Method for extracting vanadium from calcified roasted clinker with countercurrent acid leaching

A technology of calcification roasting and countercurrent acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

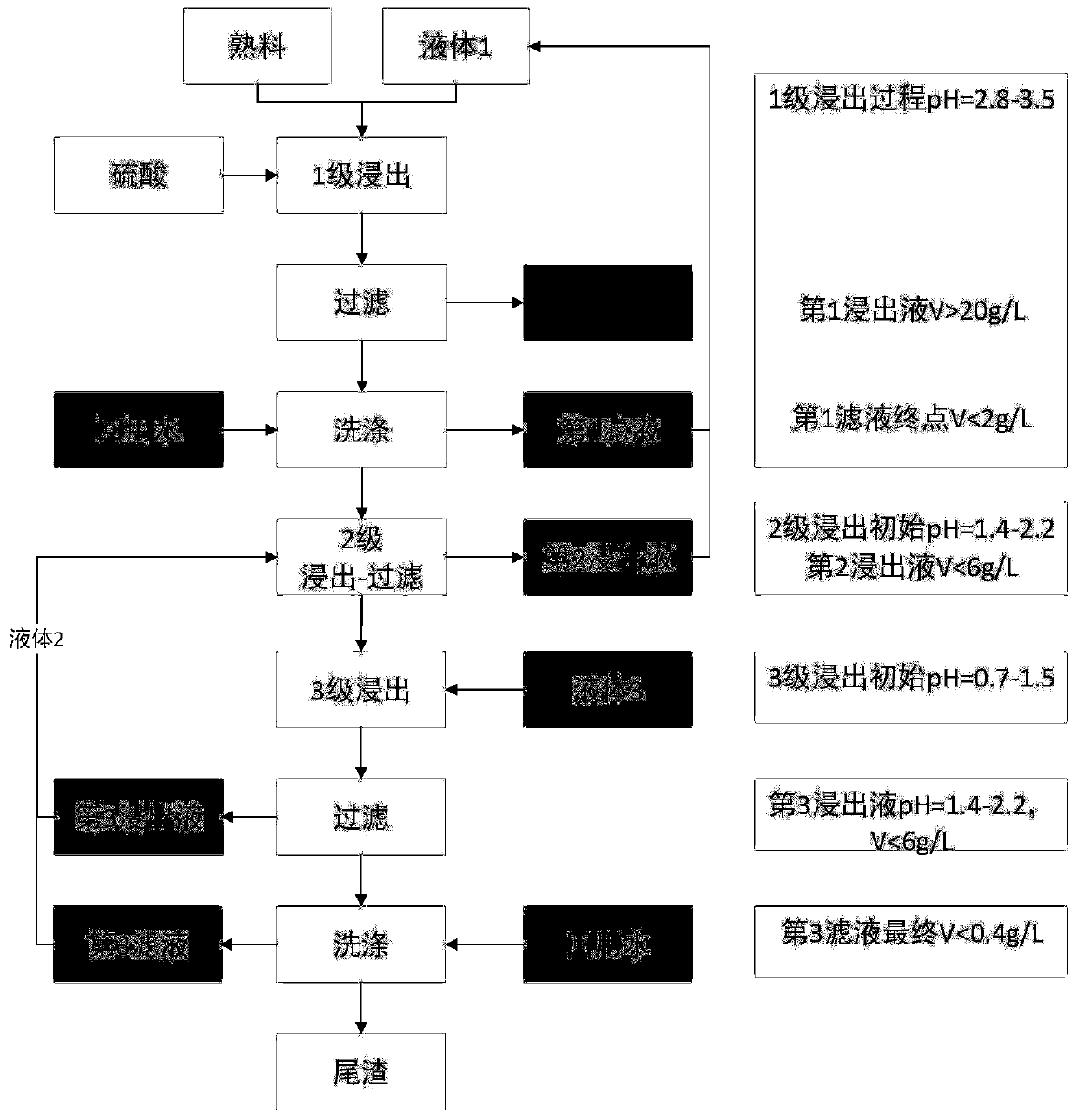

Method used

Image

Examples

Embodiment 1

[0045] First-stage leaching: Add 200 g of calcified roasted clinker (TV=8.66%) to the mixed solution of pH=2.6, 150 mL of the first-stage filtrate and 350 mL of the second-stage leaching liquid, and use sulfuric acid to control the system pH=2.8-3.0 under stirring conditions , control the temperature at 50°C and leaching for 45 minutes, filter the first-stage leachate and filter residue, measure TV=33.87g / L, P=0.02g / L in the first-stage leachate, the pH of the first-stage leachate is 3.1; =7 times of washing with water, the pH of the first stage filtrate is 3.5;

[0046] Second-stage leaching: After washing, the filter residue is leached with the mixed solution of the third-stage leachate + third-stage filtrate with a pH of 1.42, and filtered to obtain the second-stage leachate with pH = 2.5;

[0047] The third stage leaching: add the filter residue to pH=0.7, 200mL reuse water for leaching the third stage leaching, stir and react for 10 minutes and then filter, the pH of the ...

Embodiment 2

[0050] The first stage leaching: to pH = 2.8, the first stage filtrate 12m 3 and the second level leachate 6m 3 Add 6t of calcified roasted clinker (TV=8.66%) to the mixed solution, control the system pH=2.8-3.0 with sulfuric acid under stirring conditions, control the temperature at 41°C for 60 minutes, and filter to obtain the first-stage leachate and filter residue. TV=32.67g / L, P=0.02g / L in the first-stage leachate, the pH of the first-stage leachate is 3.05; the filter residue is washed with reused water at pH=6.78, and the pH of the first-stage filtrate is 3.41;

[0051] Second-stage leaching: After washing, the filter residue is leached with a third-stage leachate with a pH of 1.6, and filtered to obtain a second-stage leachate with a pH of 2.7;

[0052] The third stage leaching: filter residue is added to pH=1.4, 7m 3 The third-stage leaching was carried out with recycled water, and the pH of the third-stage leachate was 1.6 after stirring and reacting for 10 minutes...

Embodiment 3

[0055] The first stage leaching: to pH = 2.7, the first stage filtrate 12m 3 and the second level leachate 6m 3 Add 6.5t of calcified roasted clinker (TV=8.12%) to the mixed solution, use sulfuric acid to control the system pH=2.8-3.0 under stirring conditions, and control the temperature to 56°C for 60 minutes of leaching, and filter to obtain the first-stage leachate and filter residue, measured TV=34.35g / L, P=0.02g / L in the first-stage leachate, the pH of the first-stage leachate is 2.94; the filter residue is washed with pH=7 reuse water, and the pH of the first-stage filtrate is 2.98;

[0056] Second-stage leaching: After washing, the filter residue is leached with a third-stage leachate with a pH of 1.45, and filtered to obtain a second-stage leachate with a pH of 2.5;

[0057] The third stage leaching: filter residue is added to pH=1.0, 7m 3The third-stage leaching was carried out with recycled water, stirred and reacted for 7 minutes, and then filtered, the pH of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com