Reaction device and process for preparing cyclohexene by selectively hydrogenating benzene

A technology for preparing cyclohexene and hydrogen, applied in the field of chemical equipment, can solve the problems of high by-product rate, high energy consumption, low conversion rate of cyclohexene, etc., and achieve the effects of reducing loss, high yield and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

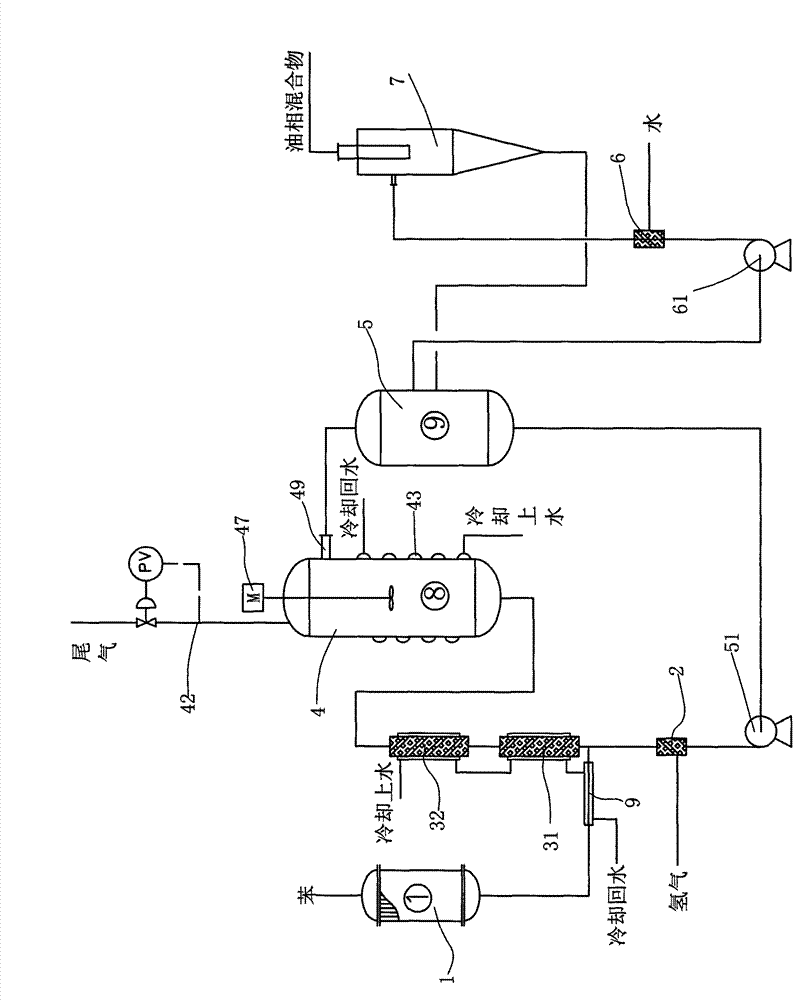

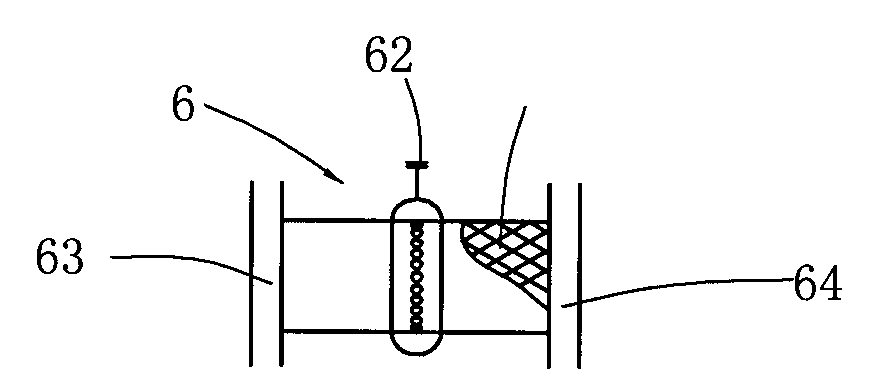

[0052] Such as Figure 1 to Figure 5 As shown, the selective hydrogenation of benzene to prepare cyclohexene reaction unit comprises:

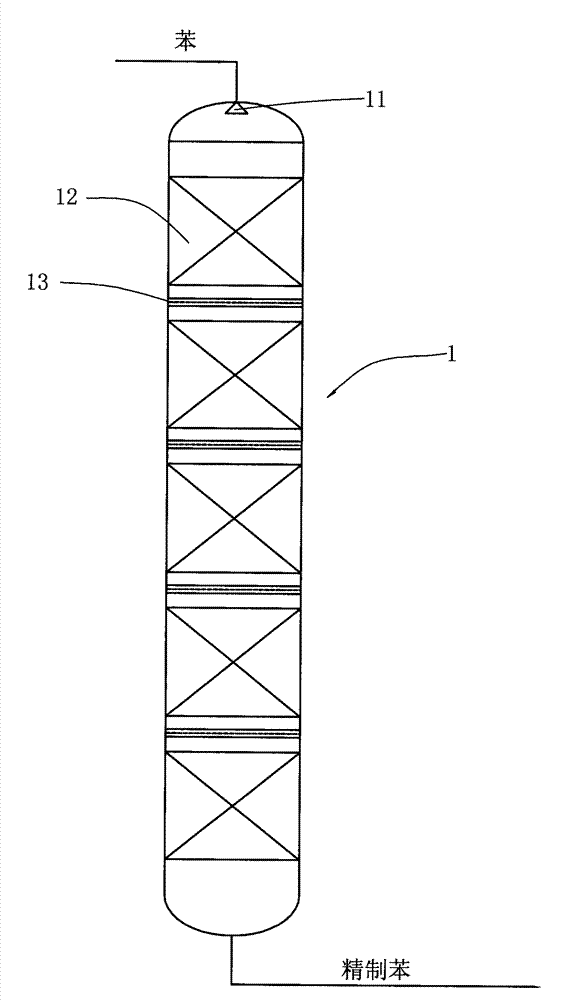

[0053] The benzene refiner 1 is equipped with an adsorbent packing layer 12 filled with desulfurization adsorbent, which is a fixed bed layer; a high-efficiency nozzle 11 and a liquid redistributor 13 are installed at the entrance of the benzene refiner. The liquid redistributor has four layers spaced between the layers of adsorbent packing. The liquid redistributor is a disc-type sieve structure, the sieve hole diameter is 2-8mm, and the sum of the surface areas of each sieve hole is 5-20% of the cross-sectional area of the benzene refiner. The outlet of the benzene refiner is connected to the benzene inlet of the first static mixing reactor 31 after heat exchange by the jacketed heat exchanger 9 .

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com