Low water-air ratio and middle water-air ratio carbon monoxide (CO) conversion process

A water-gas ratio and process technology, applied in the field of CO shift process, can solve the problems of short service life of pre-shift catalyst, hydrogen consumption in the methanation section, and large number of shift furnaces or reaction sections, so as to achieve stable steam parameters in the pipe network and reduce shift The number of furnace or shift reaction stages, the effect of low water-to-gas ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

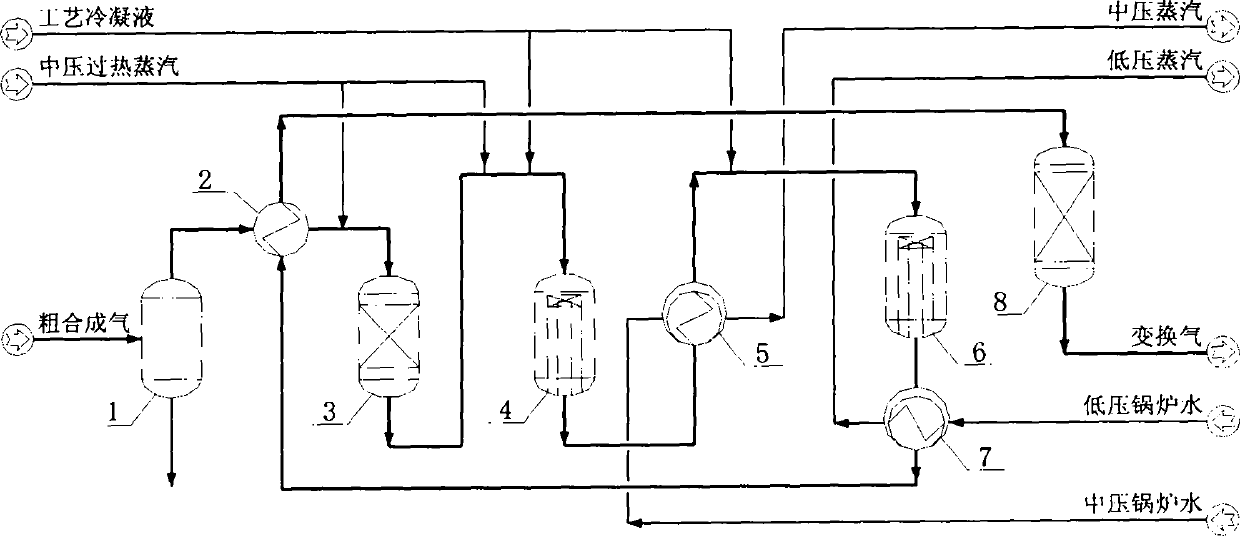

[0031] As shown in Figure 1, the CO conversion process of this embodiment is as follows:

[0032] ①The raw gas saturated with water vapor sent from the pulverized coal gasification section has a temperature of 160°C and a pressure of 3.7Mpa. Due to heat loss during the process of sending the crude gas from the gasification section to the transformation section through pipelines, a small amount of crude gas Water vapor will be condensed to form condensate, and the coexistence of crude gas and condensate in the pipeline system will cause corrosion and vibration of pipelines and equipment, so the condensate in the crude gas needs to be separated before entering the pre-shift furnace, so this implementation For example, the crude gas is first sent into the gas-liquid separator 1, and the liquid flows out from the bottom outlet of the gas-liquid separator 1. The liquid-separated crude gas coming out from the top of the gas-liquid separator 1 is sent to the pre-shift furnace 3 after...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com