High-temperature and high-pressure slurry bed reaction device

A reaction device, high temperature and high pressure technology, applied in chemical/physical processes, chemical instruments and methods, etc., to achieve the effect of improving conversion rate, improving efficiency, and simple internal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment -1

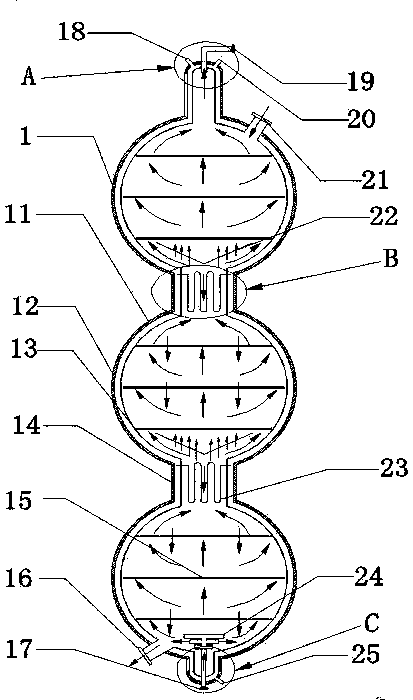

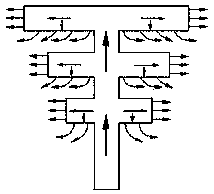

[0040] refer to figure 2 , the cold model experiment of the spherical series reactor was carried out. The spherical series reactor selected in the experiment was composed of three spherical reactors in series. The diameter of the outer shell of the spherical reactor was 500mm, and the diameter of the inner tank was 460mm; the diameter of the connecting cylinder was 200mm, and the height was 250mm; the inverted cone diameter of the conical deflector is 180mm, the height is 60mm, and the opening rate is 10%; each spherical reaction is placed with 3 ridge-shaped redistributors, and the coverage rate of each redistributor is 70%. The rate is 40%; the opening rate of the gas distributor is 1%.

[0041] Operating conditions: superficial gas velocity 0.1m / s, superficial liquid velocity 0.001m / s, solid density 960kg / m 3 , Alumina with a particle size of 150 μm has a solid content of 15%.

[0042] The relationship between gas holdup, solid holdup and radial position at the largest d...

Embodiment -2

[0044] The reactor used in Example-1 is subjected to cold mold amplification, and the operating conditions are consistent. The spherical series reactor selected in the experiment is composed of 3 spherical reactors connected in series. The diameter of the spherical reactor shell is 1000mm, and the diameter of the inner tank is 950mm; The diameter of the cylinder is 450mm, and the height is 400mm; the diameter of the inverted cone of the conical deflector is 350mm, the height is 100mm, and the opening rate is 10%; each spherical reaction places 3 ridge-shaped redistributors, and each redistributor The coverage rate is 70%, and the opening rate is 40%; the opening rate of the gas distributor is 1%.

[0045] The relationship between gas holdup, solid holdup and radial position at the largest diameter of the spherical reactor was measured. The uniformity of gas holdup in the reactor was 82%, and the uniformity of solid holdup was 86%.

Embodiment -3

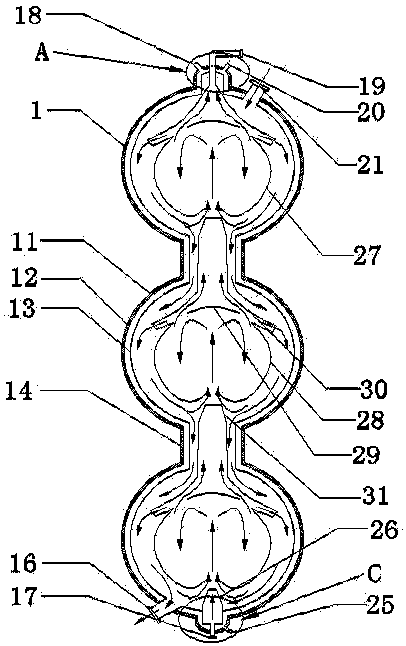

[0047] refer to image 3 , the cold model experiment of spherical series reactors was carried out, the solid and liquid phases were added at one time, and the outlet was closed. The spherical series reactor selected in the experiment is composed of three spherical reactors connected in series. The diameter of the outer shell of the spherical reactor is 500 mm, and the diameter of the inner tank is 460 mm; the diameter of the connecting cylinder is 200 mm, and the height is 250 mm. The diameter of the apple-shaped inner guide tube is 600mm.

[0048] Operating conditions: superficial gas velocity 0.1m / s, superficial liquid velocity 0.001m / s, solid density 960kg / m 3 , Alumina with a particle size of 150 μm has a solid content of 15%.

[0049] Measure the change of solid hold rate inside and outside the spherical guide tube with time, the average solid hold rate at the central position is 16.2%, and the average solid hold rate at the side wall is 13.3%. After 120 hours of contin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com