Calcification roasting clinker counter-flow acid pickling vanadium extracting method

A technology of calcification roasting and countercurrent acid is applied in the direction of improving process efficiency, which can solve the problems of low vanadium extraction rate and low vanadium product quality, and achieve the effects of high concentration, fast and efficient leaching, and high vanadium product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

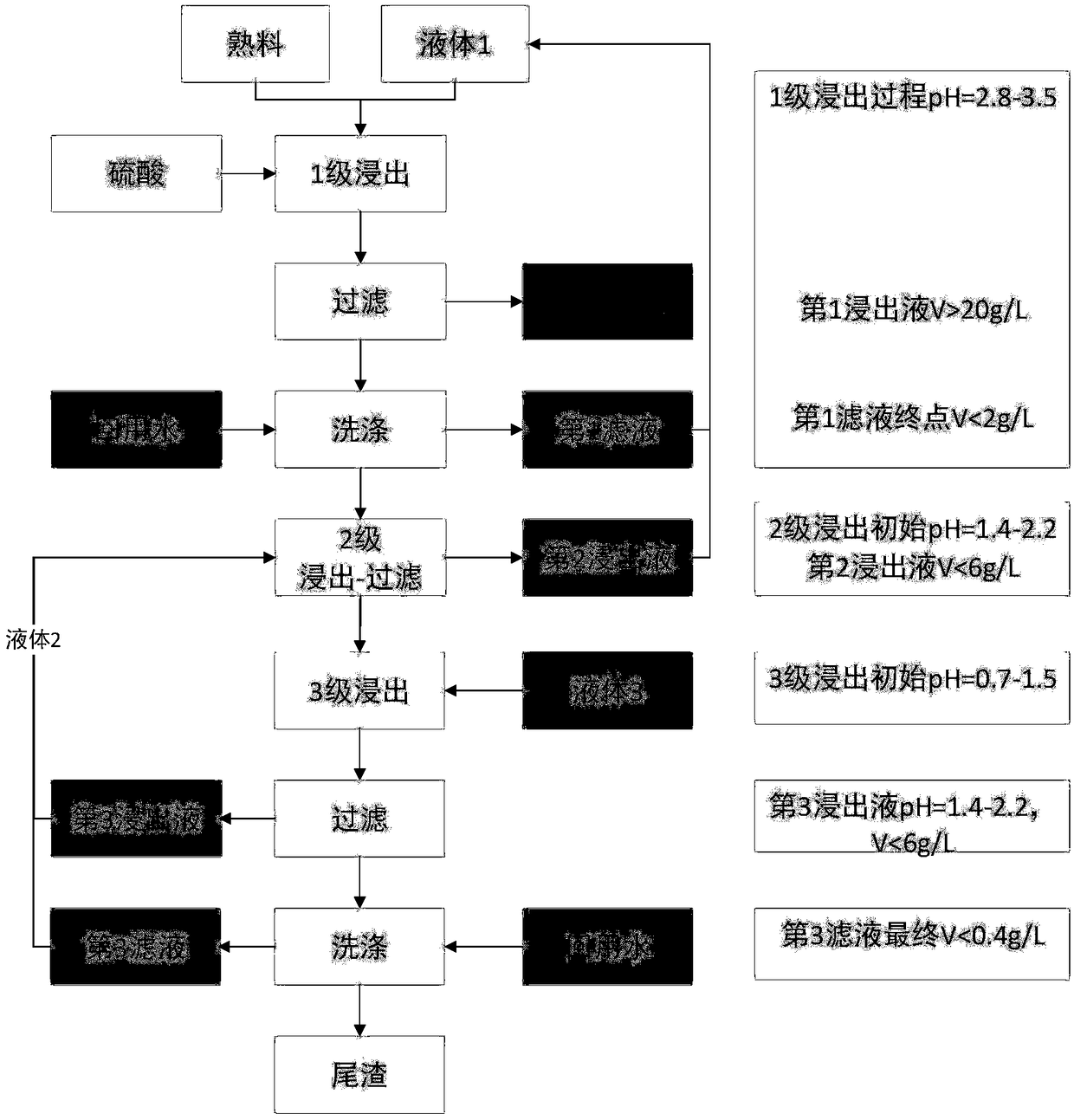

[0045] First-stage leaching: Add 200 g of calcified roasted clinker (TV=8.66%) to the mixed solution of pH=2.6, 150 mL of the first-stage filtrate and 350 mL of the second-stage leaching liquid, and use sulfuric acid to control the system pH=2.8-3.0 under stirring conditions , control the temperature at 50°C and leaching for 45 minutes, filter the first-stage leachate and filter residue, measure TV=33.87g / L, P=0.02g / L in the first-stage leachate, the pH of the first-stage leachate is 3.1; =7 times of washing with water, the pH of the first stage filtrate is 3.5;

[0046] Second-stage leaching: After washing, the filter residue is leached with the mixed solution of the third-stage leachate + third-stage filtrate with a pH of 1.42, and filtered to obtain the second-stage leachate with pH = 2.5;

[0047] The third stage leaching: add the filter residue to pH=0.7, 200mL reuse water for leaching the third stage leaching, stir and react for 10 minutes and then filter, the pH of the ...

Embodiment 2

[0050] The first stage leaching: to pH = 2.8, the first stage filtrate 12m 3 and the second level leachate 6m 3 Add 6t of calcified roasted clinker (TV=8.66%) to the mixed solution, control the system pH=2.8-3.0 with sulfuric acid under stirring conditions, control the temperature at 41°C for 60 minutes, and filter to obtain the first-stage leachate and filter residue. TV=32.67g / L, P=0.02g / L in the first-stage leachate, the pH of the first-stage leachate is 3.05; the filter residue is washed with reused water at pH=6.78, and the pH of the first-stage filtrate is 3.41;

[0051] Second-stage leaching: After washing, the filter residue is leached with a third-stage leachate with a pH of 1.6, and filtered to obtain a second-stage leachate with a pH of 2.7;

[0052] The third stage leaching: filter residue is added to pH=1.4, 7m 3 The third-stage leaching was carried out with recycled water, and the pH of the third-stage leachate was 1.6 after stirring and reacting for 10 minutes...

Embodiment 3

[0055] The first stage leaching: to pH = 2.7, the first stage filtrate 12m 3 and the second level leachate 6m 3 Add 6.5t of calcified roasted clinker (TV=8.12%) to the mixed solution, use sulfuric acid to control the system pH=2.8-3.0 under stirring conditions, and control the temperature to 56°C for 60 minutes of leaching, and filter to obtain the first-stage leachate and filter residue, measured TV=34.35g / L, P=0.02g / L in the first-stage leachate, the pH of the first-stage leachate is 2.94; the filter residue is washed with pH=7 reuse water, and the pH of the first-stage filtrate is 2.98;

[0056] Second-stage leaching: After washing, the filter residue is leached with a third-stage leachate with a pH of 1.45, and filtered to obtain a second-stage leachate with a pH of 2.5;

[0057] The third stage leaching: filter residue is added to pH=1.0, 7m 3The third-stage leaching was carried out with reused water, stirred and reacted for 7 minutes, and then filtered. The pH of the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com