Microfluidic channel carrier structure for large-scale culture of stem cells and immune cells

A technology for large-scale culture and immune cells, applied in the field of microfluidic carrier structure, can solve the problems of difficulty in improving the quality of stem cell culture, low quality, and affecting the growth of adherent cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

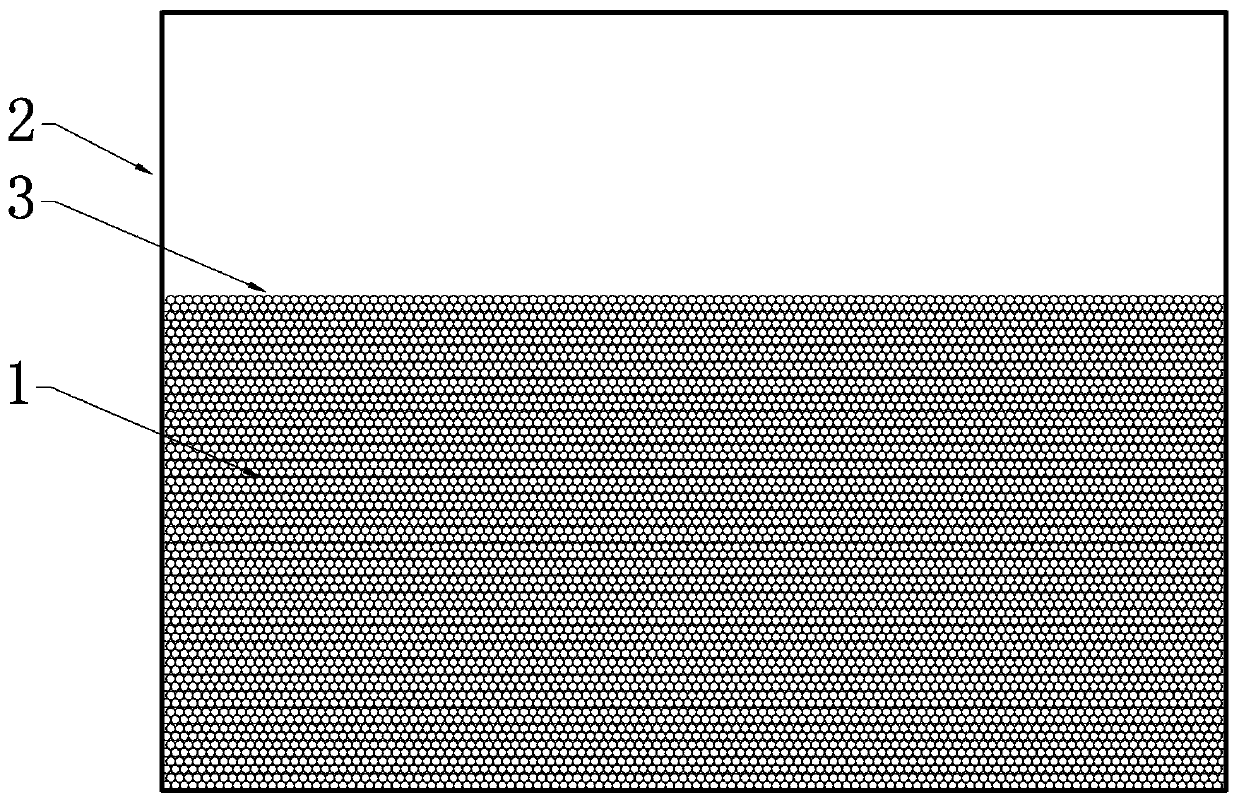

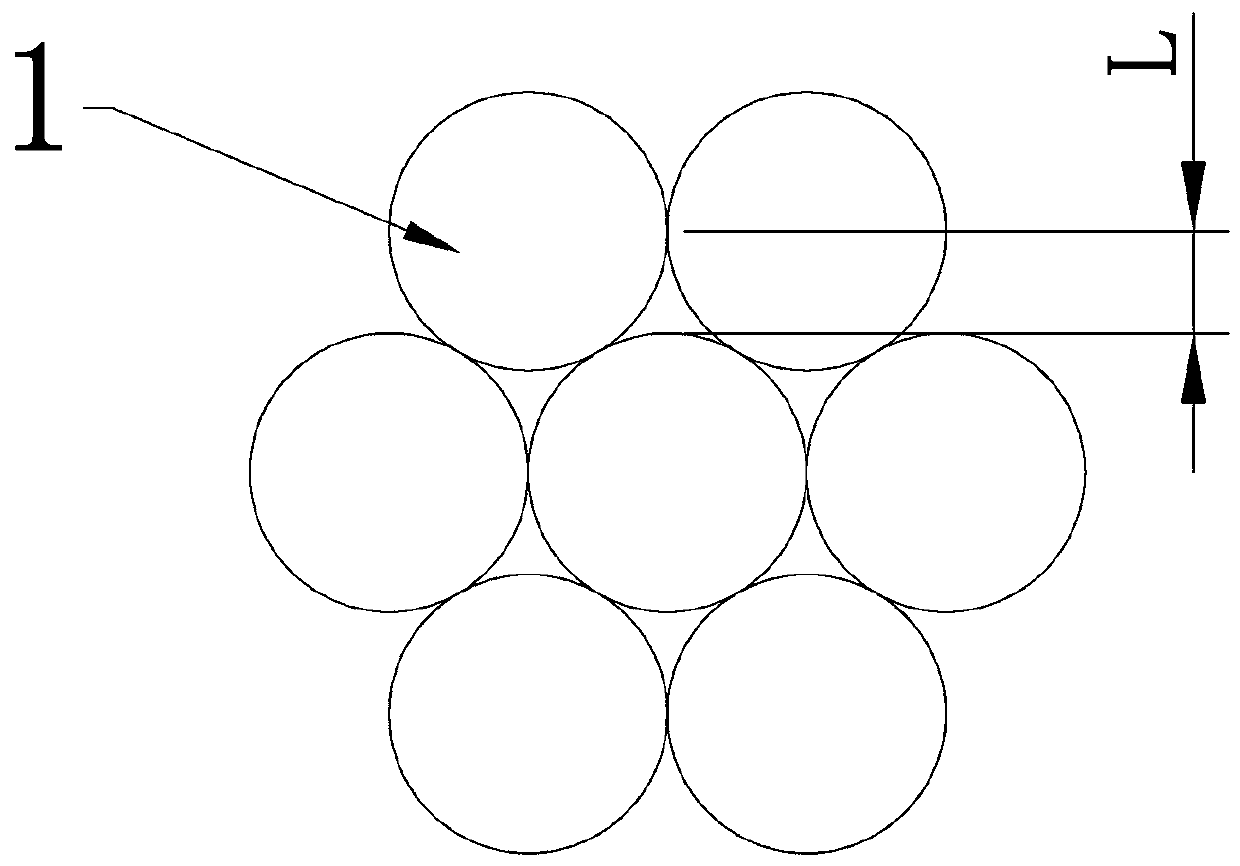

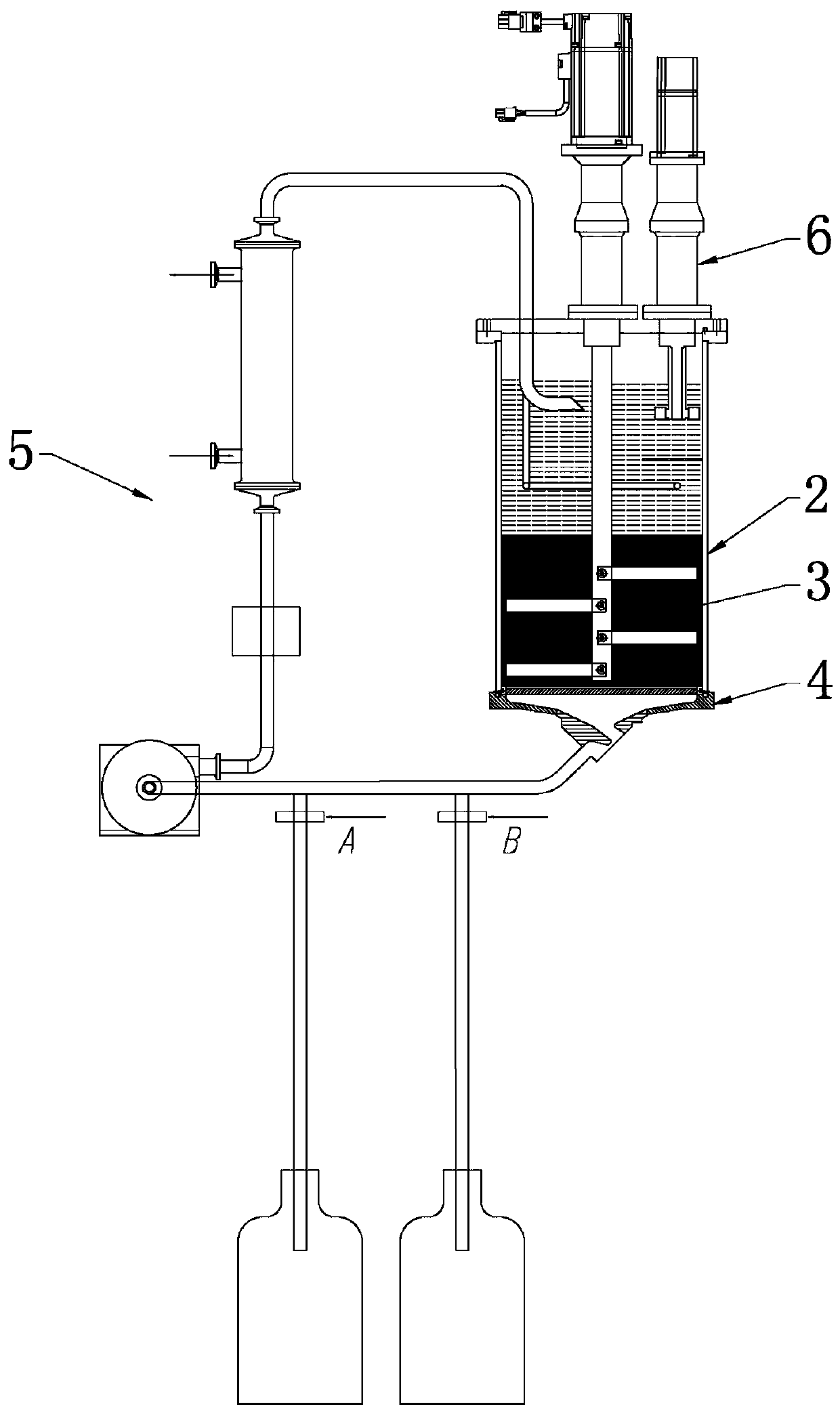

[0019] Such as Figure 1-2 Shown: a microfluidic carrier structure for large-scale culture of stem cells and immune cells, the microfluidic carrier structure includes a plurality of microspheres 1, the diameter of the microspheres 1 is 0.5 mm to 2.7 mm, and the microspheres 1 are stacked A micro-channel carrier structure is formed in the fixed-bed bioreactor 2, and the maximum linear space dimension L between adjacent microspheres 1 in the micro-channel carrier structure is 0.183 mm to 0.988 mm.

[0020] The microspheres 1 are ceramic balls, glass balls or balls made of polymer materials.

[0021] In order to obtain better performance, microspheres 1 with the same particle size are selected in the same microfluidic carrier structure.

[0022] For the existing fixed-bed bioreactor 2 with an inner cavity diameter of 20 mm to 1000 mm, the thickness of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com