Combined type radial dust removal and denitration reactor

A denitration reactor and combined technology, applied in chemical instruments and methods, dispersed particle filtration, gas treatment, etc., can solve the problems of large floor space, secondary pollution, and large catalyst consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

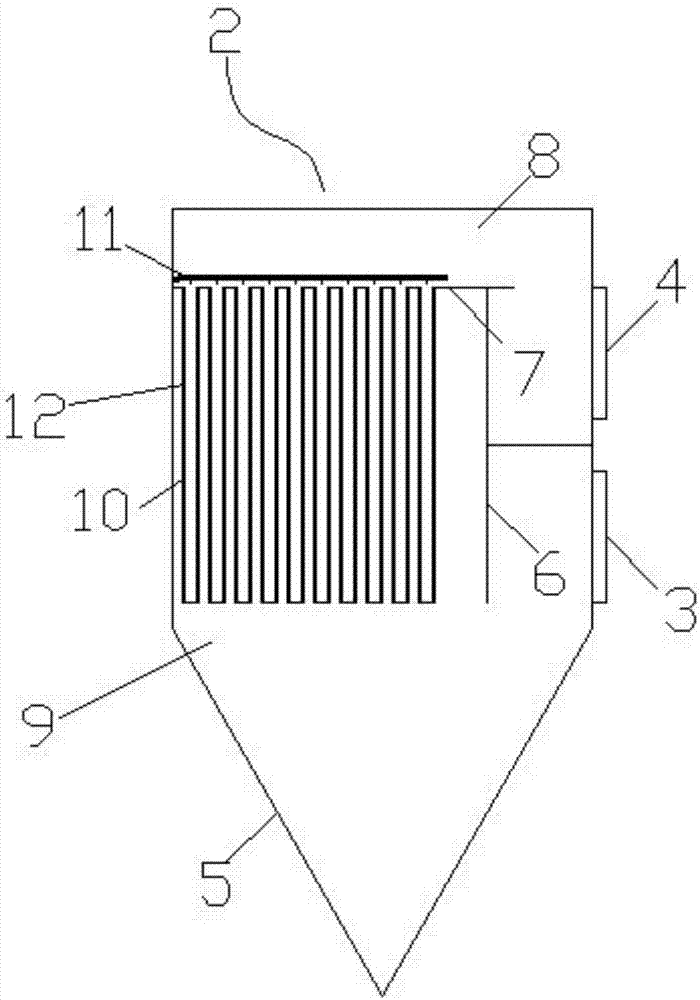

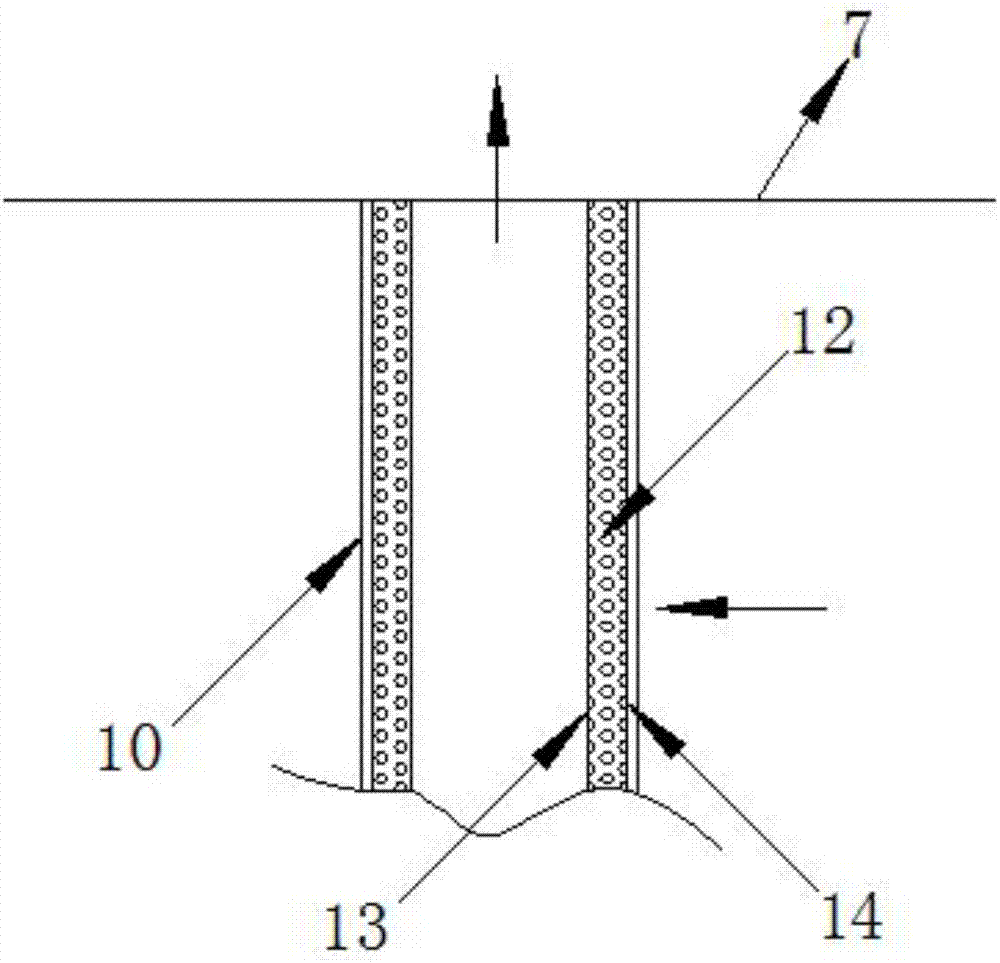

[0032] figure 2 is the schematic diagram of the first embodiment of the radial denitration bed, image 3 It is a partial view of the first embodiment.

[0033] like Figures 2 to 3 As shown, the radial denitration bed 12 is a bag-cage structure, and its shape is cylindrical, each radial denitration bed 12 corresponds to a dust removal bag 10, and the radial denitration bed 12 is close to the inner surface of the dust removal bag 10. , inserted into the bag cage of the dust filter bag 10, the radial denitration bed 12 includes an inner wall 13 and an outer wall 14, the inner wall 13 and the outer wall 14 are both mesh-shaped, and there is a space between the inner wall 13 and the outer wall 14 for flue gas Granular medium and low temperature SCR denitration catalyst for denitration.

no. 2 example

[0035] Figure 4 is the schematic diagram of the second embodiment of the radial denitration bed, Figure 5 A partial view of the second embodiment.

[0036] like Figures 4 to 5 As shown, the radial denitration bed 12 is a cover-type structure, and its shape is cylindrical, each radial denitration bed 12 corresponds to a dust bag 10, and the radial denitration bed 12 is arranged on the flower plate 7 and the soot blowing pipe. Between 11 and 11, the cover is buckled on the flower plate 7, and is located directly above the bag mouth of the dust bag 10. The radial denitration bed 12 includes an inner wall 13 and an outer wall 14, and the inner wall 13 and the outer wall 14 are both mesh-shaped. A granular medium and low temperature SCR denitration catalyst for flue gas denitration is placed between the inner wall 13 and the outer wall 14 .

no. 3 example

[0038] Image 6 It is a schematic diagram of the third embodiment of the radial denitration bed.

[0039] like Image 6As shown in the figure, the radial denitration bed 12 is a warehouse façade type structure, which is a panel shape, is vertically located in the upper warehouse 8 and is close to the part of the flue gas outlet, and its left and right two planes are mesh-shaped, and the two A granular medium and low temperature SCR denitration catalyst for flue gas denitration is placed between the planes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com