Sequencing batch type combined biofilm integrated apparatus for treating high concentration organic wastewater

A technology of organic wastewater and biofilm, which is applied in the field of environmental protection and sewage treatment, can solve the problems of large footprint, complex civil construction, inconvenient management, etc., and achieve the effect of small footprint, low investment and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the drawings and embodiments:

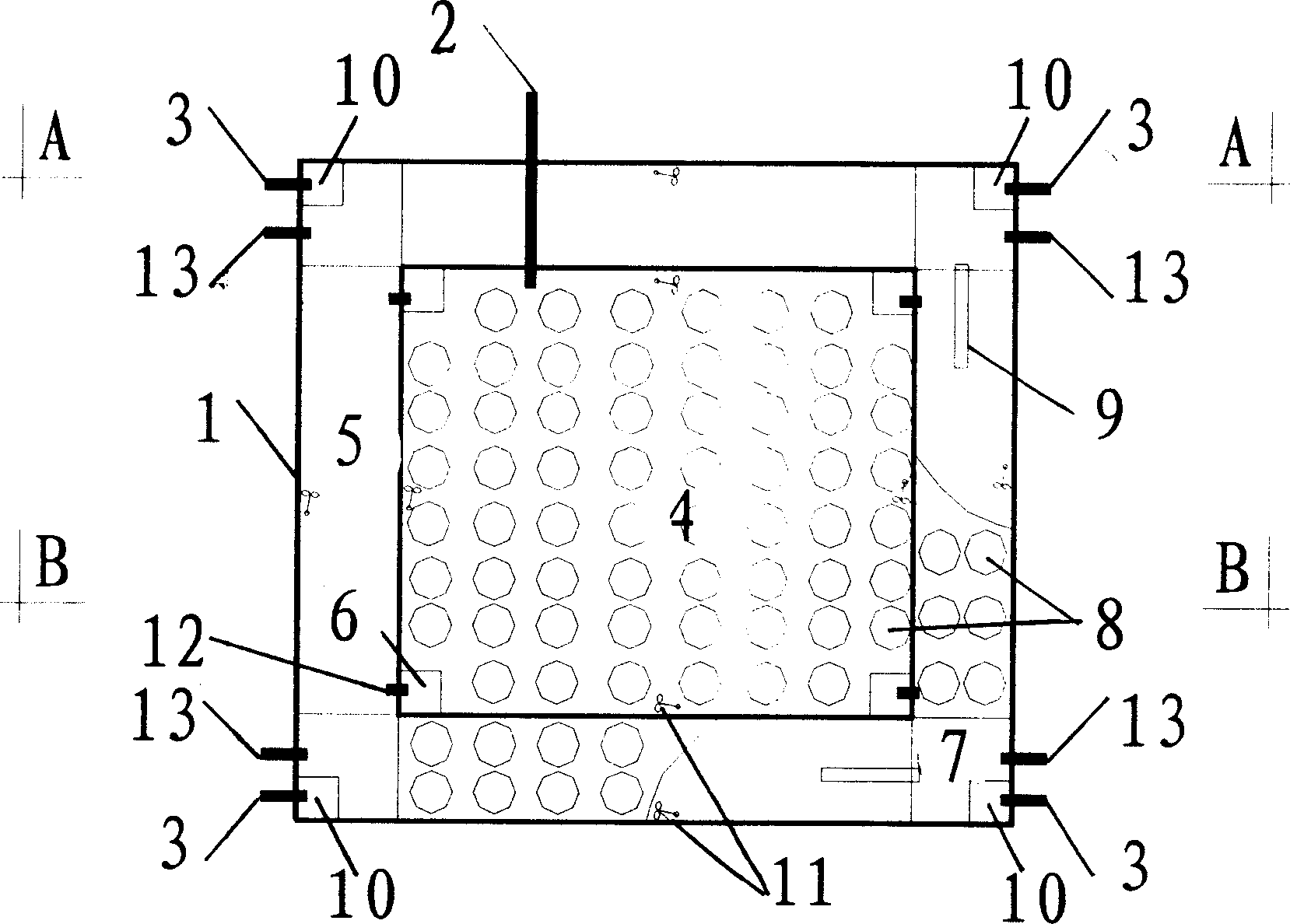

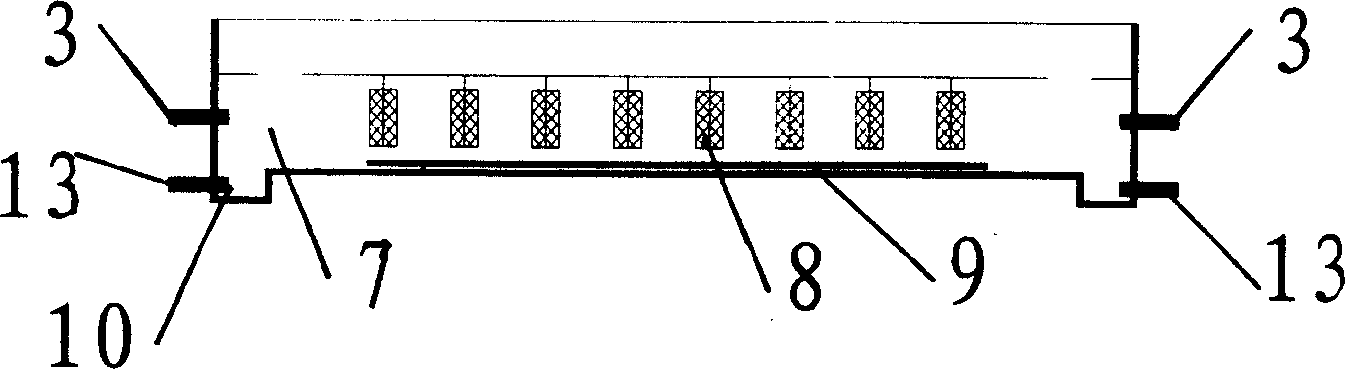

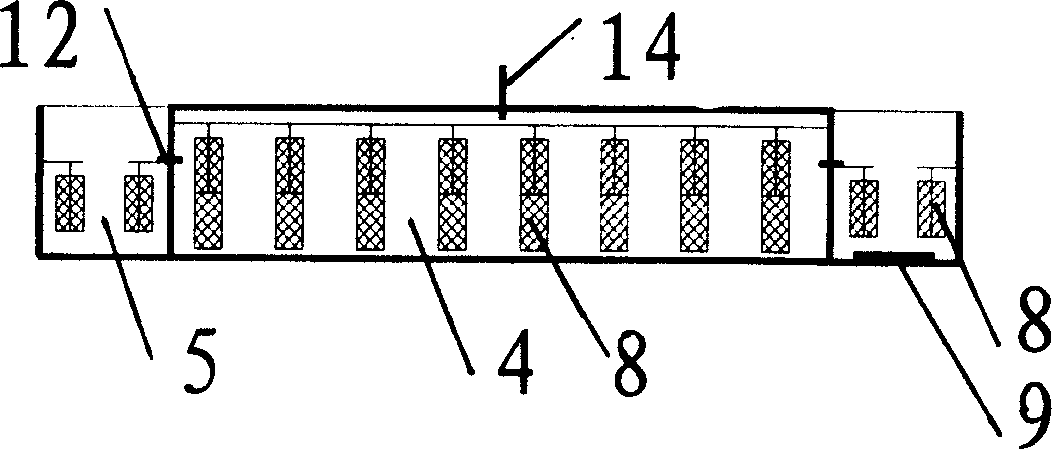

[0023] See figure 1 , 2 , 3. This treatment equipment is composed of a pool body 1, an inlet pipe 2, and a drain pipe 3. The tank body is divided into two reaction zones: the middle is the anaerobic submerged biofilm reaction zone 4, and the periphery is the aerobic submerged biofilm reaction zone 5, using a square tank body. Semi-soft fiber filler 8 is arranged in each reaction zone, and drainage zones 6, 7 are arranged on the four corners of each reaction zone. The water inlet pipe 2 of the equipment directly enters the anaerobic submerged biofilm reaction zone 4 from the upper part. The drainage area 6 of the anaerobic submerged biofilm reaction zone is connected to the peripheral aerobic submerged biofilm through a drain pipe 12 with a gate valve. Reaction zone 5. The aerobic submerged biofilm reaction zone 5 is also provided with a drain pipe 3 with a gate valve a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com