Preparation method for diacetylmonoxime

A technology of methyl ethyl ketone oxime and methyl ethyl ketone, which is applied in the field of chemical process, can solve the problems of low utilization rate of hydroxylamine sulfate, low product yield, high content of butanone, etc., and achieves easy operation and control, good mass transfer condition and long residence time short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

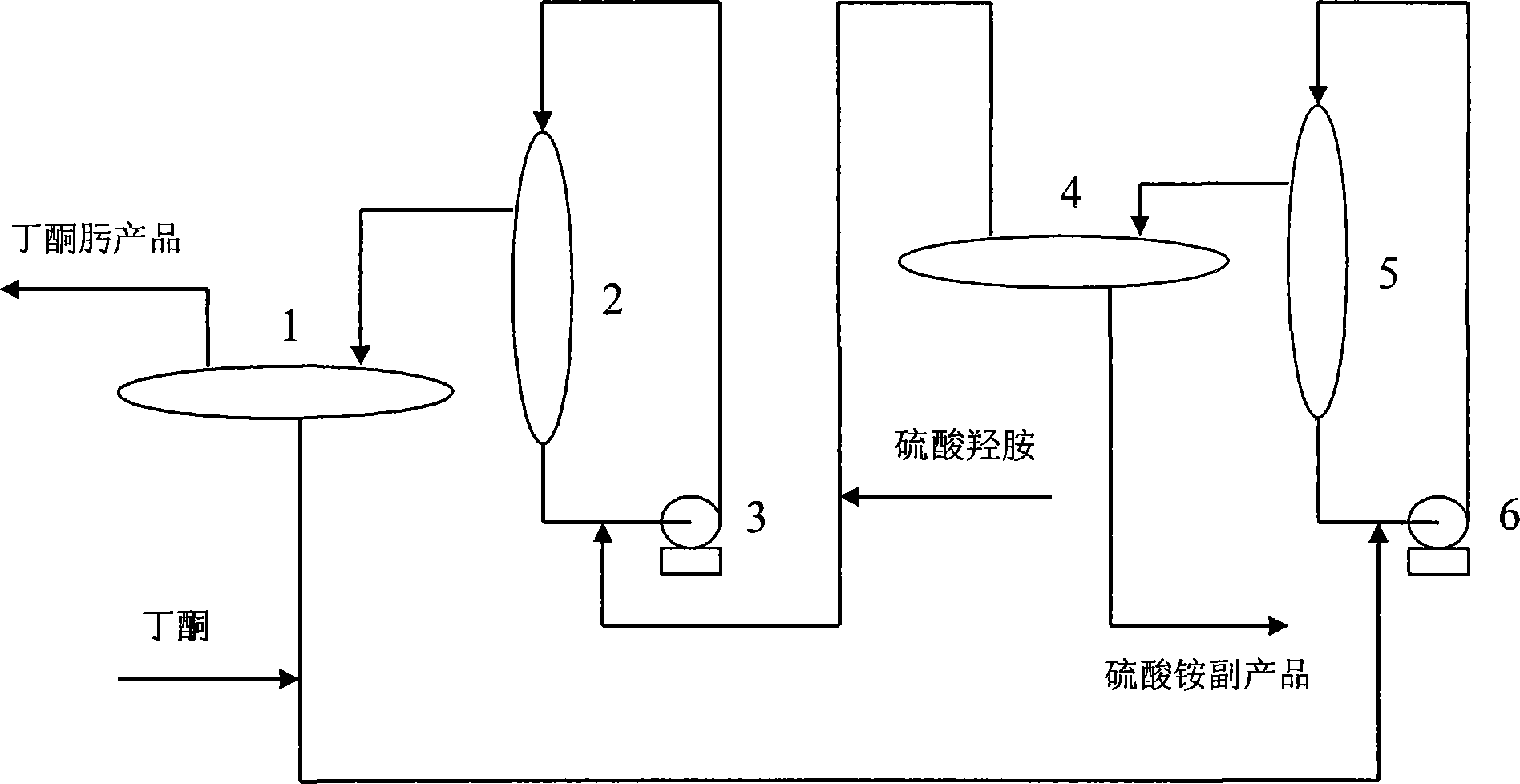

[0017] A butanone oxime plant adopts a two-stage countercurrent oximation process as shown in the attached figure, and its operating parameters are: the feed molar ratio of butanone and hydroxylamine sulfate is 1:1; 1 # The reaction temperature in the oximation reactor is 35°C-40°C, and the pH value is 5-5.5; 2 # The reaction temperature in the oximation reactor is 45°C-50°C, and the pH value is 3.5-4. The obtained butanone oxime product has a content of 99.9%, a water content of 0.02%, and a butanone content of 0.020%; the by-product ammonium sulfate contains hydroxylamine sulfate of 0.03 mg / l.

Embodiment 2

[0019] A butanone oxime plant adopts a two-stage countercurrent oximation process as shown in the attached figure, and its operating parameters are: the feed molar ratio of butanone and hydroxylamine sulfate is 1:1; 1 # The reaction temperature in the oximation reactor is 40°C-45°C, and the pH value is 4-4.5; 2 # The reaction temperature in the oximation reactor is 50°C-55°C, and the pH value is 3-3.5. The obtained butanone oxime product has a content of 99.9%, a water content of 0.02%, and a butanone content of 0.018%; the by-product ammonium sulfate contains hydroxylamine sulfate of 0.025 mg / l.

Embodiment 3

[0021] A butanone oxime plant adopts a two-stage countercurrent oximation process as shown in the attached figure, and its operating parameters are: the feed molar ratio of butanone and hydroxylamine sulfate is 1:1; 1 # The reaction temperature in the oximation reactor is 65°C to 70°C, and the pH value is 5 to 5.5; 2 # The reaction temperature in the oximation reactor is 70°C-75°C, and the pH value is 4-5. The obtained butanone oxime product has a content of 99.8%, a water content of 0.03%, and a butanone content of 0.022%; the by-product ammonium sulfate contains hydroxylamine sulfate of 0.035 mg / l.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com