Patents

Literature

39results about How to "Big reaction force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

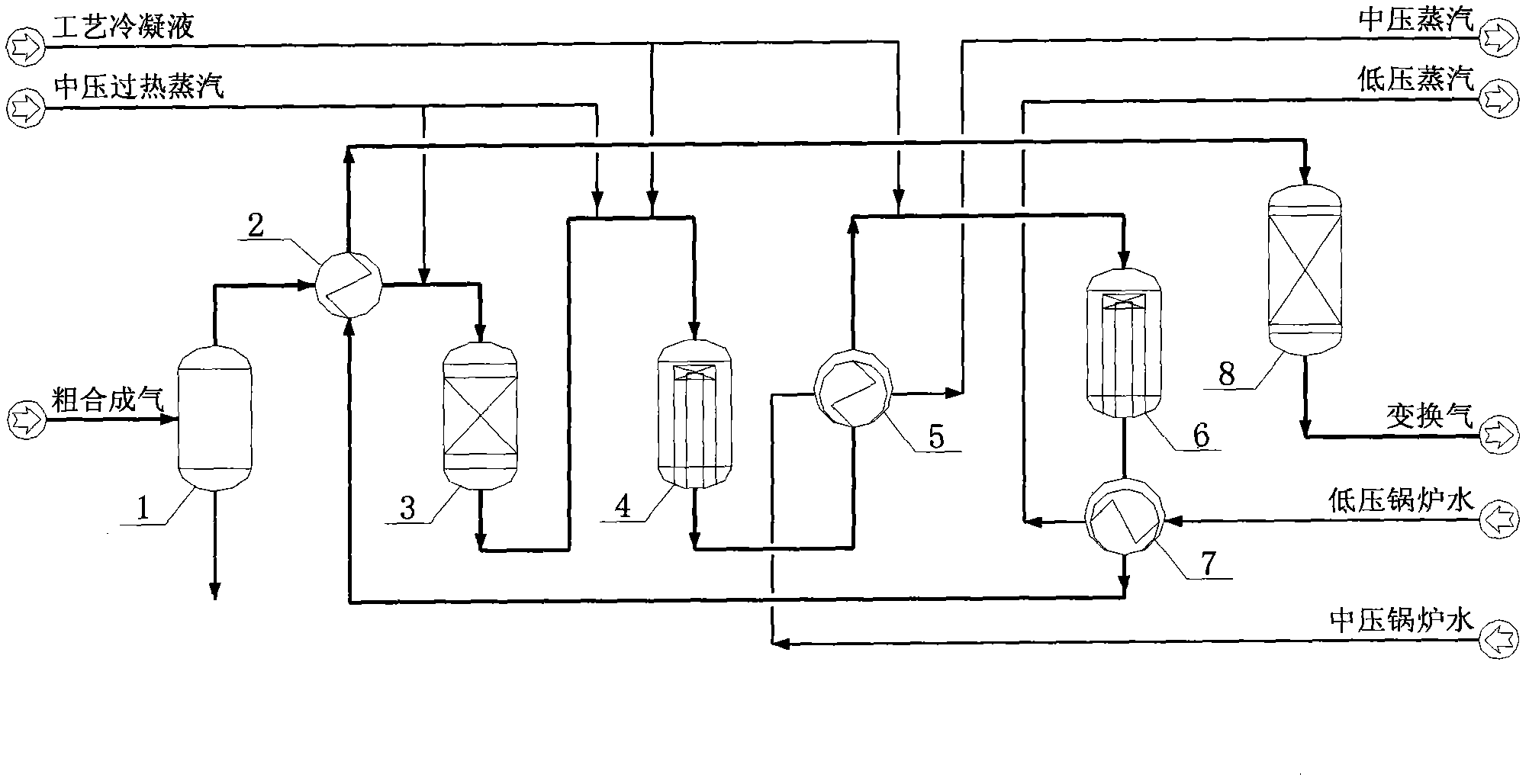

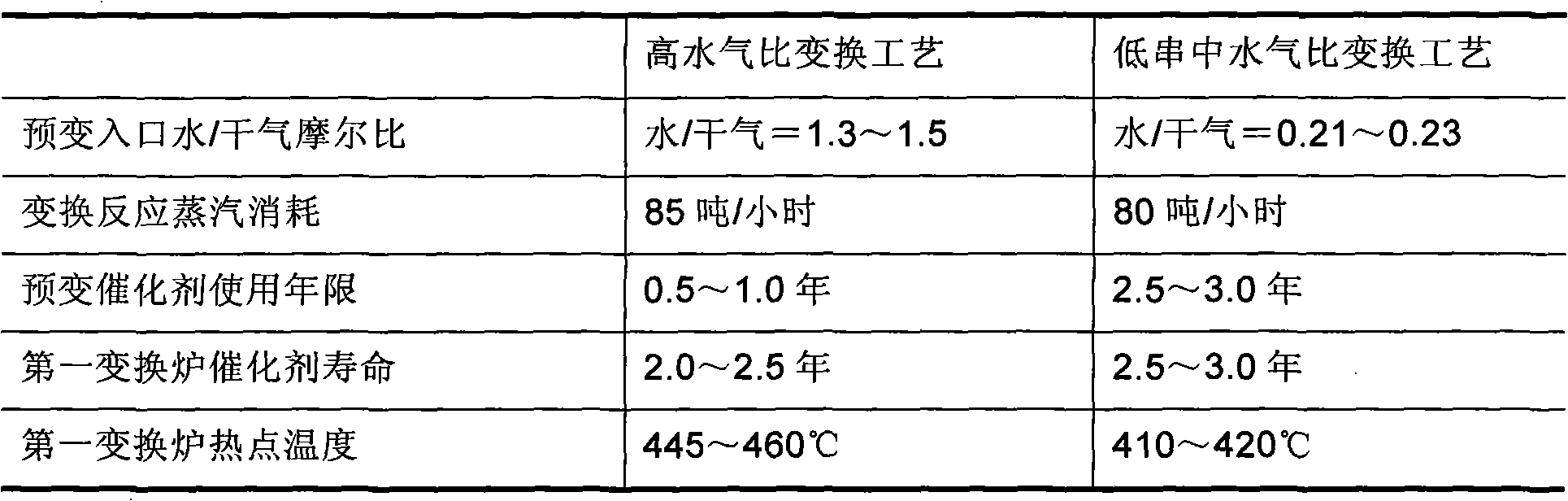

Low water-air ratio and middle water-air ratio carbon monoxide (CO) conversion process

ActiveCN102002403AReduce dosageReduce energy consumptionCombustible gas catalytic treatmentMixed gasDepth conversion

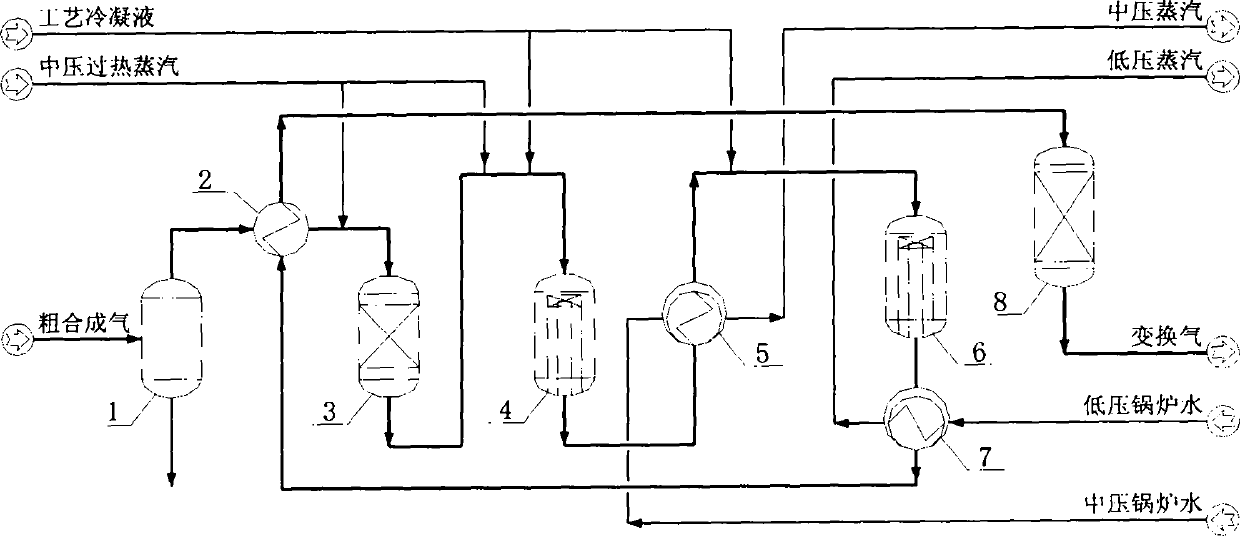

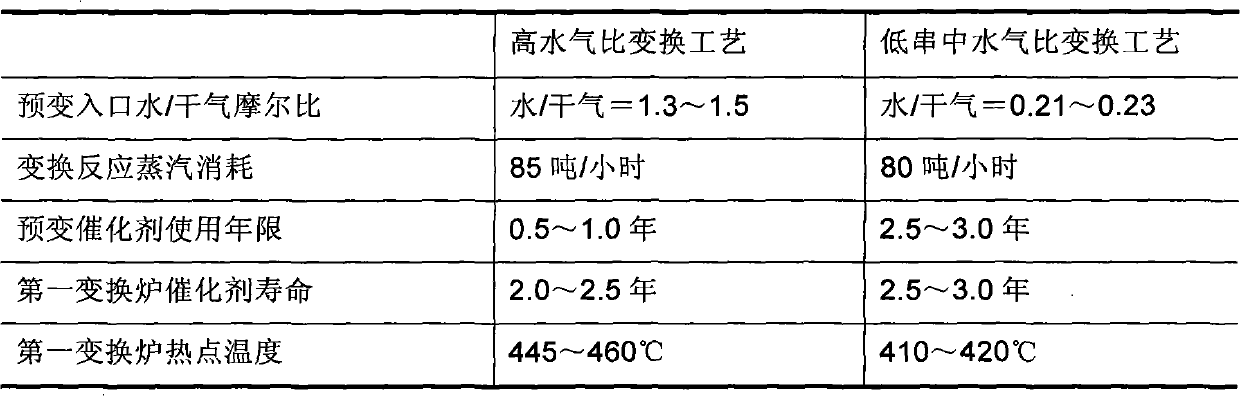

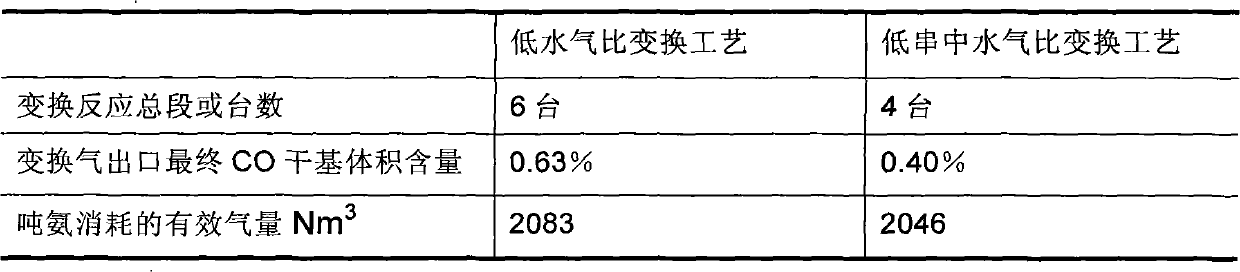

The invention relates to a low water-air ratio and middle water-air ratio carbon monoxide (CO) conversion process. The process comprises the following steps of: (1) feeding raw gas into a pre-converter, wherein the temperature of the raw gas entering the inlet of the pre-converter is between 210 and 250 DEG C and the mole ratio of water to dried gas is 0.21 to 0.23; (2) feeding pre-converted mixed gas into a first converter to perform depth conversion, wherein the temperature of the pre-converted mixed gas entering the inlet of the first converter is between 260 and 290 DEG C and the mole ratio of water to dried gas is 0.8 to 1.0; (3) feeding the mixed gas passing through the first converter into a second converter, wherein the temperature of the mixed gas entering the inlet of the secondconverter is between 220 and 250 DEG C and the mole ratio of water to dried gas is 0.5 to 0.7; (4) feeding the mixed gas passing through the second converter into a third converter, wherein the temperature of the secondary conversion mixed gas entering the inlet of the third converter is between 205and 235 DEG C; and performing conversion on the mixed gas by using the third converter to obtain the mixed gas with the CO content lower than 0.40 percent. The process is unique and has the characteristics of high CO conversion rate, low energy consumption in the conversion process and the like.

Owner:CHINA PETROLEUM & CHEM CORP +2

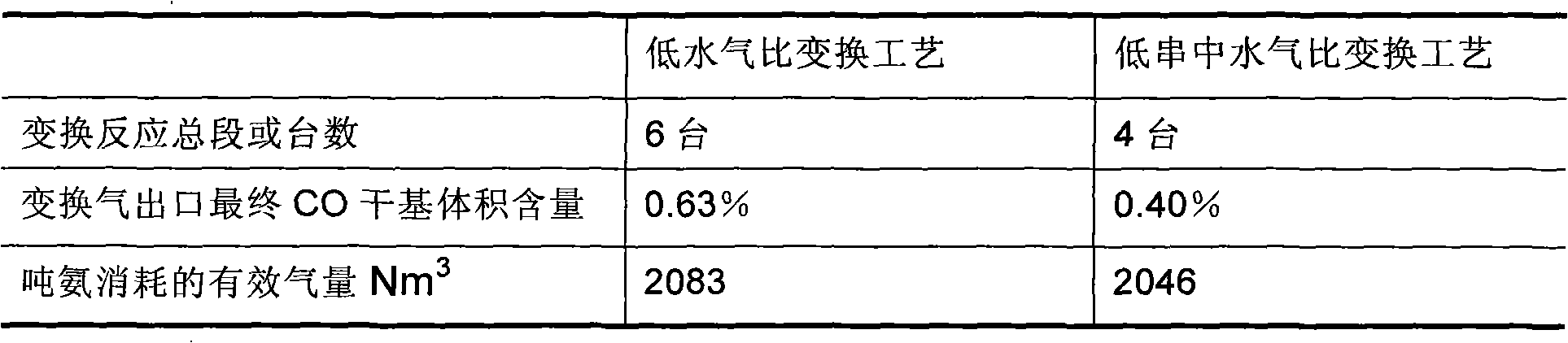

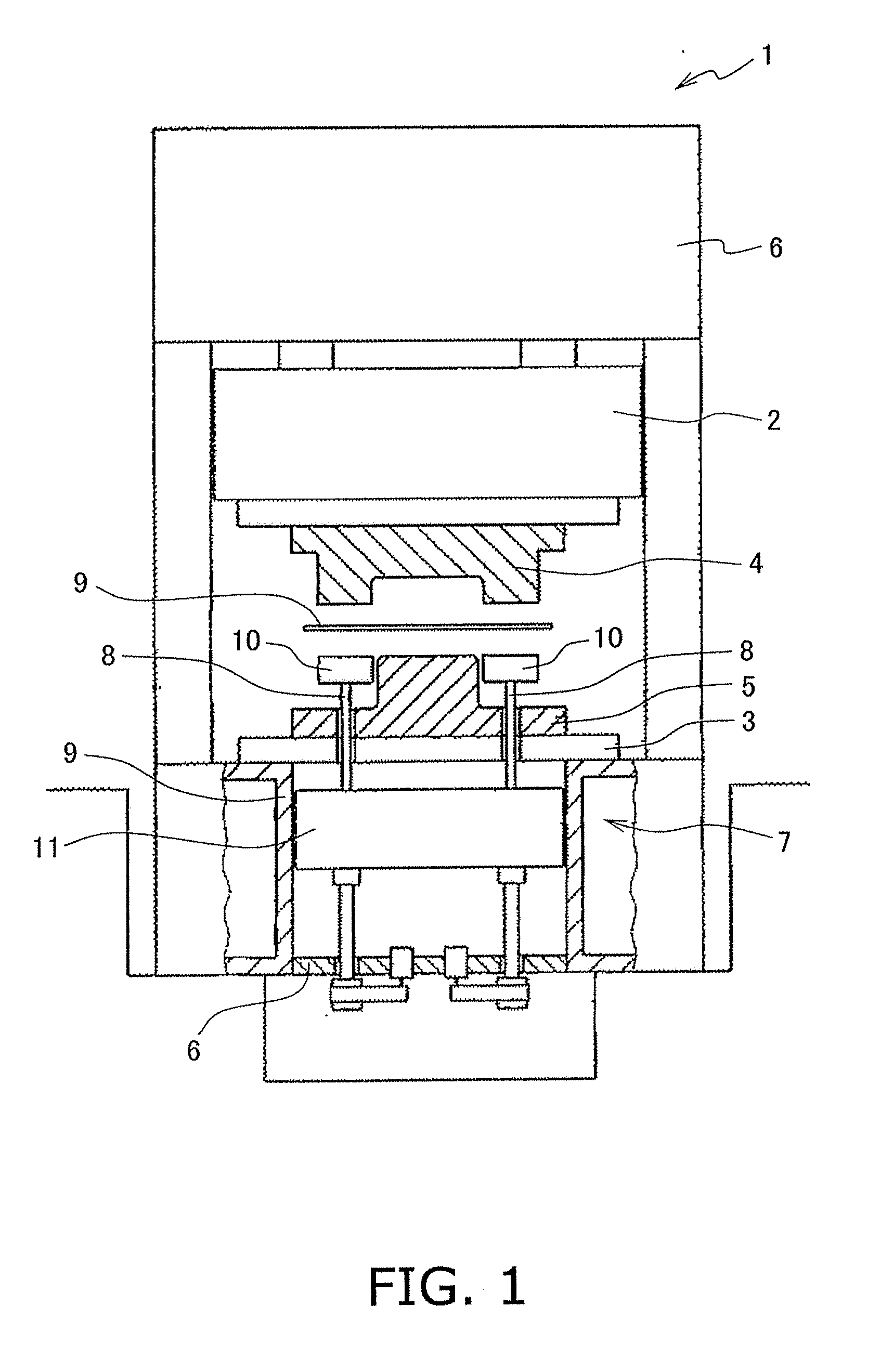

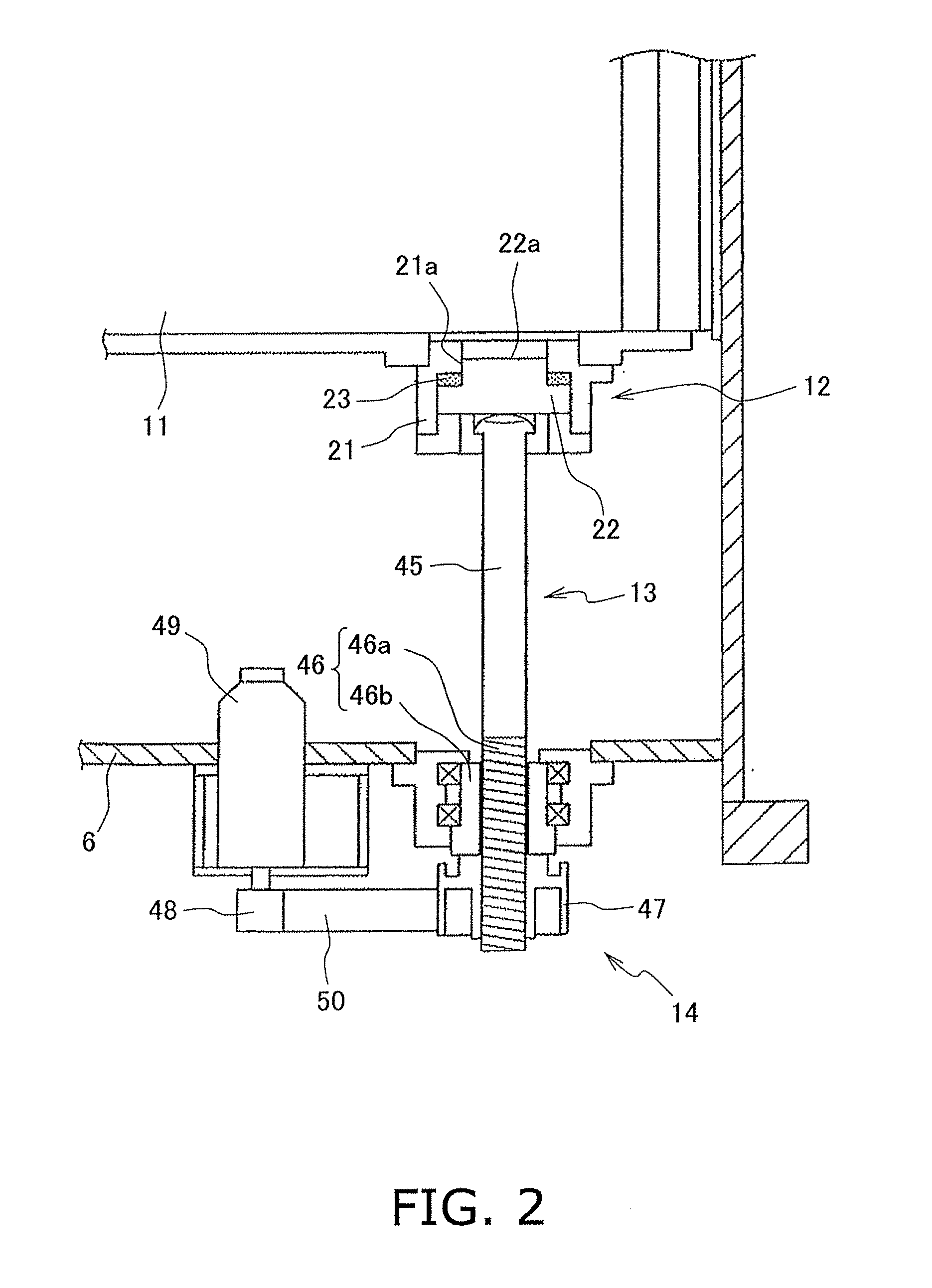

Die cushion device

ActiveUS20110045113A1Big reaction forceImprove loading timeLiquid springsAuxillary shaping apparatusRelative displacementTime changes

In the die cushion device, a shock absorber device relieves shock between a cushion pad and a support section. The shock absorber device includes a damping section and an elastic section. The damping section generates reaction force in accordance with the relative speed of the cushion pad with respect to the support section. The elastic section generates reaction force in accordance with the relative displacement of the cushion pad with respect to the support section. The controller section controls a servomotor so that a speed difference between the speed of the slide member and the speed of the support section is set to be a predetermined target speed difference value that changes over time.

Owner:KOMATSU LTD +1

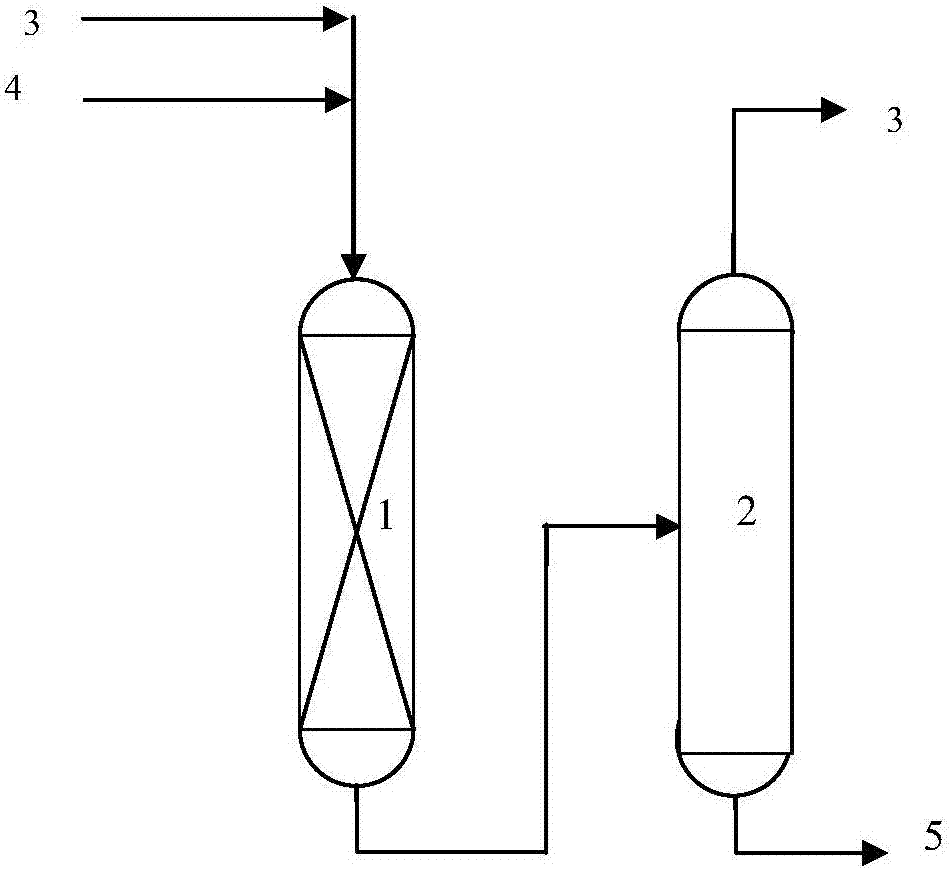

Technology for producing diisobutylene from C4 mixture

ActiveCN107473917ASimple structureReduce energy consumptionChemical industryDistillation purification/separationChemical synthesisFixed bed

The invention belongs to the technical field of chemical synthesis, and specifically relates to a technology for producing diisobutylene from a C4 mixture. The technology comprises: pumping a C4 mixture and tert-butyl alcohol by a metering pump to a static mixer for mixing, performing pre-heating, allowing the obtained product to enter a fixed bed reactor, performing a dimerization reaction of isobutene in the function of a resin catalyst in a gas-liquid mixed phase state, allowing a diisobutylene product generated from a reactor outlet to enter a rectifying tower for separation, and obtaining the C4 mixture from the tower top and the diisobutylene product from the column bottom. The technology is low in pressure, high in reaction selectivity, simple in reactor structure, saved in energy consumption of the reactor and rectifying tower, and reduced in investment.

Owner:CHINA PETROLEUM & CHEM CORP

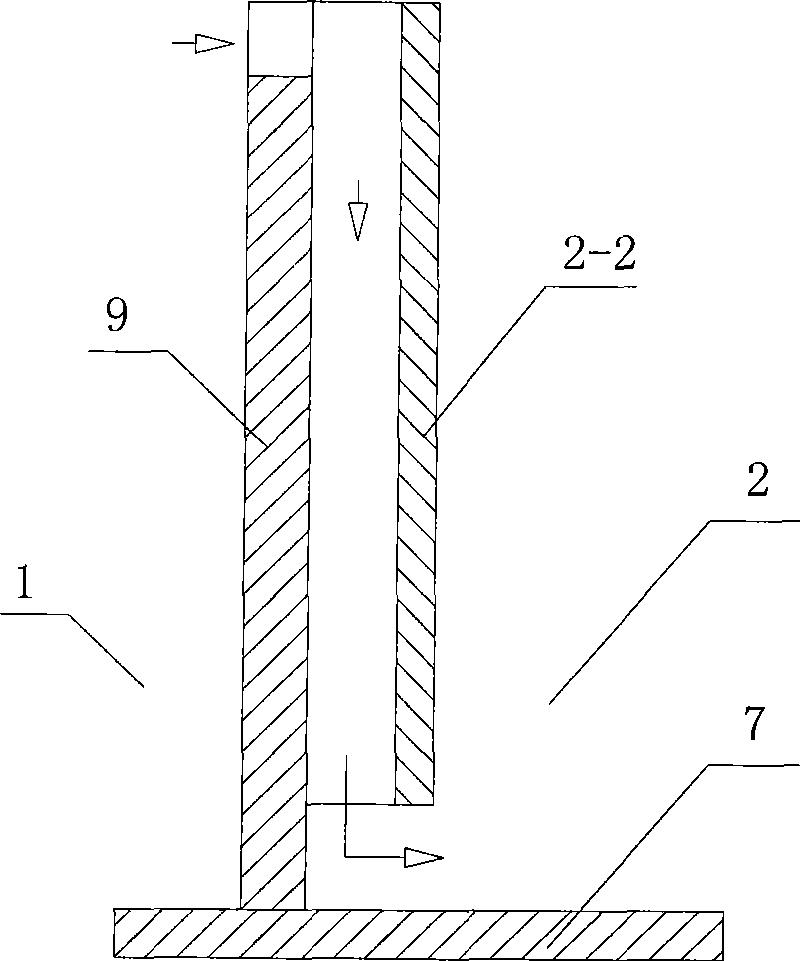

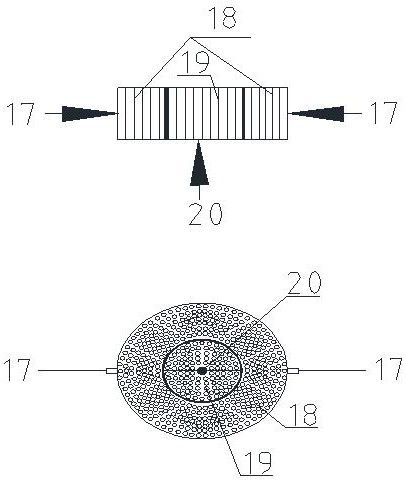

Process and device for continuous ultrasound desulfurization of scrapped lead paste

InactiveCN101518711AReduce the number of settingsSmall footprintDispersed particle separationIonSodium carbonate

The invention relates to a process and a device for continuous ultrasound desulfurization of scrapped lead paste. The process for continuous ultrasound desulfurization of scrapped lead paste comprises the following steps: (1) sodium carbonate or ammonium carbonate is selected as desulfurizing agent, and the desulfurizing agent and the scrapped lead paste are taken according to the mole ratio (1.2 to 2.2:1) of the Na iron or the (NH4)2 iron in the desulfurizing agent to the S iron in the scrapped lead paste; (2) the scrapped lead paste, the desulfurizing agent and water are prepared into flowing pulp with solid-liquid (S / L) weight ratio being equal to 3 / 5 to 4 / 5 in a pulping tank; (3) under the condition of ultrasonic wave, the flowing pulp enters a first reaction chamber for heating and stirring from the lower end part in the first reaction chamber, is discharged out from an overflow opening at the upper end of the first reaction chamber, then enters a second reaction chamber for heating and stirring from the lower end part of the second reaction chamber and finally, and is discharged out from a discharging opening at the upper end of an nth (ranging from 3 to 12) reaction chamber after sequent flow for reaction and discharge. The process has the advantages of low cost, small occupied area, continuous production and high efficiency.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

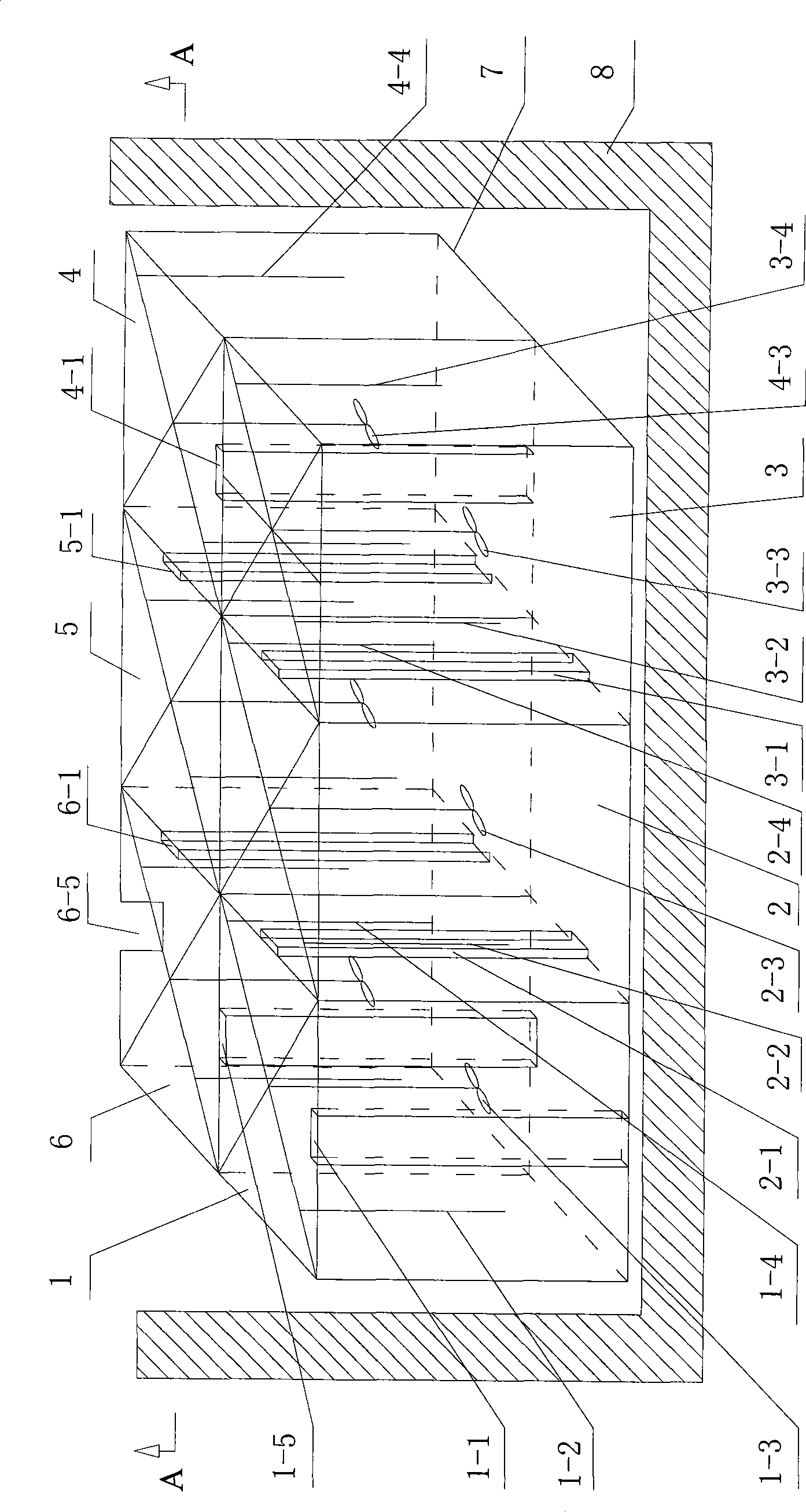

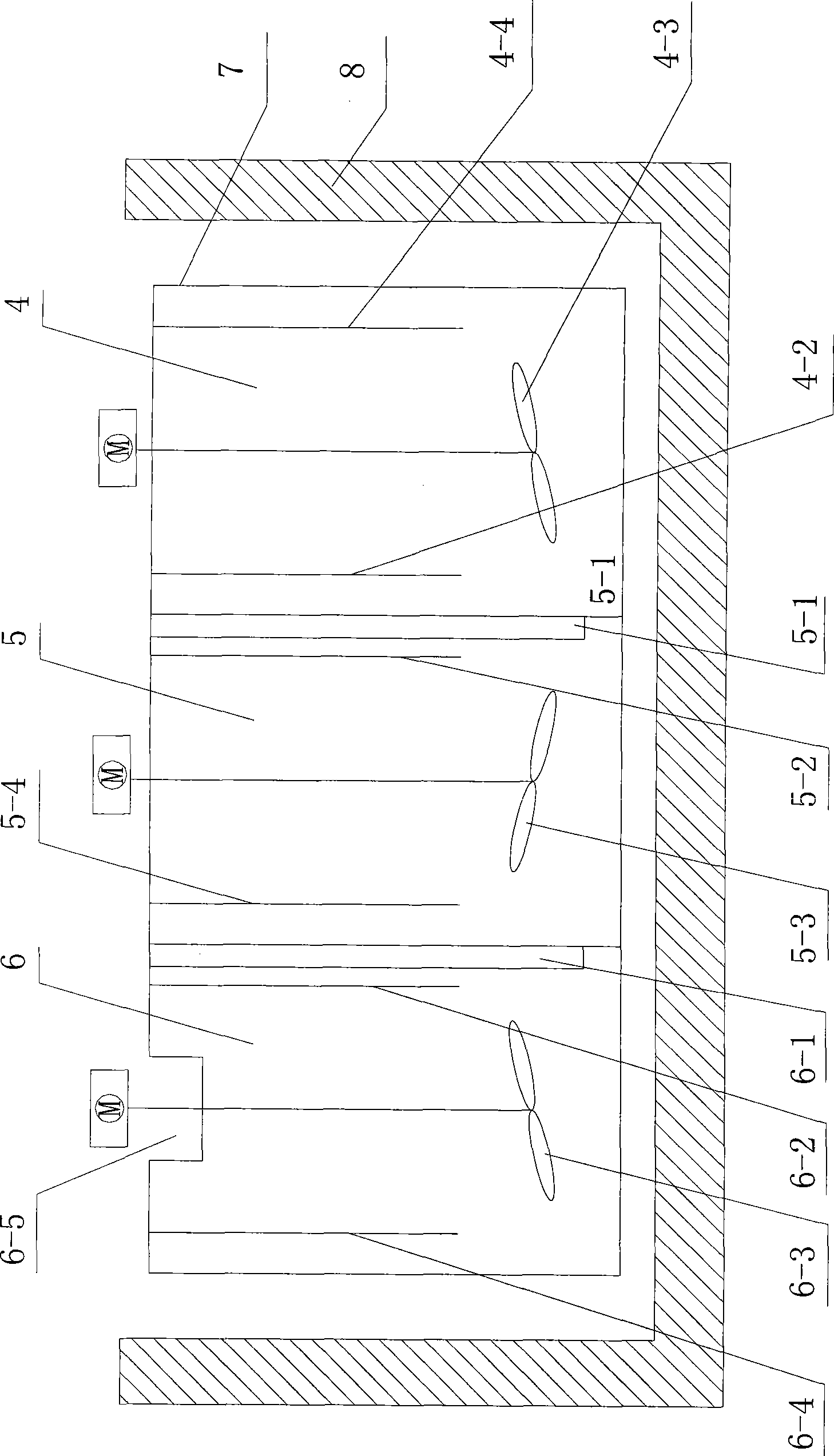

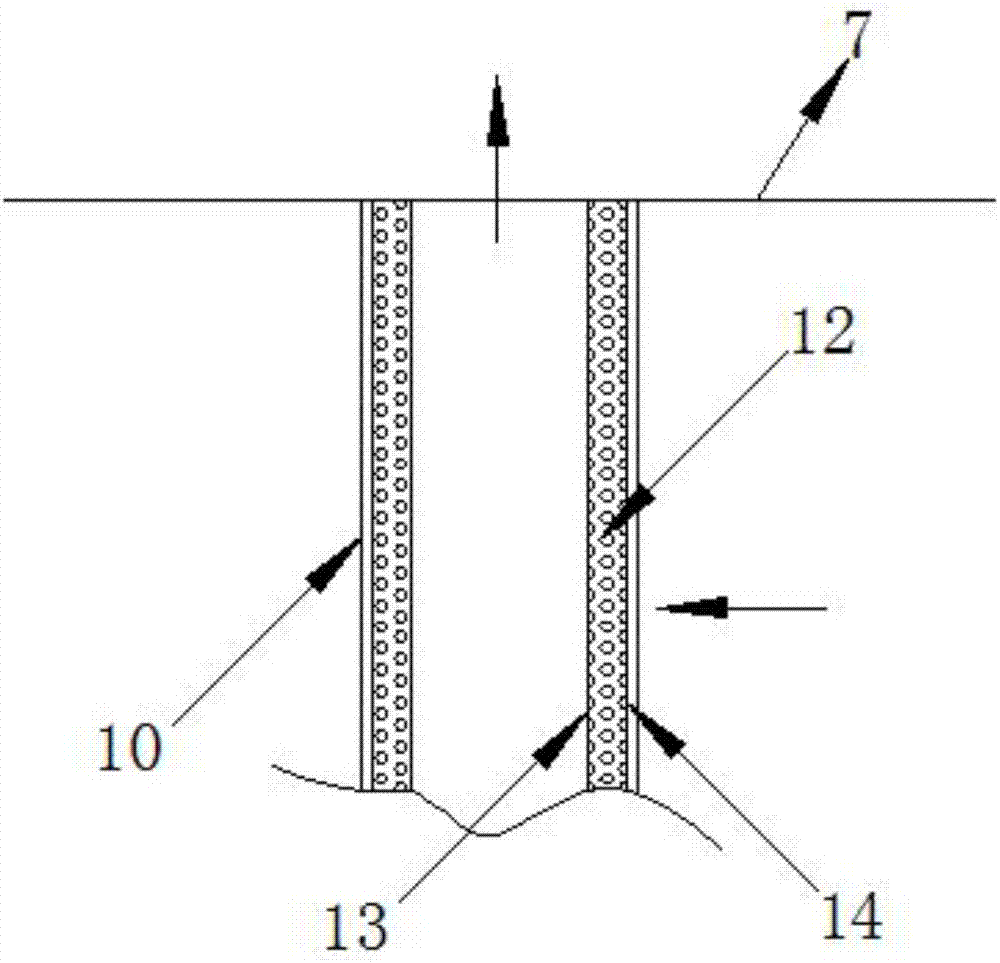

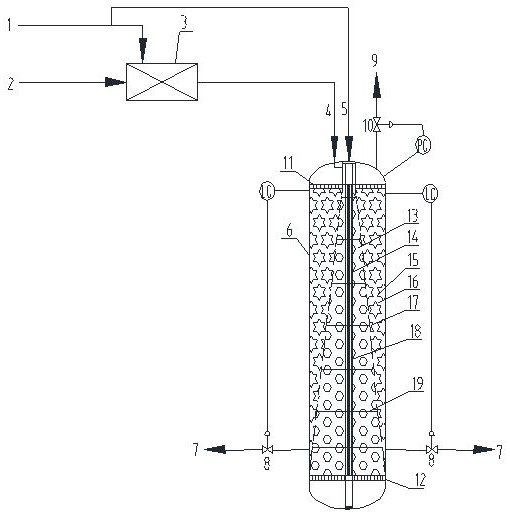

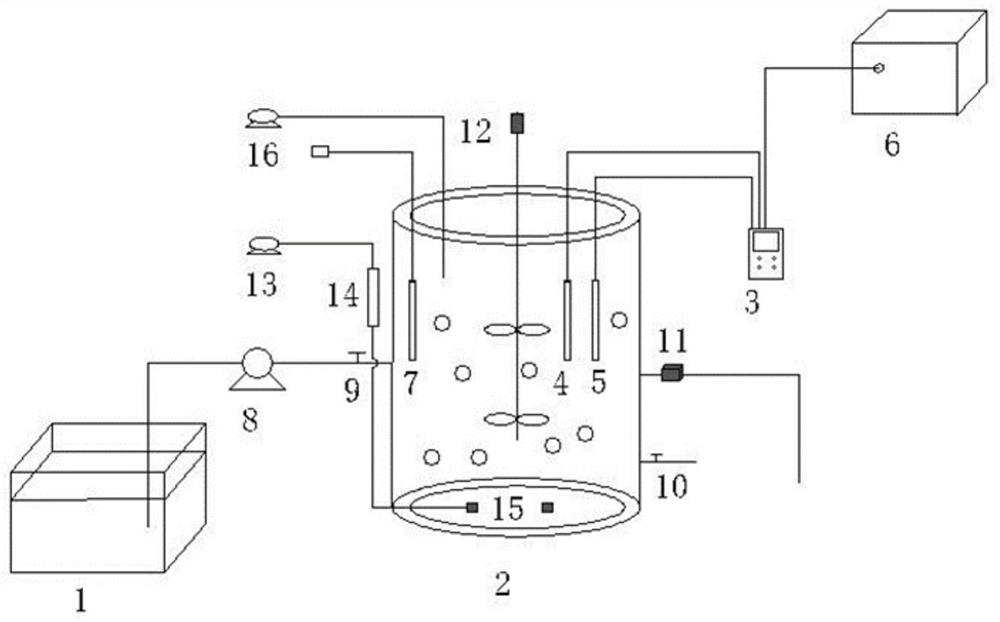

Sequencing batch type combined biofilm integrated apparatus for treating high concentration organic wastewater

InactiveCN1699219ABig reaction forceShock load resistant and adaptableTreatment with aerobic and anaerobic processesSustainable biological treatmentPropellerChemistry

The invention discloses a sequencing batch type combined biofilm integrated apparatus for treating high concentration organic wastewater, wherein a tank body is provided with two submerged biological film reaction zones, the center of the tank body is an anaerobic submerged biological film reaction zone, the periphery of the tank body is an aerobic submerged biological film reaction zone, the anaerobic submerged biological film reaction zone is closed, the two reaction zones are provided with half-soft fiber fillings internally and a a underwater propeller on the bottom, the packing of the anaerobic submerged biological film reaction zone is provided with a underwater aeration apparatus on the bottom.

Owner:CHONGQING UNIV

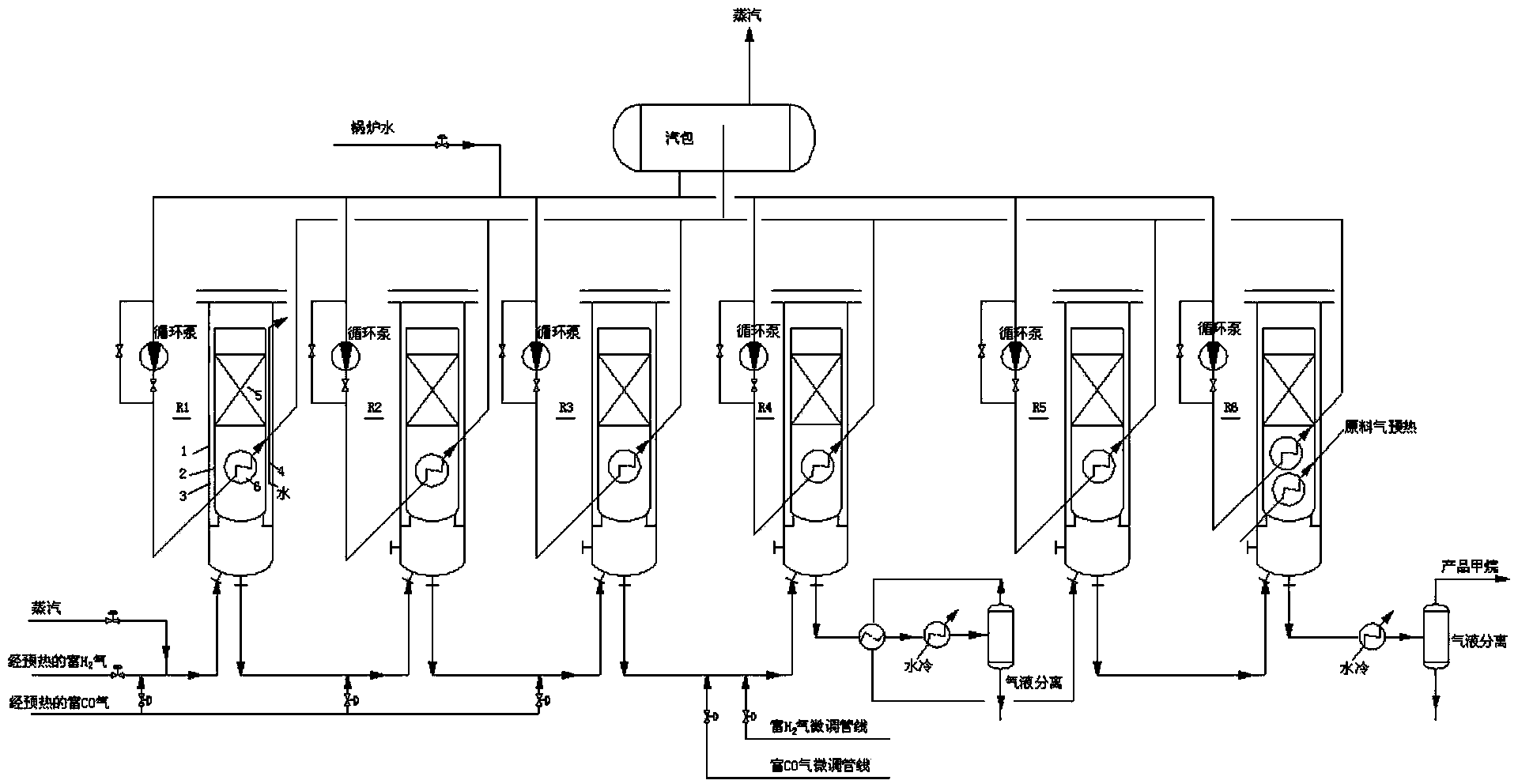

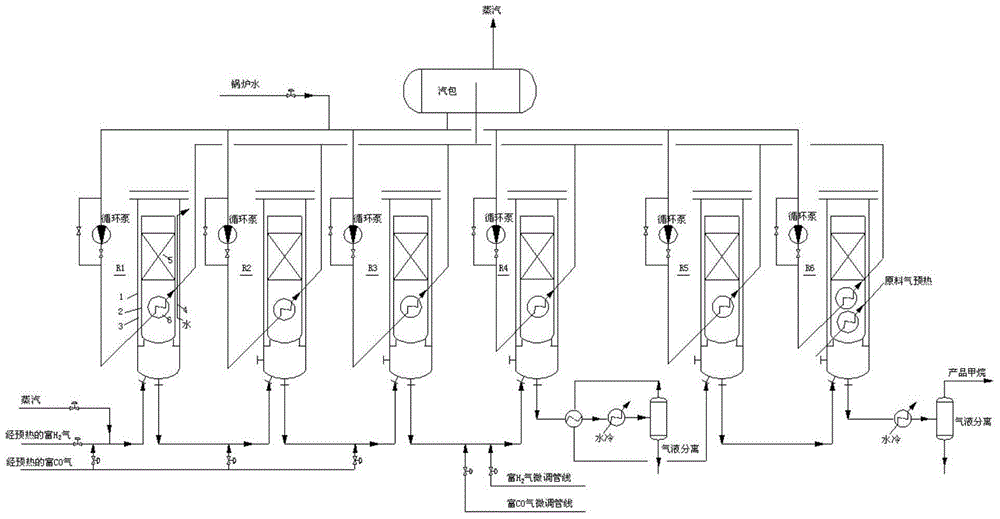

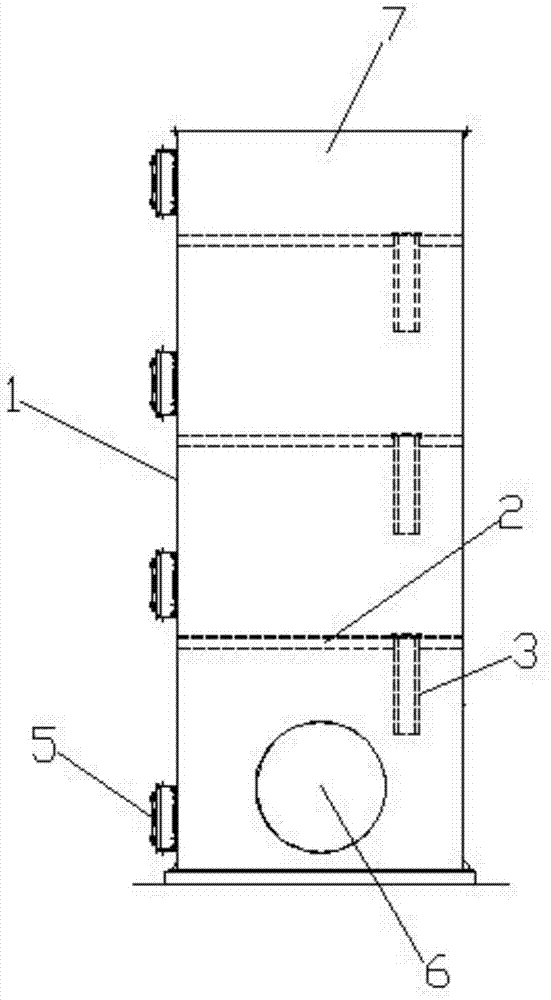

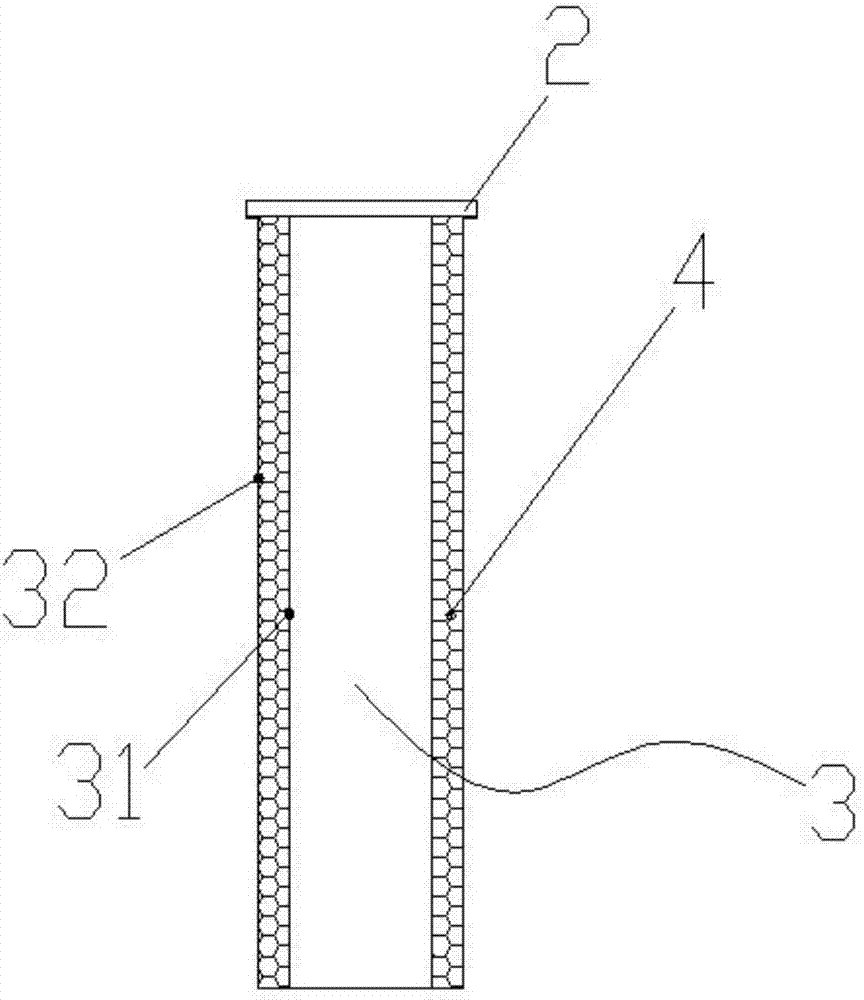

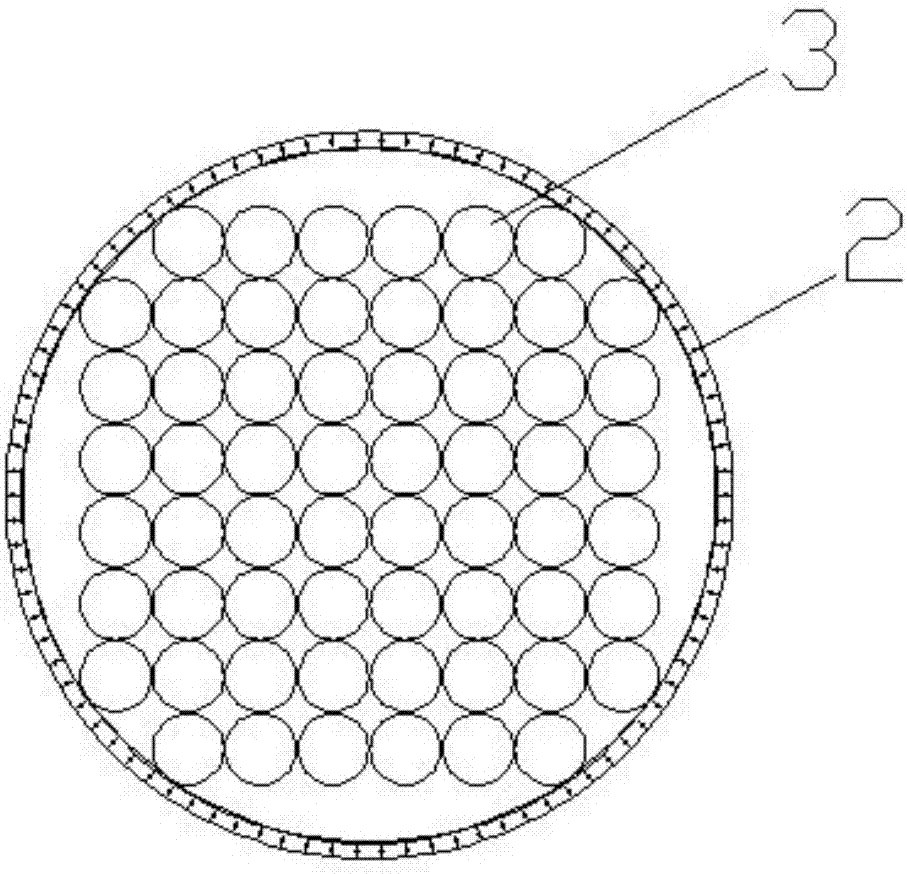

Circulation-free methanation system

The invention discloses a circulation-free methanation system which comprises a gas distribution methanation stage and a supplementation methanation stage, wherein in the gas distribution methanation stage, 1 to 3 stages of serially connected high-temperature reactors are adopted; in the supplementation methanation stage, 2 to 3 stages of serially connected low and medium-temperature reactors are adopted; the final-stage reactor in the gas distribution methanation stage is connected in series with the head-stage reactor in the supplementation methanation stage; technical gas discharged by the former stage of the reactor is used as part of or all the synthesized gas of the next stage of the reactor; technical gas discharged by the final-stage reactor is subjected to cooling separation to obtain a final methane product. The technical system is simple, and the reaction is steady, safe and reliable; the running cost and the manufacturing cost are low.

Owner:BEIJING HUAFU ENG +2

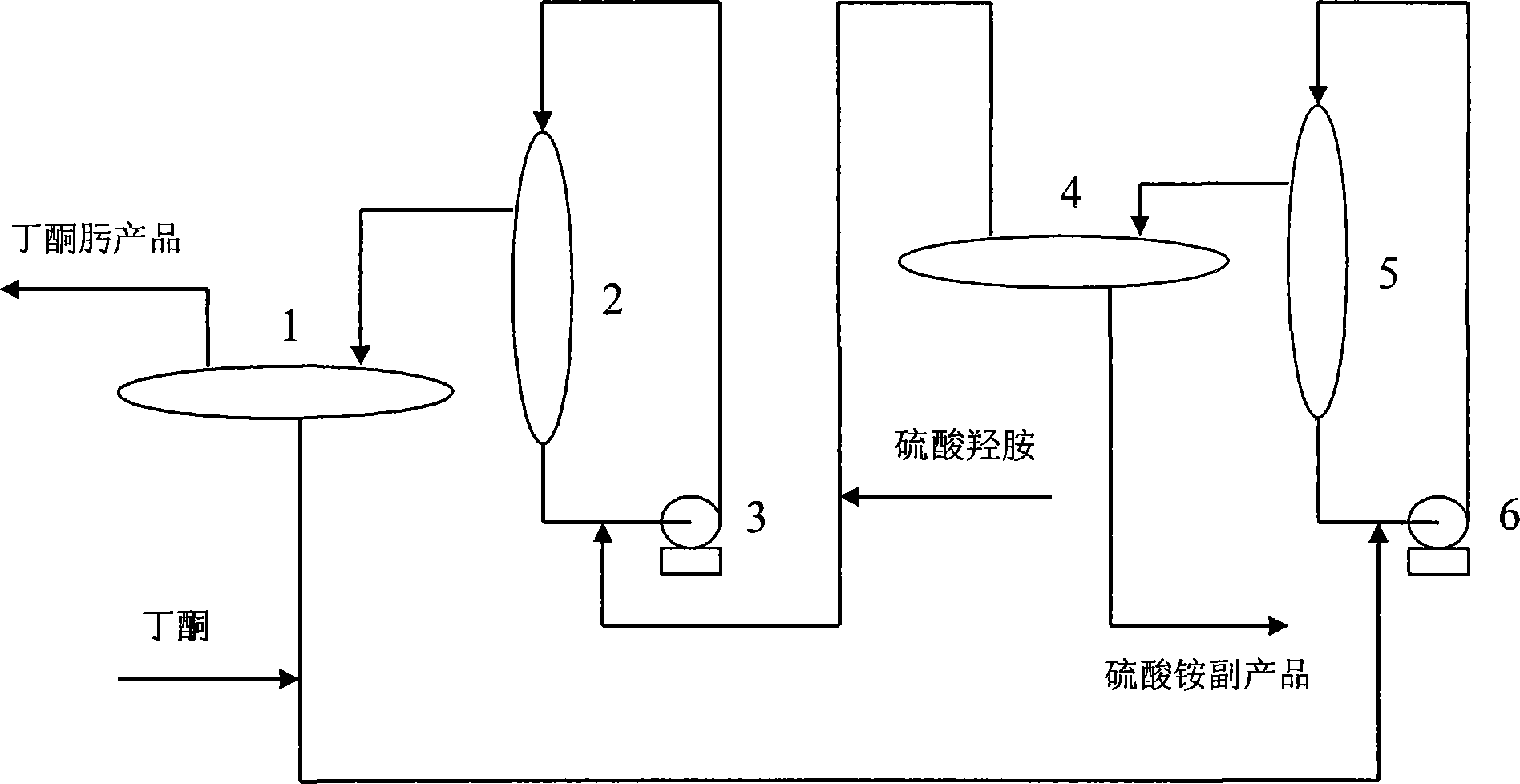

Preparation method for diacetylmonoxime

The invention discloses a making method of butanone oxime, which comprises the following steps: adopting two-segment reflow oximation technique flow path with oximation reactor, oximation separator and oximation circulating pump; making the quantity of butanone surplus in the 1# oximation reactor; reacting sulfuric hydroxylamine completely; making the sulfuric hydroxylamine excess in the 2# oximation reactor; reacting the butanone completely; setting the molar rate of butanone and sulfuric hydroxylamine at 1: 1 in the whole flow path. The invention improves utilizing rate of raw material and simplifies the equipment, which shortens the staying time of material with good condition of mass transfer.

Owner:QUZHOU JUHUA POLYAMIDE FIBER +1

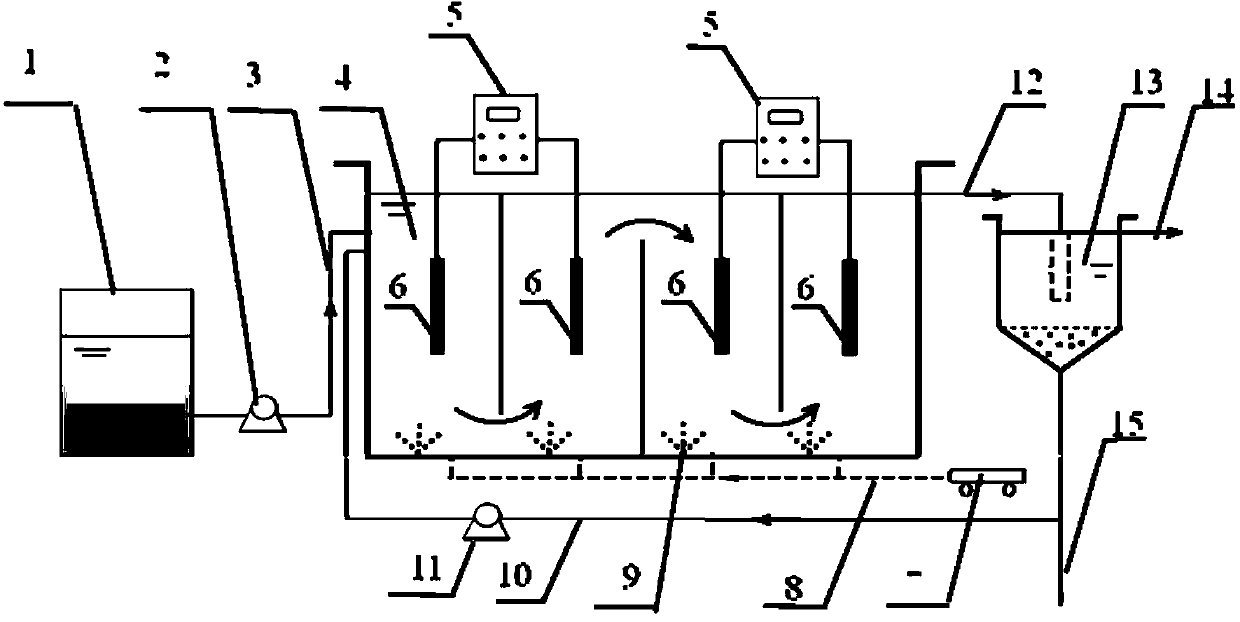

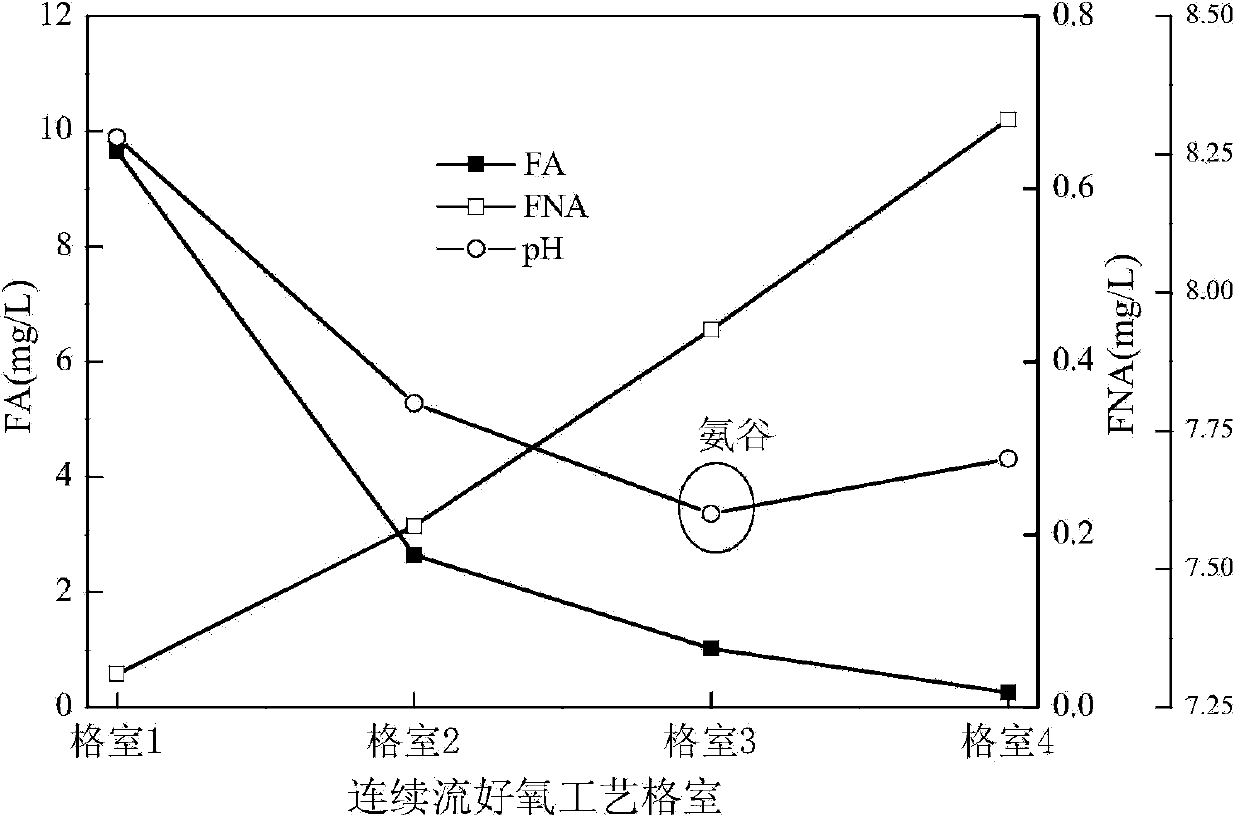

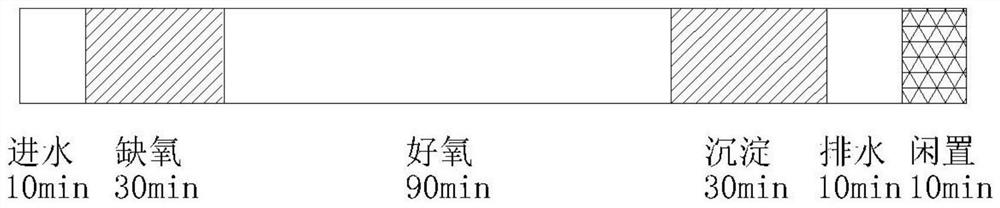

Device and method for synergistic inhibition of nitrifying bacteria activity to achieve partial nitrification employing free ammonia and free nitrous acid

InactiveCN103739060AAchieve short-cut nitrificationAchieve inhibitionTreatment using aerobic processesSustainable biological treatmentChemistryWater pipe

The invention discloses a device and a method for synergistic inhibition of nitrifying bacteria activity to achieve partial nitrification employing free ammonia and free nitrous acid, and belongs to the field of biological nitrification of continuous flow process wastewater. The device mainly comprises a raw water tank, an intake pump, an intake pipe, an aerobic nitrification pond, a pH determinator, a pH sensor, a blast blower, an aerator tube, an air diffuser, a sludge reflux pipe, a sludge reflux pump, an aerobic nitrification pond drain pipe, a settling pond, a settling pond drain pipe, and a residue sludge discharge pipe. On the basis of the synergistic inhibition mechanism of the free ammonia (FA) and free nitrous acid (FNA) on activity of nitrite-oxidizing bacteria, rapid start and stable maintaining of partial nitrification at normal temperature are achieved by controlling the FA concentration inside the aerobic nitrification pond at 5.9-63.1mg / L, the problem of a bottleneck of partial nitrification of the continuous process is solved, and the device has the characteristics of being high in nitrification efficiency, rapid in reaction rate, and the like, the operation cost is saved, and excellent water is obtained.

Owner:LANZHOU JIAOTONG UNIV

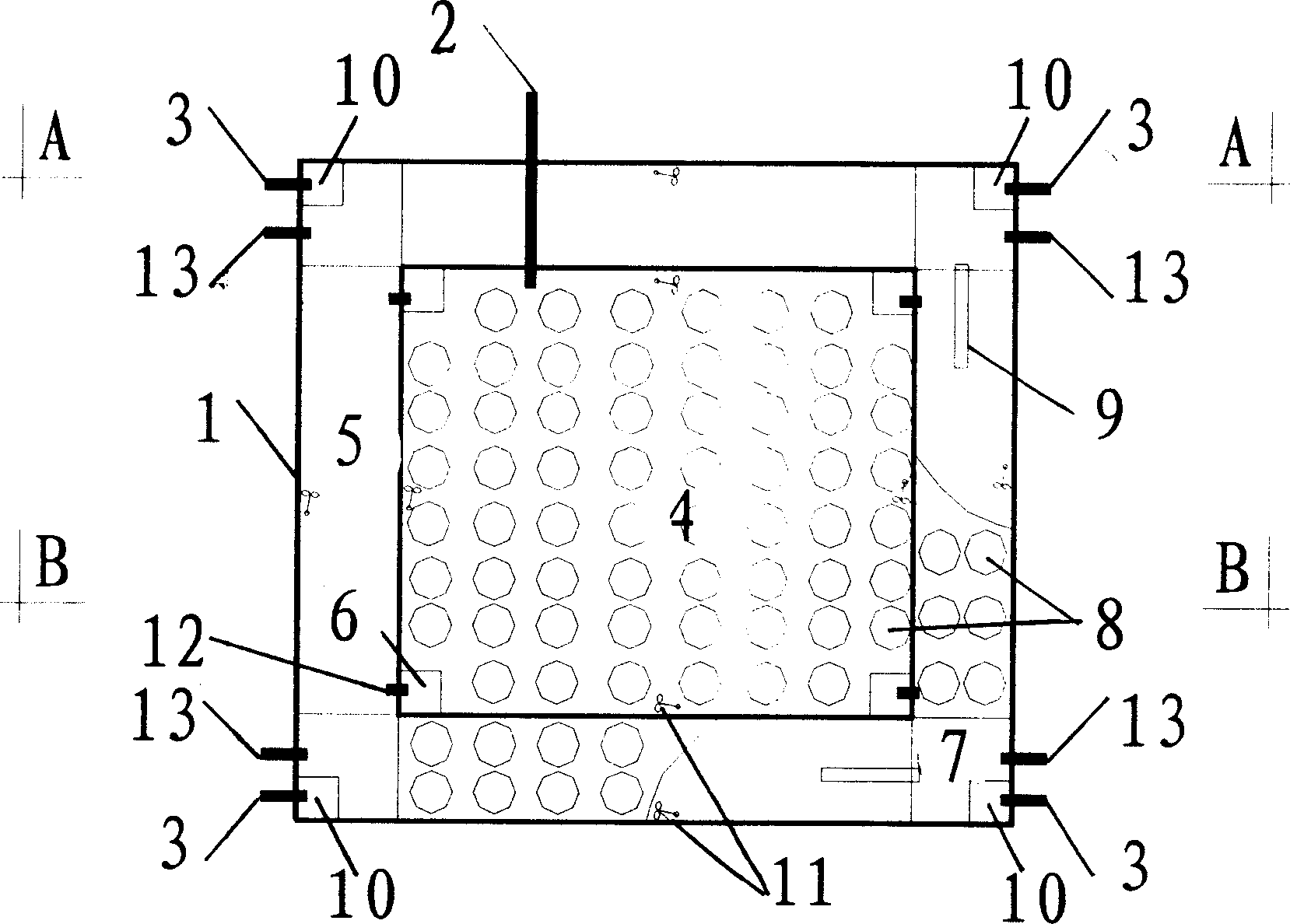

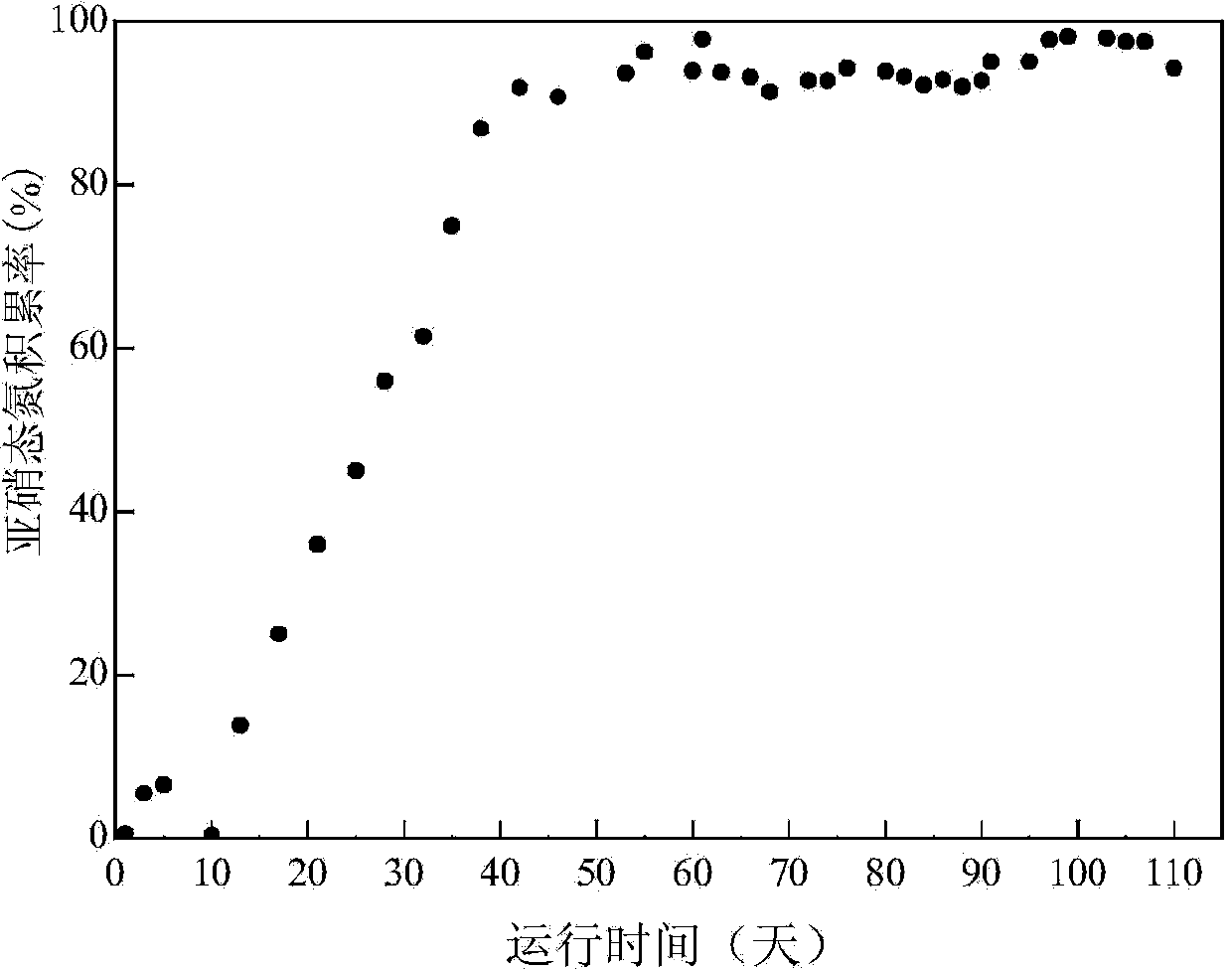

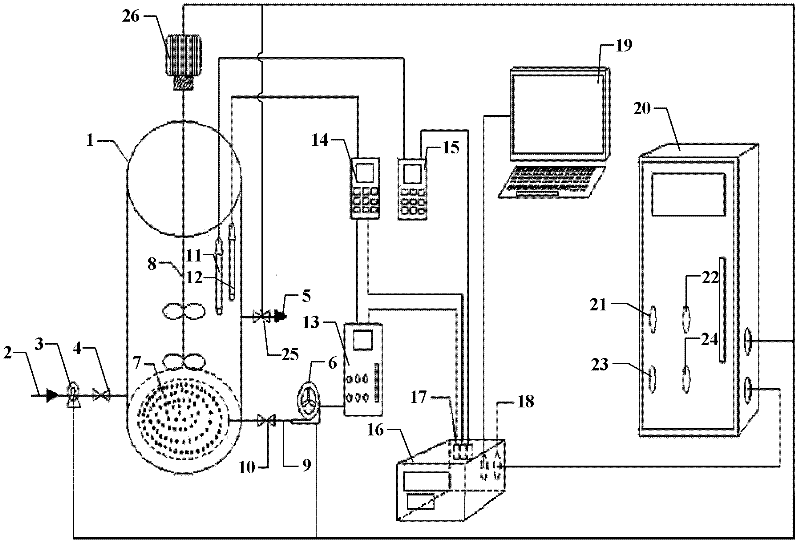

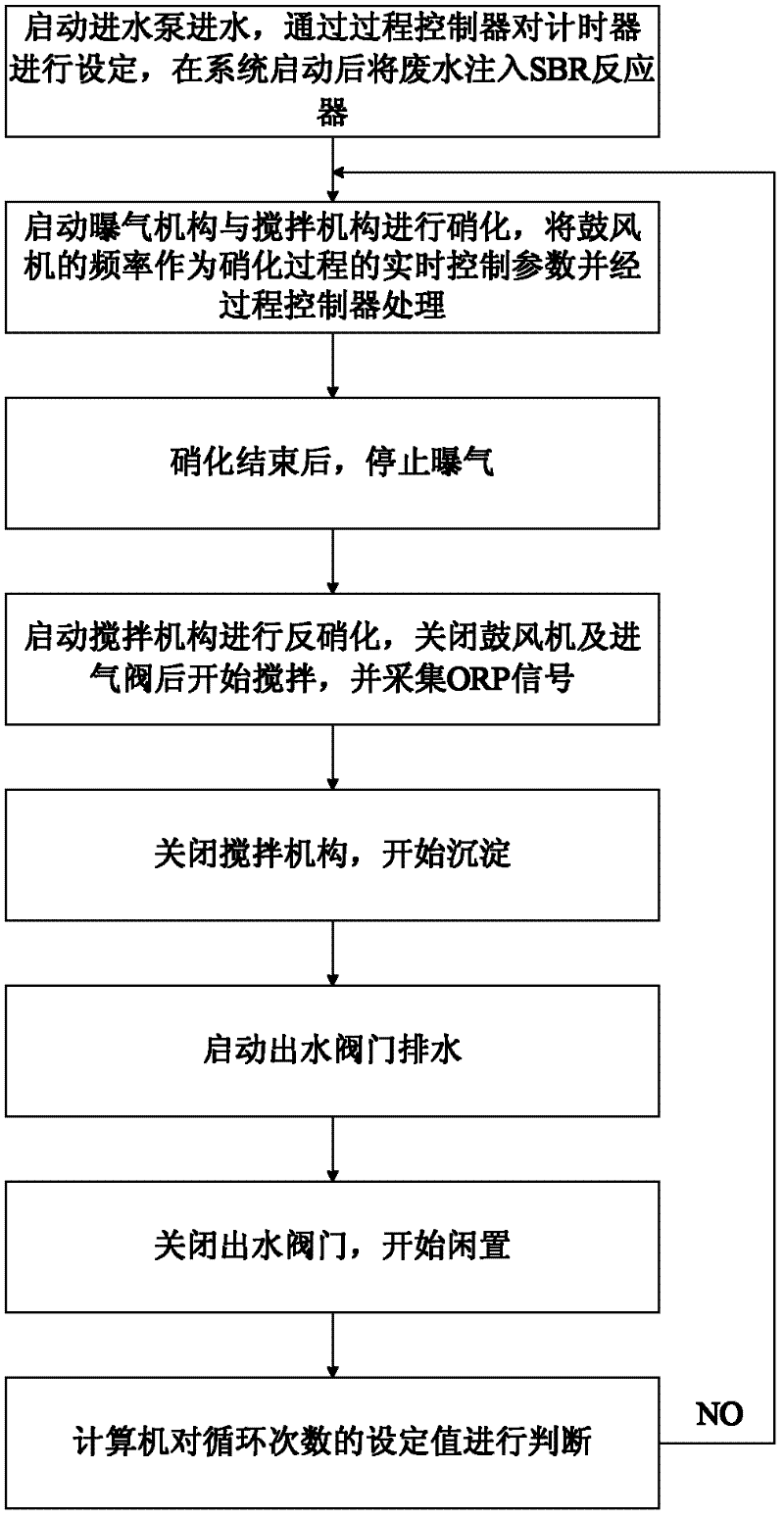

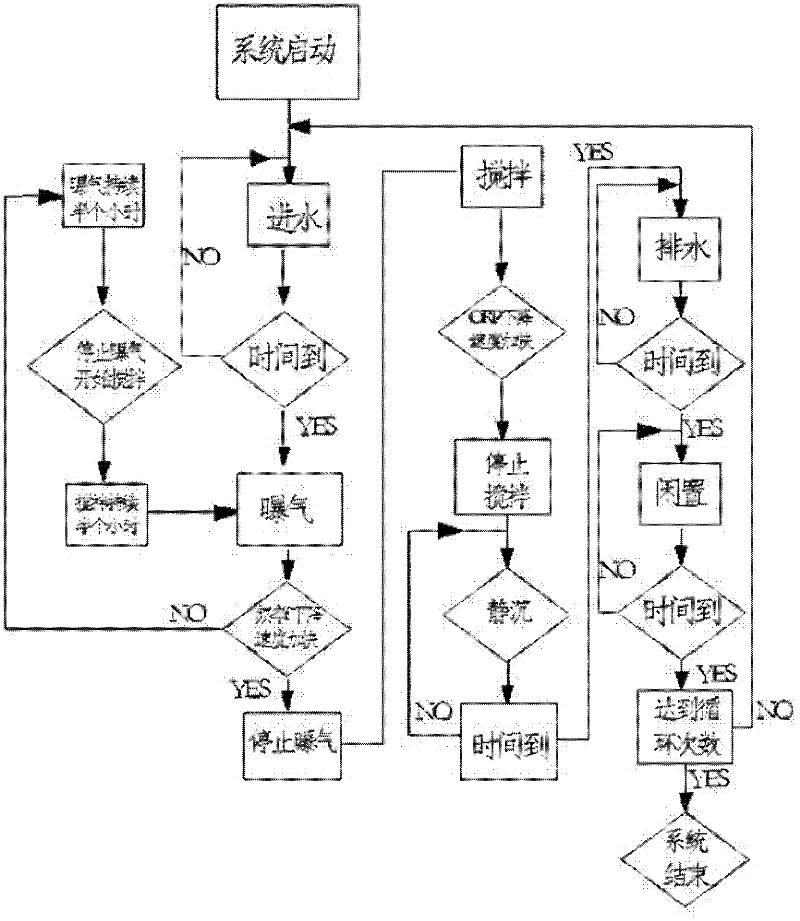

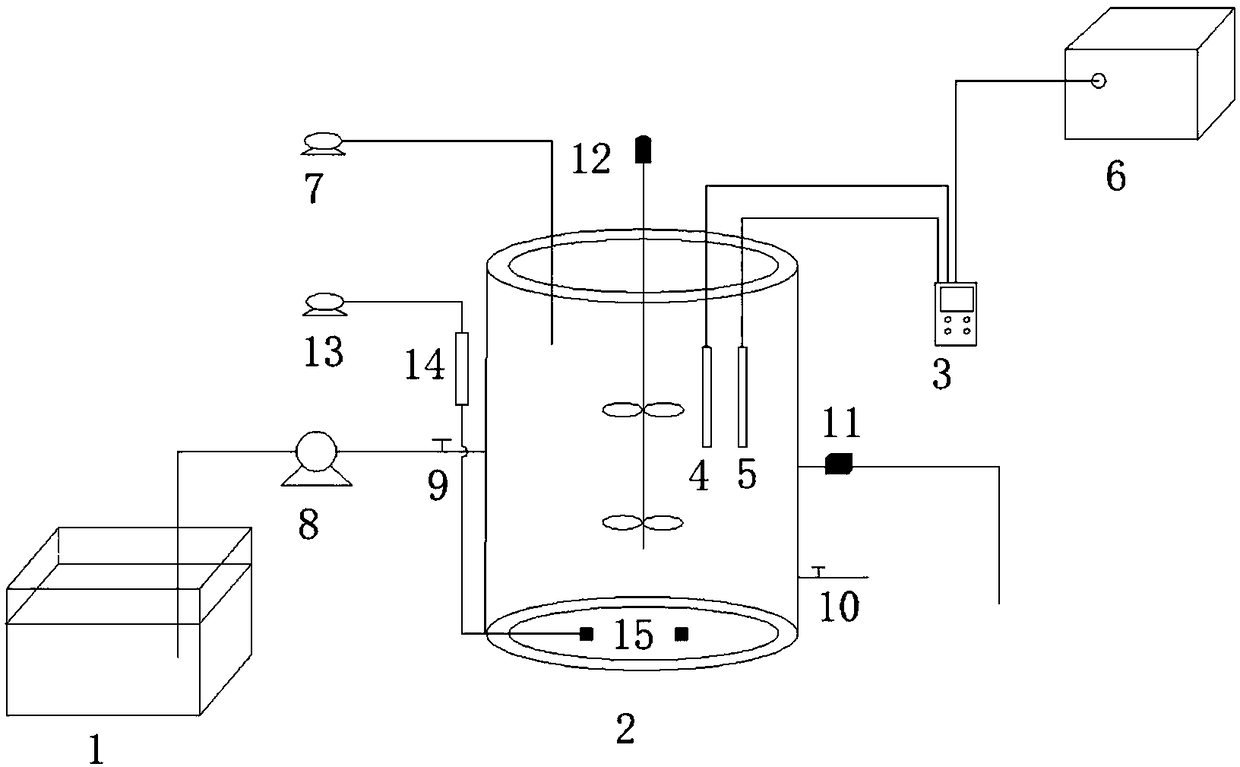

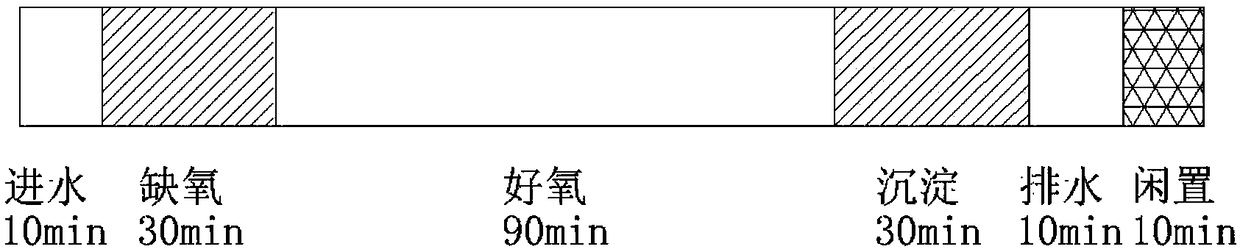

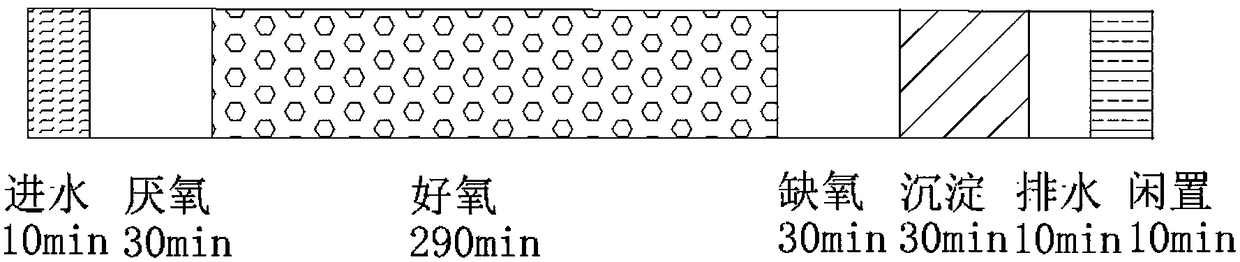

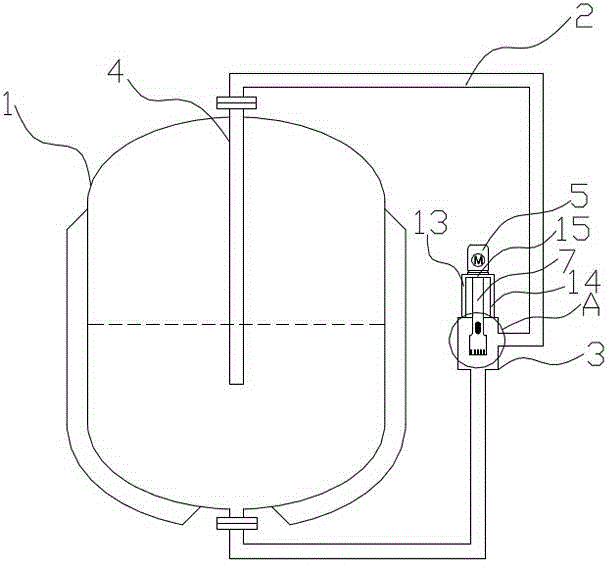

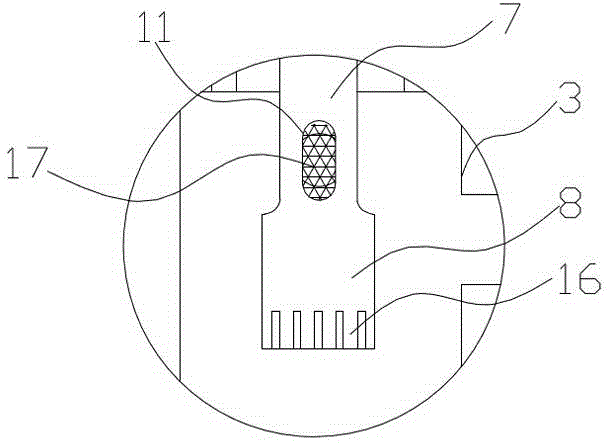

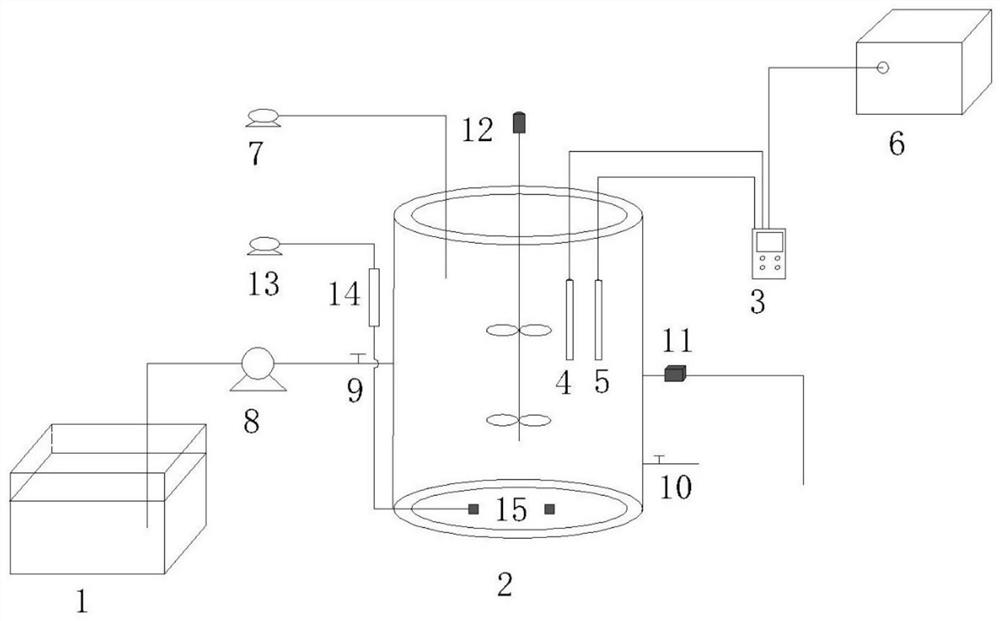

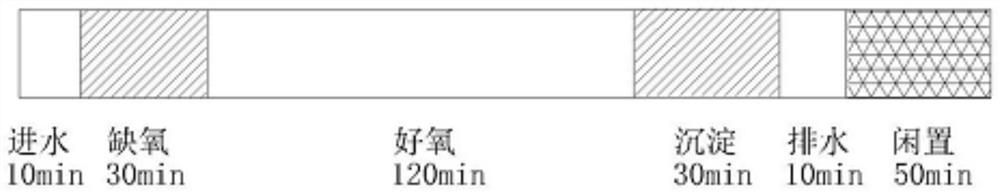

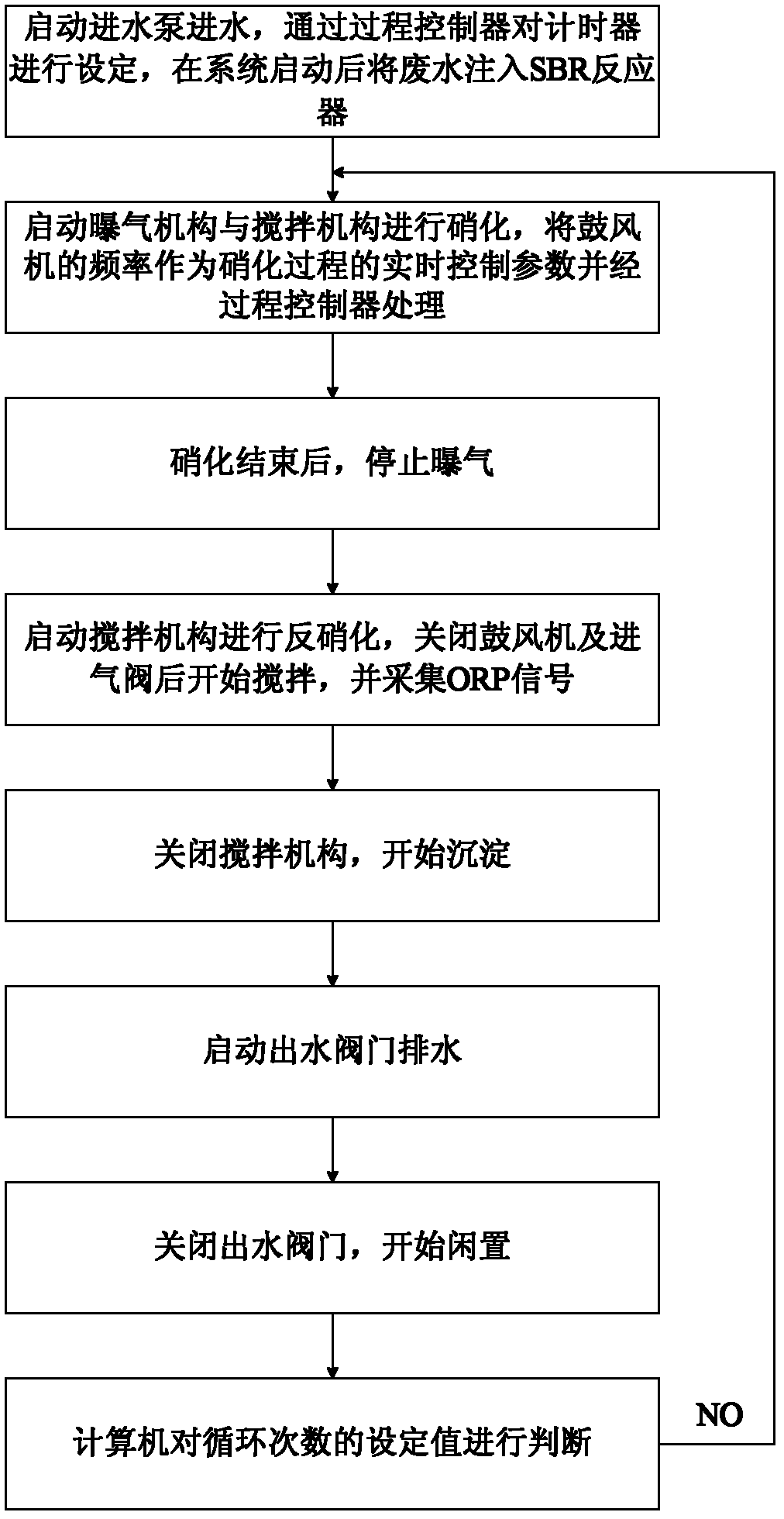

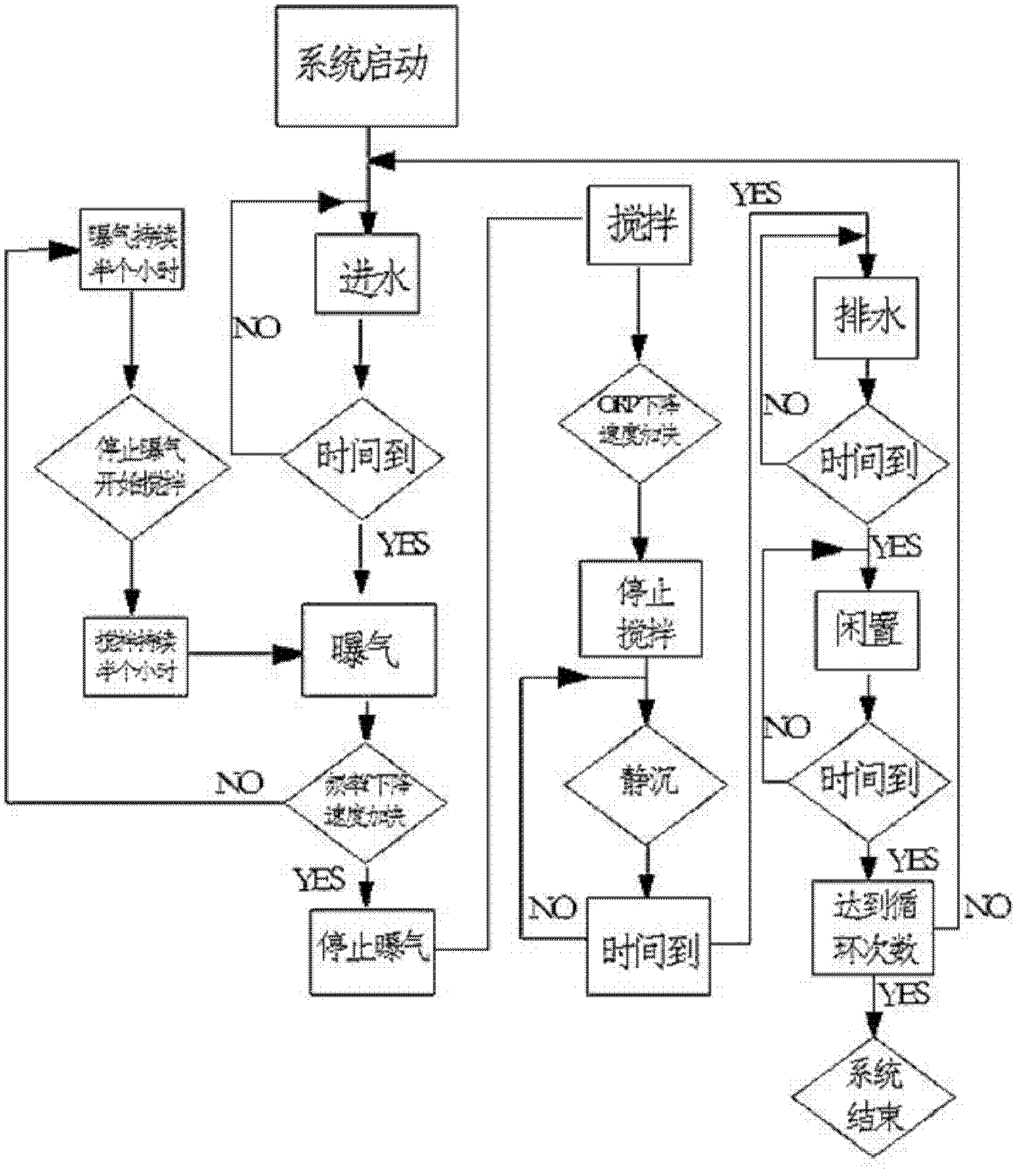

System and method for conducting deep denitrification processing on medium-term landfill leachate

ActiveCN102557254ASimple structureBig reaction forceTreatment with aerobic and anaerobic processesSequencing batch reactorNitration

The invention provides a system and a method for conducting deep denitrification processing on medium-term landfill leachate. A dissolved oxygen (DO) sensor and an oxidation reduction potential (ORP) sensor are respectively connected with a DO tester and an ORP tester, the DO tester, the ORP tester and an aeration mechanism are all connected with a transducer, the ORP tester, the DO tester and the transducer are all connected with a process controller through a computer, and the process controller is respectively connected with a stirring mechanism, a water inlet mechanism, a water outlet mechanism and the aeration mechanism. The steps of applying the processing method of the system are sequentially injecting waste water in a sequencing batch reactor (SBR) and starting the system, enabling the aeration mechanism and the stirring mechanism to conduct nitration, starting the stirring mechanism to conduct denitrification, sediment, dewatering and leaving unused, and enabling the computerto judge the set value of cycle times. The system and the method can solve processing problems of the medium-term landfill leachate, improve use ratio of an organic carbon source in raw water in a processing process, and achieve deep denitrification with low processing cost.

Owner:BEIJING UNIV OF TECH

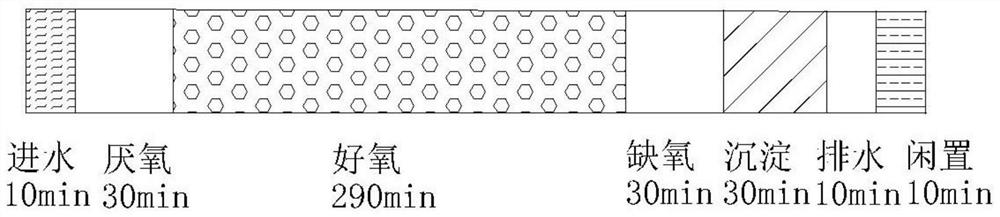

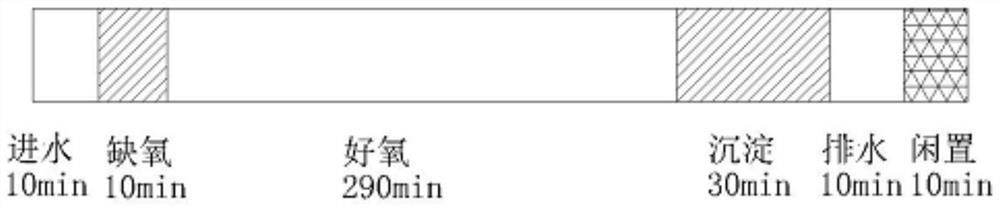

Device and method for realizing synchronous short-process nitrification and denitrification dephosphorization to treat urban sewage on basis of hydroxylamine

ActiveCN108128897AAvoid competitionGood removal effectTreatment with aerobic and anaerobic processesHydroxylamineHydroxylamine Hydrochloride

The invention provides a device and a method for realizing synchronous short-process nitrification and denitrification dephosphorization to treat urban sewage on the basis of hydroxylamine, and belongs to the field of urban domestic sewage biological treatment. The domestic sewage enters a synchronous short-process nitrification and denitrification dephosphorization reactor through a water inlet pump. In the synchronous short-process nitrification and denitrification dephosphorization reactor, during anaerobic stirring, phosphorus-accumulating bacteria sufficiently utilize carbon source release phosphorus in raw water; during the aerobiotic treatment, the stable short-process nitrification is realized through addition of hydroxylamine; under the anoxic condition, denitrifying phosphorus-accumulating bacteria use nitrite nitrogen as electron acceptors to absorb phosphorus in the water; nitrite nitrogen is reduced into nitrogen gas. Compared with a conventional denitrification dephosphorization process, the process has the advantages that the carbon source is saved; the aeration quantity is reduced.

Owner:BEIJING UNIV OF TECH

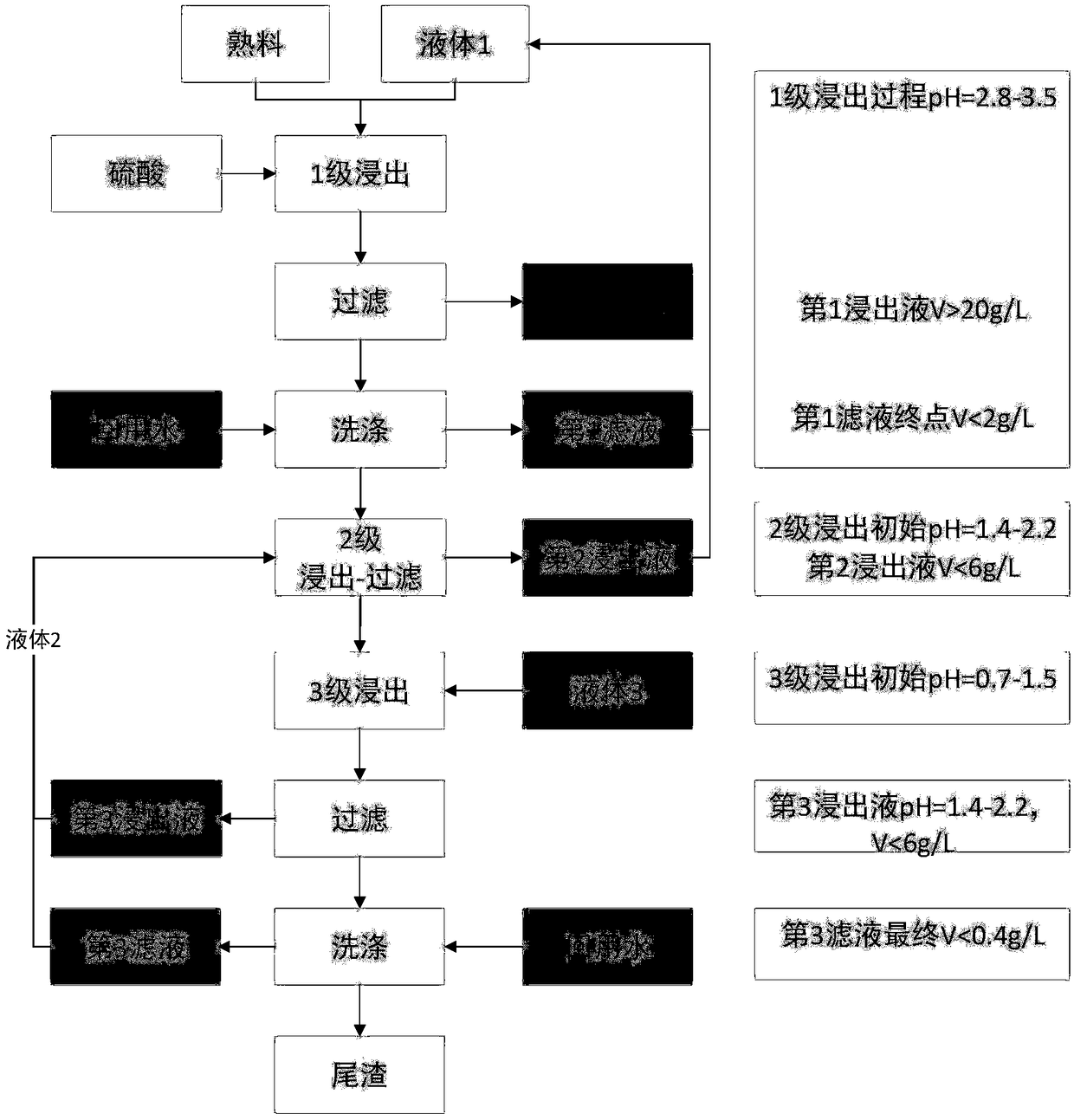

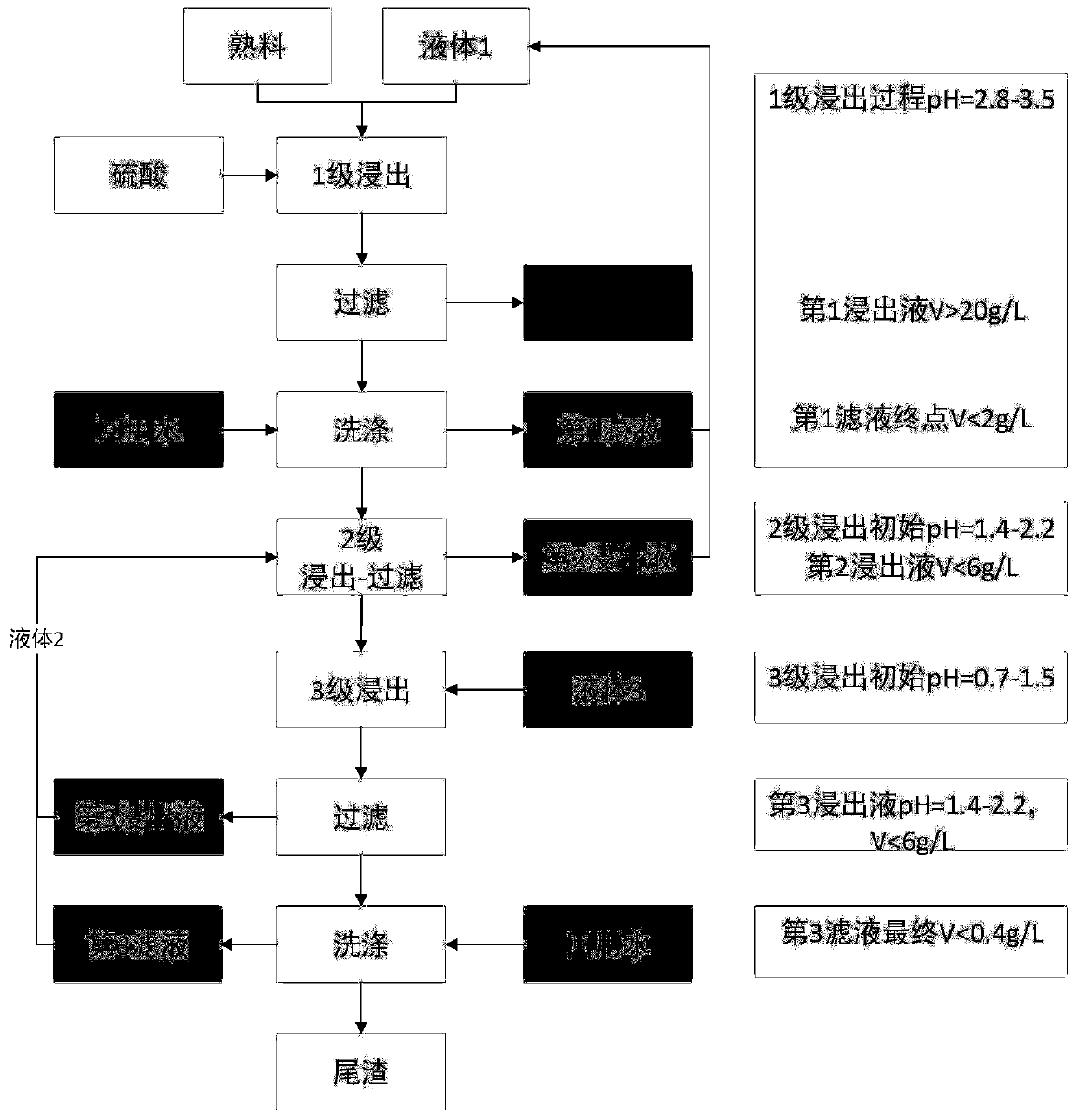

Calcification roasting clinker counter-flow acid pickling vanadium extracting method

ActiveCN109338103AIncreased dissolution and leaching rateHigh total vanadium concentrationProcess efficiency improvementProcess systemsPregnant leach solution

The invention belongs to the technical field of vanadium extraction and particularly relates to a calcification roasting clinker counter-flow acid pickling vanadium extracting method. To solve technical problems, the calcification roasting clinker counter-flow acid pickling vanadium extracting method is provided. The method comprises the following steps that a, clinker and primary filter liquor and / or secondary lixivium are mixed, sulfuric acid is added for leaching, the pH of a primary leaching process system is controlled to be 2.8-3.5, solid-liquid separation is performed to obtain primarylixivium and solids, and washing is performed to obtain primary filter liquor and solids; b, the solids are subjected to leaching by adopting tertiary lixivium or / and tertiary filter liquor, and the pH of a second leaching terminal system is controlled to be 1.8-3.5, and solid-liquid separation is performed to obtain secondary lixivium and solids; and c, the solids are subjected to leaching, the pH of a third leaching terminal system is controlled to be 1.4-2.2, solid-liquid separation is performed to obtain tertiary lixivium and solids, and washing is performed to obtain tertiary filter liquor and vanadium extracting tailings. The method provided by the invention has the advantages of high leaching vanadium extracting rate and low cost.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD +1

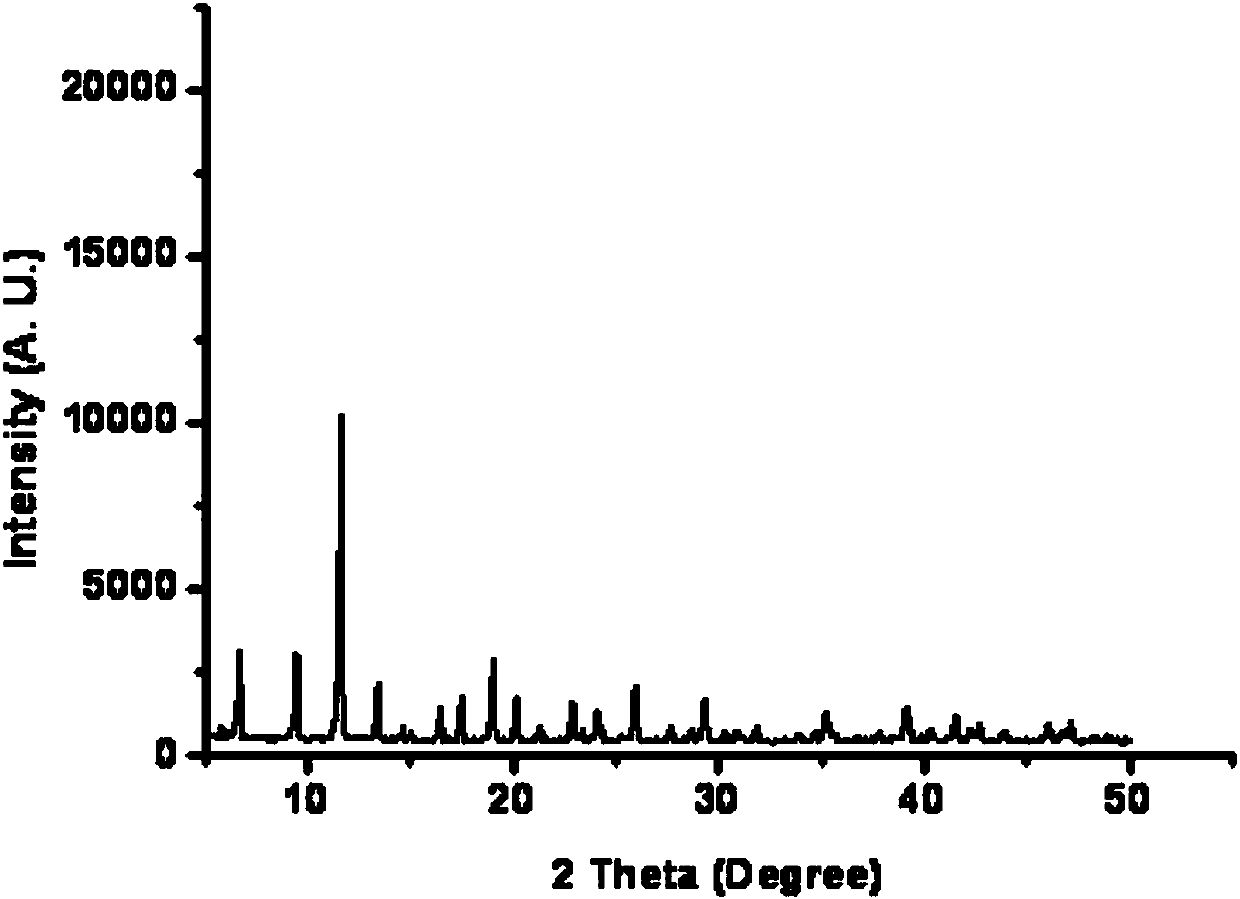

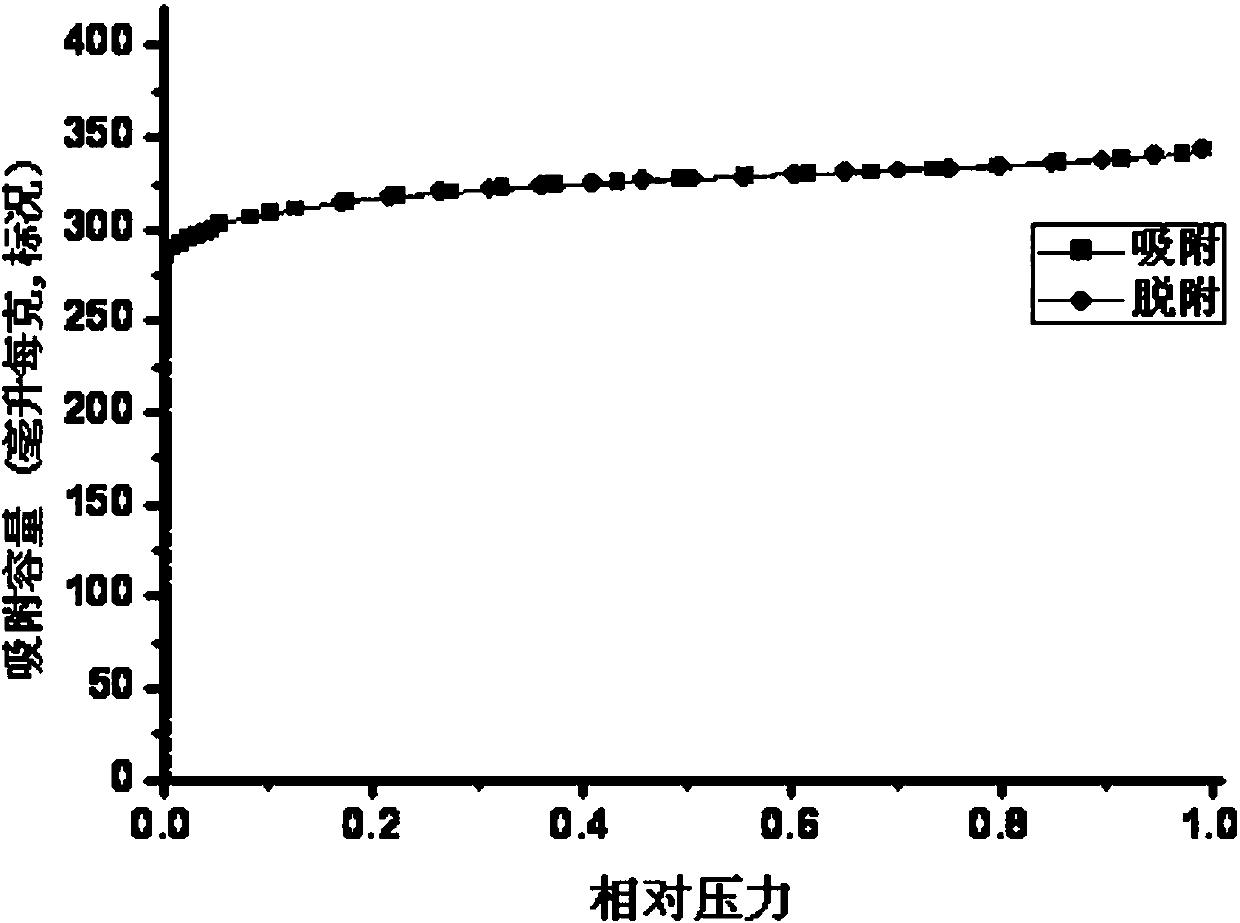

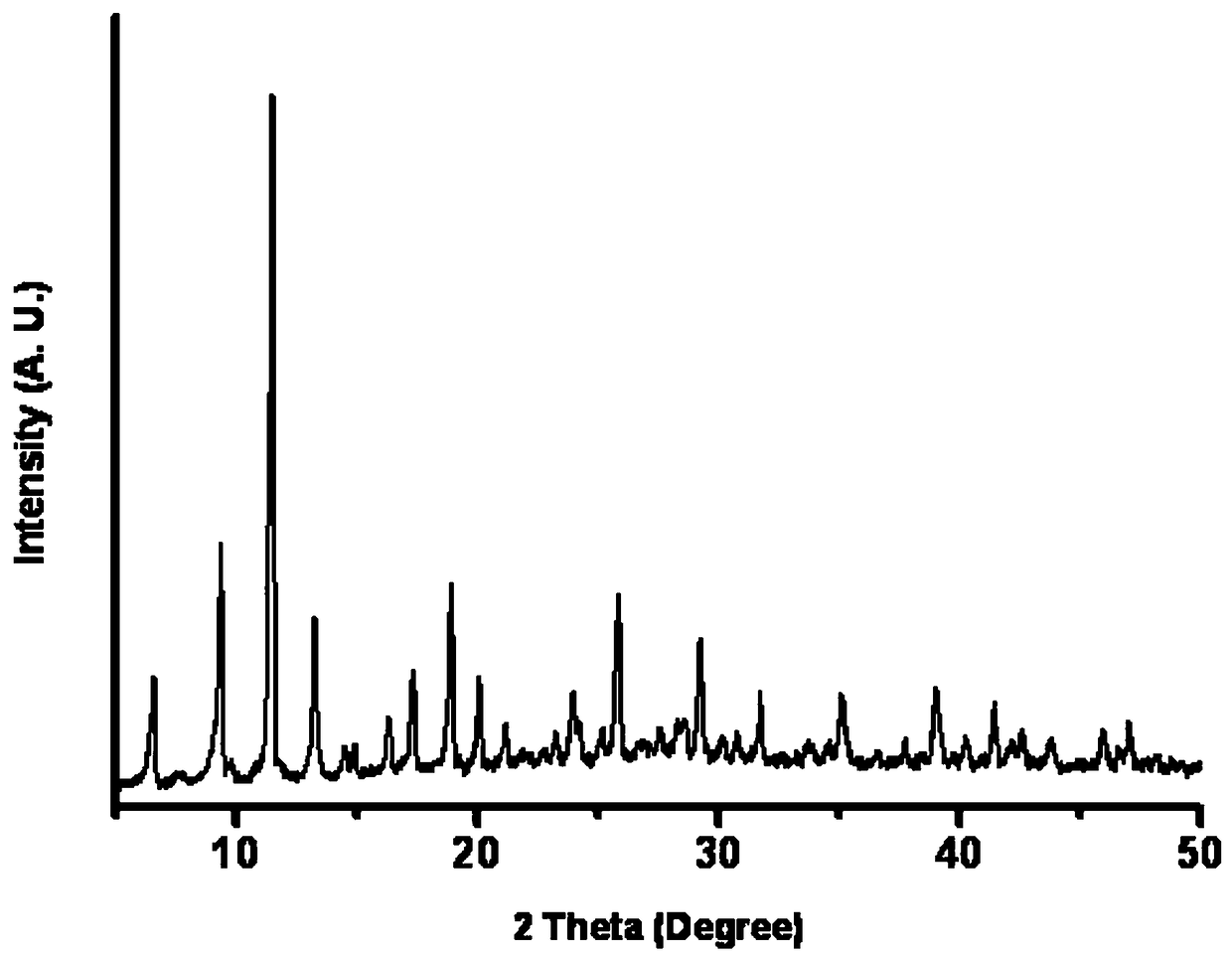

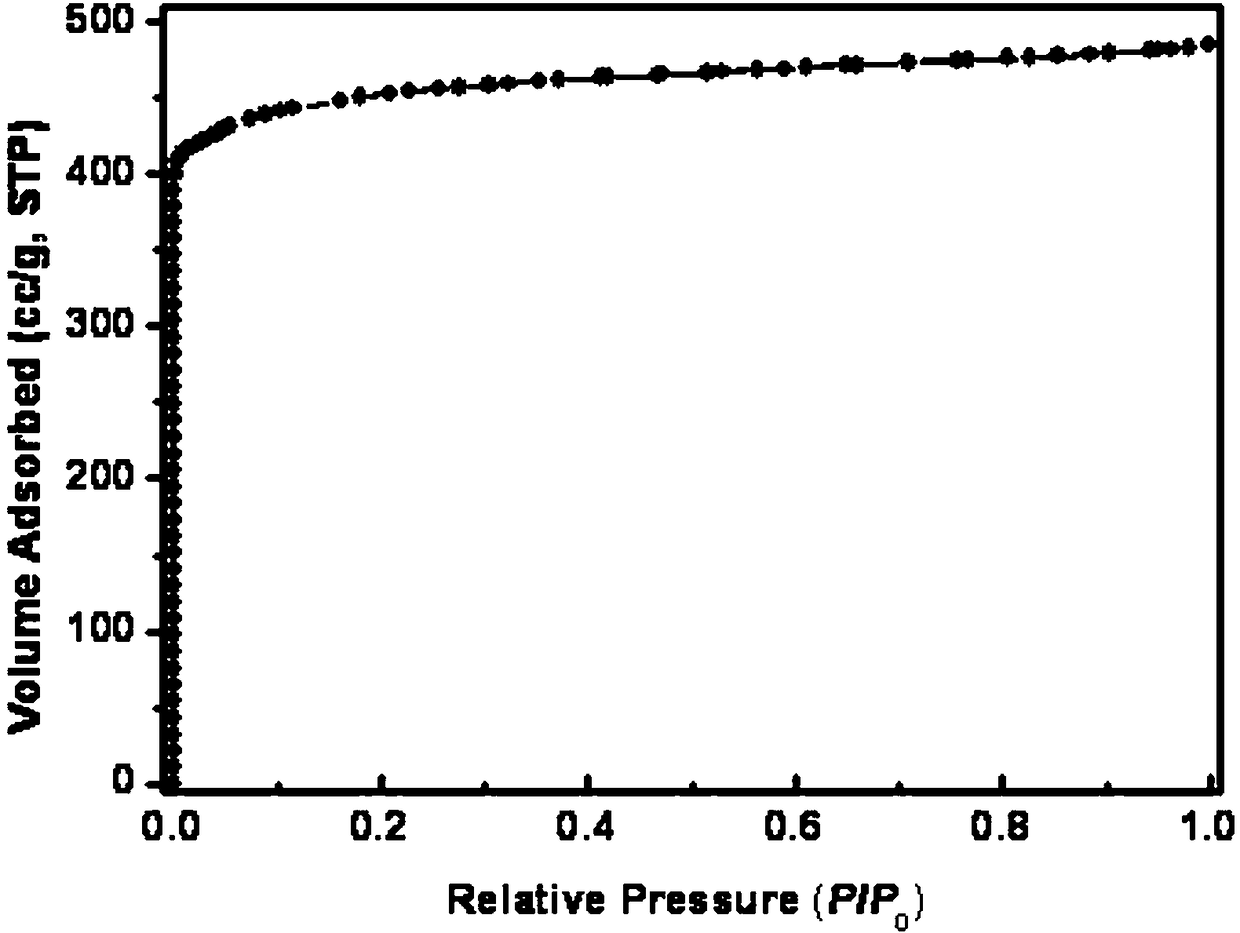

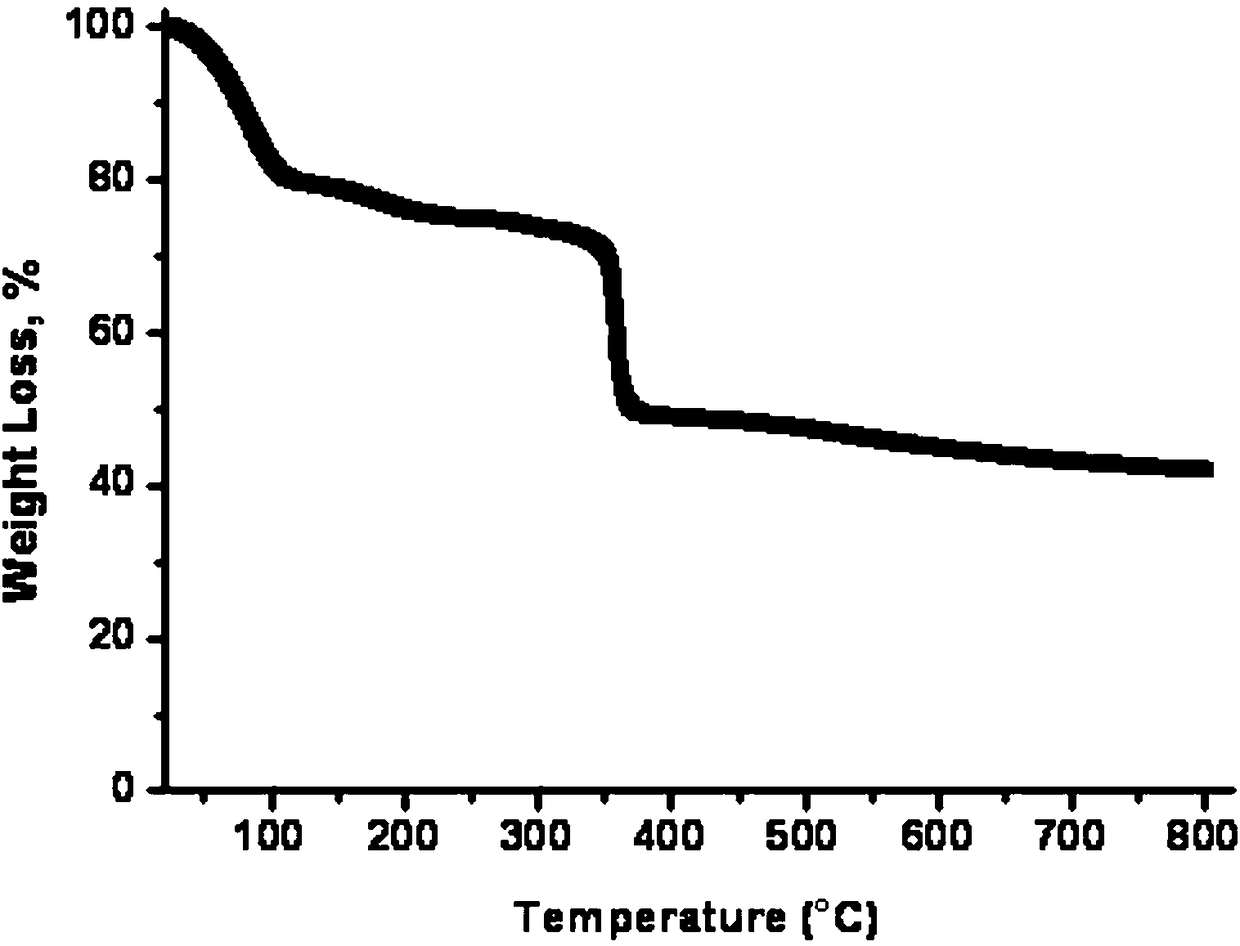

Slurry state synthetic method for porous composite framework material

InactiveCN107674088ANarrow particle size distributionWide particle size distributionGroup 1/11 organic compounds without C-metal linkagesOther chemical processesMass ratioSynthesis methods

The invention belongs to the technical field of preparation of porous composite materials, and provides a slurry state synthetic method for a porous composite framework material. The mass ratio of a solvent to a solid reactant is controlled, so that the reactant is at different saturations, an inorganic-organic composite framework material is obtained through heating in a sealed container, and thecrystal size and distribution of the composite framework material are regulated and controlled. Under a room temperature, an inorganic metal source is dispersed into the solvent, and then mixed witha polycarboxylic acid organic compound to form a slurry material, and the slurry material is sealed in a self-pressurized reaction kettle, the obtained material is heated to 70-170 DEG C, a reaction is performed for 0.5-240 hours, drying is performed at the room temperature, and therefore the porous composite framework material is obtained. According to the invention, the crystal size is controllable, and the method provides a novel synthetic route for controlling the particle size of the composite framework material; the yield is higher, washing is not needed, the operating costs are low, theoperation is easy, the emission is zero, the method is green, environmentally friendly, economical and practicable, and the large-scale intensive production is easy to realize; and the obtained large-particle composite framework material has a higher adsorption capacity in the gas adsorption aspect.

Owner:TAIYUAN UNIV OF TECH

Method for extracting vanadium from calcified roasted clinker with countercurrent acid leaching

ActiveCN109338103BIncreased dissolution and leaching rateHigh total vanadium concentrationProcess efficiency improvementPhysical chemistryChemical engineering

The invention belongs to the technical field of vanadium extraction and particularly relates to a calcification roasting clinker counter-flow acid pickling vanadium extracting method. To solve technical problems, the calcification roasting clinker counter-flow acid pickling vanadium extracting method is provided. The method comprises the following steps that a, clinker and primary filter liquor and / or secondary lixivium are mixed, sulfuric acid is added for leaching, the pH of a primary leaching process system is controlled to be 2.8-3.5, solid-liquid separation is performed to obtain primarylixivium and solids, and washing is performed to obtain primary filter liquor and solids; b, the solids are subjected to leaching by adopting tertiary lixivium or / and tertiary filter liquor, and the pH of a second leaching terminal system is controlled to be 1.8-3.5, and solid-liquid separation is performed to obtain secondary lixivium and solids; and c, the solids are subjected to leaching, the pH of a third leaching terminal system is controlled to be 1.4-2.2, solid-liquid separation is performed to obtain tertiary lixivium and solids, and washing is performed to obtain tertiary filter liquor and vanadium extracting tailings. The method provided by the invention has the advantages of high leaching vanadium extracting rate and low cost.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD +1

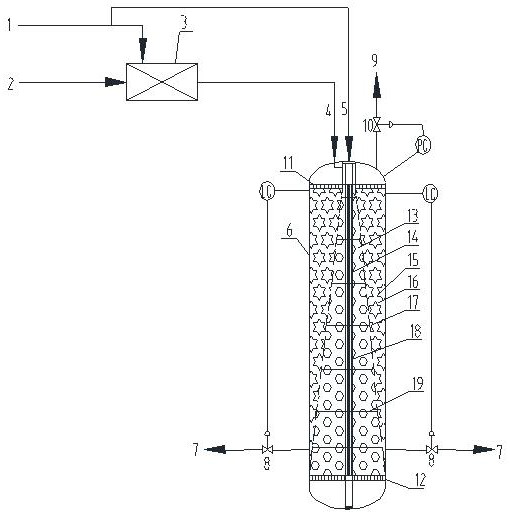

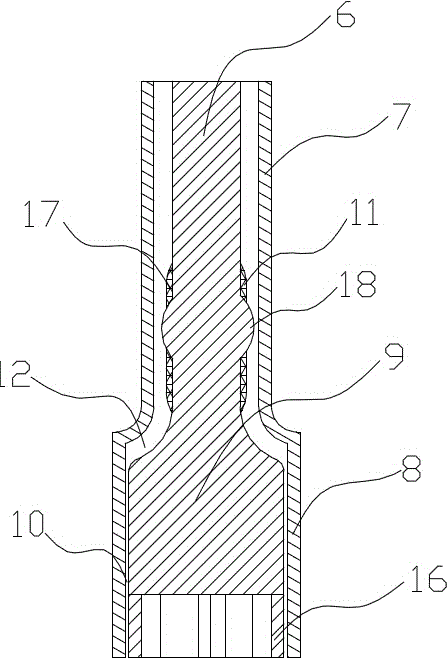

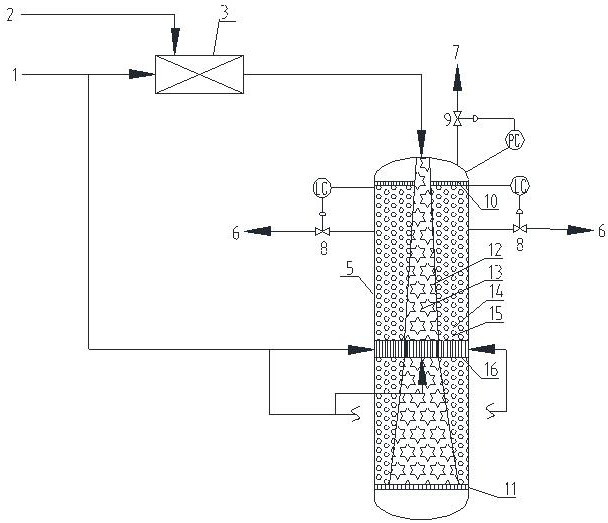

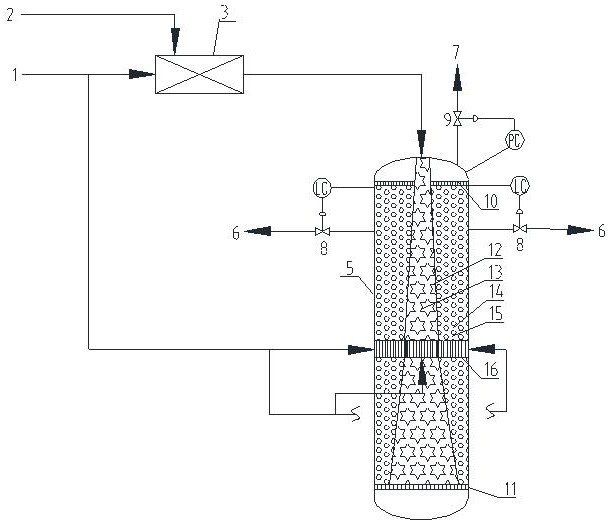

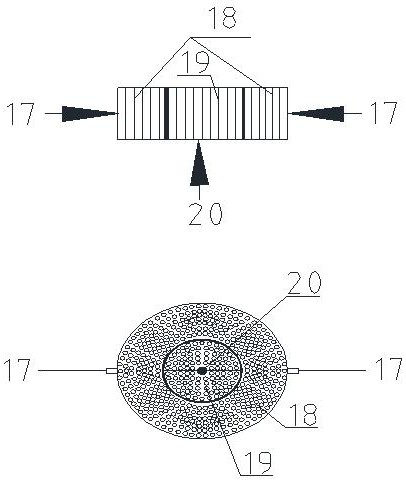

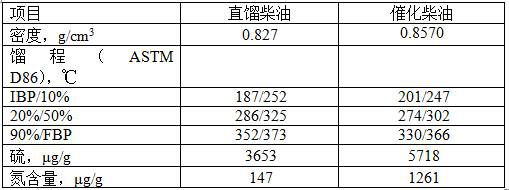

Liquid-phase hydrogenation reactor and hydrogenation process

ActiveCN112705117AControl contact timeControl temperature riseTreatment with hydrotreatment processesChemical/physical processesPtru catalystFluid phase

The invention relates to a liquid-phase hydrogenation reactor and a hydrogenation process, the liquid-phase hydrogenation reactor comprises an inner cylinder and a reactor shell, the inner cylinder is conical, the top and the bottom of the inner cylinder are open, the edge of the bottom of the inner cylinder is hermetically connected with the inner wall of the reactor, and a plurality of small holes are formed in the wall of the inner cylinder; a ceramic membrane tube bundle is vertically arranged in the axial direction of the reactor and is communicated with external hydrogen; the inner cylinder is filled with a hydrogenation catalyst I, the annular cavity is filled with a hydrogenation catalyst II, and the activity of the hydrogenation catalyst I is higher than that of the hydrogenation catalyst II; the reactor raw material inlet communicates with the top of the inner cylinder; the materials flow in the inner cylinder from top to bottom; the materials flow in the annular cavity from top to bottom. According to the method, the contact time of the material and the catalyst in the whole hydrogenation reaction process can be effectively controlled, so that the temperature rise of a catalyst bed layer is more uniform, the problems of severe heat release and reaction conversion rate inhibition in the reaction process are solved, and higher hydrogenation reaction rate and conversion rate in the whole liquid-phase hydrogenation reaction process are achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

High-efficiency preparation process of epoxidized soybean oil

InactiveCN104946406AImprove reaction stabilitySufficient heat exchangeFatty acid oxidationHigh concentrationEpoxy

The invention discloses a high-efficiency preparation process of epoxidized soybean oil. According to the high-efficiency preparation process, a prepared high-concentration peroxyacetic acid and soybean oil are taken as the raw materials to directly have an epoxidation reaction in an external-circulation epoxidation reaction kettle; a high-concentration peroxycarboxylic acid is capable of increasing the reaction promotion power so that the epoxidation reaction rate can be greatly increased; besides, due to the use of the external-circulation epoxidation reaction kettle, the heat exchange of the materials during the reaction is thorough, the reaction stability is good, and the grease (soybean oil) can be dispersed into micro-droplets to form a large interphase mass transfer area; the high-concentration peroxycarboxylic acid is mixed with the raw material grease micro-droplets directly and strong, and therefore, the contact area is increased, the reaction rate is greatly increased and the epoxidation time is shortened (0.5-1.5h). According to the high-efficiency preparation process of the epoxidized soybean oil, the process and the reaction kettle are optimized, and due to the synergistic effect of the process and the reaction kettle, the reaction rate is greatly increased, the epoxidation reaction time is reduced and the energy consumption is reduced; besides, the product is low in ring-opening decomposition, few in byproducts and low in impurity content, and the technical indexes of the product such as the epoxy value meet the related national standard requirements.

Owner:JIAXING UNIV +2

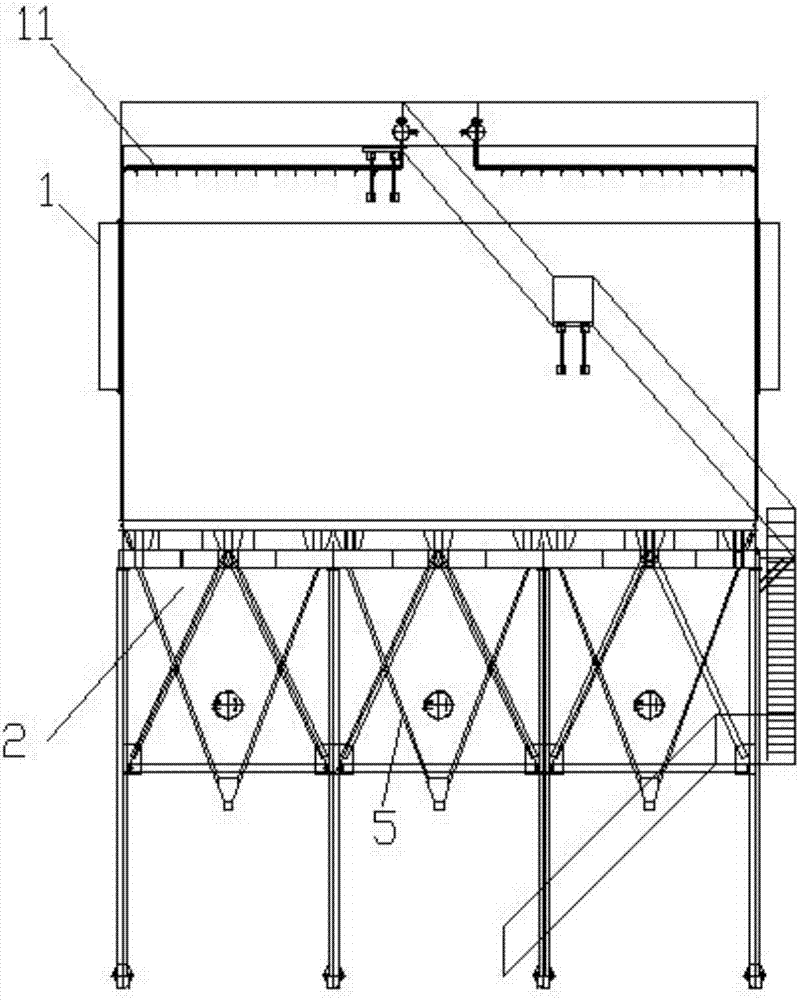

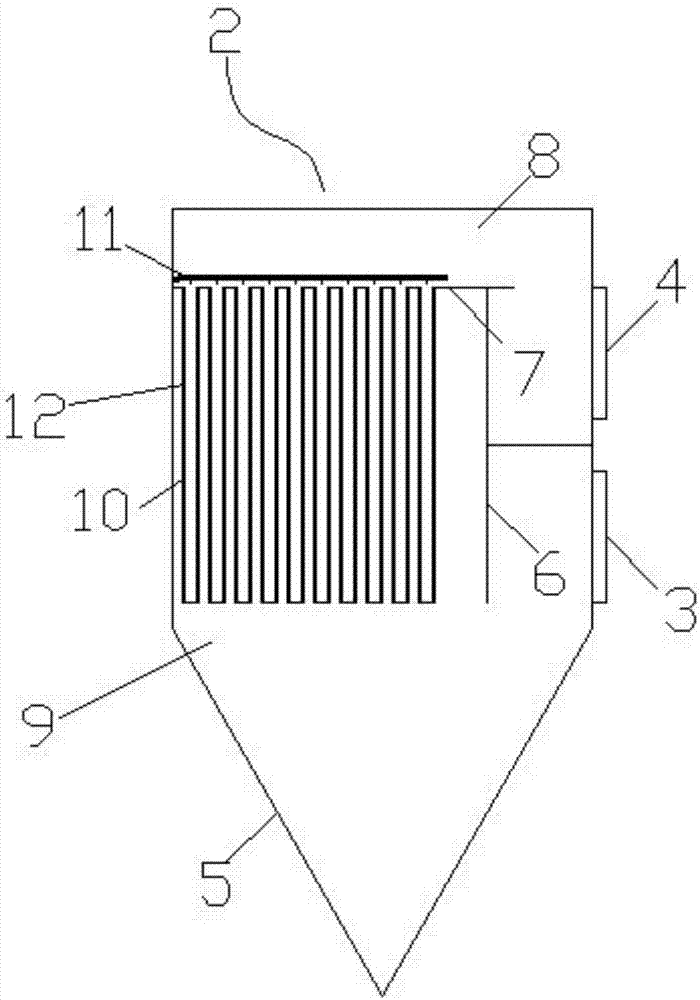

Combined type radial dust removal and denitration reactor

PendingCN106964213ASimple structureNovel structureGas treatmentDispersed particle filtrationThermodynamicsFlue gas

The invention discloses a combined type radial dust removal and denitration reactor. The combined type radial dust removal and denitration reactor comprises a reactor body, and is characterized in that a plurality groups of chambers for dust removal and denitration of flue gas are mounted in the reactor body; and each chamber is provided with a gas inlet and a gas outlet, the interior of each chamber is divided into an upper chamber and a lower chamber by a division plate and a horizontal pattern plate, the gas inlet is communicated with the lower chamber, the gas outlet is communicated with the upper chamber, a plurality of dust collecting cloth bags are arranged in the lower chamber, bag openings of the plurality of dust collecting cloth bags are buckled on the pattern plate, a soot blowing pipeline is mounted above the pattern plate, a radial denitration bed layer corresponding to the dust collecting cloth bags isalso arranged in the chamber, and the flue gas penetrates through the dust collecting cloth bags and the radial denitration bed layer sequentially in a radial flowing mode. The combined type radial dust removal and denitration reactor provided by the invention is simple and novel in structure, integrates a denitration device and a dust removal device, does not need to add a flue gas uniform distribution device, and reduces investment and equipment floor area while ensuring the denitration efficiency.

Owner:安徽晨晰洁净科技有限公司

Method for conversion of dry powder for synthesis of porous composite framework material

InactiveCN108689832AImprove adsorption capacityPromote absorptionOrganic compound preparationCarboxylic acid salt preparationOperational costsCarboxylic acid

The invention belongs to the technical field of preparation of porous composite materials, and provides a method for conversion of dry powder for synthesis of a porous composite framework material inorder to solve the problem in the prior art that a large amount of a solvent is used in the synthesis process of a porous composite framework material, yield is reduced, cost is increased and environmental pollution is increased. The method comprises the following steps: using metal salt or metal base as a coordinated metal source and using a carboxylic acid organic compound as a ligand; grinding,stirring and uniformly mixing the coordinated metal source and the ligand at room temperature to form a dry material; presetting a liquid phase at the bottom of a reaction kettle with the dry material in the container not directly contacting with the liquid phase; heating the reaction kettle, letting liquid vapor be contacted with the dry material to carry out a reaction, cooling and collecting asample in the container, and drying at room temperature to obtain a porous composite framework material. The method has advantages of zero emission of waste liquids, high yield, no washing, low operational cost, easy operation, low labor intensity, environmental protection and economic feasibility, and is easy to achieve large-scale intensive production. The obtained large granular composite framework material has higher adsorption capacity in terms of gas adsorption.

Owner:TAIYUAN UNIV OF TECH

Liquid-phase hydrogenation reactor and hydrogenation method thereof

ActiveCN112705122AEffective control of initial activityControl initial activityTreatment with hydrotreatment processesChemical/physical processesPtru catalystFluid phase

The invention discloses a liquid phase hydrogenation reactor and a hydrogenation method thereof. The liquid phase hydrogenation reactor comprises an inner cylinder and a reactor shell, the inner cylinder is conical, an annular cavity is formed between the inner cylinder and the reactor shell, and the cross section area of the annular cavity is gradually increased from bottom to top; the top of the inner cylinder penetrates through a upper seal head and is communicated with a material inlet at top of the reactor; a ceramic membrane nano / micron assembly is horizontally arranged in the middle of the reactor and is communicated with external hydrogen; the inner cylinder is filled with a hydrogenation catalyst I, the annular cavity is filled with a hydrogenation catalyst II, and the activity of the hydrogenation catalyst I is lower than that of the hydrogenation catalyst II; the material flows in the inner barrel from top to bottom; and the material flows in the annular cavity from bottom to top. According to the method, the initial activity of the liquid phase hydrogenation reaction can be effectively controlled through the internal structure of the reactor, the material flow mode and catalyst grading, and the later conversion rate of the reaction is increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

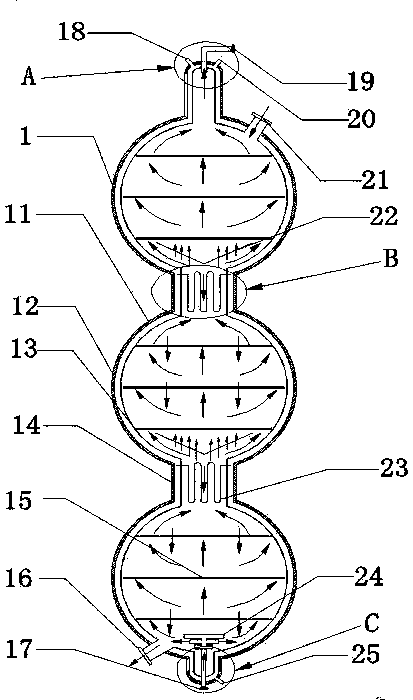

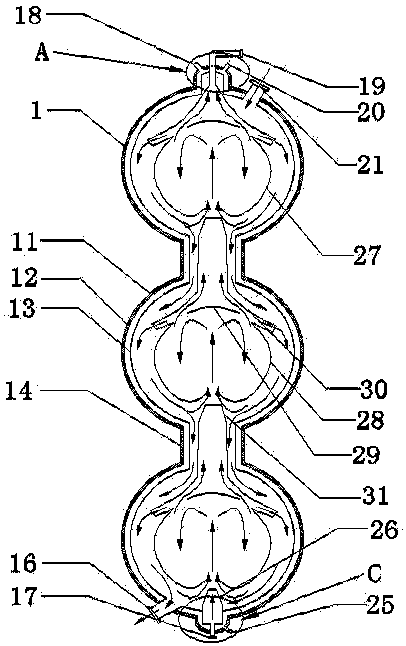

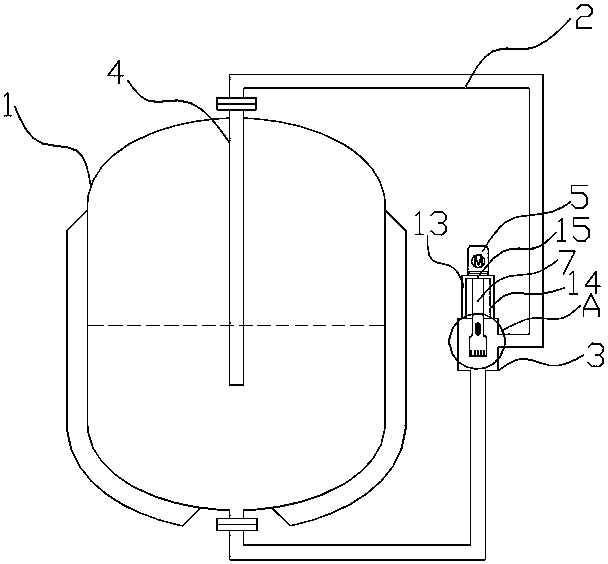

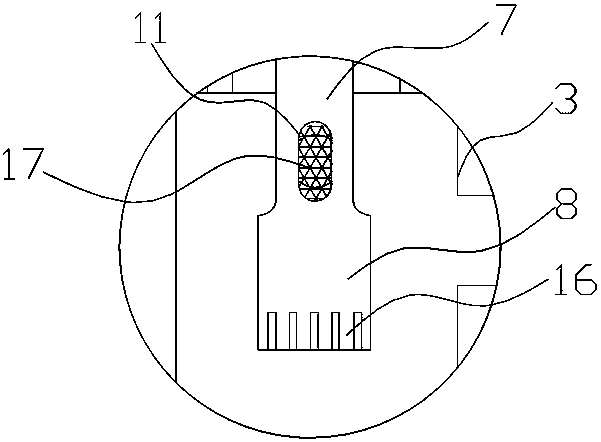

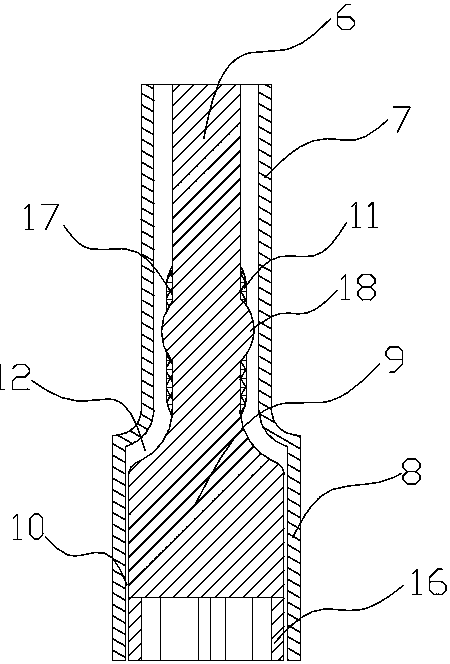

High-temperature and high-pressure slurry bed reaction device

ActiveCN107551961ASolve the problem of poor pressure bearing capacityImprove efficiencyChemical/physical processesVapor–liquid separatorCompound (substance)

The invention belongs to the technical field of chemical engineering, and discloses a high-temperature and high-pressure slurry bed reaction device which comprises a spherical serial reactor, a gas-liquid separator, a gas purifier, a membrane filter and the like. More than two spherical reactors are serially connected with each other by connecting barrels to form the spherical serial reactor. Thespherical serial reactor comprises inner containers and shells, the spherical reactors are connected with one another by the barrels, and internal components are arranged in the spherical serial reactor. The high-temperature and high-pressure slurry bed reaction device has the advantages of high pressure bearing capacity and gas-liquid-solid mass transfer efficiency, uniform gas-liquid distribution, capability of effectively promoting reaction and preventing catalyst accumulation, and the like.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Low water-air ratio and middle water-air ratio carbon monoxide (CO) conversion process

ActiveCN102002403BReduce dosageReduce energy consumptionCombustible gas catalytic treatmentMixed gasDepth conversion

The invention relates to a low water-air ratio and middle water-air ratio carbon monoxide (CO) conversion process. The process comprises the following steps of: (1) feeding raw gas into a pre-converter, wherein the temperature of the raw gas entering the inlet of the pre-converter is between 210 and 250 DEG C and the mole ratio of water to dried gas is 0.21 to 0.23; (2) feeding pre-converted mixed gas into a first converter to perform depth conversion, wherein the temperature of the pre-converted mixed gas entering the inlet of the first converter is between 260 and 290 DEG C and the mole ratio of water to dried gas is 0.8 to 1.0; (3) feeding the mixed gas passing through the first converter into a second converter, wherein the temperature of the mixed gas entering the inlet of the secondconverter is between 220 and 250 DEG C and the mole ratio of water to dried gas is 0.5 to 0.7; (4) feeding the mixed gas passing through the second converter into a third converter, wherein the temperature of the secondary conversion mixed gas entering the inlet of the third converter is between 205and 235 DEG C; and performing conversion on the mixed gas by using the third converter to obtain the mixed gas with the CO content lower than 0.40 percent. The process is unique and has the characteristics of high CO conversion rate, low energy consumption in the conversion process and the like.

Owner:CHINA PETROLEUM & CHEM CORP +2

A kind of high-efficiency preparation process of epoxidized soybean oil

InactiveCN104946406BImprove reaction stabilitySufficient heat exchangeFatty acid oxidationHigh concentrationEpoxy

The invention discloses a high-efficiency preparation process of epoxidized soybean oil. According to the high-efficiency preparation process, a prepared high-concentration peroxyacetic acid and soybean oil are taken as the raw materials to directly have an epoxidation reaction in an external-circulation epoxidation reaction kettle; a high-concentration peroxycarboxylic acid is capable of increasing the reaction promotion power so that the epoxidation reaction rate can be greatly increased; besides, due to the use of the external-circulation epoxidation reaction kettle, the heat exchange of the materials during the reaction is thorough, the reaction stability is good, and the grease (soybean oil) can be dispersed into micro-droplets to form a large interphase mass transfer area; the high-concentration peroxycarboxylic acid is mixed with the raw material grease micro-droplets directly and strong, and therefore, the contact area is increased, the reaction rate is greatly increased and the epoxidation time is shortened (0.5-1.5h). According to the high-efficiency preparation process of the epoxidized soybean oil, the process and the reaction kettle are optimized, and due to the synergistic effect of the process and the reaction kettle, the reaction rate is greatly increased, the epoxidation reaction time is reduced and the energy consumption is reduced; besides, the product is low in ring-opening decomposition, few in byproducts and low in impurity content, and the technical indexes of the product such as the epoxy value meet the related national standard requirements.

Owner:JIAXING UNIV +2

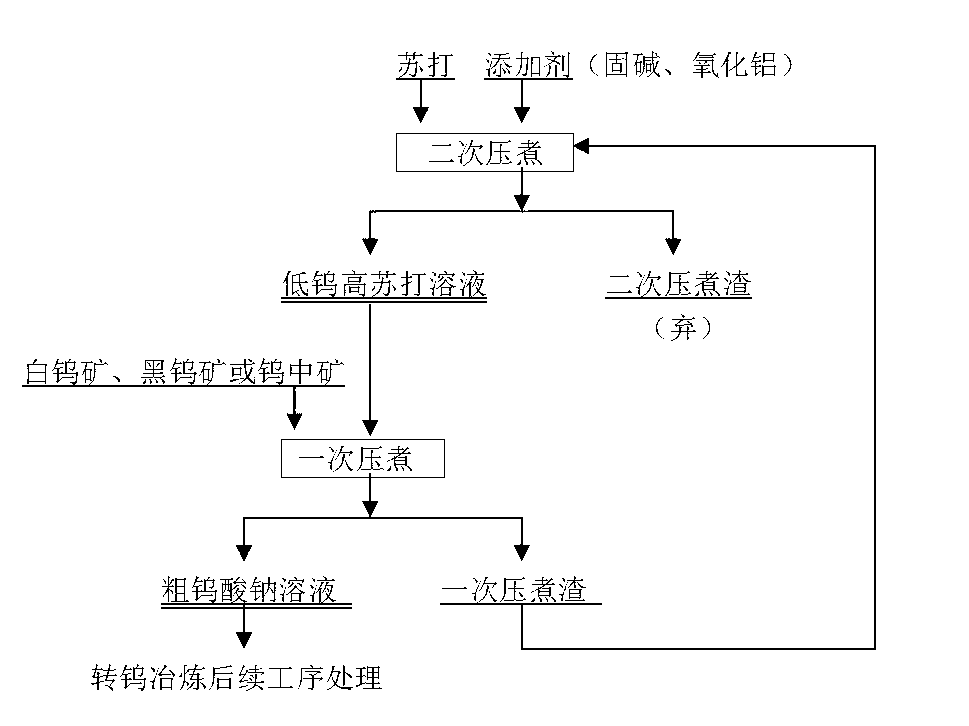

Method for extracting tungsten from tungsten mineral by using soda and adopting high-pressure leaching process

ActiveCN102747223BImprove decomposition rateReduce excess factorProcess efficiency improvementSlagTungstate

The invention discloses a method for extracting tungsten from tungsten mineral by using soda and adopting high-pressure leaching process, comprising the following steps: adding soda and additives into primary tungsten autoclaving slag, carrying out secondary autoclaving at high temperature and pressure; separating the leaching solution from the slag; carrying out primary autoclaving to the tungsten by the leaching solution; separating the primary autoclaving slag from the crude sodium tungstate solution, wherein the primary autoclaving slag is used as the raw material; and mixing the tungstate with the secondary autoclaving leaching solution to prepare slurry. The liquid-solid ratio is controlled to be (3-5):1 in the step of adding the soda and the additives into the primary autoclaving slag and mixing to prepare the slurry, and the soda has the excess coefficient of 2.0-2.5. The liquid-solid ratio is controlled to be (3-5):1 in the step of mixing the tungstate with the secondary autoclaving leaching solution to prepare the slurry. The primary autoclaving temperature and the secondary autoclaving temperature are both 170-240 DEG C, the primary autoclaving pressure and the secondary autoclaving pressure are both 0.9-2.8MPa, and the primary autoclaving time and the secondary autoclaving time are both 2-4 hours. The additives are solid caustic soda and alumina. The method adopts the soda to autoclave the tungsten mineral to extract tungsten at counterflow by using soda at high pressure, so that the leaching rate of the tungsten mineral is more than 99%, the content of WO3 in the tungsten slag is less than 1.0%, the use amount of soda is reduced, and the content of soda in the leaching solution is reduced effectively.

Owner:江西省修水赣北钨业有限公司

A kind of liquid phase hydrogenation reactor and hydrogenation method

ActiveCN112705122BEffective control of initial activityControl initial activityTreatment with hydrotreatment processesChemical/physical processesPtru catalystFluid phase

Owner:CHINA PETROLEUM & CHEM CORP +1

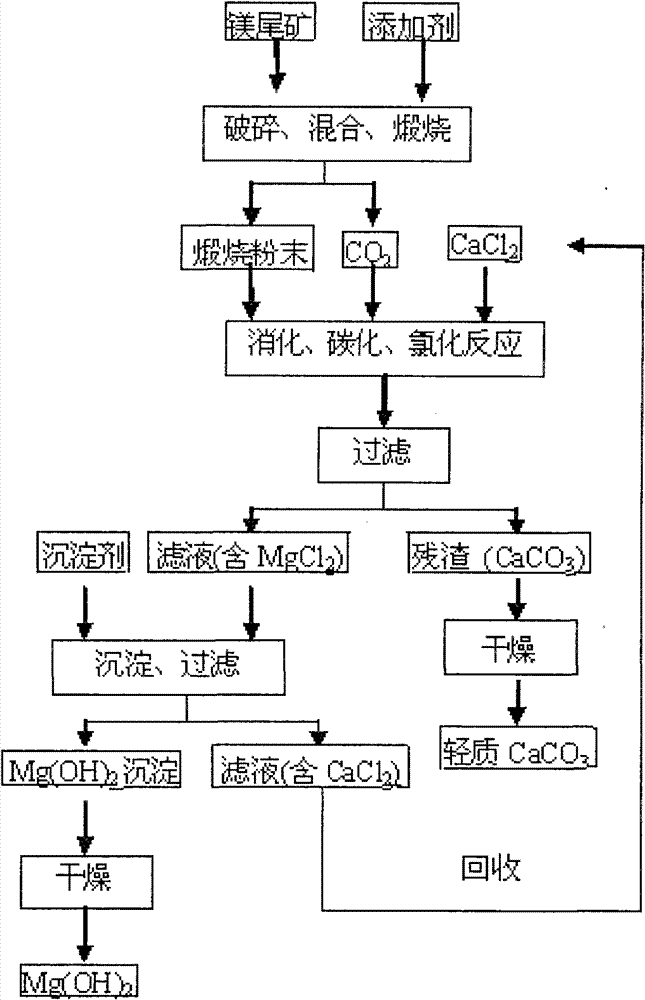

Method for preparing light calcium carbonate and magnesium hydroxide from magnesium tailings

InactiveCN101857258BPromote decompositionSolve pollutionCalcium/strontium/barium carbonatesSolid waste disposalCarbonizationMagnesium carbonate hydroxide

The invention discloses a method for preparing light calcium carbonate and magnesium hydroxide from magnesium tailings. A raw material is the magnesium tailings contain 18 to 36 weight percent of calcium oxide. The method comprises the following steps of: crushing and calcining the magnesium tailings to obtain calcined powder and CO2; performing digestion, carbonization and chlorination reaction on the calcined powder and the CO2 in the CO2 atmosphere under the condition of stirring so as to obtain MgCl2-containing solution and light CaCO3 precipitate; and reacting MgCl2 with a precipitator to generate Mg(OH)2 precipitate. In the method, the light calcium carbonate and magnesium hydroxide are prepared from the magnesium tailings discharged in a large quantity and other raw materials so asto solve the problem of environmental pollution and fulfill the aim of fully utilizing calcium and magnesium resources.

Owner:NORTHEASTERN UNIV LIAONING

A liquid phase hydrogenation reactor and hydrogenation process

ActiveCN112705117BControl contact timeControl temperature riseTreatment with hydrotreatment processesChemical/physical processesPtru catalystFluid phase

The invention discloses a liquid-phase hydrogenation reactor and a hydrogenation process, comprising an inner cylinder and a reactor shell, the inner cylinder is conical, the top and bottom of the inner cylinder are open, the bottom edge is tightly connected with the inner wall of the reactor, and the inner cylinder is open. A number of small holes are opened on the cylinder wall; a ceramic membrane tube bundle is vertically arranged on the axial direction of the reactor, and the ceramic membrane tube bundle communicates with external hydrogen; the inner cylinder is filled with hydrogenation catalyst I, the annular cavity is filled with hydrogenation catalyst II, and hydrogenation catalyst I The activity of the catalyst is higher than that of the hydrogenation catalyst II; the inlet of the raw material of the reactor is connected to the top of the inner cylinder; the flow mode of the material in the inner cylinder is from top to bottom; the flow mode of the material in the annular cavity is from top to bottom. The invention can effectively control the contact time between the material and the catalyst in the whole process of the hydrogenation reaction, make the temperature rise of the catalyst bed more uniform, solve the problems of severe exotherm and inhibit the reaction conversion rate in the reaction process, and realize the whole liquid phase hydrogenation reaction process Both achieve higher hydrogenation reaction rate and conversion.

Owner:CHINA PETROLEUM & CHEM CORP +1

Device and method for simultaneous short-range nitrification and denitrification phosphorus removal based on hydroxylamine to treat urban sewage

ActiveCN108128897BReduce aerationCarbon savingTreatment with aerobic and anaerobic processesHydroxylamineNitration

A device and method for realizing synchronous short-range nitrification and denitrification phosphorus removal to treat urban sewage based on hydroxylamine belongs to the field of biological treatment of urban domestic sewage. The domestic sewage enters the synchronous short-range nitrification and denitrification phosphorus removal reactor through the inlet pump. In the synchronous short-cut nitrification and denitrification phosphorus removal reactor, the phosphorus accumulating bacteria make full use of the carbon source in the raw water to release phosphorus during anaerobic stirring; the stable short-cut nitrification is achieved by adding hydroxylamine under aerobic conditions; Phosphorous bacteria use nitrite nitrogen as an electron acceptor to absorb phosphorus in water and reduce nitrite nitrogen to nitrogen gas. Compared with the traditional nitrogen and phosphorus removal process, this process saves carbon source and aeration.

Owner:BEIJING UNIV OF TECH

No cycle methanation system

ActiveCN104312651BTemperature controlEasy temperature controlGaseous fuelsMethanationProcess engineering

The invention discloses a circulation-free methanation system which comprises a gas distribution methanation stage and a supplementation methanation stage, wherein in the gas distribution methanation stage, 1 to 3 stages of serially connected high-temperature reactors are adopted; in the supplementation methanation stage, 2 to 3 stages of serially connected low and medium-temperature reactors are adopted; the final-stage reactor in the gas distribution methanation stage is connected in series with the head-stage reactor in the supplementation methanation stage; technical gas discharged by the former stage of the reactor is used as part of or all the synthesized gas of the next stage of the reactor; technical gas discharged by the final-stage reactor is subjected to cooling separation to obtain a final methane product. The technical system is simple, and the reaction is steady, safe and reliable; the running cost and the manufacturing cost are low.

Owner:BEIJING HUAFU ENG +2

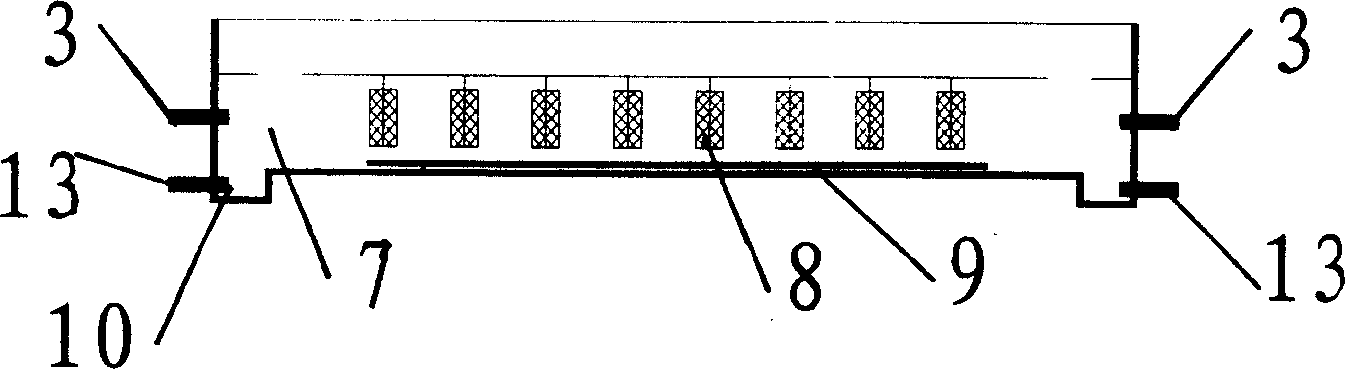

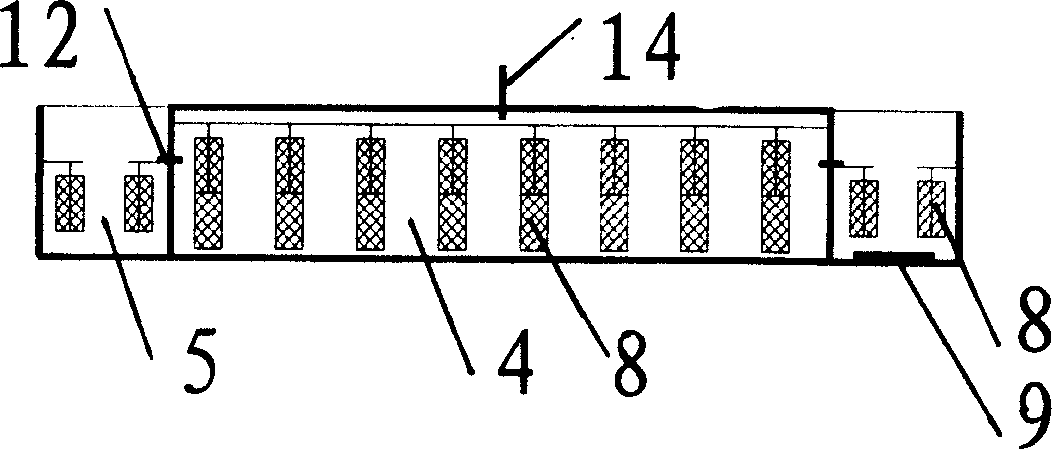

Novel SCR (Selective Catalytic Reduction) denitration reactor

PendingCN107335389AHigh mechanical strengthReduce dosageDispersed particle separationChemical/physical processesPtru catalystPhysical chemistry

The invention discloses a novel SCR (Selective Catalytic Reduction) denitration reactor which comprises a reactor body, wherein a plurality layers of pattern plates are arranged in parallel inside the reactor body; a plurality of catalyst cages are uniformly arranged on each layer of the pattern plate; the upper ends of the catalyst cages are arranged on the pattern plates in an upside down manner; the lower ends of the catalyst cages are positioned below the pattern plates; the catalyst cages take the shape of a column; the parts between the inner walls and the outer walls of the catalyst cages are filled with a granular denitration catalyst; the inner walls and the outer walls of the catalyst cages are of steel wire net structures; the bottom ends of the catalyst cages are of airtight plate structures; a manhole gate is arranged on a side wall below each layer of the pattern plate, of the reactor body. The novel SCR denitration reactor is simple and novel in structure, the facility investment is reduced, the problem of reducing operation cost and the like is solved, and the resource utilization rate is increased.

Owner:安徽晨晰洁净科技有限公司

Device and method for quick start and stable maintenance of short-cut nitrification/ANAMMOX integration based on hydroxylamine

ActiveCN108178302BHigh activityNo swellingTreatment with aerobic and anaerobic processesHydroxylamineNitration

The short-range nitrification / anammox integration device and method based on quick start and stable maintenance of hydroxylamine belong to the field of biological treatment of urban domestic sewage. For the short-cut nitrification / anammox integrated process, the stable operation of short-cut nitrification and the matching anammox bacteria activity are very important, but it is difficult to quickly start and stably maintain the city by only controlling the process parameters For short-range nitrification / anammox operation of sewage, this patent can achieve the effect of inhibiting the activity of nitrite oxidizing bacteria and improving the activity of anammox by adding hydroxylamine (HA), and start the integration in a short period of time The short-cut nitrification / anammox reactor maintains a good treatment effect. Compared with the traditional nitrification-denitrification denitrification process, the short-cut nitrification / anammox integrated process saves aeration, reduces sludge production, and saves carbon sources, especially suitable for low C / N urban domestic sewage.

Owner:BEIJING UNIV OF TECH

System and method for conducting deep denitrification processing on medium-term landfill leachate

ActiveCN102557254BSimple structureBig reaction forceTreatment with aerobic and anaerobic processesSequencing batch reactorNitration

The invention provides a system and a method for conducting deep denitrification processing on medium-term landfill leachate. A dissolved oxygen (DO) sensor and an oxidation reduction potential (ORP) sensor are respectively connected with a DO tester and an ORP tester, the DO tester, the ORP tester and an aeration mechanism are all connected with a transducer, the ORP tester, the DO tester and the transducer are all connected with a process controller through a computer, and the process controller is respectively connected with a stirring mechanism, a water inlet mechanism, a water outlet mechanism and the aeration mechanism. The steps of applying the processing method of the system are sequentially injecting waste water in a sequencing batch reactor (SBR) and starting the system, enabling the aeration mechanism and the stirring mechanism to conduct nitration, starting the stirring mechanism to conduct denitrification, sediment, dewatering and leaving unused, and enabling the computerto judge the set value of cycle times. The system and the method can solve processing problems of the medium-term landfill leachate, improve use ratio of an organic carbon source in raw water in a processing process, and achieve deep denitrification with low processing cost.

Owner:BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com