Anaerobic baffled reactor suitable for dyeing and finishing wastewater treatment

A technology for anaerobic deflection and dyeing and finishing wastewater, which is applied in textile industry wastewater treatment, anaerobic digestion treatment, waste fuel, etc., can solve the problems of increased difficulty in wastewater treatment, fluctuation of effluent water quality, and poor decolorization effect, etc. Back-mixing phenomenon, small hydraulic dead angle, and the effect of reducing disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

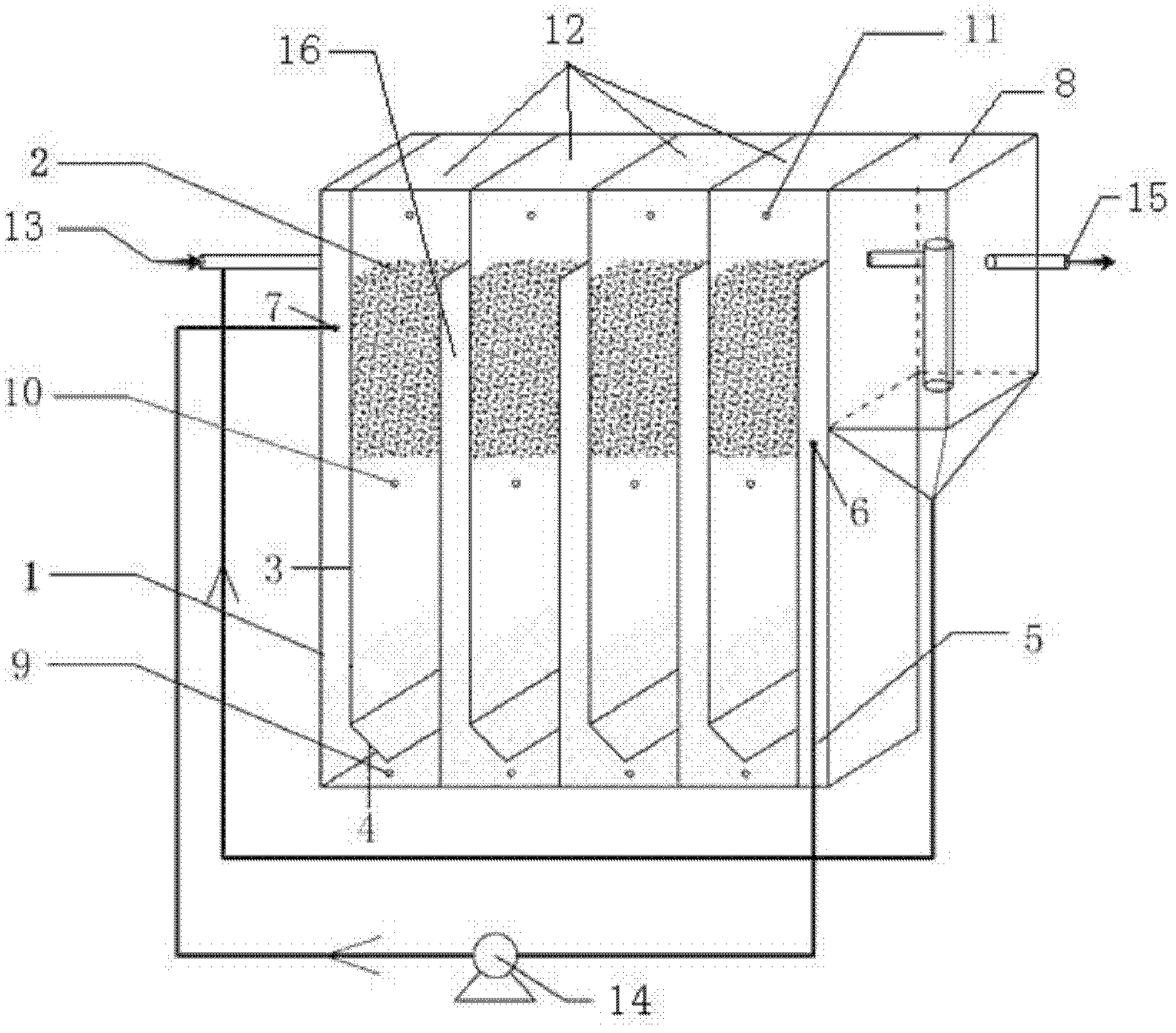

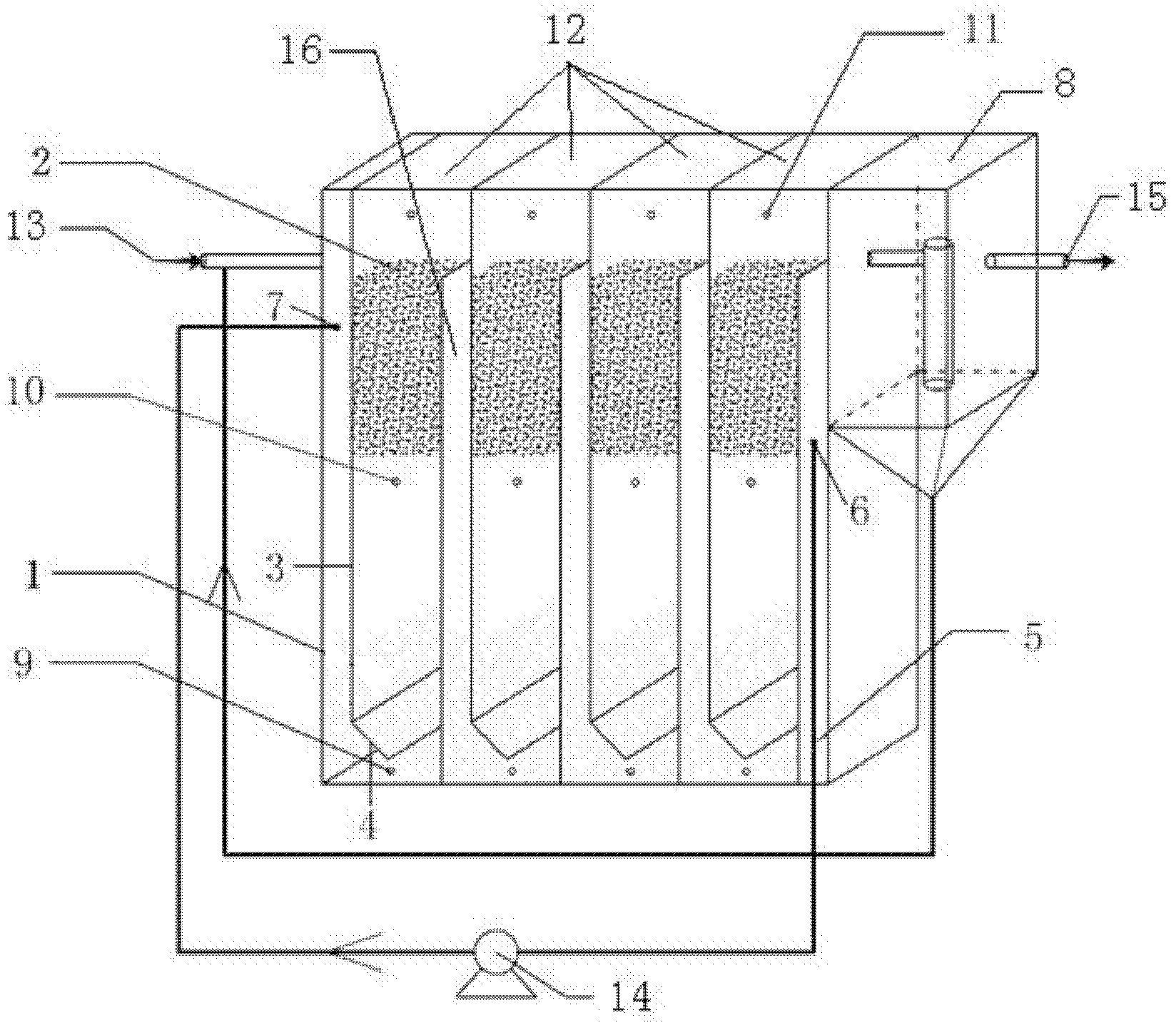

[0017] To treat high-concentration desizing wastewater from a printing and dyeing enterprise, the box is divided into four baffle chambers 12 with an effective volume of 80L. It is an anaerobic granular sludge layer of 5 kg, and composite fillers are loaded into the filler layer 2. The volume of the fillers is 30% of the effective volume of each baffle chamber 12. The composite fillers are cylindrical plastic particles with a cross-sectional diameter of 3-10 mm. Adopt the low-load start-up method, start the reactor to maintain the hydraulic retention time HRT of 24-32h, use the dilution method to control the organic load in the printing and dyeing wastewater, and increase it by no more than 0.5kgCOD / m every 7 hours 3 .d load, until the maximum load is reached, and a stable removal rate can be reached after 60 days.

[0018] Enter the high-concentration desizing waste water inlet 13 into the baffle chamber 12, use a pump to return the waste water from the reflux chamber 5 to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com