High-efficiency preparation process of epoxidized soybean oil

A technology for the preparation of epoxidized soybean oil, which is applied in the field of high-efficiency preparation of epoxidized soybean oil, can solve the problems of many by-products, poor process stability, and short reaction time, and achieve good reaction stability and less ring-opening decomposition , the effect of reducing the reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Preparation of high-concentration peracetic acid: add concentrated sulfuric acid to glacial acetic acid, stir evenly, add hydrogen peroxide solution with a concentration of 30% by mass, stir well, and let stand at room temperature for 24 hours to obtain high-concentration peroxygen Acetic acid mixture, wherein the mass ratio of glacial acetic acid, concentrated sulfuric acid and hydrogen peroxide solution is 100:10:25;

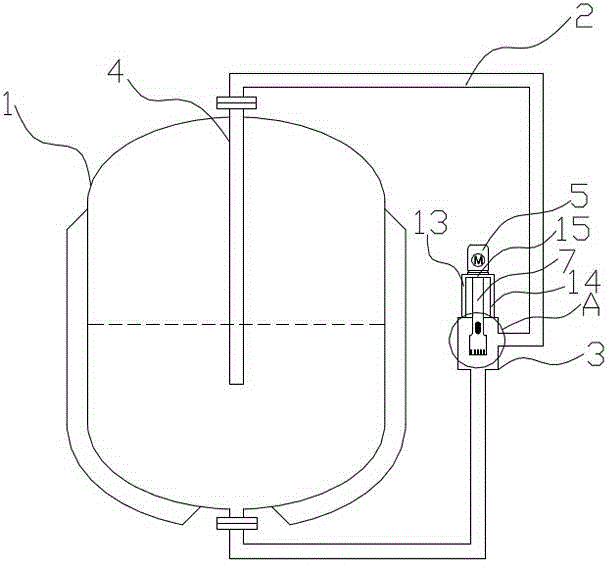

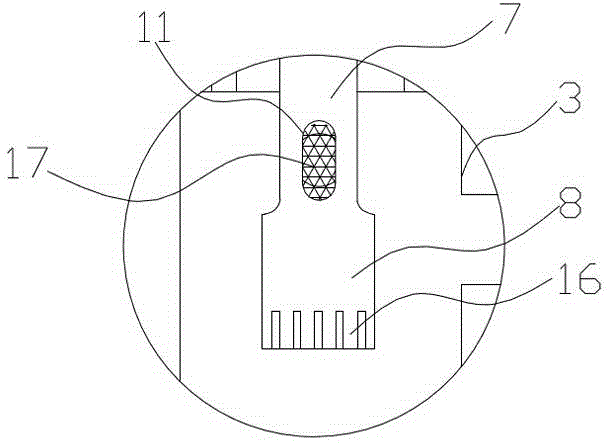

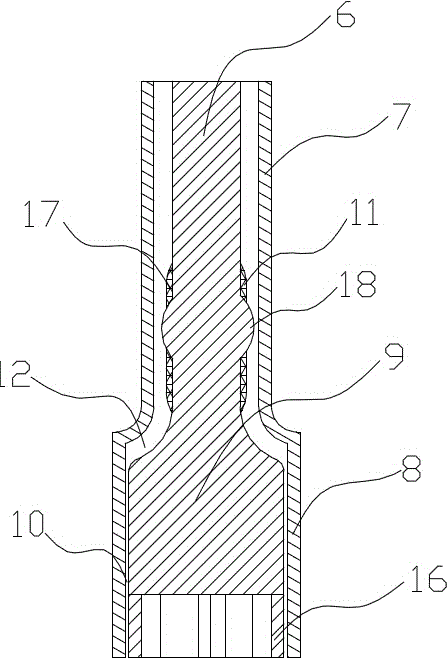

[0030] (2) Epoxidation reaction: Add the high-concentration peracetic acid solution and soybean oil in step (1) into the external circulation oxidation reaction kettle in sequence, the mass ratio of high-concentration peracetic acid solution and soybean oil is 1.5:1, Heating to 60 oC, heat preservation reaction for 1.5 hours, to obtain the crude epoxy soybean oil, continuous shear emulsification during heat preservation;

[0031] (3) Purification and refining: the epoxidized soybean oil in step (2) is washed with water to remove the acid until the p...

Embodiment 2

[0034] (1) Preparation of high-concentration peracetic acid: add concentrated sulfuric acid to formic acid, stir evenly, add hydrogen peroxide solution with a concentration of 40% by mass, stir well, and let stand at room temperature for 30 hours to obtain high-concentration peracetic acid Mixed solution, wherein the mass ratio of formic acid, concentrated sulfuric acid and hydrogen peroxide solution is 90:10:30;

[0035] (2) Epoxidation reaction: add the high-concentration peracetic acid solution and soybean oil in step (1) into the external circulation oxidation reaction kettle in sequence, the mass ratio of high-concentration peracetic acid solution and soybean oil is 1.8:1, Heating to 65 oC, heat preservation reaction for 1 hour, to obtain the crude product of epoxy soybean oil, continuous shear emulsification during heat preservation;

[0036] (3) Purification and refinement: the epoxidized soybean oil in step (2) is washed with water to remove the acid until the pH value...

Embodiment 3

[0039] (1) Preparation of high-concentration peracetic acid: add concentrated sulfuric acid to glacial acetic acid, stir evenly, add hydrogen peroxide solution with a concentration of 60% by mass, stir well, and let stand at room temperature for 72 hours to obtain high-concentration peroxygen Acetic acid mixture, wherein the mass ratio of glacial acetic acid or formic acid, concentrated sulfuric acid and hydrogen peroxide solution is 80:10:50;

[0040] (2) Epoxidation reaction: add the high-concentration peracetic acid solution and soybean oil in step (1) into the external circulation oxidation reaction kettle in sequence, the mass ratio of high-concentration peracetic acid solution and soybean oil is 2:1, Heating to 75 o C, heat preservation reaction for 0.5 hours, to obtain the crude epoxy soybean oil, continuous shear emulsification during heat preservation;

[0041] (3) Purification and refining: the epoxidized soybean oil in step (2) is washed with water to remove the aci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com