Dynamic tangential flow tubular reactor

A tubular reactor, tangential flow technology, applied in chemical/physical/physical chemical fixed reactors, chemical instruments and methods, chemical/physical/physical chemical processes, etc., can solve the problem of easy adhesion of materials and waste of materials , failure downtime and other issues, to achieve the effect of avoiding failure downtime, high heat exchange efficiency, and enhancing the overall strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

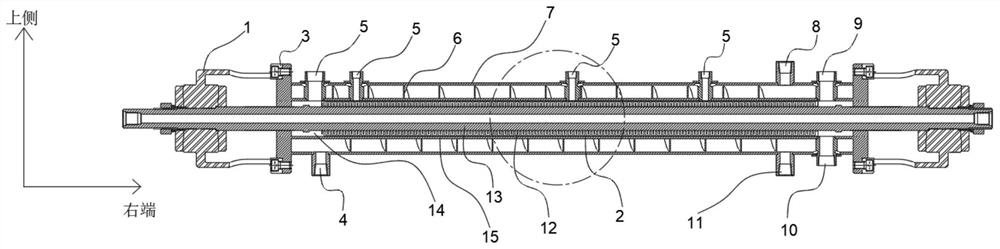

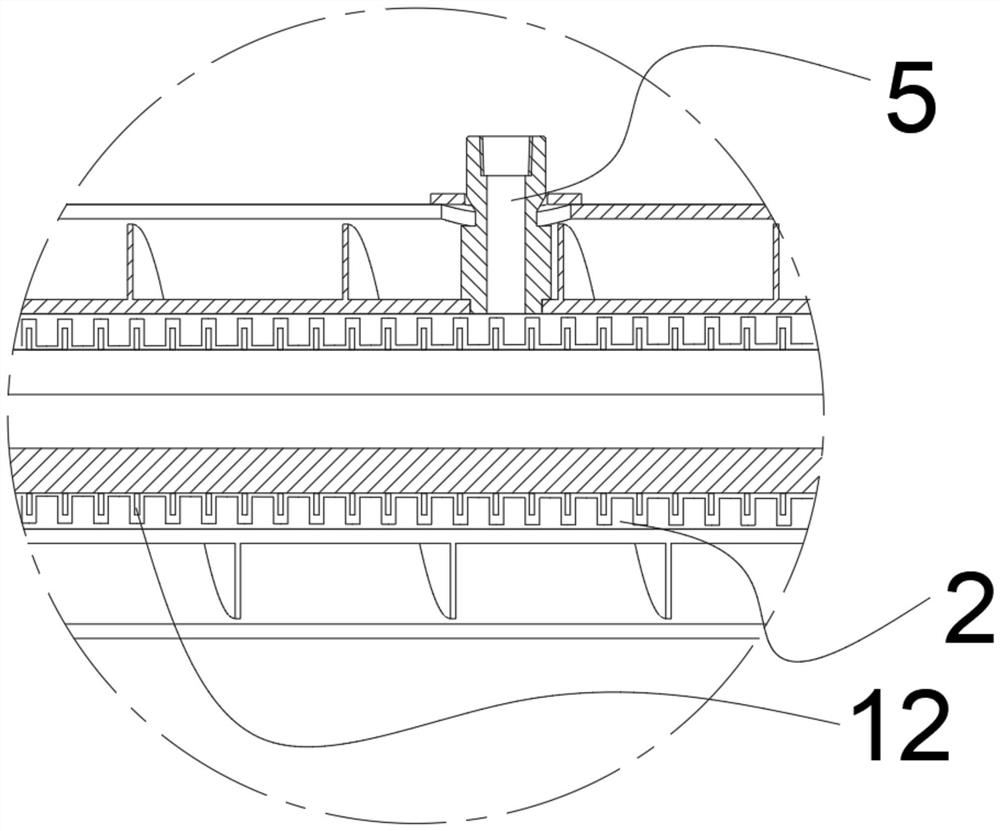

[0027] Such as Figure 1-3 As shown, a dynamic tangential flow tube reactor includes a reactor housing 15, a rotating shaft arranged in the reactor housing 15, a rotating fixture for connecting the rotating shaft and the reactor housing 15, and a device The inlet and outlet assembly on the outer wall of the reactor housing 15; the outer wall of the rotating shaft is vertically provided with a number of stirring columns 12; the inner wall of the reactor housing 15 and the outer wall of the rotating shaft are formed The reaction chamber 14; the reactor also includes a scraper assembly 2 arranged on the inner wall of the reactor housing 15; the reactor also includes a heat exchange assembly for heat exchange of materials in the reaction chamber 14; as figure 1 and 2 As shown, the outer wall of the reactor shell 15 is provided with several reinforcing ribs 6 .

[0028]In this embodiment, the rotating fixing device includes a sealing cover 3 and a rotating power assembly 1 sleeve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com