Carrier fixed bed bioreactor and water treatment system

A technology of bioreactor and fixed bed, which is applied in the field of water treatment, can solve the problems of high concentration of suspended solids in effluent, high cost, high stirring and aeration intensity, etc., and achieve the effect of small water head loss and reduced filler cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

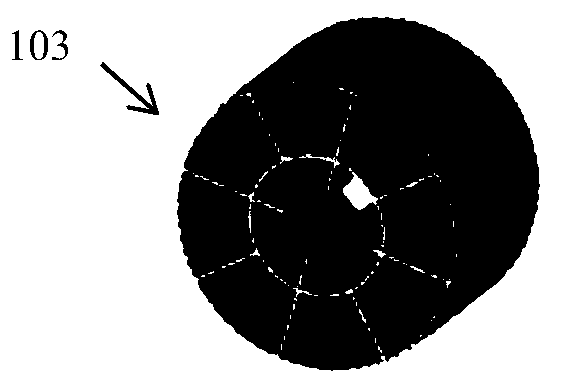

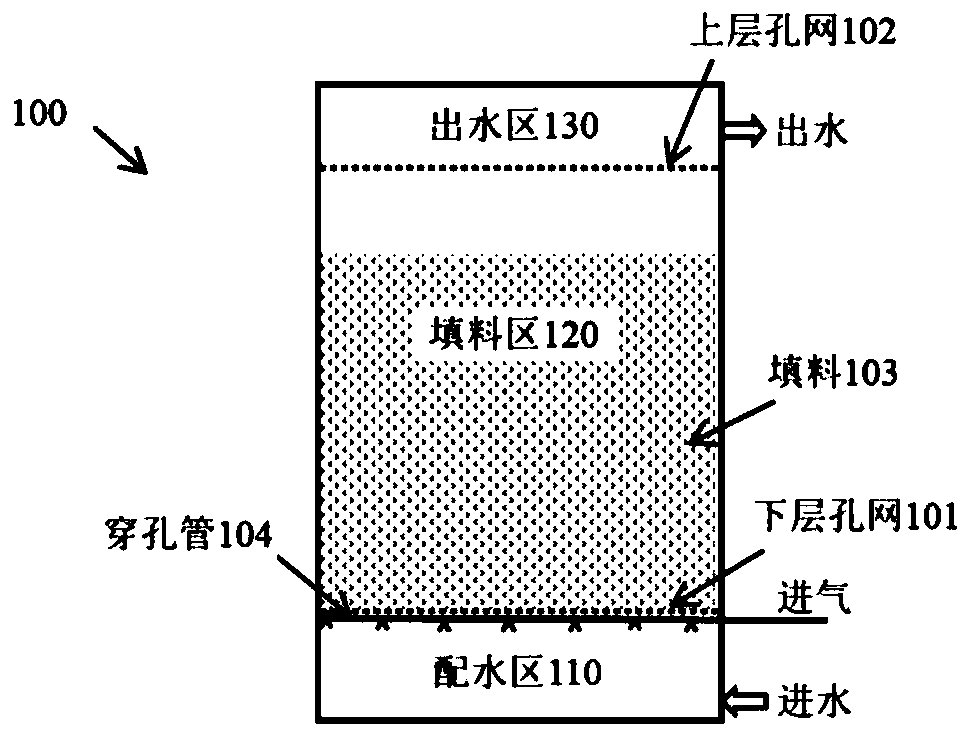

[0040] Figure 2a It is a schematic diagram of the carrier fixed bed bioreactor 100 in a static sedimentation state according to the first embodiment of the present invention. Figure 2b It is a schematic diagram of the carrier fixed bed bioreactor 100 in working and backwashing state according to the first embodiment of the present invention. The carrier fixed-bed bioreactor 100 according to the first embodiment of the present invention includes: a pool body, which can be a circular or square cross-section; a lower hole network 101 arranged at the lower part of the pool body, configured as a support packing 103, the lower layer Hole net 101 is provided with a plurality of lower openings that run through the thickness of lower net 101, and the size of the lower openings is designed to be smaller than the size of filler 103; A plurality of upper apertures running through the thickness of the upper aperture 101 are opened in the aperture 102, and the size of the upper aperture ...

no. 2 example

[0059] Figure 3a It is a schematic diagram of the carrier fixed bed bioreactor 100 in a static sedimentation state according to the second embodiment of the present invention. Figure 3b It is a schematic diagram of the working and backwashing state of the carrier fixed bed bioreactor 100 according to the second embodiment of the present invention. The difference between the carrier fixed bed bioreactor 100 according to the second embodiment and the carrier fixed bed bioreactor 100 according to the first embodiment is that aeration perforations are added inside the packing area 120 of the carrier fixed bed bioreactor 100 The tube 105, the perforated tube is provided with holes opening upwards and is configured to selectively vent air. Air is introduced into the upper part of the packing area through the aeration perforated pipe, so as to realize the pre-denitrification of the lower part of the packing area and the nitrification of the upper part of the packing area at the sa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com