A processing device and processing method for processing blind holes in perforating guns in pairs

A processing device and processing method technology, applied in the direction of accessory devices, metal processing equipment, electric processing equipment, etc., can solve problems such as poor pressure bearing capacity, and achieve the effects of high processing quality, stable transmission, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

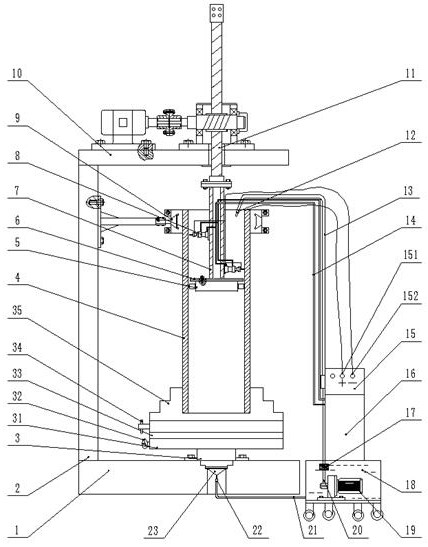

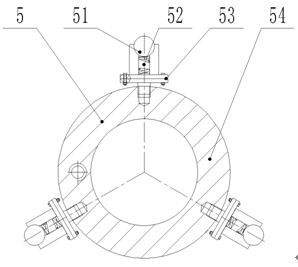

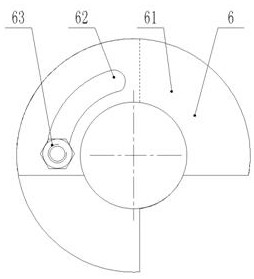

[0026] Referring to each figure, a processing device for processing blind holes in a perforating gun in pairs, the processing device includes a worktable 1, a moving and rotating mechanism 3, a spring guide wheel mechanism 5, a flow regulating device 6, a connecting frame 7, an electric spark Pulse power supply 15, electric discharge machining mechanism 8, supporting and fixing mechanism 9, power transmission mechanism 11 and working fluid circulation filtering system; the workbench 1 is fixed on the ground, and it plays a load-bearing role for the entire processing device; the moving and turning mechanism 3. Installed and fixed on the workbench 1, the mobile rotary mechanism 3 clamps and fixes the perforating gun frame 4, and can make it rotate; the mobile rotary mechanism 3 includes an indexing plate 31, an indexing plate hand wheel 32, and The blue plate 33, the three-jaw chuck 35 and the three-jaw chuck rocker 34, the index plate 31 are fixed on the workbench 1 by bolts, th...

Embodiment 2

[0028] A processing method for processing blind holes in perforating guns using a pair of processing devices for processing blind holes in perforating guns, the processing method includes the following steps:

[0029] The first step is to clamp the lower end of the perforating gun body 4 on the three-jaw chuck 35, and fix the upper end of the gun body through the supporting and fixing mechanism 9; the starting motor 111 moves the lifting screw 116 longitudinally through the power transmission mechanism 11, and connects The frame 7 and the EDM mechanism 8 extend vertically into the perforating gun body 4, and at the same time, the spring guide wheel mechanism 5 below the connecting frame 7 supports the righting EDM mechanism 8 until the paired tool electrodes 83 and the inner blind to be processed Turn off the motor 111 when the hole position reaches the same horizontal position;

[0030] The second step is to rotate the perforating gun frame 4 by moving the rotary mechanism 3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com