Shell-and-tube fixed bioreactor

A technology of bioreactor and fixed bed, which is applied in the direction of specific-purpose bioreactor/fermenter, bioreactor/fermenter combination, method of supporting/immobilizing microorganisms, etc., which can solve the problems of lack of production equipment, reduced catalytic efficiency, Reaction equipment is difficult to disassemble and other problems, to achieve the effect of improving production rate and resource utilization, reasonable and simple structure, and easy to realize

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

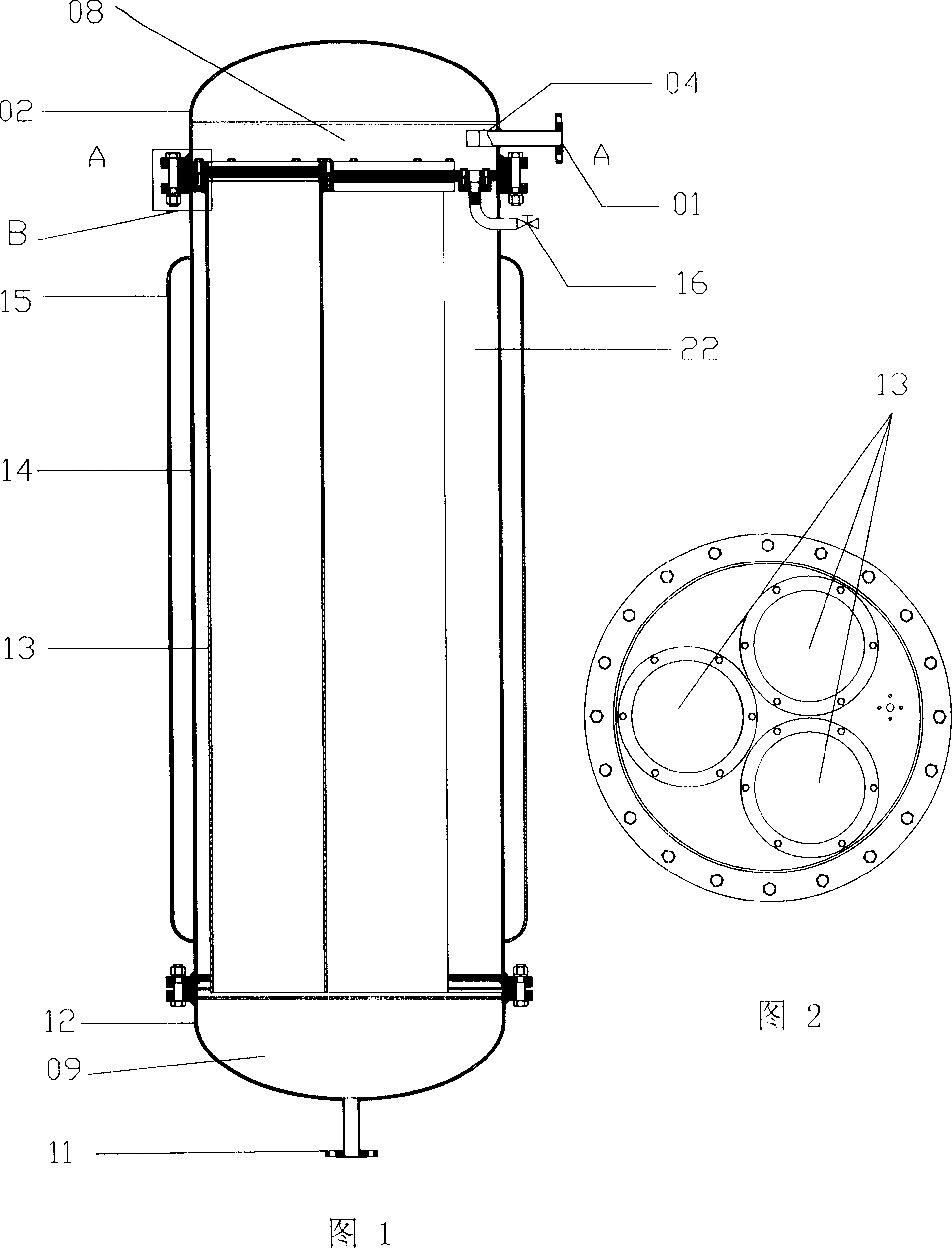

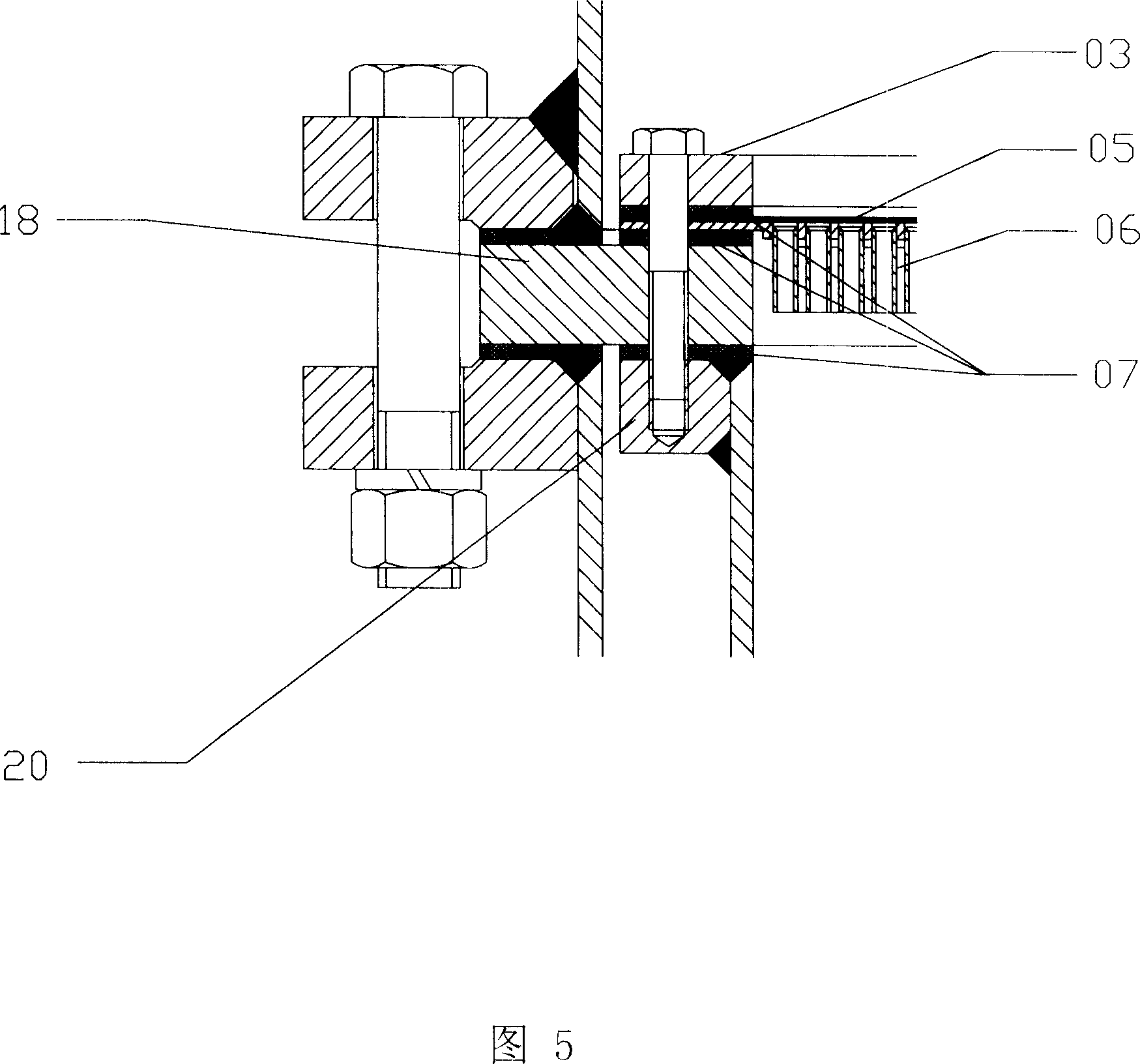

[0029] This example illustrates a preferred embodiment of the invention. Referring to Fig. 1, in this embodiment, the height of the vertical tubular fixed-bed bioreactor is about 2.5m, and the outer diameter is about 0.8m. The shell of the entire tubular fixed-bed bioreactor is mainly composed of three parts, They are the upper head body 02 , the reaction chamber 22 , the lower head body 12 , and a jacket 15 for heat transfer outside the jacket 14 . The upper head body 02, the reaction chamber 22 and the lower head body 12 have skirts so that they can be fixed with bolts and nuts between the upper head body 02 and the reaction chamber 22, and between the reaction chamber 22 and the lower head body 12. In this embodiment, the liquid inlet 01 is located on the side of the upper head body 02 , at a height of about 50 cm from the bottom of the upper head body 02 , and is connected to the liquid inlet pipe 04 . The liquid inlet pipe 04 is a straight pipe arranged in a horizontal d...

Embodiment 2

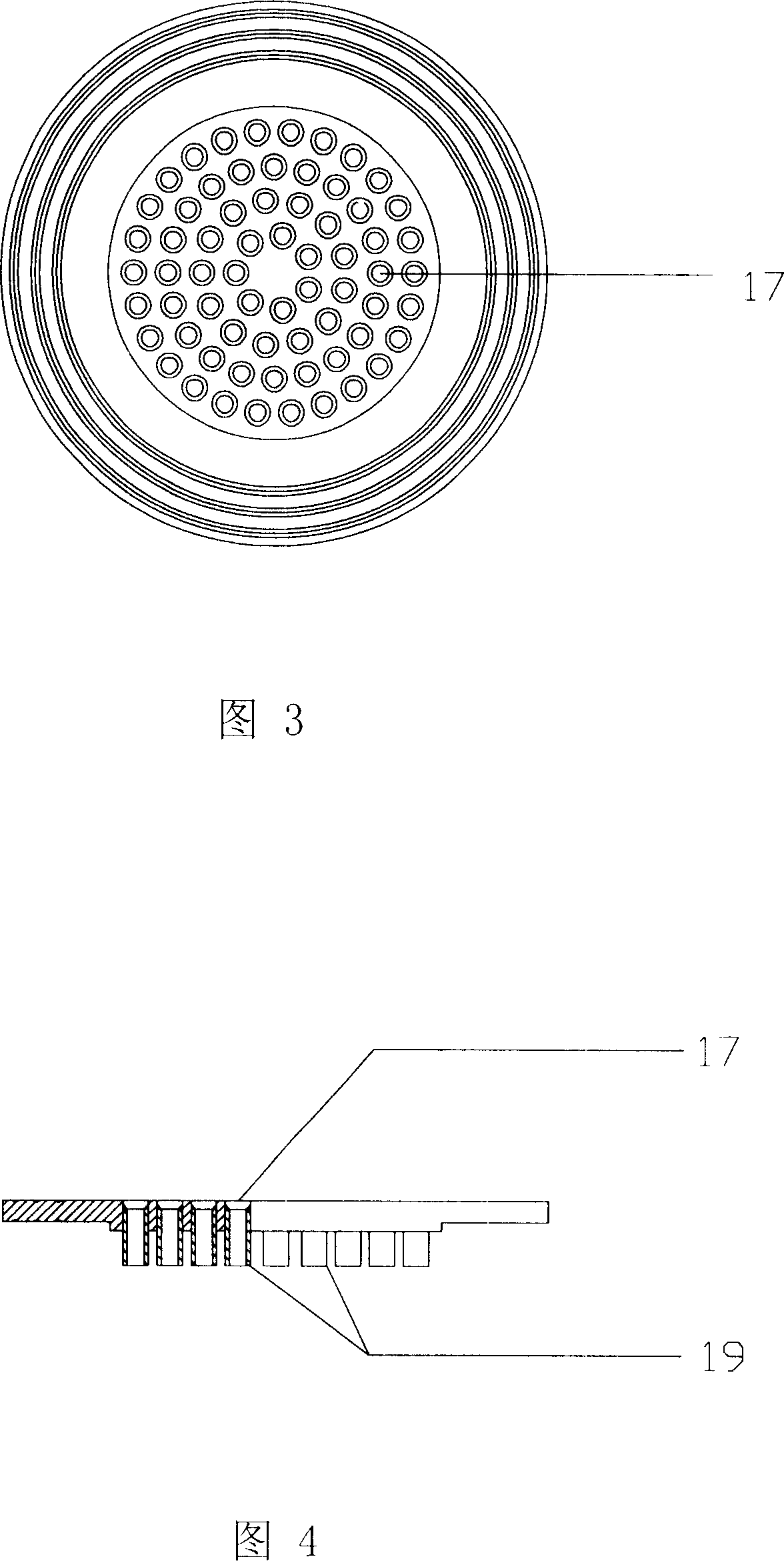

[0037]This example illustrates another embodiment of the invention and is used as an esterification reactor. The height of the tubular fixed bed bioreactor in this embodiment is about 1.8m, and the outer diameter is about 1.5m. Fix it mechanically. A liquid inlet is arranged on the top of the upper head body, and the liquid inlet communicates with the liquid inlet pipe, which is curved and extends to the bottom of the feed chamber.

[0038] There are 92 packing tubes in the reaction chamber, the outer diameter of each packing tube is 80mm, and the length is 0.7m. The upper end of the packing tube is also provided with a distributor, and there is a threaded flange near the upper part of the packing tube, and the shape and size of the distributor match the threaded flange. 68 through-holes and liquid distribution pipes are evenly distributed in the middle of each distributor. The diameter of the through-holes is 4mm, the length of the liquid distribution pipes is 10mm, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com