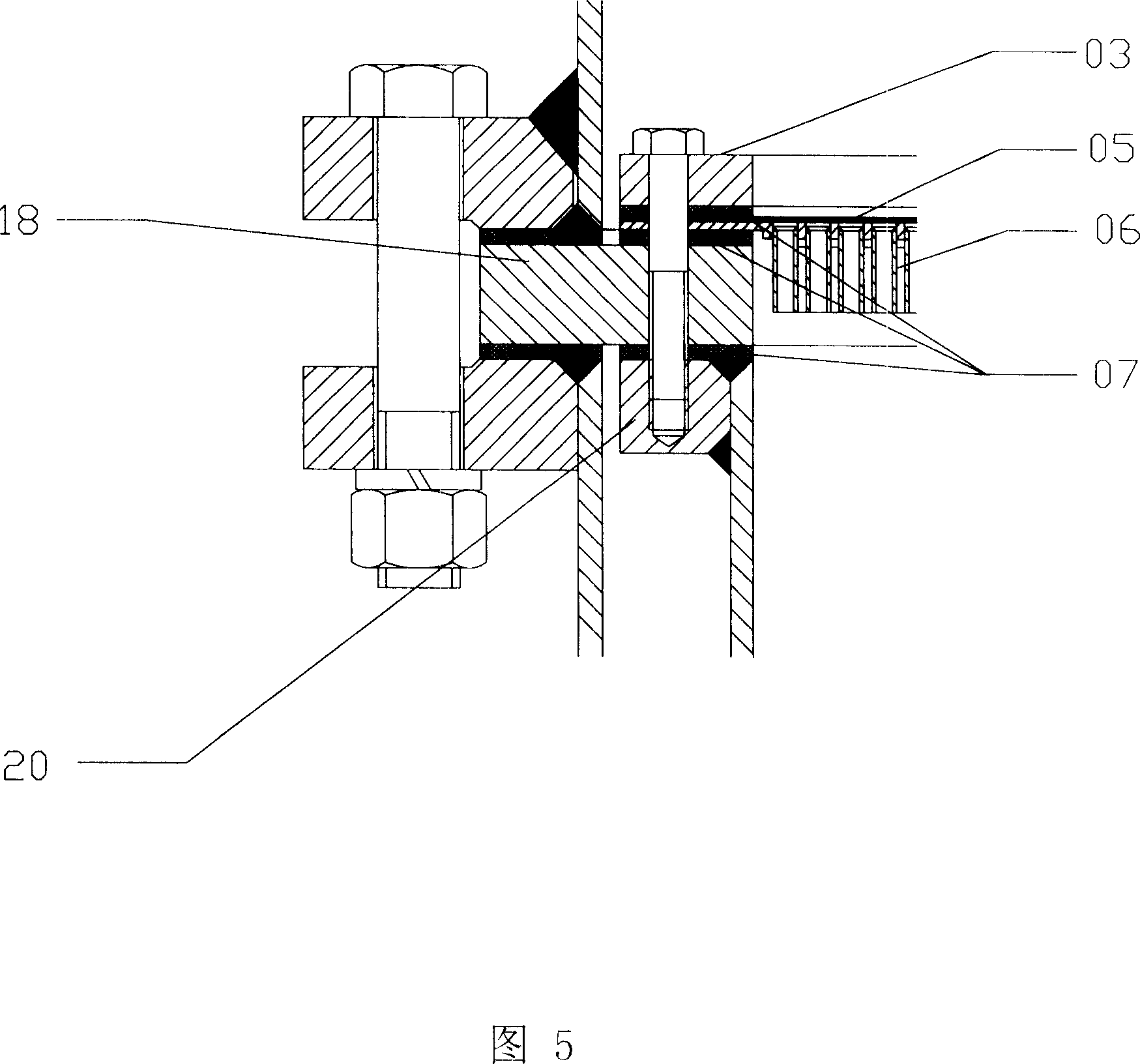

InactiveCN101020891ANo backmixingShorten the timeBioreactor/fermenter combinationsBiological substance pretreatmentsResource utilizationFixed bed bioreactor

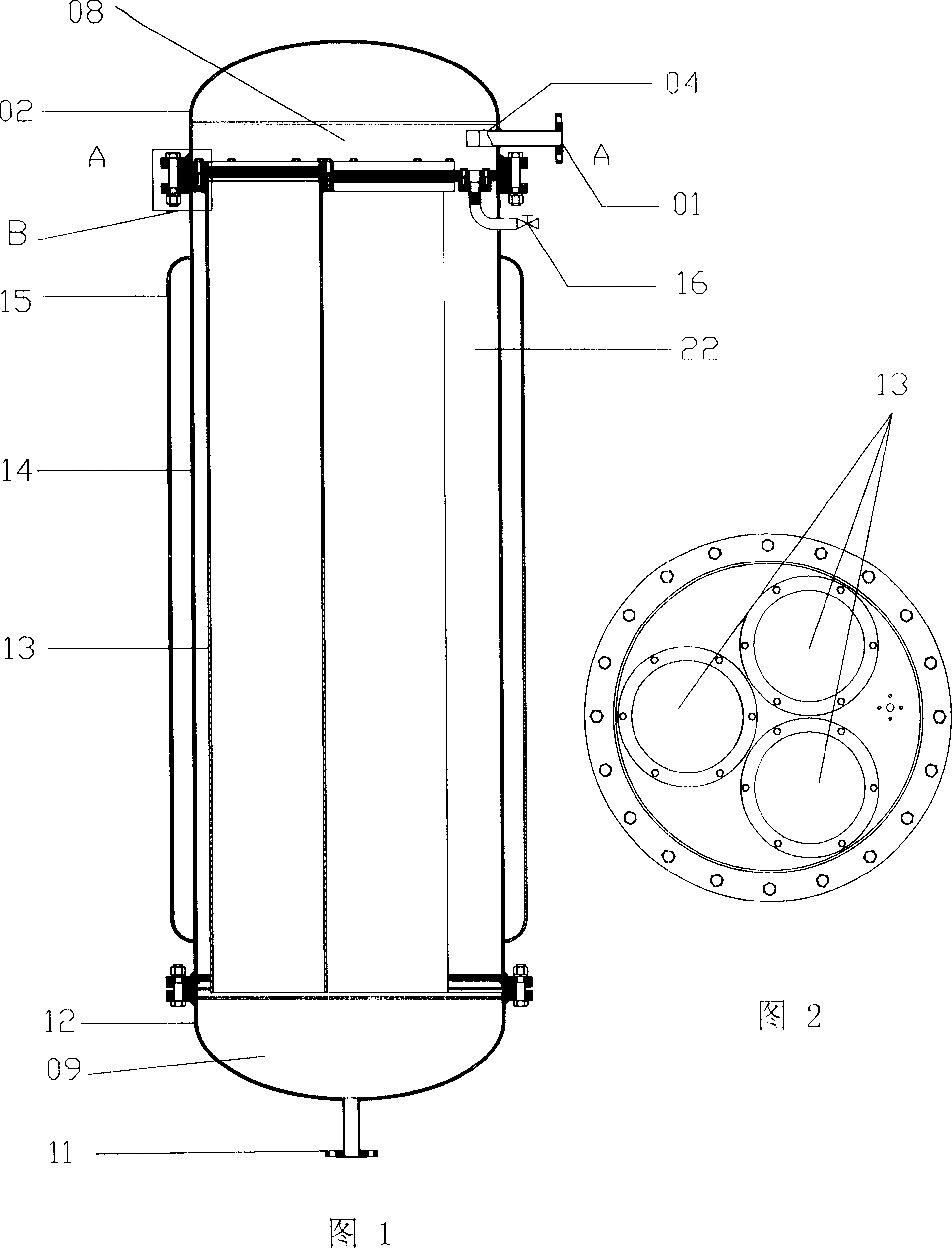

The shell-and-tube fixed bed bioreactor includes one upper end sealing body with liquid inlet; one reaction cavity with stuffing pipes filled with solid stuffing; one lower end sealing body; and one distributor in the upper end of the stuffing pipes with homogeneously distributed through holes for the liquid from the upper end sealing body to be sprayed homogeneously to inside the stuffing pipes. The shell-and-tube fixed bed bioreactor has simple structure, easy operation, high yield and high resource utilizing rate.

Owner:领先生物农业股份有限公司

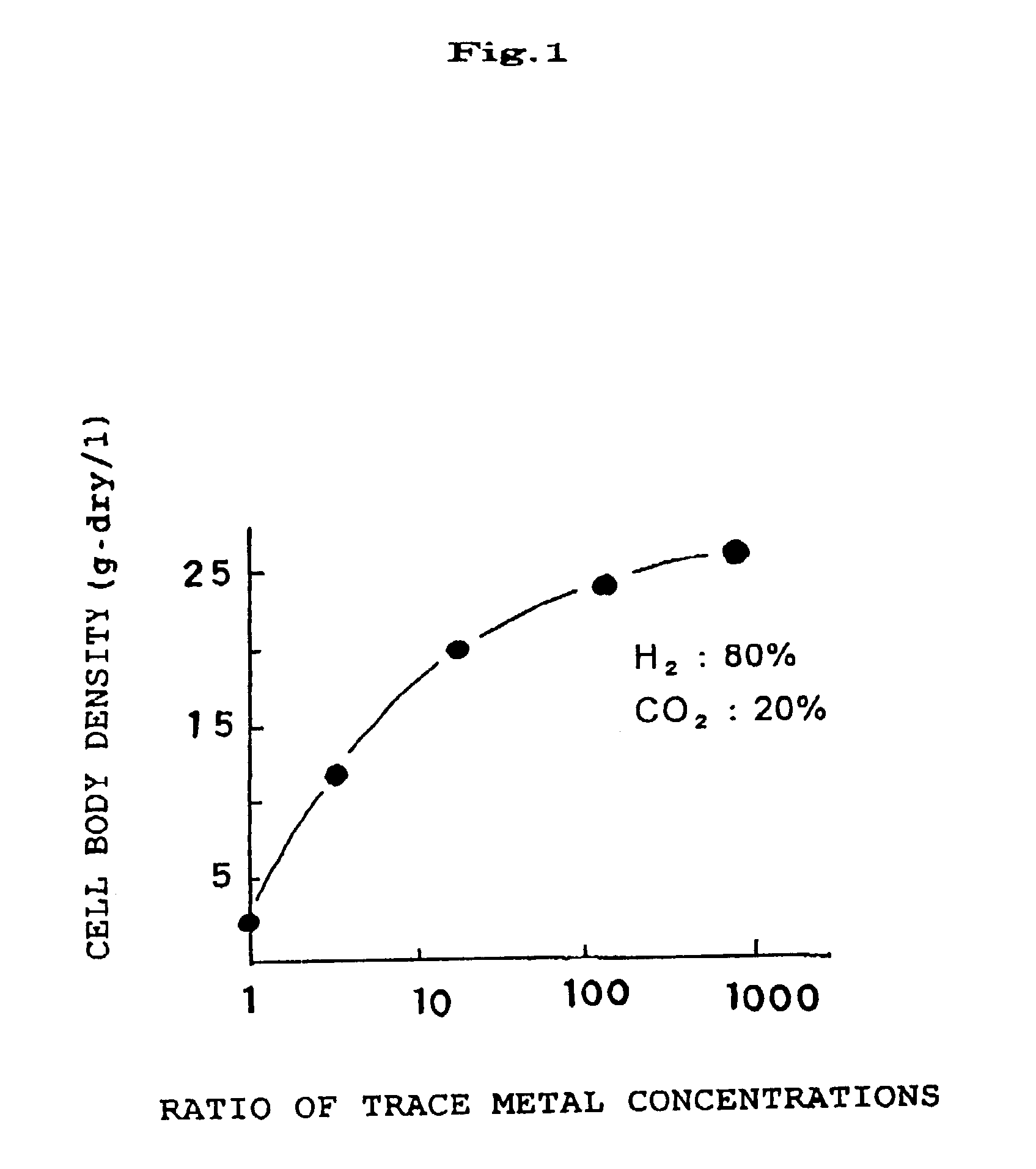

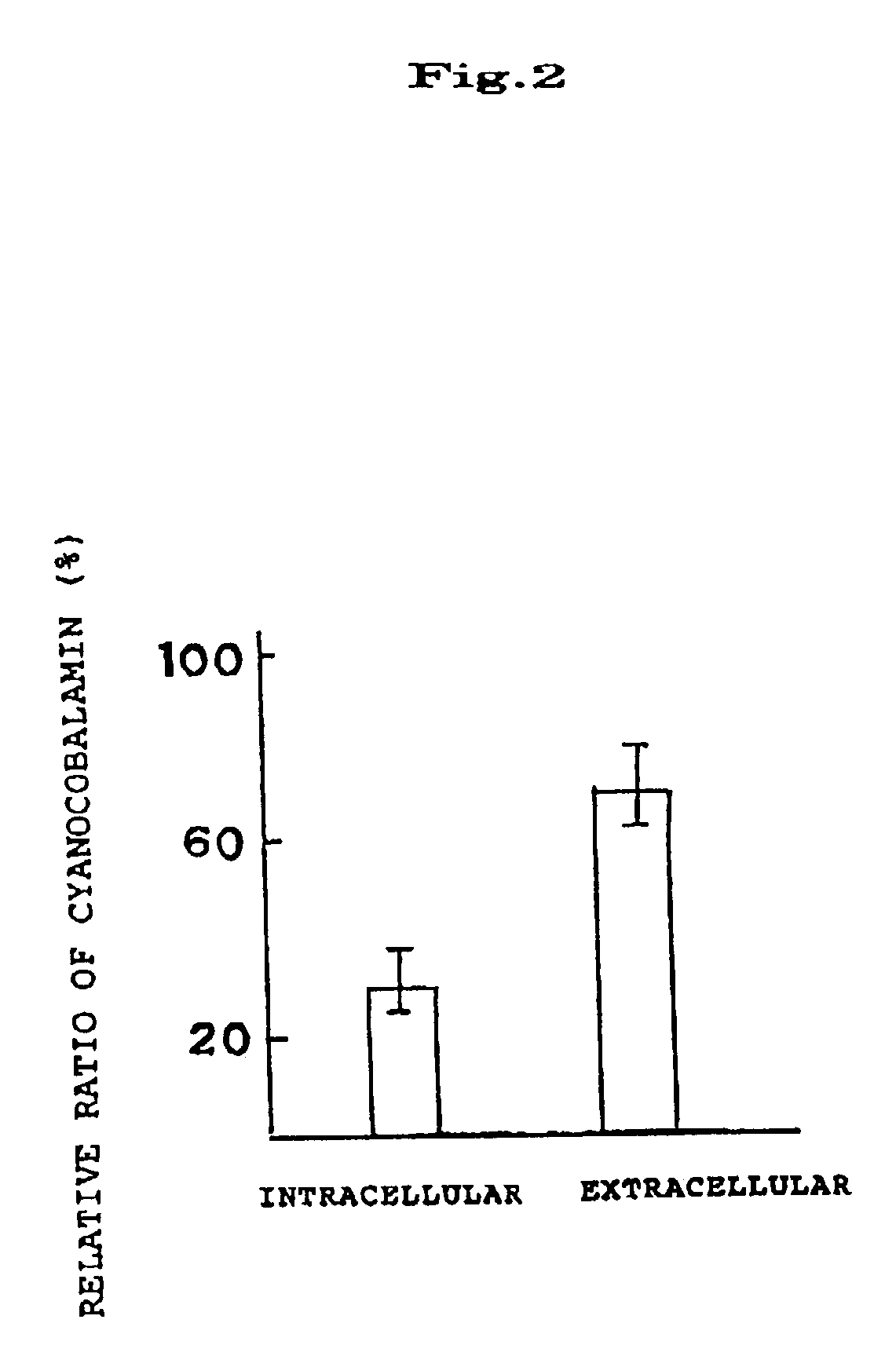

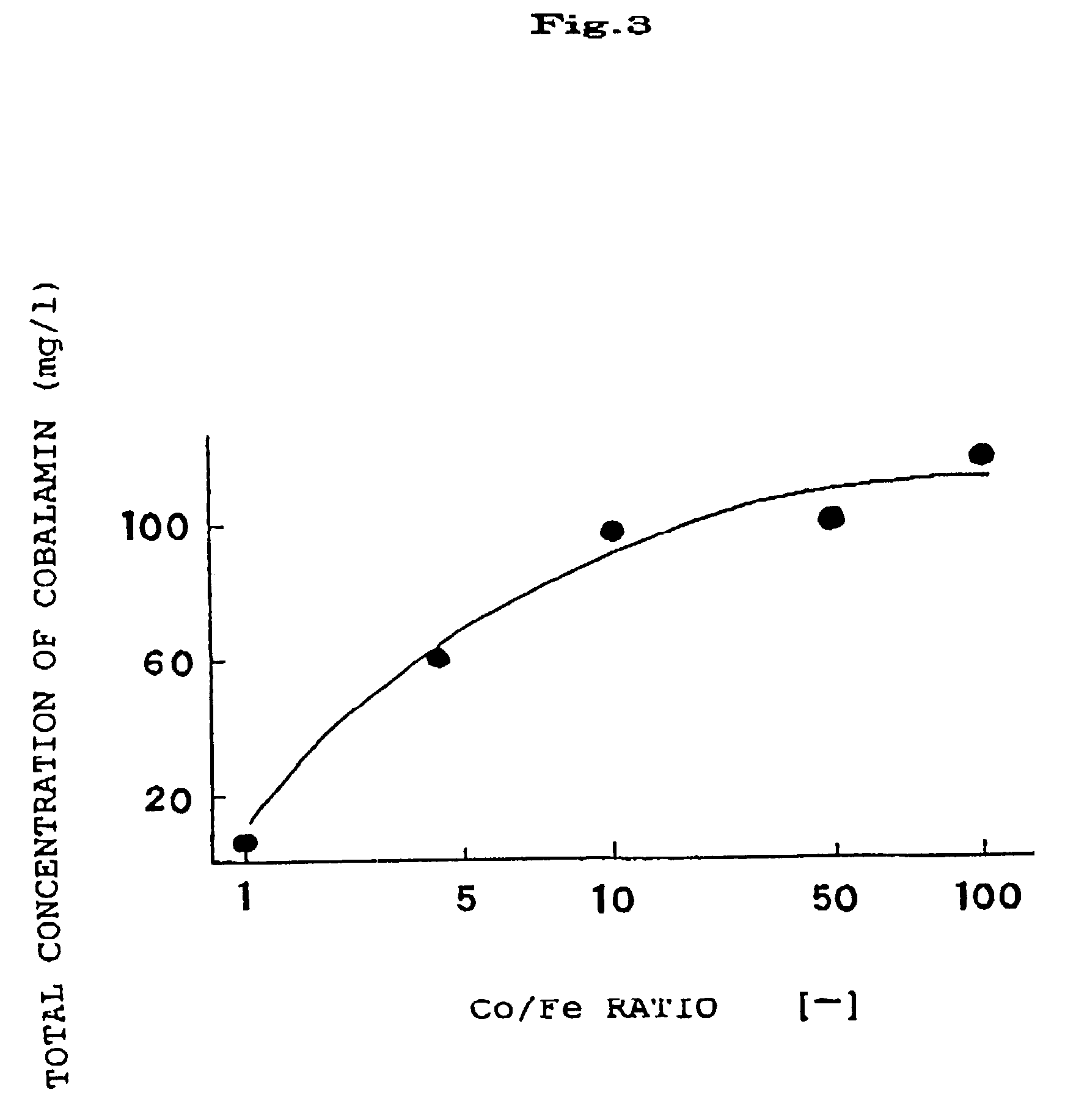

Process for producing vitamin B12 from hydrogen-metabolizing methane bacterium

InactiveUS6972188B2Efficient productionIncrease contentBiocideWaste based fuelSludgePotassium cyanide

Mesophilic methane bacteria obtained from digested sludge are acclimatized in an H2 / CO2 medium and the acclimatized methane bacteria are grown on a support inclusive of inorganic nutritional salts of trace metal elements by using an immobilized bed bioreactor. The grown bacteria are allowed to metabolize a mixed gas, prepared by adding hydrogen to at least one of coal gas and biogas, into methane and at the same time, cobalamin contained in the fermented liquor is recovered as an extracellular product in the form of cyanocobalamin by using potassium cyanide to thereby produce vitamin B12 efficiently in a high content and high yield.

Owner:JAPAN SCI & TECH CORP

Bioreactor to obtain bioactive substances through solid-state fermentation using macromycetes fungi

ActiveUS9556409B2Bioreactor/fermenter combinationsBiological substance pretreatmentsForced convectionOxygen

Fixed bed bioreactor with natural convection and forced draught to obtain bioactive substances by solid-state fermentation (SEF) using fungi macromycetes. This bioreactor may be from turn drum with pendulum motion and natural and forced convection to a tray bioreactor with natural convection. They are used in the production of bioactive substances as crude extracts of lignocellulosic enzymes and fungal polysaccharides obtained by using mixtures of lignocellulosic materials as substrates and macromycetes fungi as inoculum, controlling pH, humidity and particle size, inoculation rate and environmental conditions during fermentation such as temperature, relative humidity and carbon dioxide and oxygen concentration.

Owner:UNIV DE CALDAS

Methods for producing virus for vaccine production

InactiveCN107532150ASsRNA viruses positive-senseViral antigen ingredientsEnterovirusVaccine Production

The present invention relates to methods of producing Enterovirus A, e.g., for vaccine production, that include culturing cells in a fixed bed bioreactor. Further provided herein are an Enterovirus Aproduced by the methods of production disclosed herein, as well as compositions, immunogenic compositions, and vaccines related thereto.

Owner:TAKEDA VACCINES INC

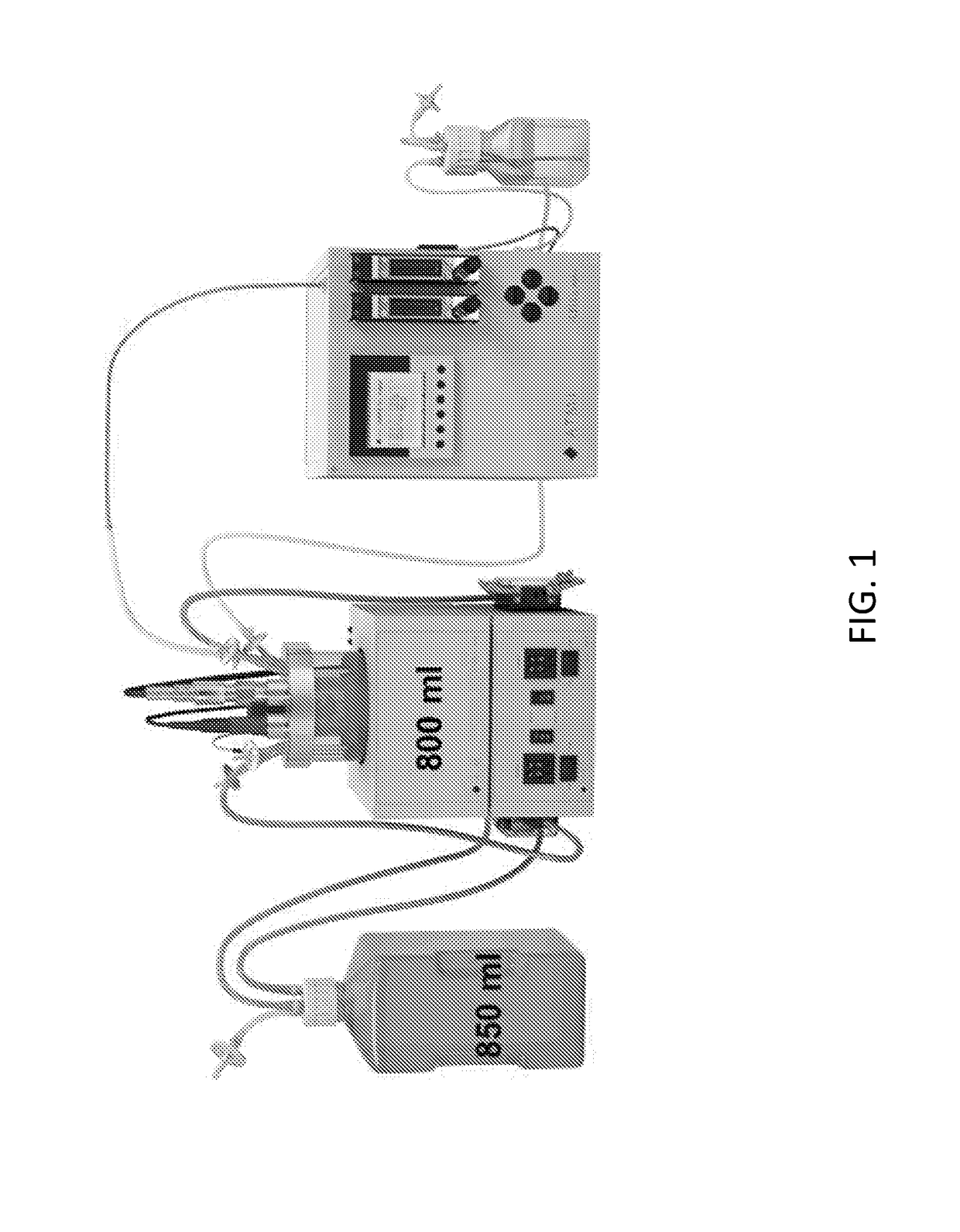

Enclosed bioreactor and cell culturing method thereof

ActiveCN108977358AEasy to clean high pressureLow sterility requirementsBioreactor/fermenter combinationsBiological substance pretreatmentsPerfusion CultureVaccine Production

The invention discloses an enclosed bioreactor. The enclosed bioreactor comprises a solution container, a collection container, a bioreaction tank, a liquid inlet pipeline and a liquid outlet pipeline, wherein the liquid inlet pipeline and the liquid outlet pipeline are provided with one four-way joint respectively. The invention further discloses a cell culturing method of the enclosed bioreactor. The cell culturing method comprises pre-culturing, bioreactor cell inoculation, bioreactor cell perfusion culture, bioreactor virus vaccination, bioreactor washing and replacement as well as bioreactor virus perfusion culture. By adopting the enclosed bioreactor, bioreactor perfusion culture can be realized, rapid liquid exchanging is realized, high-pressure cleaning is facilitated, repeated used is realized, the production cost is reduced, the pollution risk can be lowered, and the working efficiency is improved. By adopting the enclosed bioreactor and the cell culturing method thereof disclosed by the invention, the production operation of the bioreactor with a single pipeline in the existing method is substituted, and the aseptic requirement in vaccine production is effectively ensured. The enclosed bioreactor is easy and convenient to operate, and is suitable for fixed bed bioreactor large-scale culture.

Owner:GUANGZHOU PROMISE BIOLOGICAL PROD

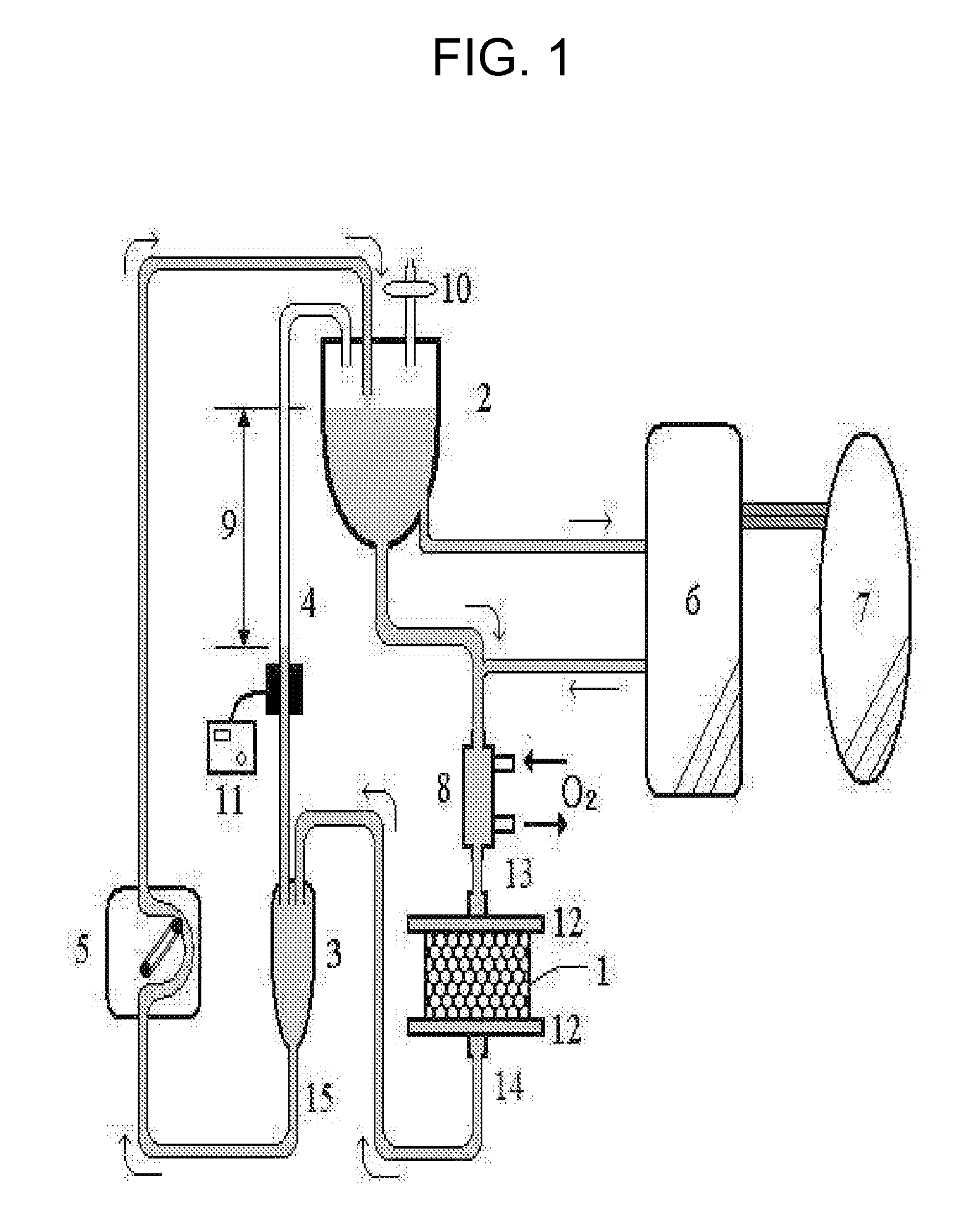

Bioartificial liver system using bioreactor packed with gel beads

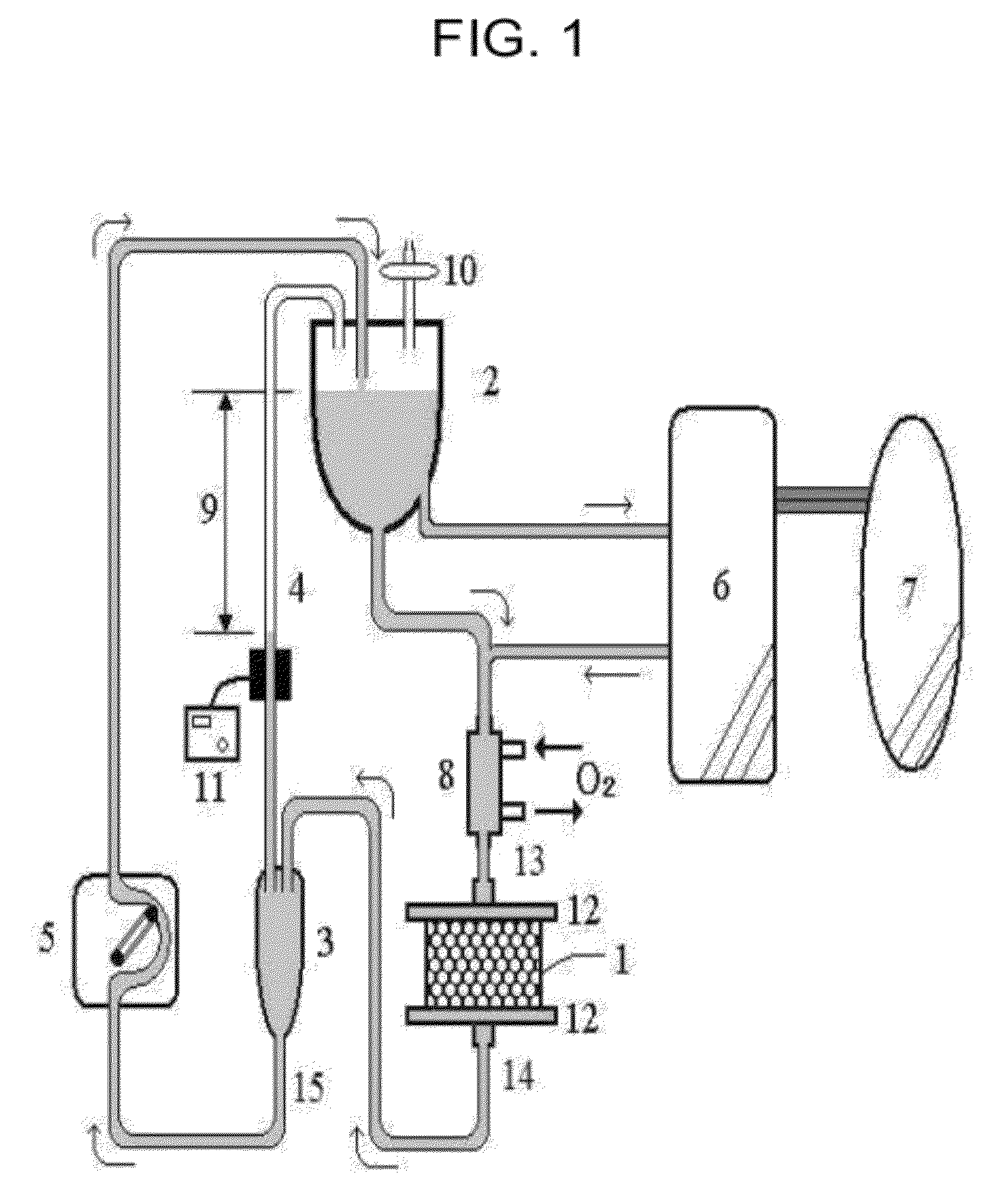

ActiveUS8329457B2Bioreactor/fermenter combinationsBiological substance pretreatmentsLiver functionFixed bed bioreactor

The present invention discloses a bioartificial liver system comprising a fixed-bed bioreactor packed with gel beads containing hepatocytes of an animal, a plasma reservoir, a plasma separator, and an efflux chamber, wherein the plasma reservoir is located at a position higher than the bioreactor, a ventilation filter in contact with atmosphere is provided at the top of the plasma reservoir, and the top of the plasma reservoir is directly connected to the efflux chamber via a connecting line. The inventive system satisfactorily performs the essential liver functions without the problems of gel bead damage or channeling.

Owner:LIFECORD +3

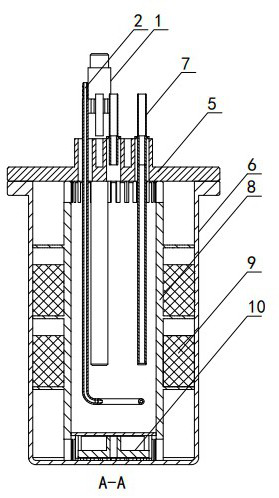

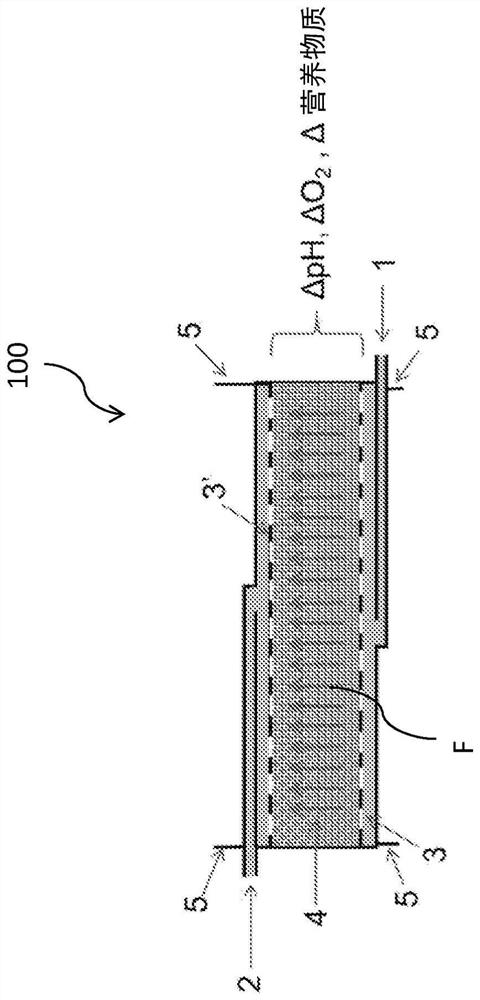

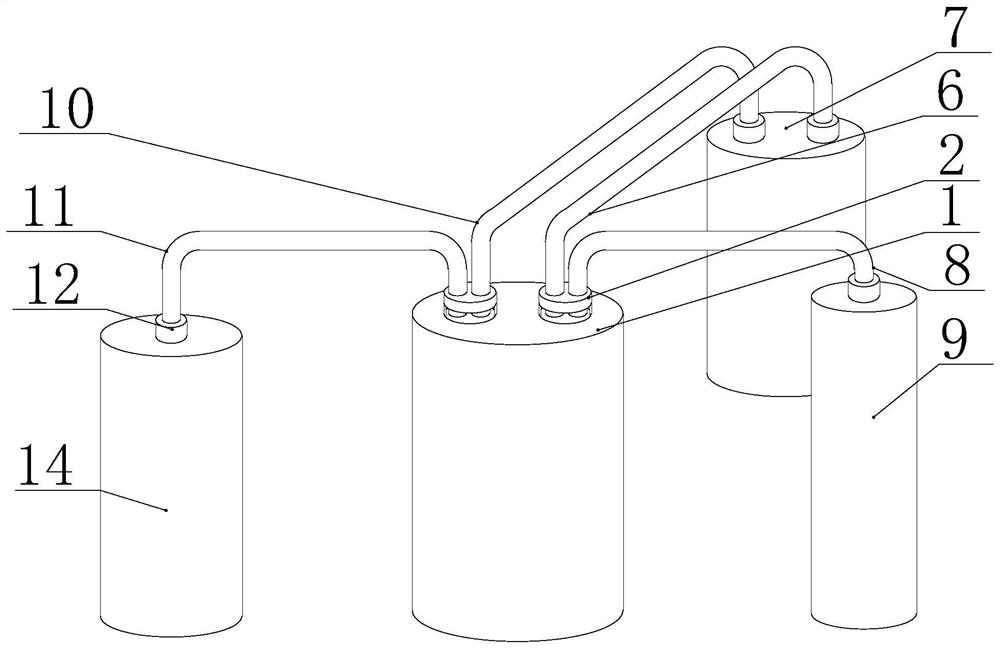

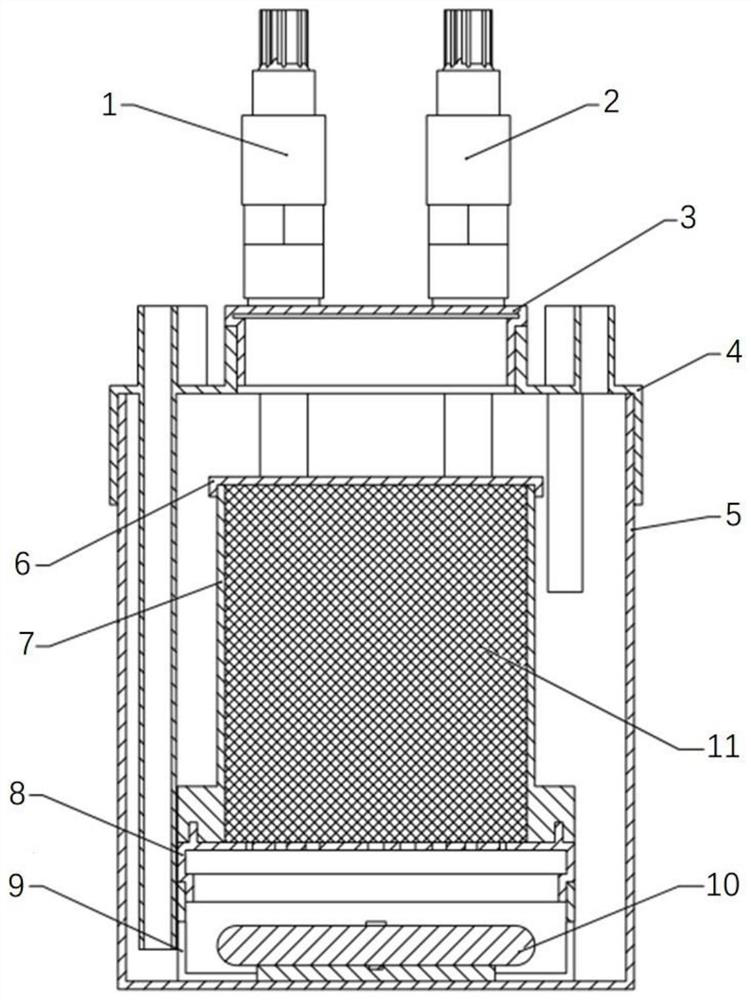

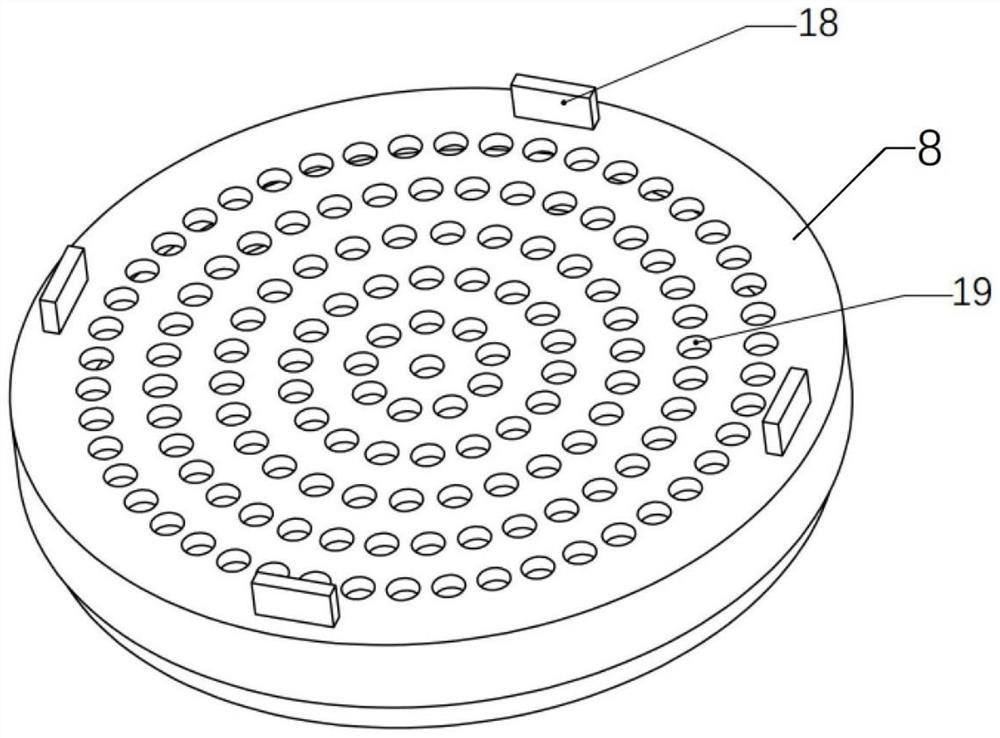

Fixed bed bioreactor

InactiveCN112375685APromote absorptionAvoid inadequate nutrient absorptionBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringEnvironmental engineering

The invention provides a fixed bed bioreactor, and belongs to the technical field of cell culture. The bioreactor comprises a tank body (6); a tank cover (5) is arranged at an upper port of the tank body (6); and a micro-carrier (9) is fixed in the tank body (6). The bioreactor is characterized in that a placing tower (8) is arranged in the tank body (6); the micro-carrier (9) is placed on an outer ring of the placing tower (8); circulating channels of a culture medium are formed between the placing tower (8) and the inner wall of the tank body (6) as well as inside the placing tower (8); anda circulation mechanism (10) for circulating the culture medium inside the circulating channels is arranged at the bottom of the placing tower (8). In the fixed bed bioreactor, the circulating mechanism is arranged, and the culture medium is circulated in the tank body by virtue of the circulating mechanism, so that when the culture medium flows upwards from the bottom of the micro-carrier, the carrier is loosened by virtue of the flowing impact force of the culture medium, and cells can absorb nutrients more favorably.

Owner:SHINVA MEDICAL INSTR CO LTD

Process for treatment of organic contaminated water

InactiveUS20070119777A1Treatment using aerobic processesWater treatment compoundsMetaboliteElectron donor

The present invention may be used in methods for treatment of drinking water contaminated with algal metabolites. An inflow of water in a drinking water treatment facility may have multiple types of algal metabolites wherein each algal metabolites has a concentration of less than 20 μg / l. The water may be dosed with a biodegradable electron donor at a concentration of less than 7 mg / l to form a water, electron donor solution. The water, electron donor solution may be processed through a fixed-bed bioreactor for an empty bed bioreactor contact time of less than 30 minutes. An effluent of the fixed-bed bioreactor may have an algal metabolite concentration for each algal metabolite of less than 10 ng / l.

Owner:BROWN JESS C +2

Bioartificial liver system using bioreactor packed with gel beads

ActiveUS20100126923A1None be problem freeHepatocytesOther chemical processesLine tubingLiver function

The present invention discloses a bioartificial liver system comprising a fixed-bed bioreactor packed with gel beads containing hepatocytes of an animal, a plasma reservoir, a plasma separator, and an efflux chamber, wherein the plasma reservoir is located at a position higher than the bioreactor, a ventilation filter in contact with atmosphere is provided at the top of the plasma reservoir, and the top of the plasma reservoir is directly connected to the efflux chamber via a connecting line. The inventive system satisfactorily performs the essential liver functions without the problems of gel bead damage or channeling.

Owner:LIFECORD +3

Shell-and-tube fixed bioreactor

InactiveCN101020891BNo backmixingShorten the timeBioreactor/fermenter combinationsBiological substance pretreatmentsResource utilizationEngineering

The shell-and-tube fixed bed bioreactor includes one upper end sealing body with liquid inlet; one reaction cavity with stuffing pipes filled with solid stuffing; one lower end sealing body; and one distributor in the upper end of the stuffing pipes with homogeneously distributed through holes for the liquid from the upper end sealing body to be sprayed homogeneously to inside the stuffing pipes.The shell-and-tube fixed bed bioreactor has simple structure, easy operation, high yield and high resource utilizing rate.

Owner:领先生物农业股份有限公司

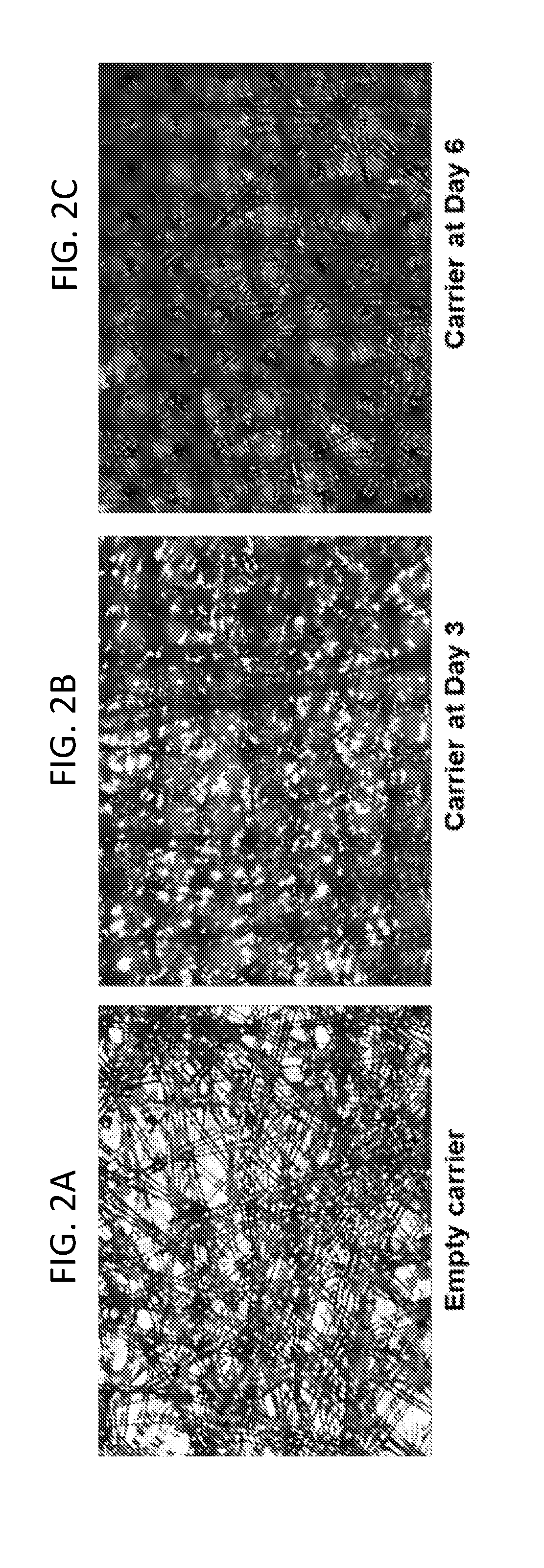

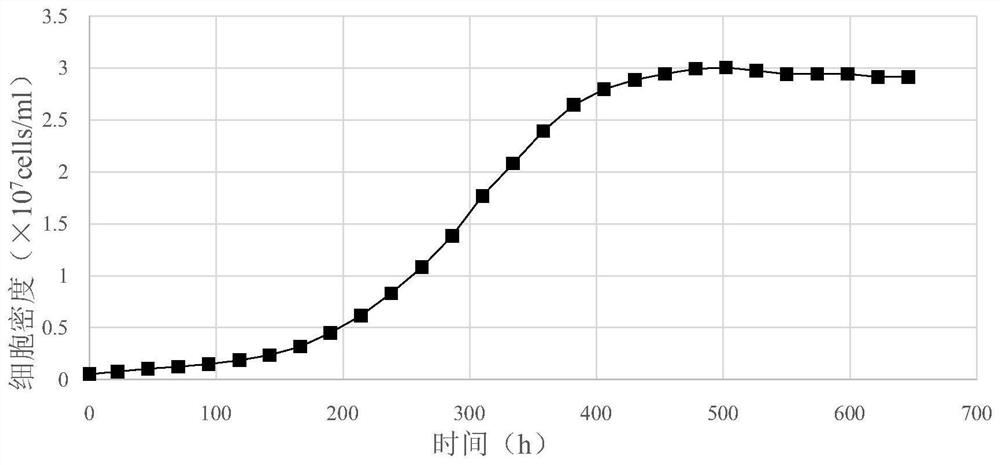

Serum-free Vero cell fixed bed bioreactor high-density culture process

ActiveCN111849870AHigh densityReduce pollutionCulture processArtificial cell constructsPerfusion CultureCulture mediums

The invention discloses a serum-free Vero cell fixed bed bioreactor high-density culture process, and belongs to the field of cell culture. The culture process comprises the following steps of: 1) inoculating Vero cells cultured by a serum-free culture medium into a fixed bed bioreactor until a solution is clear; 2) within 12-24 hours after inoculation, setting the following parameters for cultureunder a non-perfusion condition: the temperature is 37.0 + / - 0.2 DEG C, the pH value is 7.20 + / - 0.1, the dissolved oxygen is 60 + / - 20%, and the rotating speed is 90-110 rpm; and 3) starting perfusion culture 12-24 hours after the inoculation. By adopting the method disclosed by the invention, the high-density Vero cells can be cultured, and the use of bovine serum and animal pancreatin is not involved, so that the safety of biological products obtained by the Vero cells is greatly improved.

Owner:成都柏奥特克生物科技股份有限公司

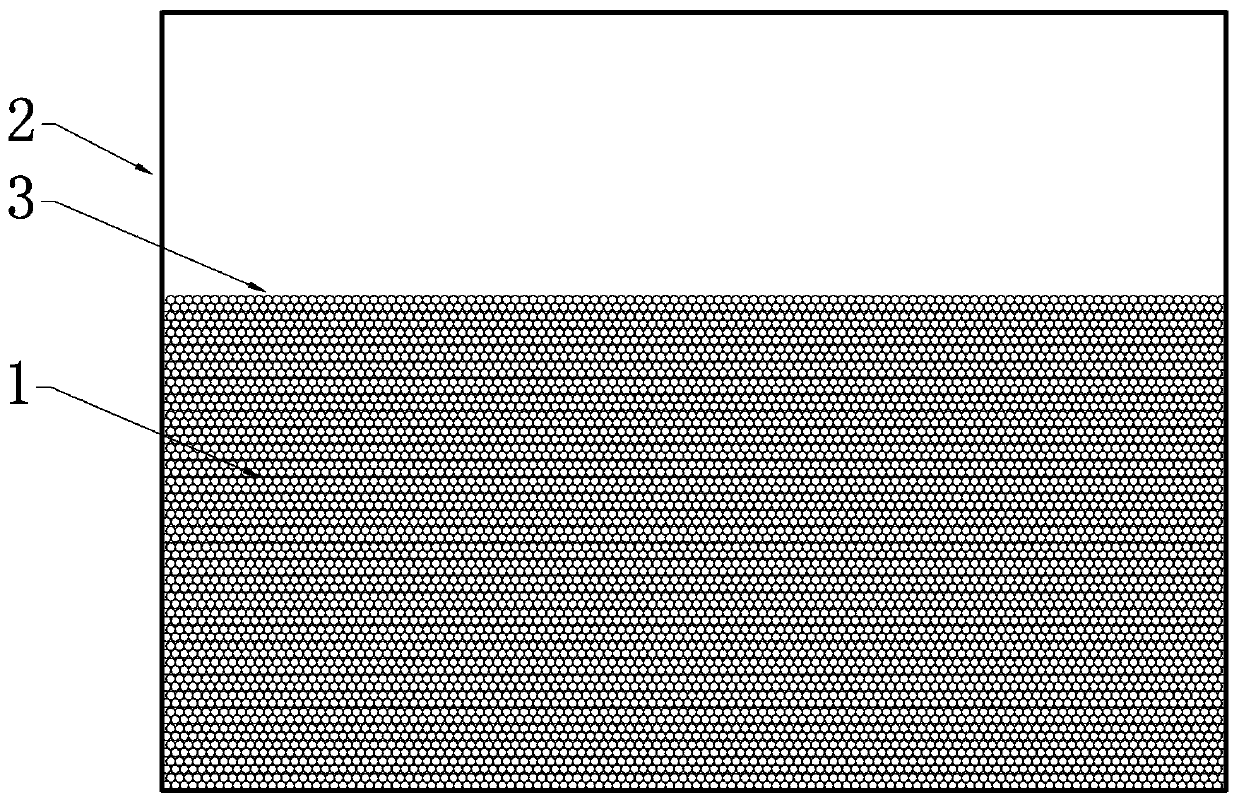

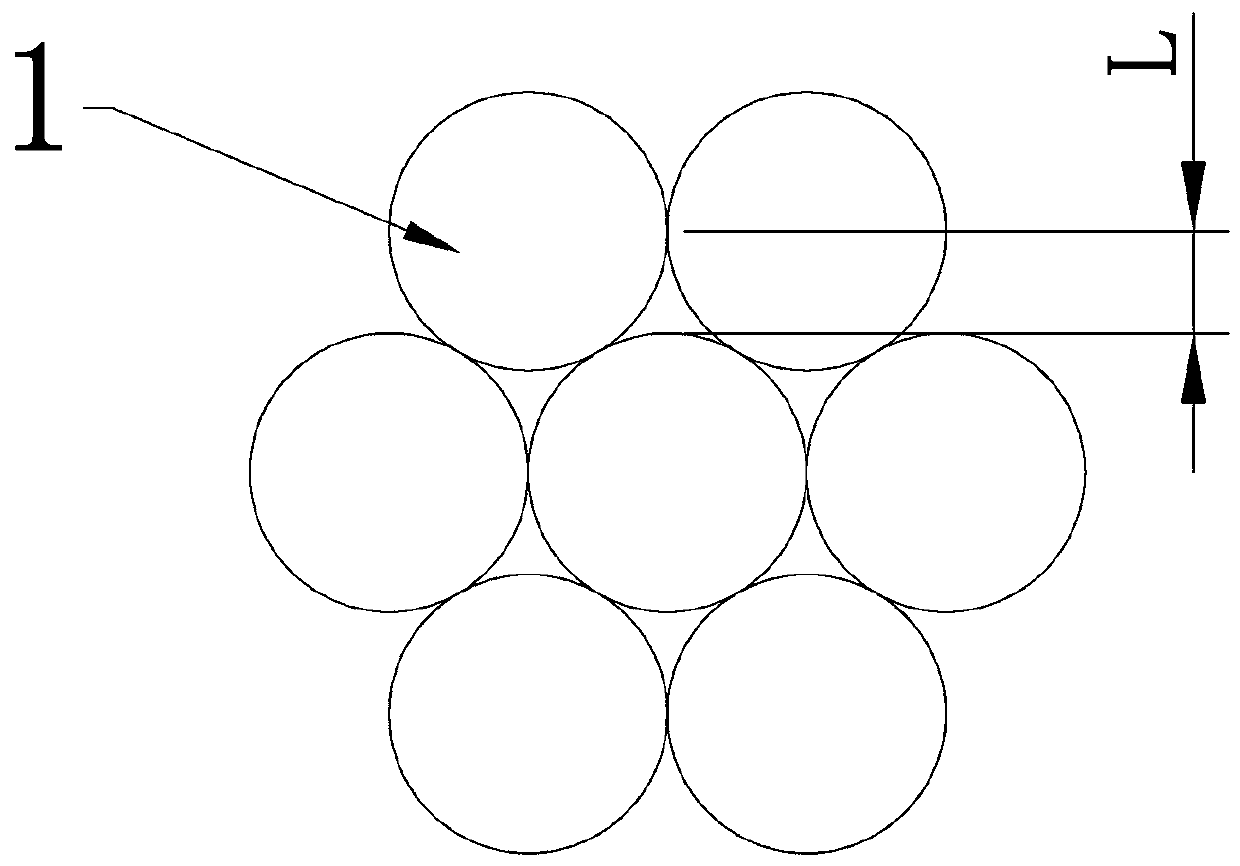

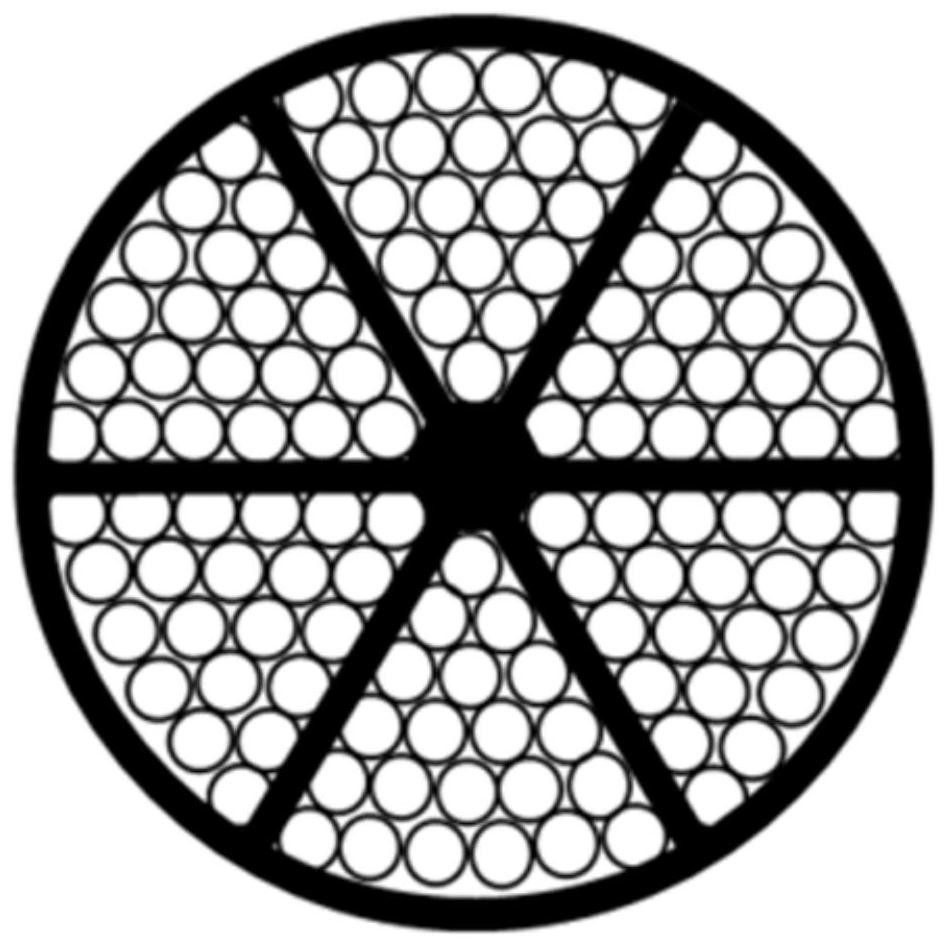

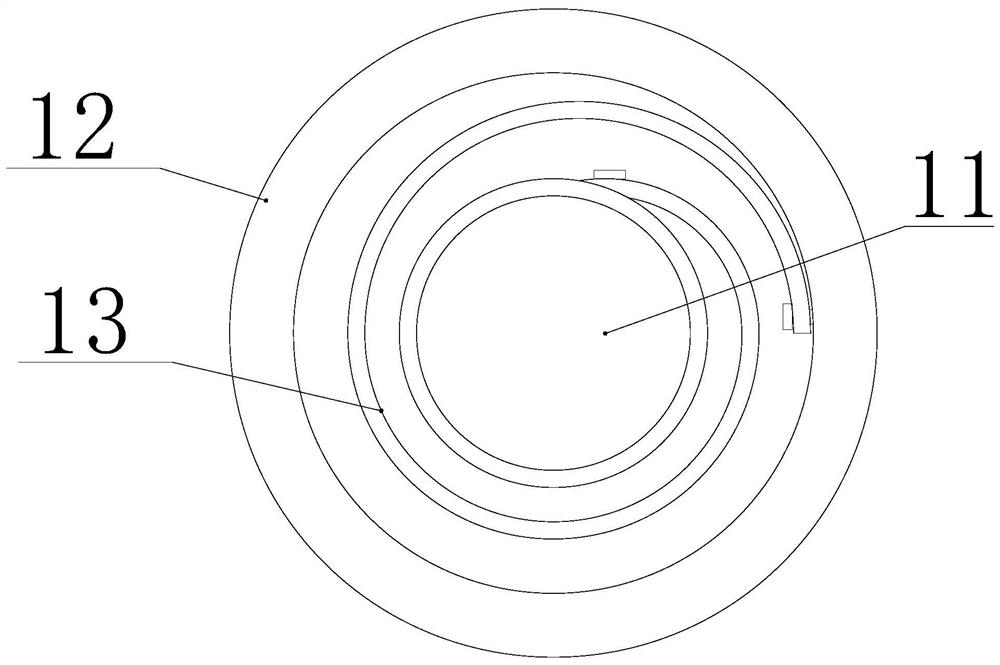

Microfluidic channel carrier structure for large-scale culture of stem cells and immune cells

PendingCN110903978APromote amplificationImprove interactivityTissue/virus culture apparatusMicroorganism fixing/supporting apparatusCell-Extracellular MatrixFixed bed bioreactor

The invention discloses a microfluidic channel carrier structure for large-scale culture of stem cells and immune cells. The microfluidic channel carrier structure includes a plurality of microspheres(1). The diameter of the microspheres (1) is 0.5 mm to 2.7 mm. The microspheres (1) are stacked in a fixed bed bioreactor (2) to form a fixed bed (3), and the fixed bed (3) forms a microfluidic channel carrier structure. The maximum linear space dimension L between adjacent microspheres (1) in the microfluidic channel carrier structure is 0.183 mm to 0.988 mm. The microfluidic channel carrier structure of the invention is formed by stacking a plurality of microspheres. The microfluidic channel in the microfluidic channel carrier structure can provide cells with a micro-environment closer to that in human tissues, facilitate the interaction and signal transmission between cells and between cells and extracellular matrix, facilitate the expansion of cells, and can expand the number of cellscultured simultaneously to 100-200 billion.

Owner:南京比瑞生物科技有限公司

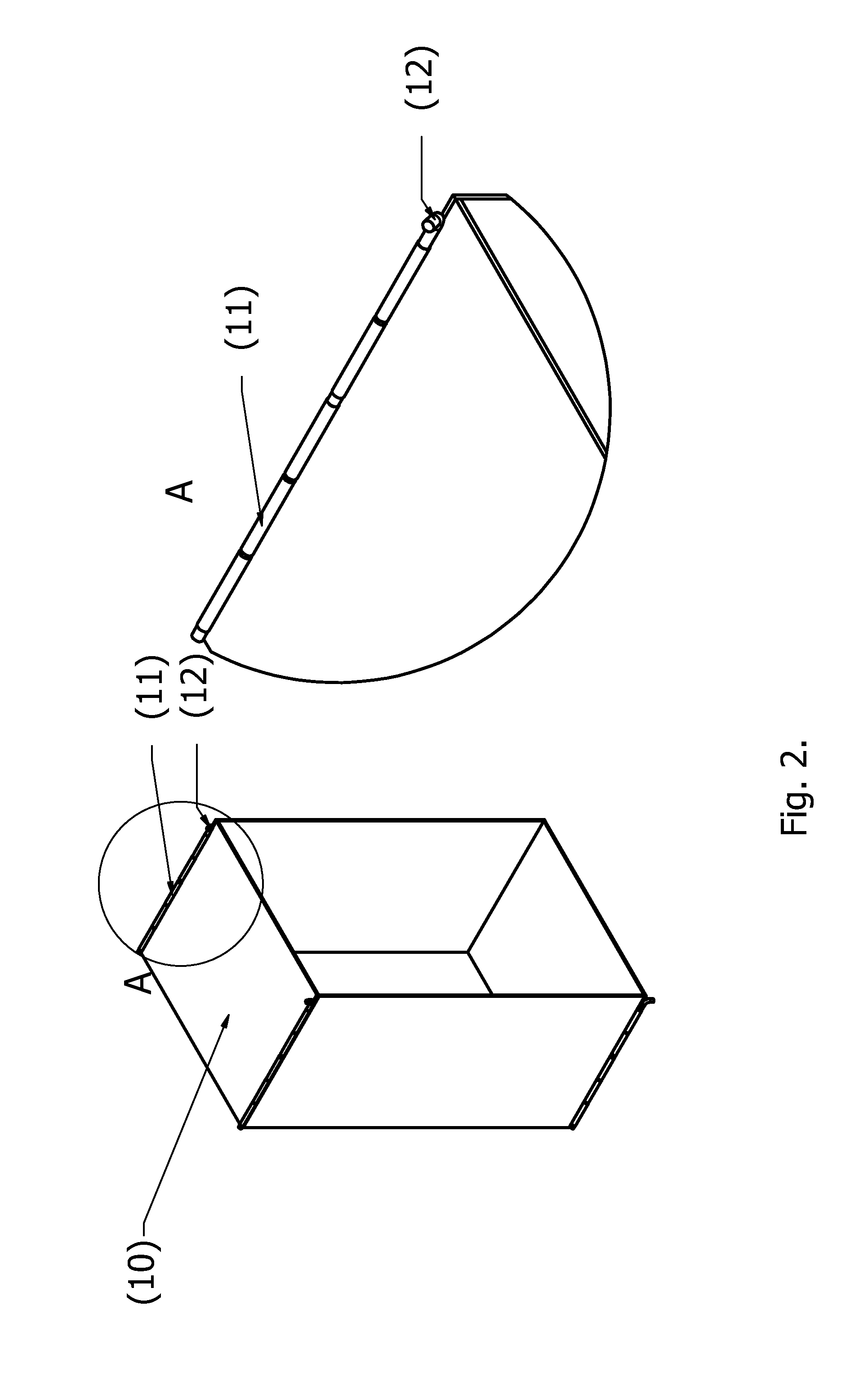

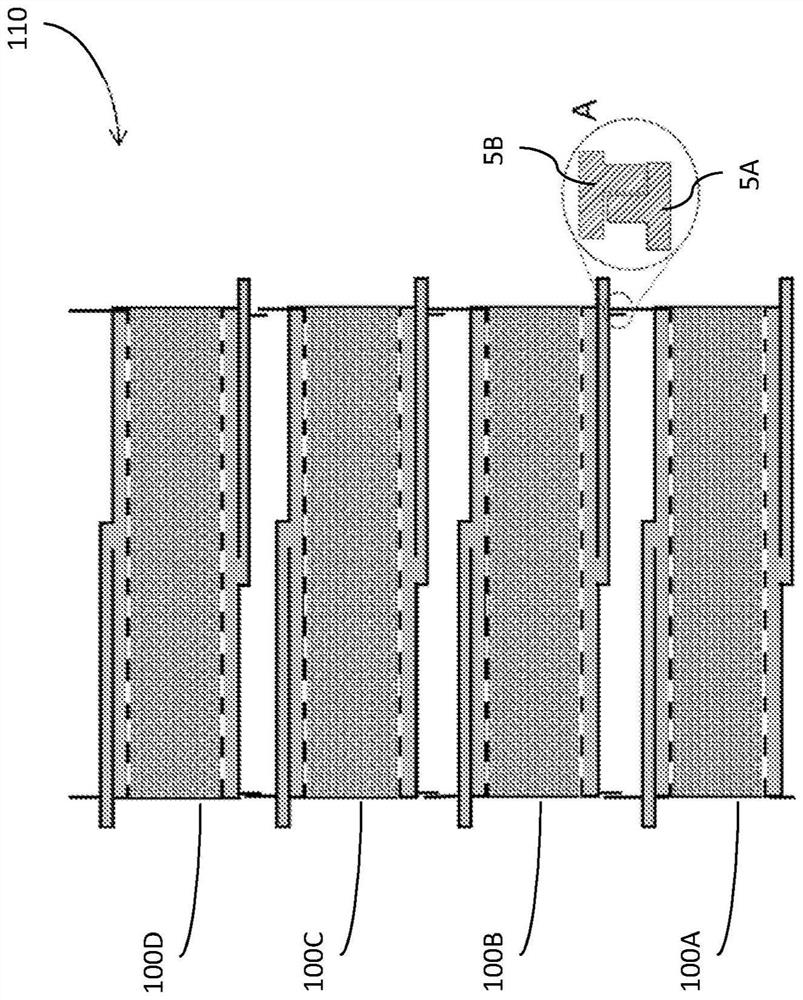

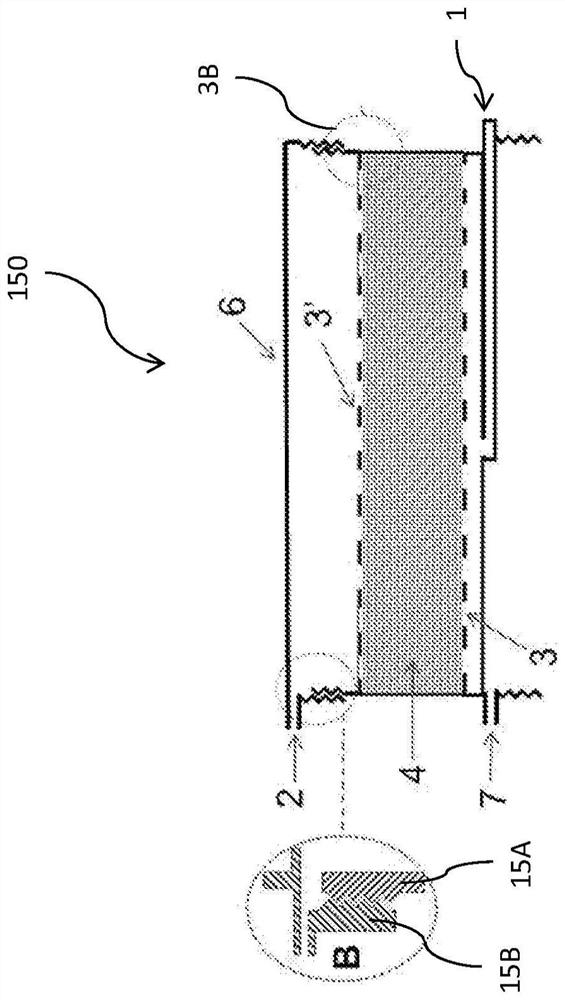

Stacked fixed bed bioreactor and method of use thereof

PendingCN114746540ABioreactor/fermenter combinationsBiological substance pretreatmentsCell culture mediaEngineering

A modular and stacked cell culture system includes individual cell culture subunits having an internal chamber for containing a cell culture substrate in a cell culture space, a fluid inlet for supplying fluid to the cell culture space, and a fluid outlet for removing fluid from the chamber. The chamber is arranged for fluid to flow in from the fluid inlet, through the cell culture space, and then out through the fluid outlet. The subunit further includes an alignment feature on at least one of a top and a bottom of an individual cell culture subunit, where the alignment feature is aligned with an alignment feature of another individual cell culture subunit such that a plurality of individual cell culture subunits are stackable.

Owner:CORNING INC

Process for treatment of organic contaminated water

InactiveUS7294273B2Water treatment parameter controlTreatment using aerobic processesMetaboliteElectron donor

The present invention may be used in methods for treatment of drinking water contaminated with algal metabolites. An inflow of water in a drinking water treatment facility may have multiple types of algal metabolites wherein each algal metabolites has a concentration of less than 20 μg / l. The water may contain indigenous bacteria that may serve as a bioreactor inoculum. The water may be dosed with a biodegradable electron donor at a concentration of less than 7 mg / l to form water, electron donor solution. The water, electron donor solution may be processed through a fixed-bed bioreactor for an empty bed bioreactor contact time of less than 30 minutes. An effluent of the fixed-bed bioreactor may have an algal metabolite concentration for each algal metabolite of less than 10 ng / l.

Owner:SEMOTO

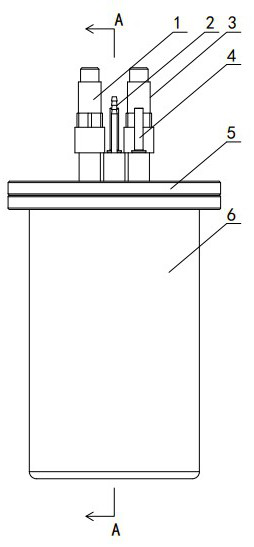

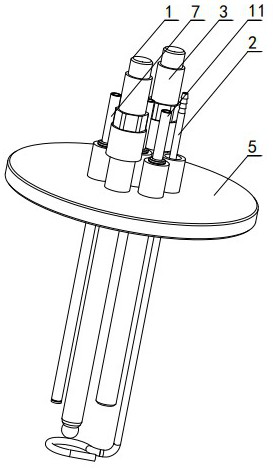

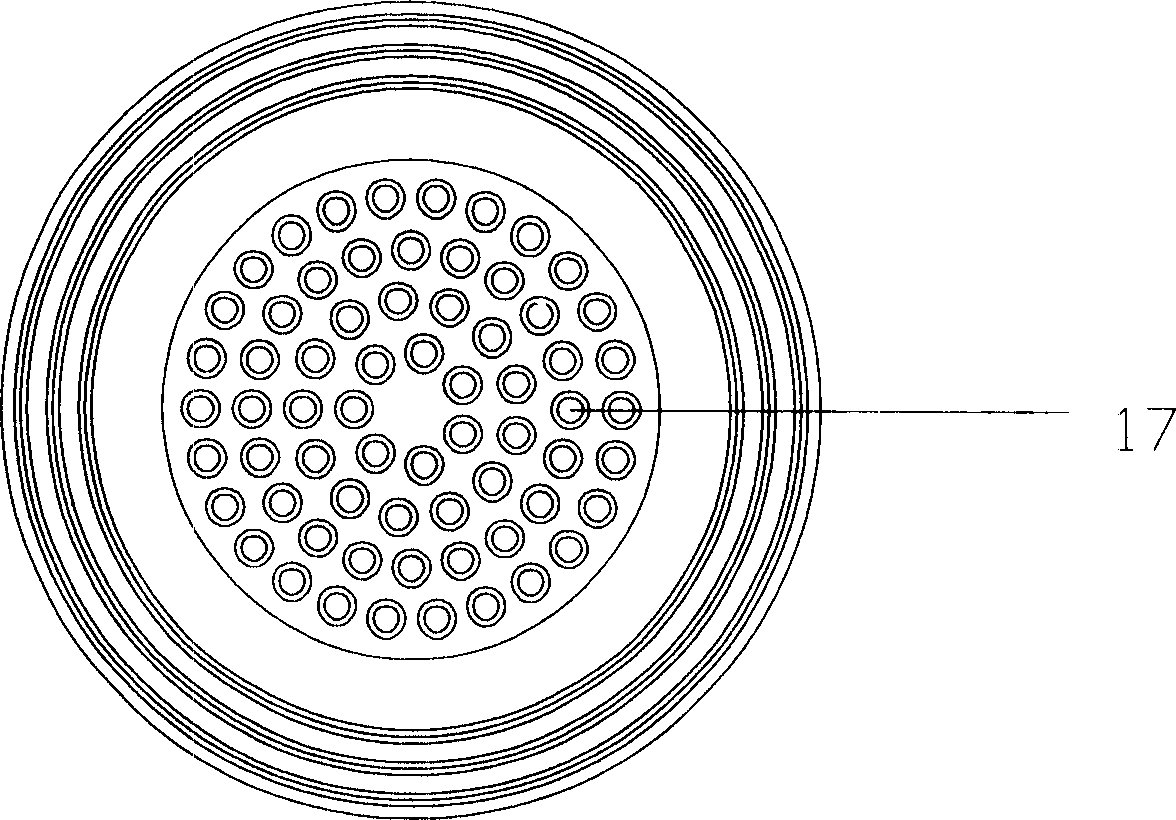

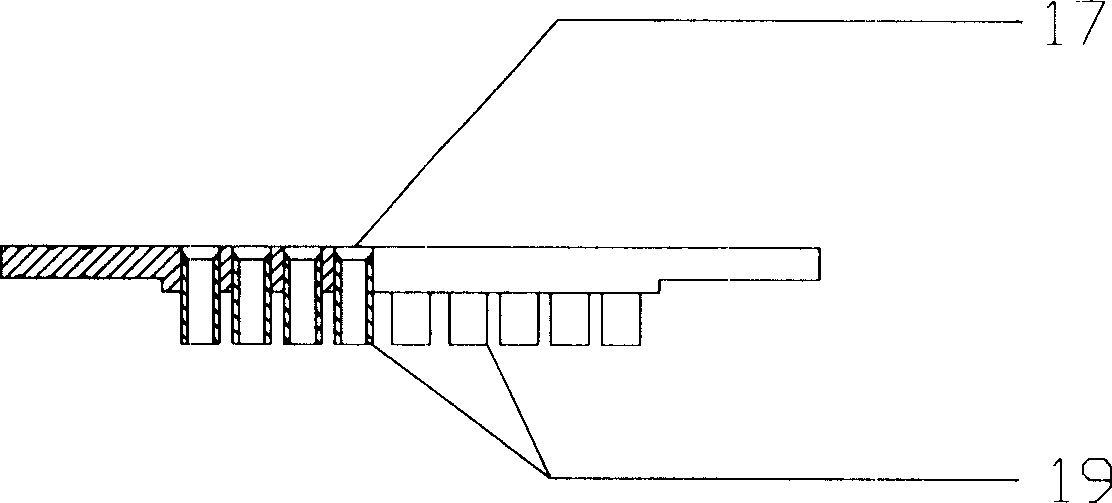

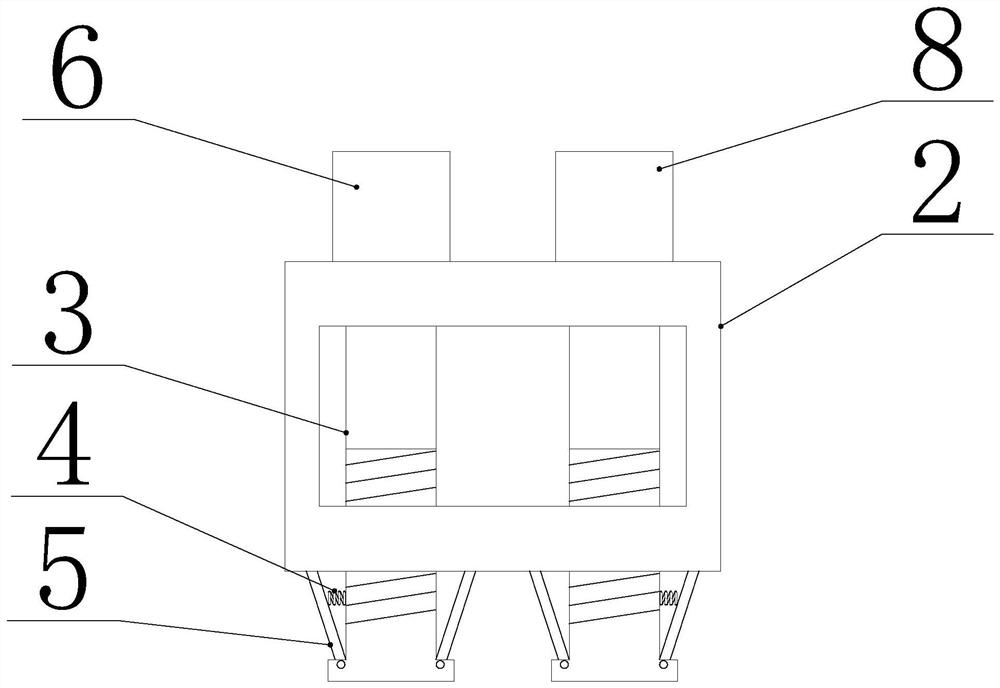

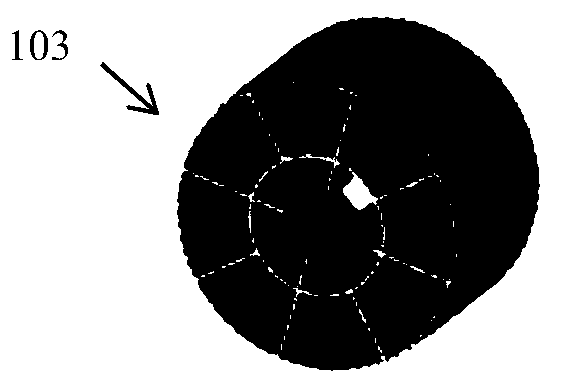

Hollow tube bundle type fixed bed bioreactor for adherent culture of mammalian cells

PendingCN112980649AEvenly attachedEvenly distributedBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringFixed bed bioreactor

The invention provides a hollow tube bundle type fixed bed bioreactor for adherent culture of mammalian cells, and can effectively solve the technical problems that cells are unevenly distributed on a carrier, the center of a carrier stack is prone to produce a cell-free "dead zone", shear force of a fluid medium in the reactor is large, and the cells are difficult to harvest. The hollow tube bundle type fixed bed cell bioreactor comprises a tank body, a carrier, a culture medium driving unit and a gas supply unit; a flange cover is mounted at the top of the tank body, and the carrier is arranged in the tank body. The hollow tube bundle type fixed bed cell bioreactor is characterized in that only flow channels vertical and evenly distributed are arranged in the carrier; gaps are arranged between the upper end of the carrier and the flange cover and between the carrier and the side wall of the tank body; and culture mediums in the tank body flow in from the opening at lower ends of the flow channels under the action of the culture medium driving unit, and then return to the bottom of the tank body after sequentially passing through the flow channels, the gap between the carrier and the flange cover and the gap between the carrier and the side wall of the tank body.

Owner:JIANGNAN UNIV

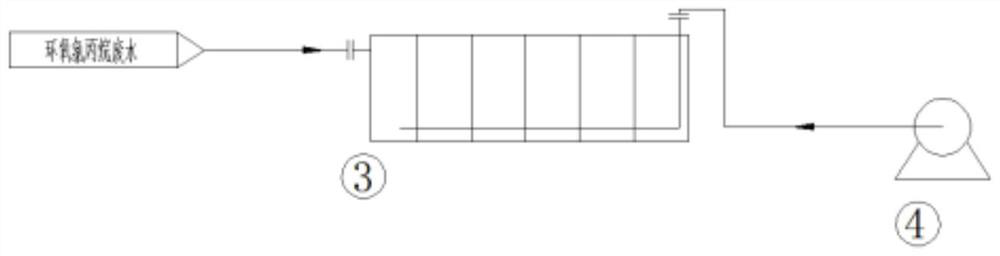

Epoxy chloropropane wastewater treatment method

PendingCN113354215ALow costSimple processTreatment using aerobic processesWater contaminantsEpoxyChemical oxygen demand

The invention relates to an epoxy chloropropane wastewater treatment method which comprises the following steps: 1, introducing epoxy chloropropane wastewater into an ozone catalytic oxidation tower, filling a catalyst in the catalytic oxidation tower, and carrying out catalytic oxidation decomposition on the epoxy chloropropane wastewater to obtain small molecule and biochemical organic matters; and 2, the oxidized epoxy chloropropane wastewater enters a biochemical pool for biochemical decomposition, and the treated epoxy chloropropane wastewater reaches the standard and is discharged. The biological bacteria culture mode in the biochemical pool adopts a gradual slow culture mode, firstly, COD (Chemical Oxygen Demand) of the wastewater is diluted to 500mg / l by adding water, the wastewater is cultured for 5-14 days, then the COD concentration of the wastewater is gradually increased, and the culture is continued. If the COD concentration of the epoxy chloropropane wastewater is higher than 8000 ppm, the wastewater is firstly subjected to ozone catalytic oxidation, then a middle unit of the honeycomb type fixed bed bioreactor is set as a catalytic oxidation regulating water tank, and the wastewater is conveyed to a catalytic oxidation tower through a pump for secondary oxidation. The wastewater treatment efficiency is improved, and the treatment cost is reduced.

Owner:山东产研生态环境研究院有限公司

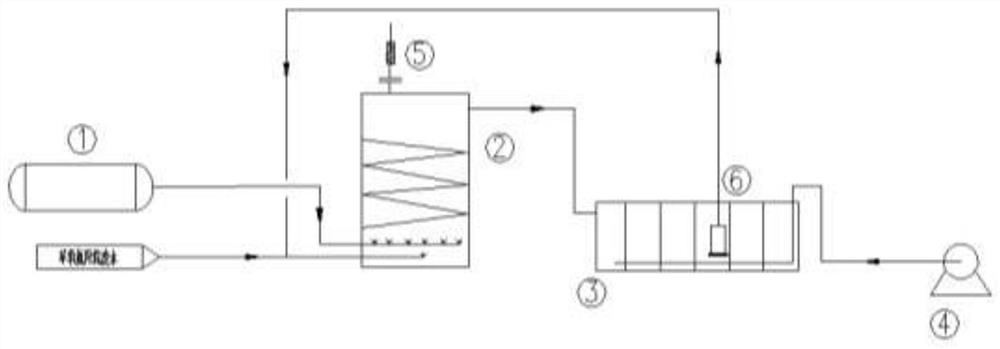

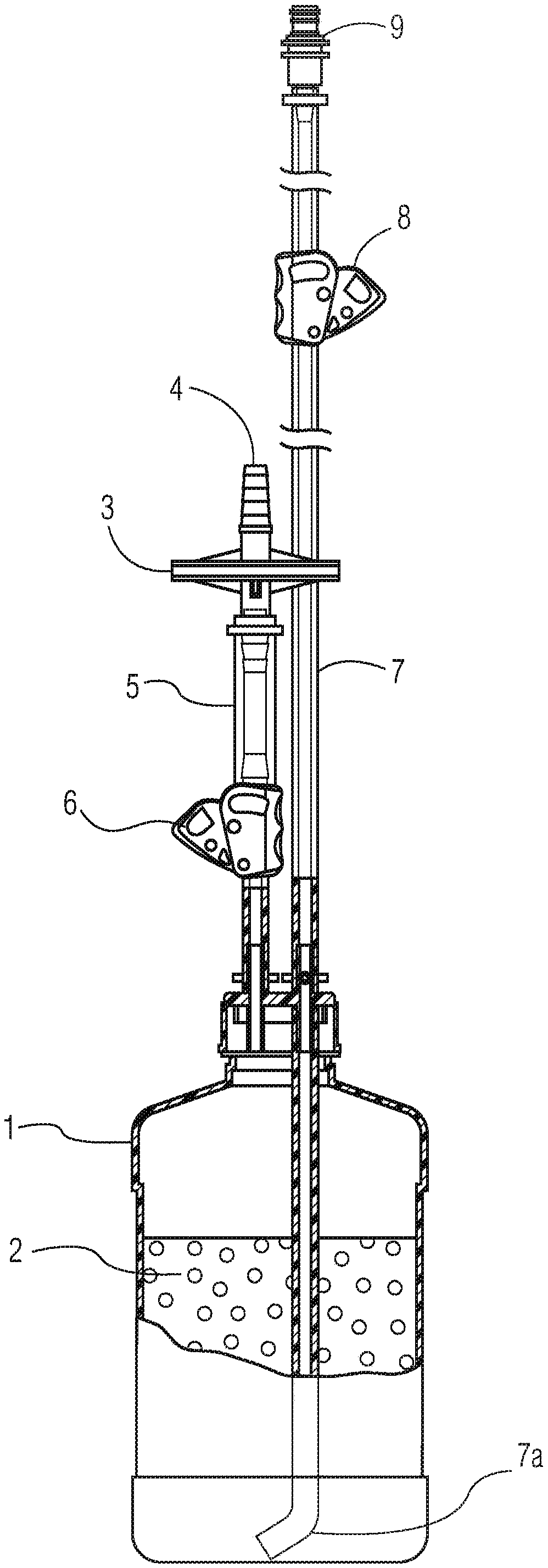

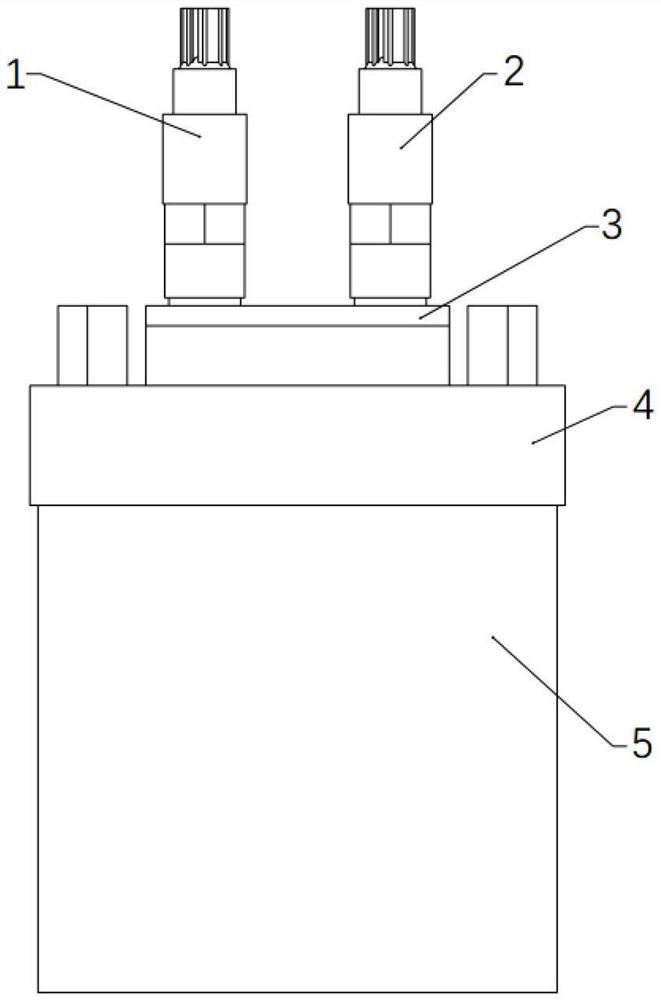

Fixed bed bioreactor for viral vector vaccine culture and use method thereof

PendingCN113564048APrevent loosening and twistingAvoid bendingBioreactor/fermenter combinationsBiological substance pretreatmentsContinuous perfusionPolyethylene terephthalate glycol

The invention provides a fixed bed bioreactor for viral vector vaccine culture and a use method thereof. The fixed bed bioreactor comprises a main tank body, a circulating perfusion bottle, a material supplementing bottle and a harvesting bottle, wherein the top of the main tank body is fixedly connected with two limiting blocks; and the tops of the circulating perfusion bottle, the material supplementing bottle and the harvesting bottle are fixedly connected with fixing blocks. The fixed bed bioreactor has the beneficial effects that the limiting blocks are used for preventing the looseness and twisting of a pipeline, so that the untight sealing is avoided; the fixing blocks are used, so that the angle of the pipeline is conveniently maintained, and the pipeline is prevented from bending; and a rotary type non-woven polyethylene terephthalate (PET) fixed bed is used, so that the fixing of cells is convenient, and the cells are prevented from flowing out of a reaction tank; by using the combined type of continuous perfusion and circulating perfusion, the virus infection efficiency is improved.

Owner:SHEN ZHEN TSINGHUA YUANXING BIO PHARM SCI & TECHNOL

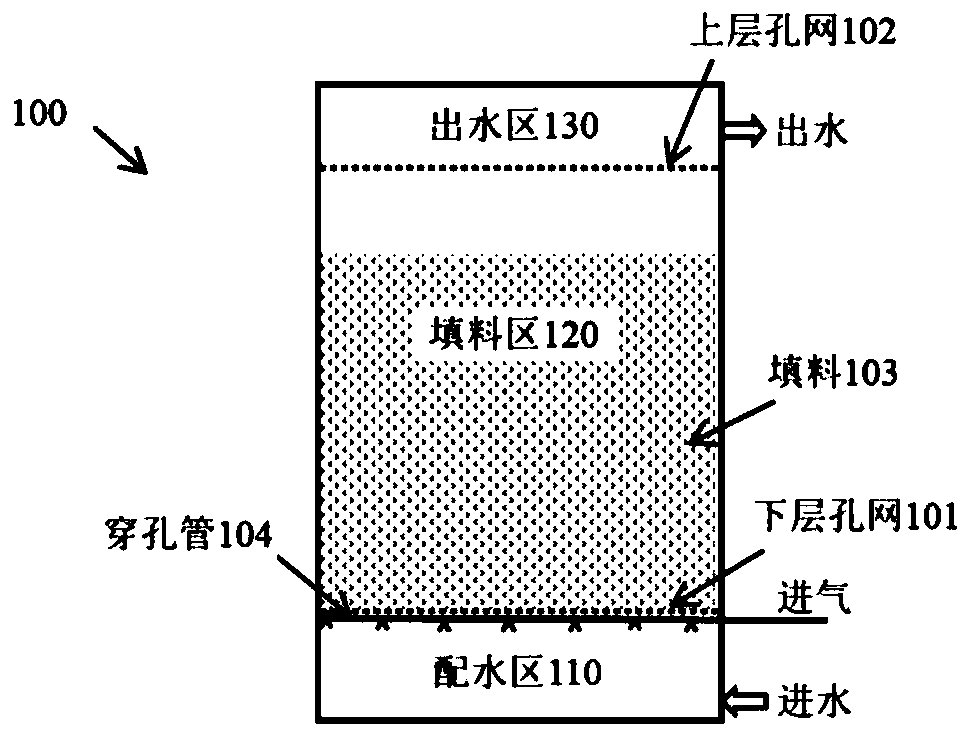

Carrier fixed bed bioreactor and water treatment system

InactiveCN110627204AReduce lossesReduced strength requirementsWater contaminantsTreatment with anaerobic digestion processesWater treatment systemEngineering

The invention discloses a carrier fixed bed bioreactor and a water treatment system comprising the carrier fixed bed bioreactor. The carrier fixed bed bioreactor comprises a tank body and a fillter; alower-layer hole net is arranged at the lower part of the tank body and is used for supporting a filler, a plurality of lower holes penetrating through the lower-layer hole net in the thickness direction are formed in the lower-layer hole net, and the diameter of the lower holes are designed to be smaller than the diameter of the filler; an upper-layer hole net is arranged at the upper part of the tank body and is used for blocking the filler, a plurality of upper holes penetrating through the upper-layer hole net along the thickness direction are formed in the upper-layer hole net, and the diamerter of the upper holes is designed to be smaller than that of the filler; the filler is kept in a space defined by the lower-layer hole net, the upper-layer hole net and the corresponding side walls of the tank body, and the total volume of the filler is smaller than the volume of the space, so that when the filler is deposited on the lower-layer hole net, the top of the filler is separated from the upper-layer hole net, wherein the density of the filler is slightly larger than that of water, so that the filler is deposited on the lower-layer hole net when water introduction is stopped, and the filler floats and is blocked by the upper-layer hole net when the flow speed of introduced water reaches a preset flow speed or above.

Owner:SUEZ WATER TREATMENT CO LTD

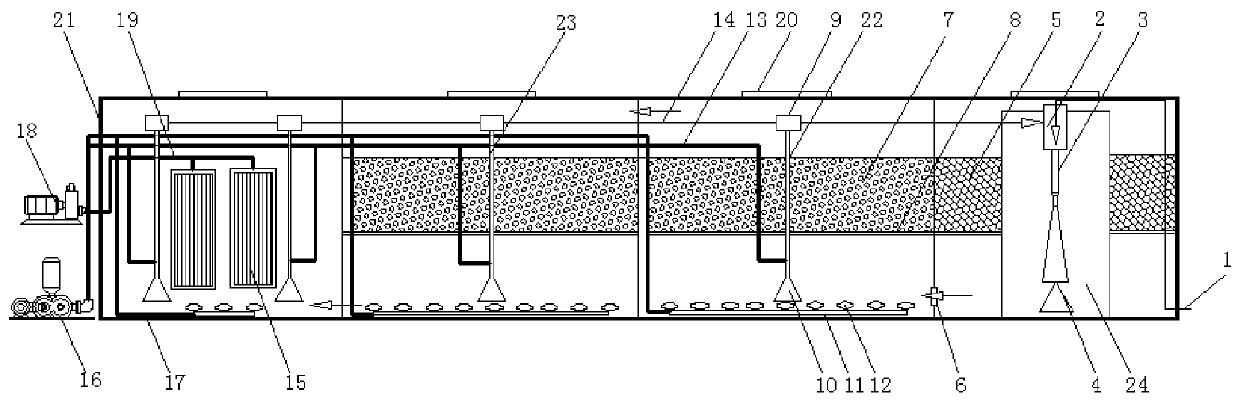

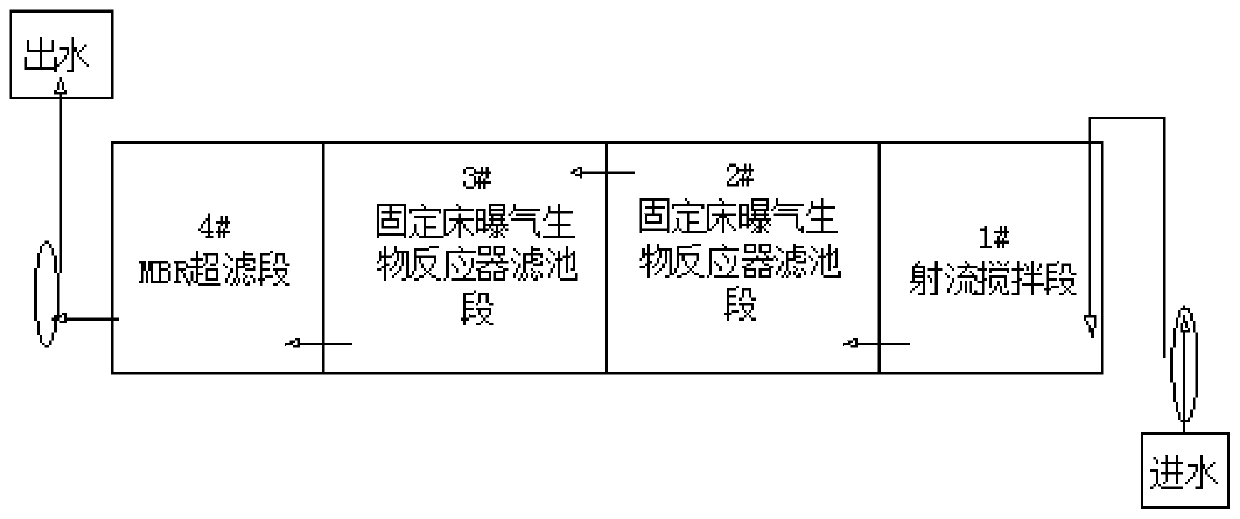

Denitrification sewage treatment device with high emission standard and low carbon nitrogen ratio

InactiveCN110228915AImprove targeting specificityImprove denitrification effectWater contaminantsTreatment involving filtrationSludgeSeparation technology

The invention discloses a denitrification sewage treatment device with high emission standard and low carbon nitrogen ratio. The device comprises a tank shell. The outer wall of one side of the tank shell is provided with an air compressor and a self-priming pump, and the air compressor is connected with an exposure module and sludge treatment modules through a pipeline. The inside of the tank shell is divided into a filter bin, an aeration fluidizing bin and a homogenizing bin, and the inner wall of the homogenizing bin is provided with a homogenizing tank. The two sludge treatment modules are arranged in the aeration fluidizing bin, and the other two sludge treatment modules are disposed inside the filter bin. By the technology of combining a fixed bed bioreactor, an obligate oligonitrophilic bacteria and an MBR biological ultrafilter, and by a directional separation technology, mud samples are collected at the construction site and are screened and cultivated in a laboratory. The low-carbon-source denitrification effect is greatly enhanced. Clay ceramsite which is cheap and easily available is used as a filler for domestic sewage treatment. The device can be designed to be movable and integrated. Thus, land occupation of the equipment is small, investment is saved, and unattended operation can be achieved.

Owner:HAINAN CHENGTAI ENVIRONMENT ENG

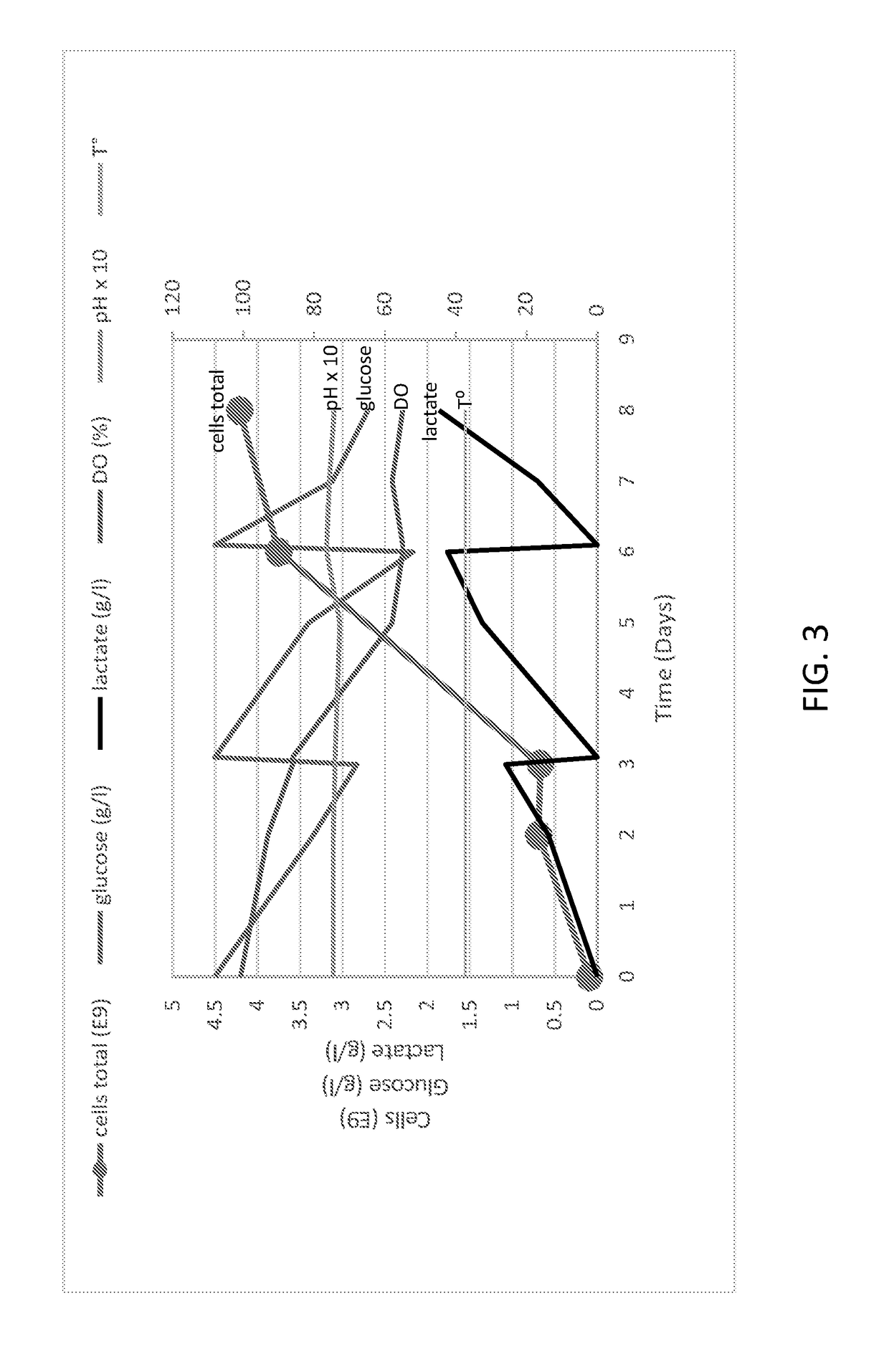

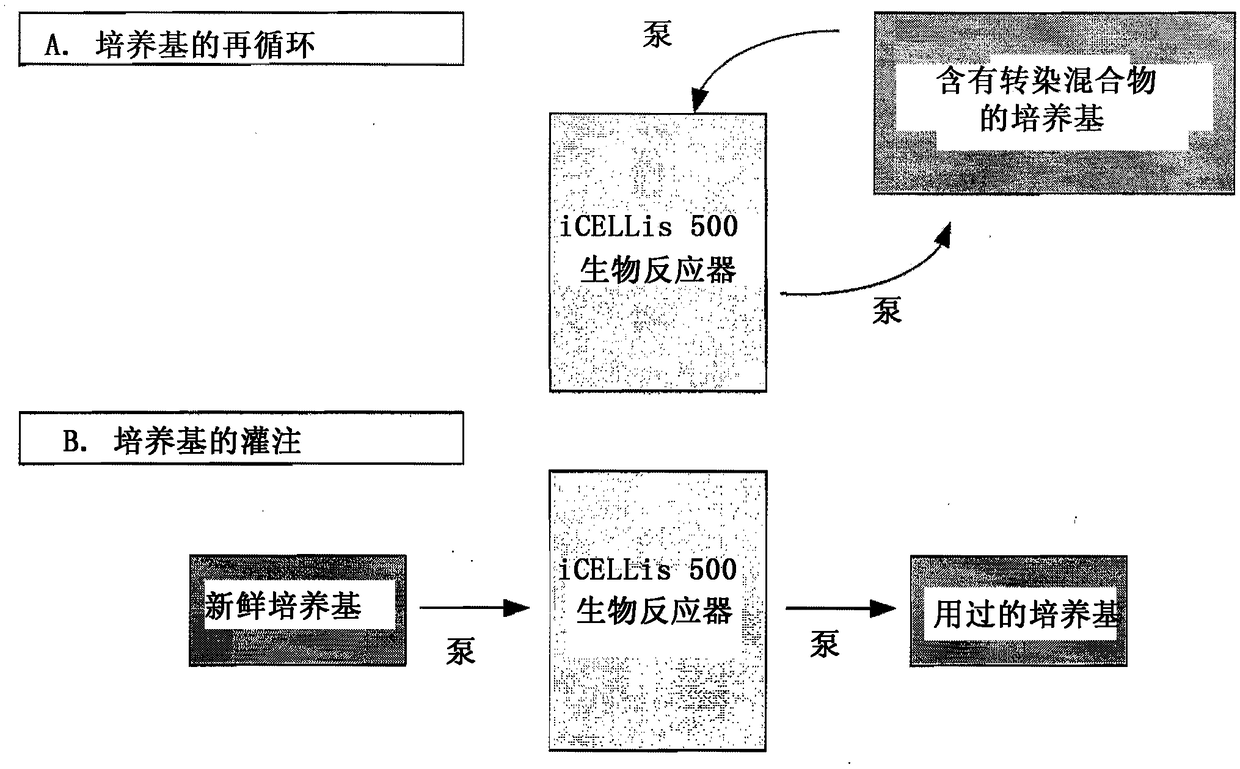

Fixed-bed bioreactor with constant-flow pump/tubing system

PendingCN109071594ABioreactor/fermenter combinationsBiological substance pretreatmentsProduction rateCell culture media

We have modified a commercially-available adherent cell culture bioreactor in several ways to increase productivity of cultured cells, while decreasing contamination risk. We found that modifying a commercially-available adherent cell culture bioreactor to provide for slower cell culture medium flow unexpectedly and dramatically increases the productivity of the cultured adherent cells. We also developed a new sampling manifold configuration and new way of taking samples, to reduce contamination risk.

Owner:TRIZELL LTD

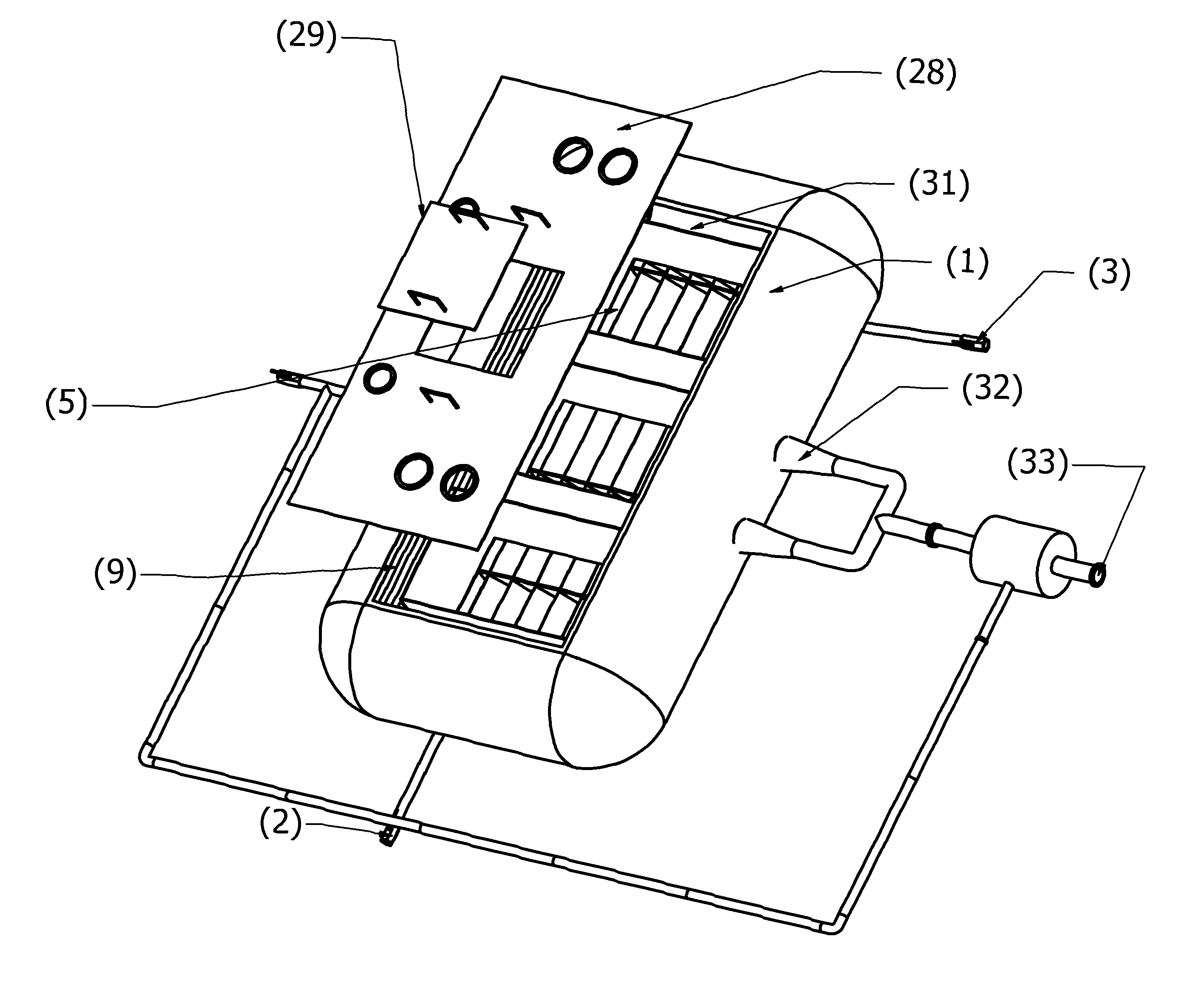

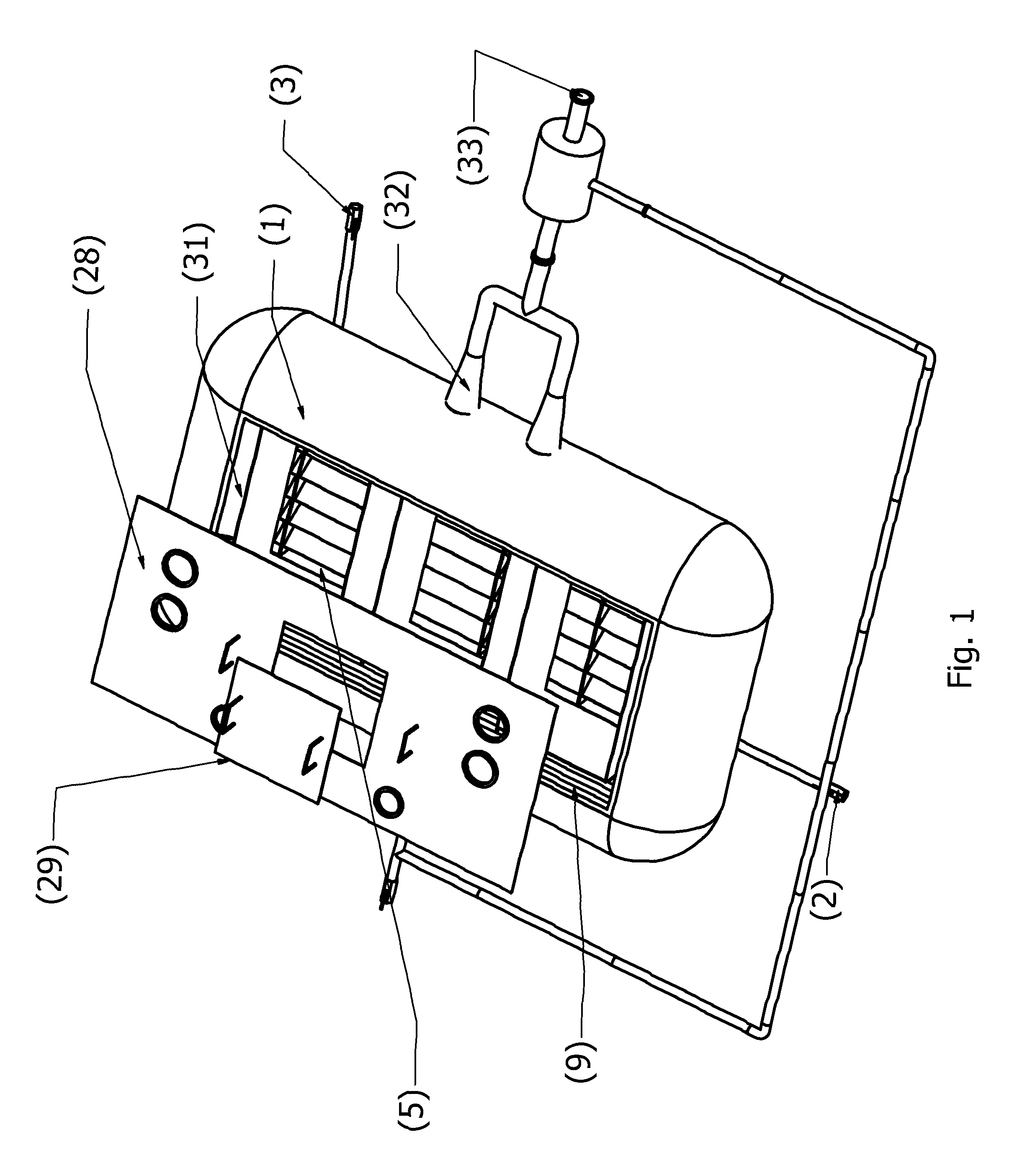

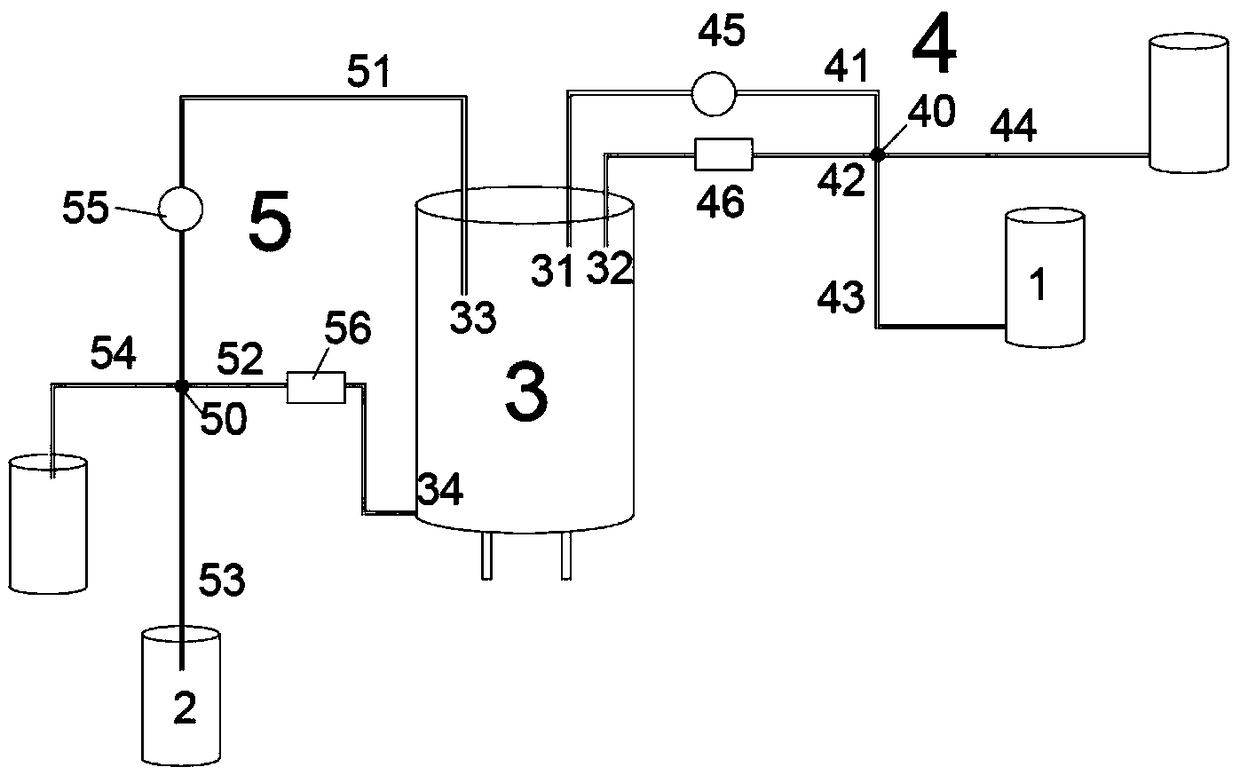

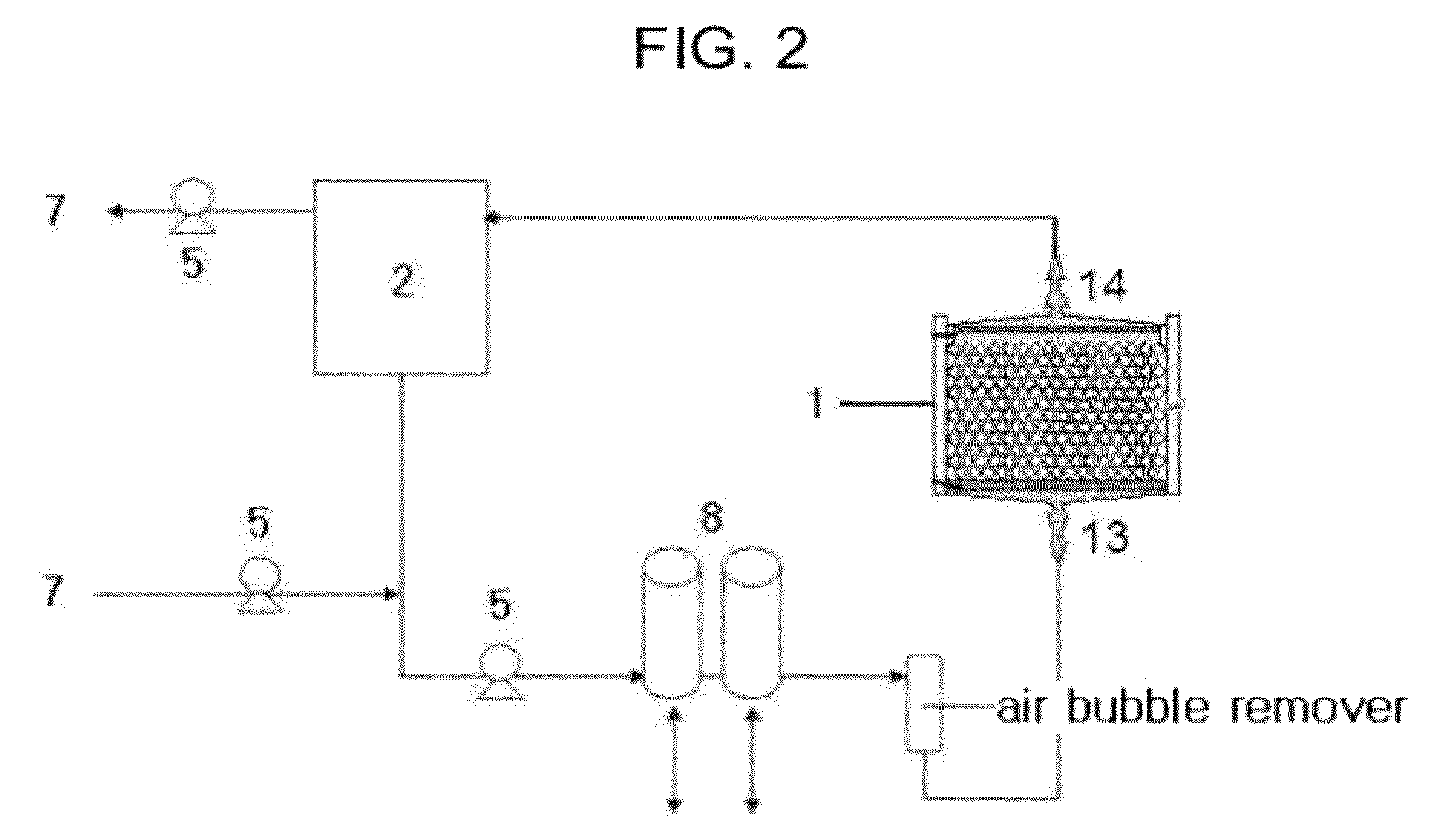

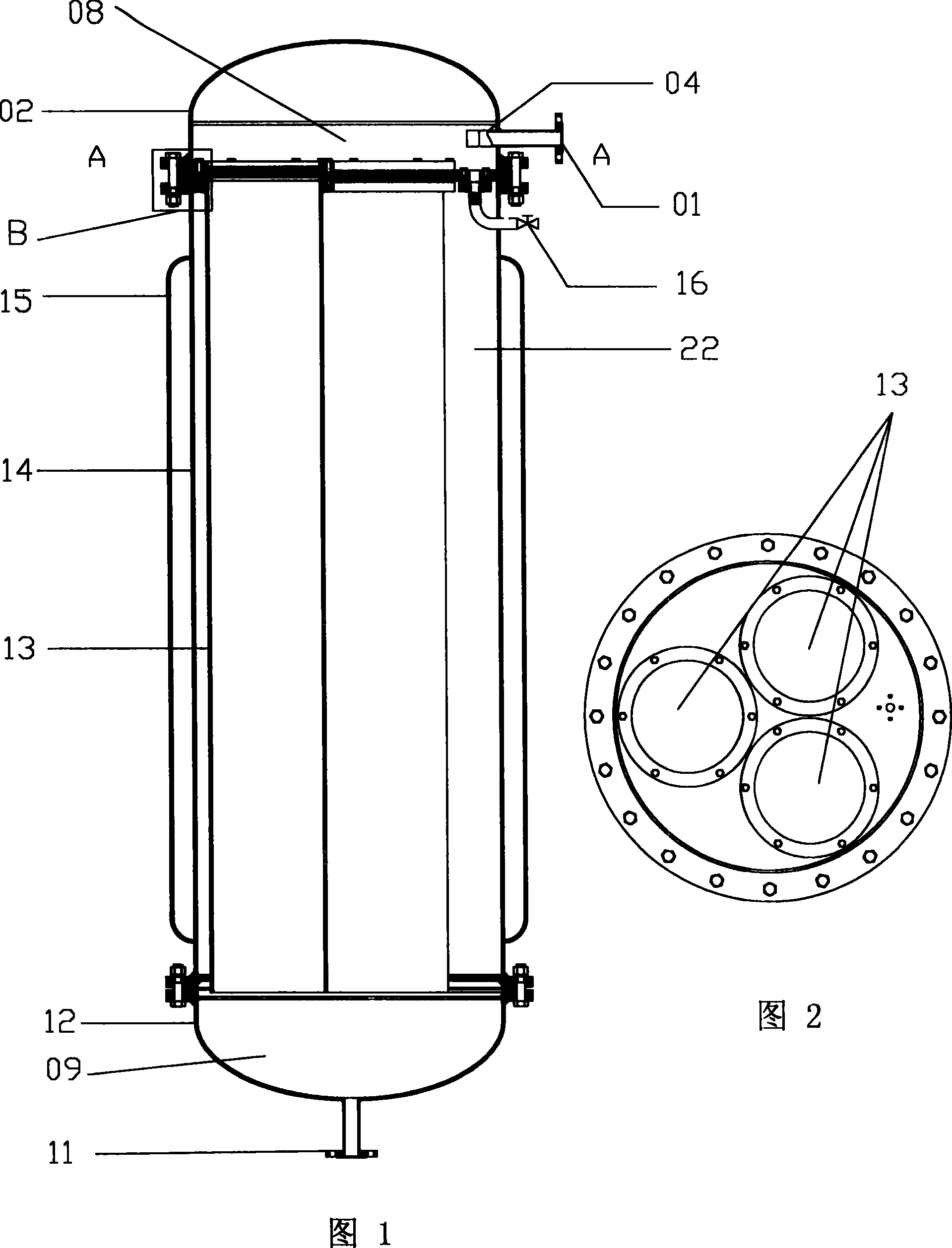

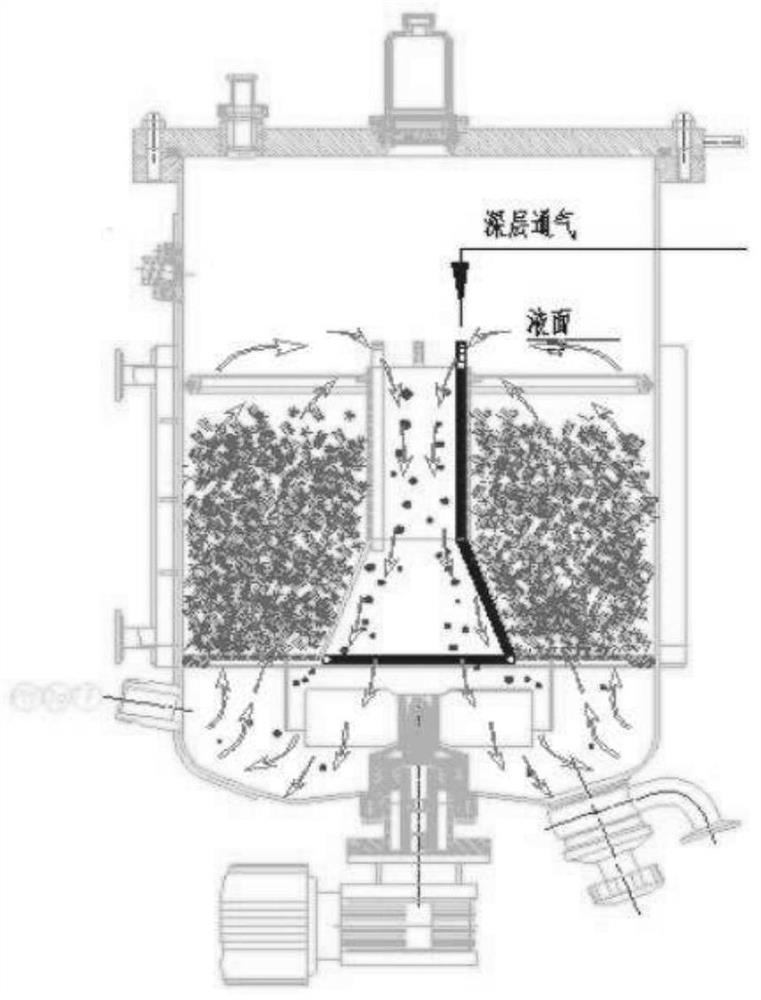

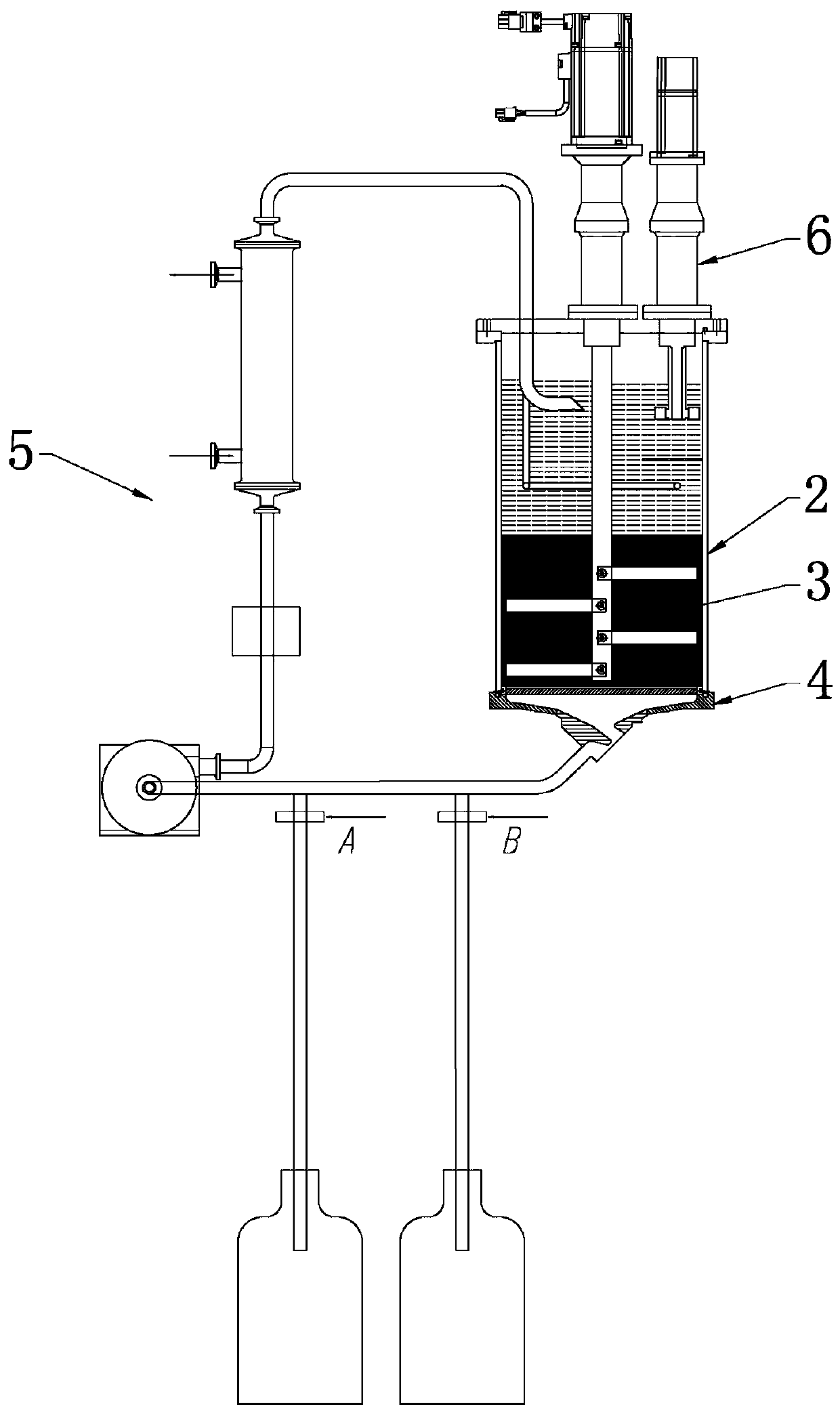

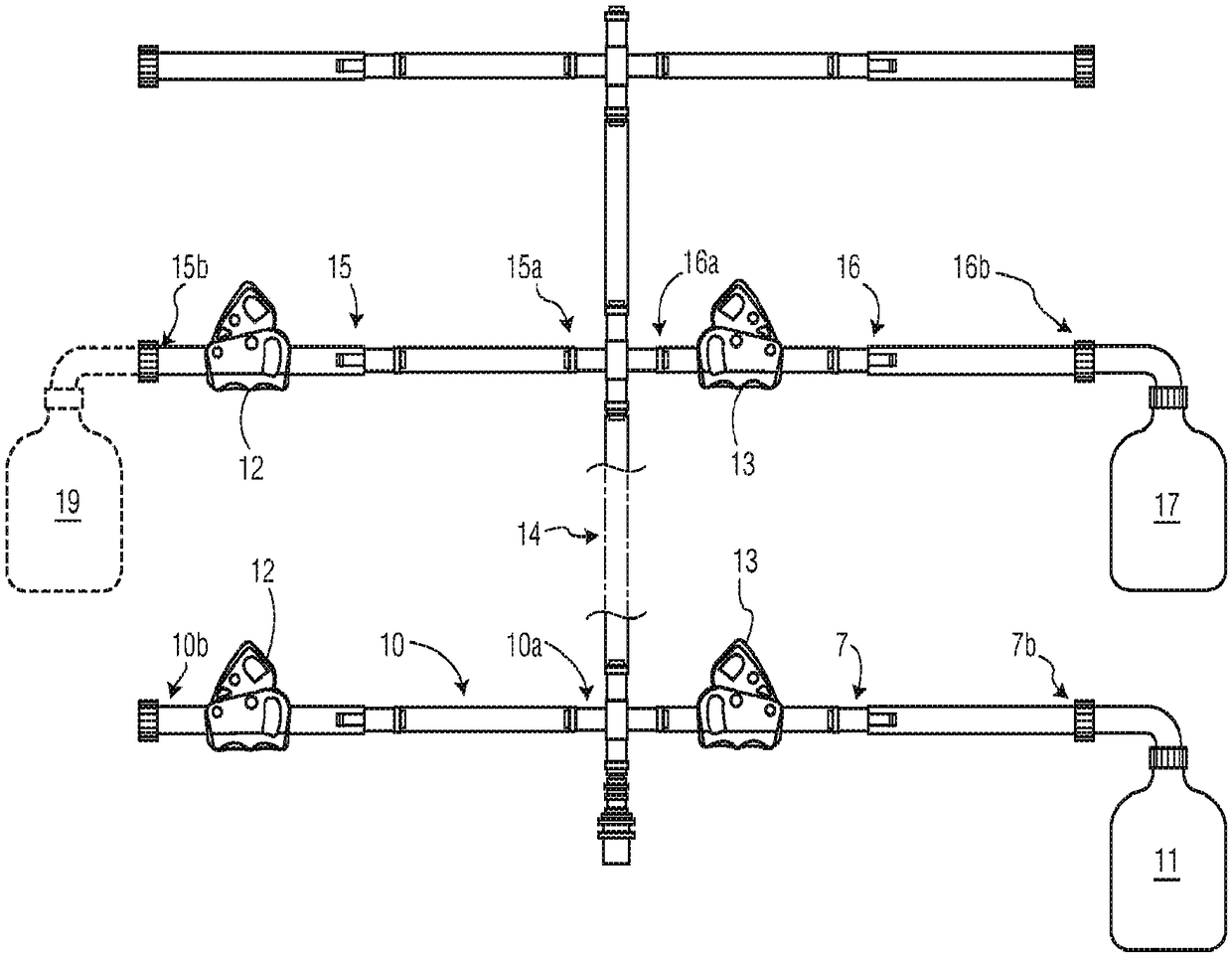

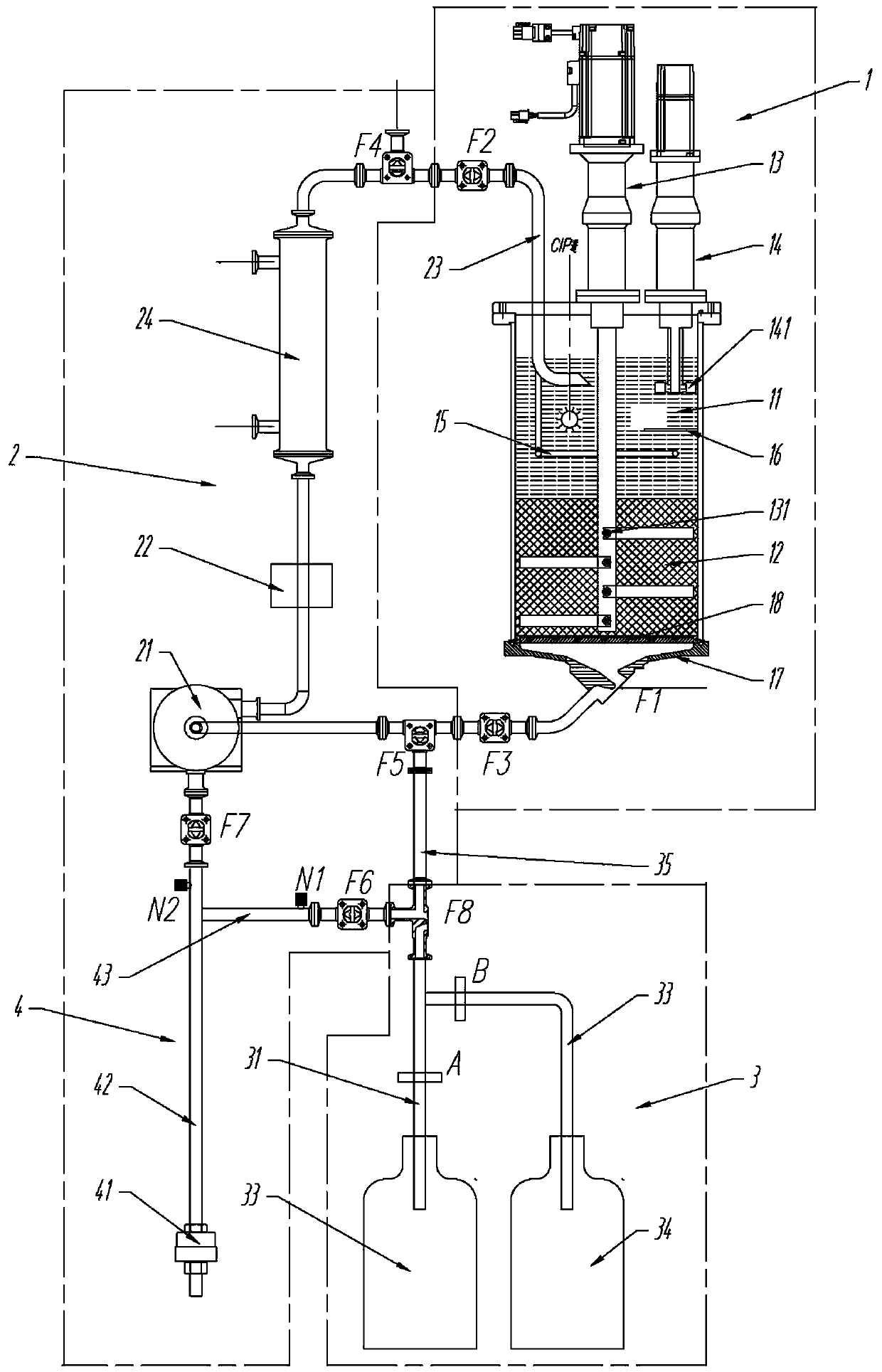

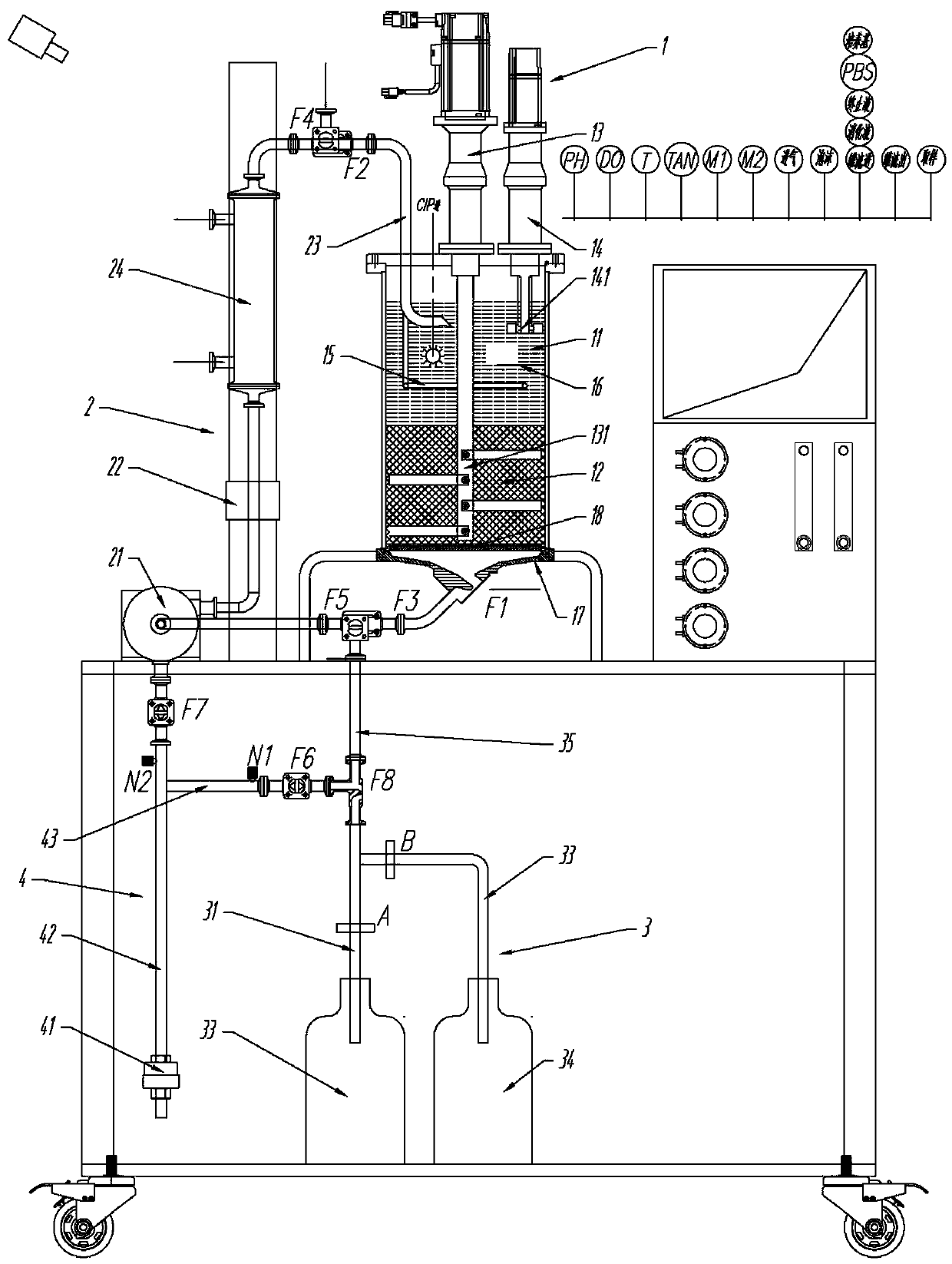

Fixed-bed bioreactor system for large-scale production of mesenchymal stem cells

PendingCN110551631AImprove the quality of trainingReduce manufacturing costBioreactor/fermenter combinationsBiological substance pretreatmentsMesenchymal stem cellEngineering

The invention discloses a fixed-bed bioreactor system for large-scale production of mesenchymal stem cells. The system comprises a bioreactor (1), an outer circulation mechanism (2) and a collecting mechanism (3), wherein the bioreactor (1) is used for amplifying the mesenchymal stem cells; the outer circulation mechanism (2) is used for receiving a culture medium discharged from the bottom of thebioreactor (1) and conveying the culture medium to a culture medium mixing tank (11) at the upper part of the bioreactor (1) to realize circulation of the culture medium and is internally provided with a flow meter (22) to monitor a flow velocity of the culture medium and regulate substance exchange of the culture medium according to the flow velocity; and the collecting mechanism (3) can collectthe mesenchymal stem cells cultured by the bioreactor (1) and waste liquid produced during culture of the mesenchymal stem cells. For the fixed-bed bioreactor system provided by the invention, through external circulation of the culture medium, the flow velocity of the culture medium passing through a fixed bed can be accurately controlled, so that large-scale culture of the mesenchymal stem cells is realized.

Owner:南京比瑞生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com