Epoxy chloropropane wastewater treatment method

A technology of epichlorohydrin and a treatment method, which is applied in the field of wastewater treatment, can solve the problem of high comprehensive treatment cost, and achieve the effects of low cost, high treatment efficiency and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

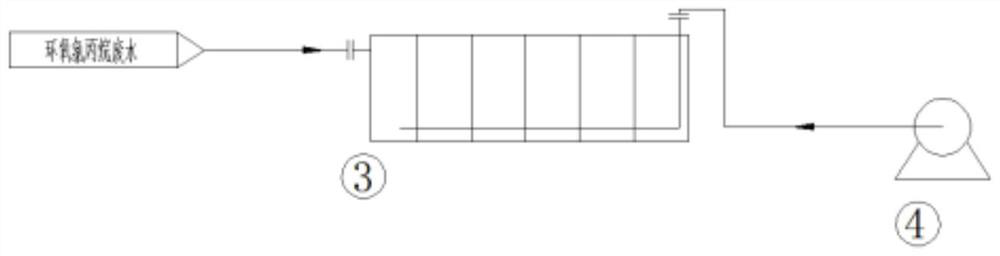

[0068] see figure 1 , the concentration of epichlorohydrin wastewater is 1500mg / L, the water temperature is 45°C, the pH value is 6.8, and the wastewater flow rate is 2.5m 3 / h, the salt content of wastewater is 2%.

[0069] Directly adopt the biochemical system of the present invention to carry out wastewater treatment, first dilute the COD concentration of the wastewater to 500mg / L, cultivate for 7 days, then raise the COD concentration to 1500mg / L, pass it into the honeycomb fixed bed bioreactor 3, biochemical pool The bottom is connected to Roots blower 4 for aeration, the biochemical residence time is 18h, and the COD of water and wastewater is 89mg / L after detection.

Embodiment 2

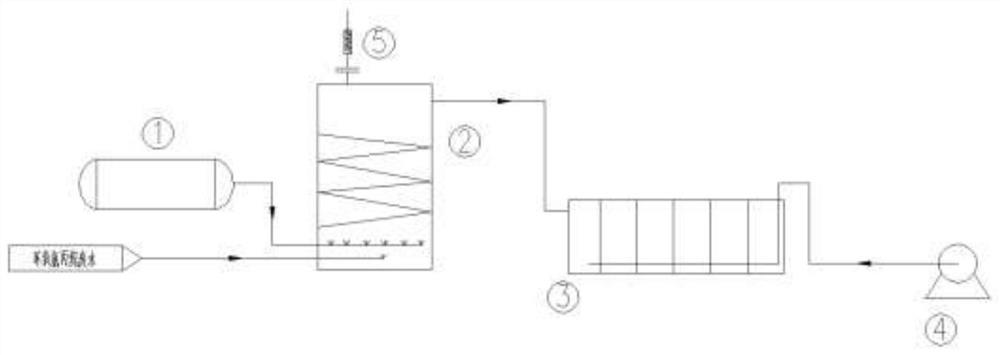

[0071] The COD concentration of epichlorohydrin wastewater is 6500mg / L, the water temperature is 30°C, the pH value is 7.0, and the wastewater flow rate is 1m 3 / h, the salt content of wastewater is 1.8%.

[0072] First use ozone to carry out catalytic oxidation of wastewater, the amount of ozone in the ozone generator 1 is 1-3.2kg / h, and the ozone concentration is 100mg / m 3 , ozone is passed into the catalytic oxidation tower 2 to catalyze the oxidation of wastewater, and the top of the catalytic oxidation tower 2 is provided with an ozone digester 5. After testing, the COD concentration of the wastewater at the outlet of the catalytic oxidation tower is 3200mg / L.

[0073] The COD concentration of the wastewater at the outlet of the catalytic oxidation tower is first diluted to 500 mg / L, and then enters the honeycomb fixed-bed bioreactor 3 for cultivation for 7 days, and the bottom of the biochemical pool is connected to the Roots blower 4 for aeration. Then adjust the conce...

Embodiment 3

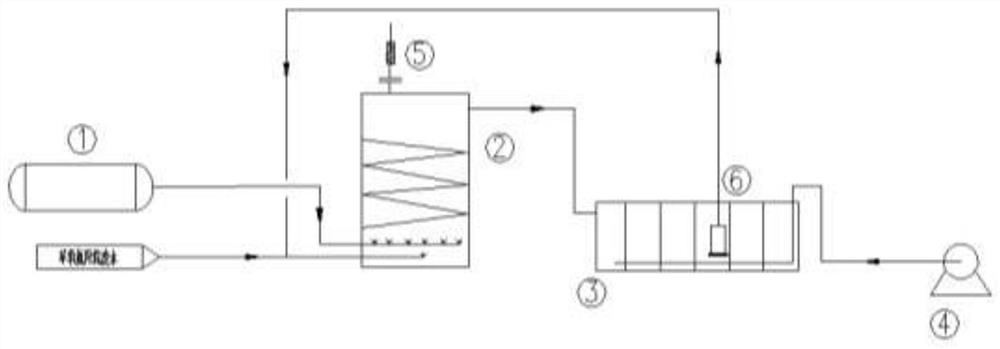

[0075] The COD concentration of epichlorohydrin wastewater is 15000mg / L, the water temperature is 25°C, the pH value is 7.6, and the wastewater flow rate is 2m 3 / h, the salt content of wastewater is 1.8%.

[0076] First, ozone is used to catalyze the oxidation of wastewater. The amount of ozone used in the ozone generator 1 is 9.0kg / h, and the ozone concentration is 120mg / m 3 , ozone passes into the catalytic oxidation tower 2 to catalyze the oxidation of waste water, and the top of the catalytic oxidation tower 2 is provided with an ozone digester 5, and the COD outlet concentration is 8750 mg / L after testing.

[0077] The size of the biochemical reaction pool is 10.0(L)*1.0(W)*2.2m(H). There are 8 cells in total, and the 8 biochemical pools are connected in sequence. Each biochemical pool unit forms different types of biological flora.

[0078] The COD concentration of the wastewater at the outlet of the ozone catalytic reactor is first diluted to 1000mg / L and entered int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com