High-concentration vanadium electrolyte and preparation method thereof

An electrolyte and high-concentration technology, used in regenerative fuel cells and other directions, can solve problems such as restricting specific energy, and achieve the effects of high total vanadium concentration, good stability and electrochemical activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0020] Explanation: In the examples described below, SA represents a kind of sulfonic acid, and the sulfonic acid used is methanesulfonic acid.

[0021] Example 1 VO(SA) 2 Preparation: Weigh an appropriate amount of sulfonic acid and V 2 o 5 . , put the sulfonic acid in a small beaker and add appropriate amount of distilled water, put V 2 o 5 into the solution, gradually adding oxalic acid until V 2 o 5 Completely dissolved, VO(SA) up to 4.5mol / L can be configured 2 solution.

[0022] With 100ml4.5mol / L VO(SA) 2 .

[0023] ① Weigh V 2 o 5 41.0g.

[0024] ② Take sulfonic acid and add a small amount of distilled water to a 250ml beaker.

[0025] ③The weighed V 2 o 5 Add all to ② beaker.

[0026] ④ Add oxalic acid and stir until V 2 o 5 Dissolve completely.

[0027] ⑤ Add distilled water to make up to 100ml. Serve.

Embodiment 2

[0028] Embodiment 2 Negative electrode liquid V (SA) 3 Preparation: Add appropriate amount of VO(SA) to the positive and negative chambers in the electrolytic cell 2 , electrolysis was carried out at an appropriate current density. After electrolysis for a suitable time, the negative electrode solution V(SA) is obtained in the negative electrode cavity 3 . V(SA) up to 4.0mol / L can be obtained 3 .

[0029] Prepare 3mol / LV(SA) 3 .

[0030] Electrolyte: 3mol / LVO(SA) 2 , 25ml;

[0031] Current: 300mA

[0032] Electrolysis time: 10h.

[0033] As in the above experiment, the negative electrode liquid is 3mol / LV(SA) in the negative electrode cavity 3

Embodiment 3

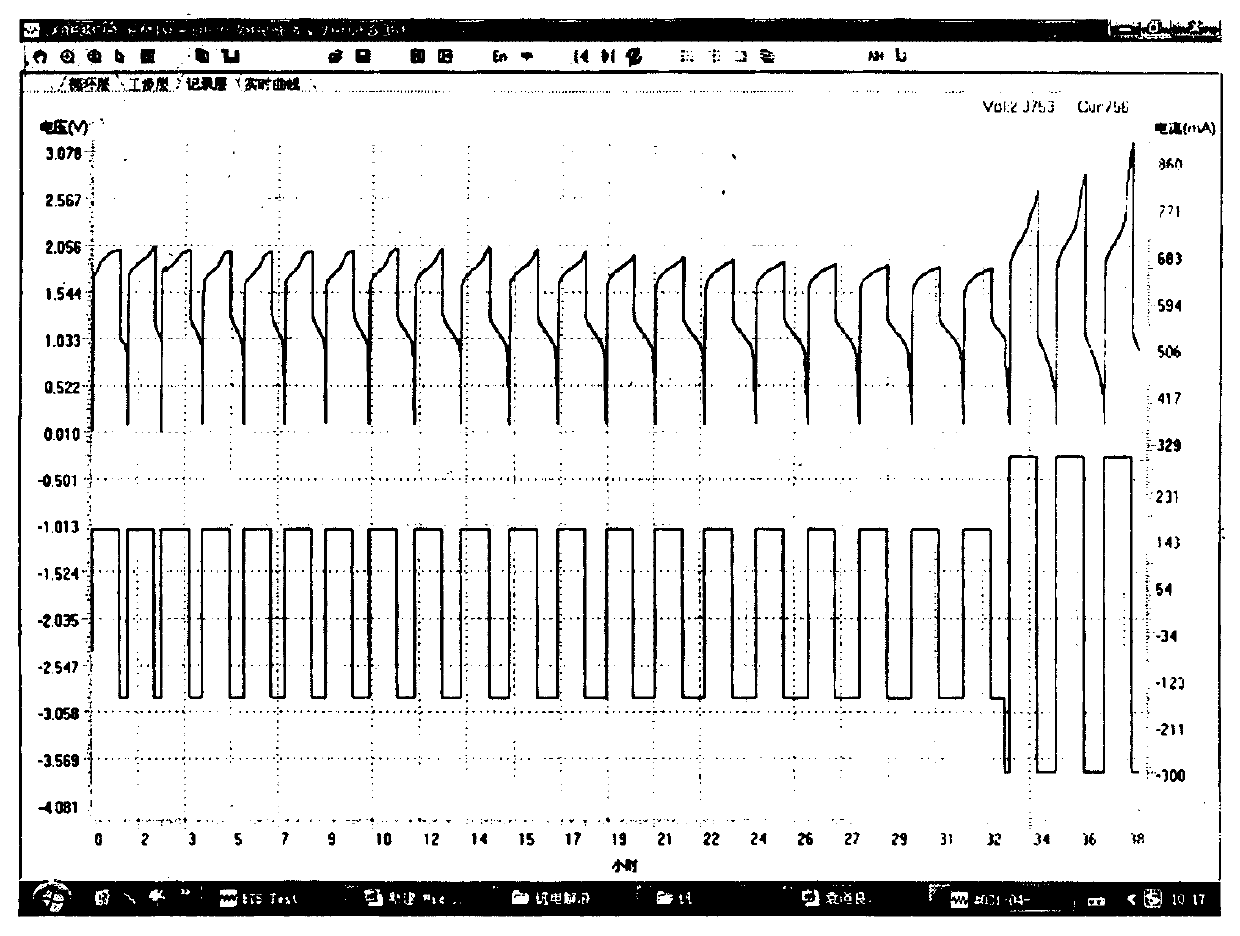

[0034] Embodiment 3 All-vanadium battery: the battery separates the positive and negative electrode chambers with a cation exchange membrane, the positive and negative electrode materials are carbon felt, and the positive electrode solution is 3mol / LVO (SA) 2 , the negative electrode solution is 3mol / LVO(SA) 2 . Charge and discharge current 200mA, time 1 hour. The highest charging voltage is 2.0V. The highest discharge voltage is 1.3V, and the discharge time above 1V can reach 32min., and the discharge time above 0.1V can reach 50min. in one cycle. Charge and discharge performance such as figure 1 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com