System and method for removing benzene in natural gas

A natural gas and benzene removal technology, which is applied in the field of natural gas benzene removal, can solve the problems of large investment in absorption tower equipment and lower benzene removal efficiency, and achieve the effect of reducing the number of theoretical plates, reducing equipment investment, and improving removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

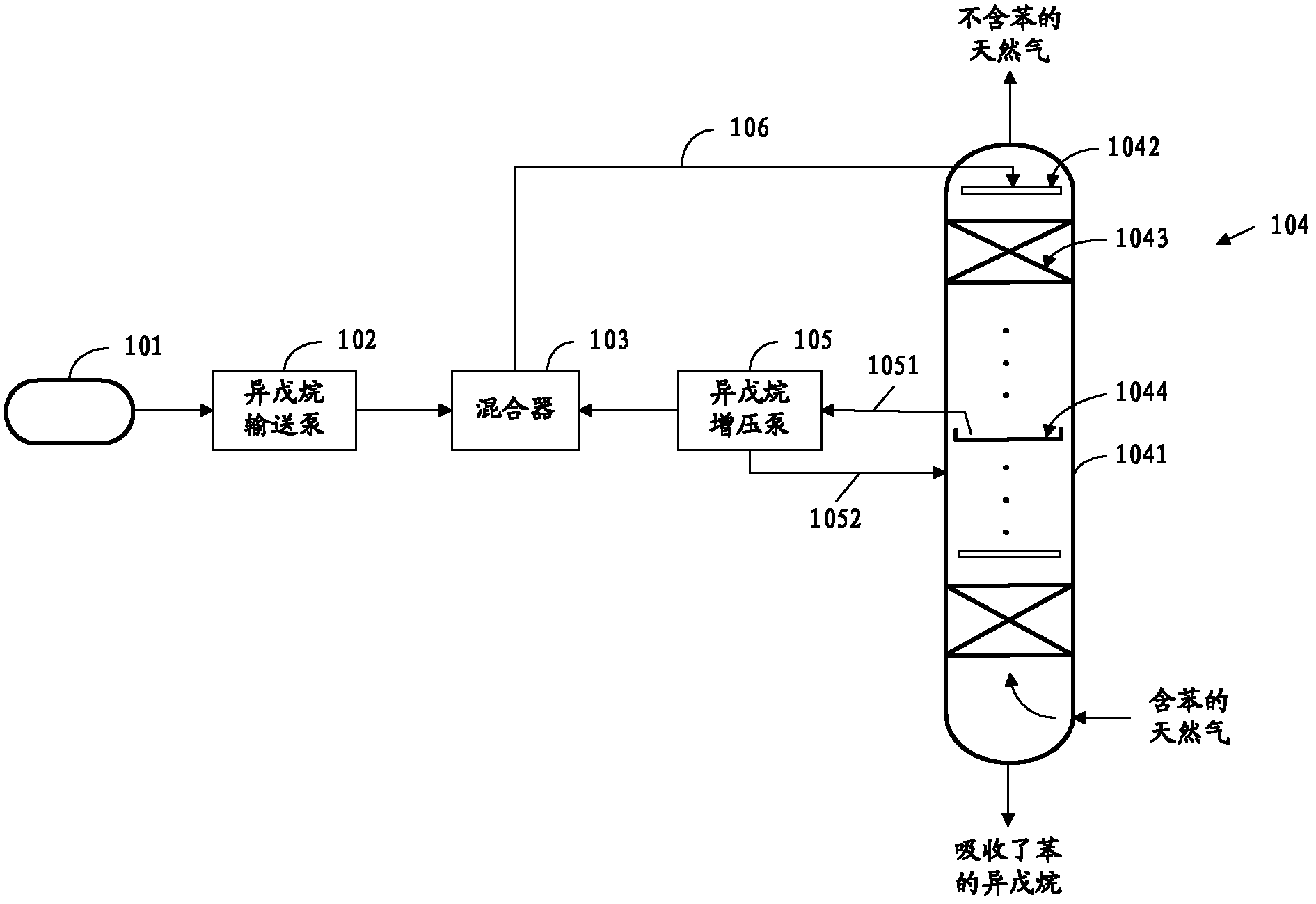

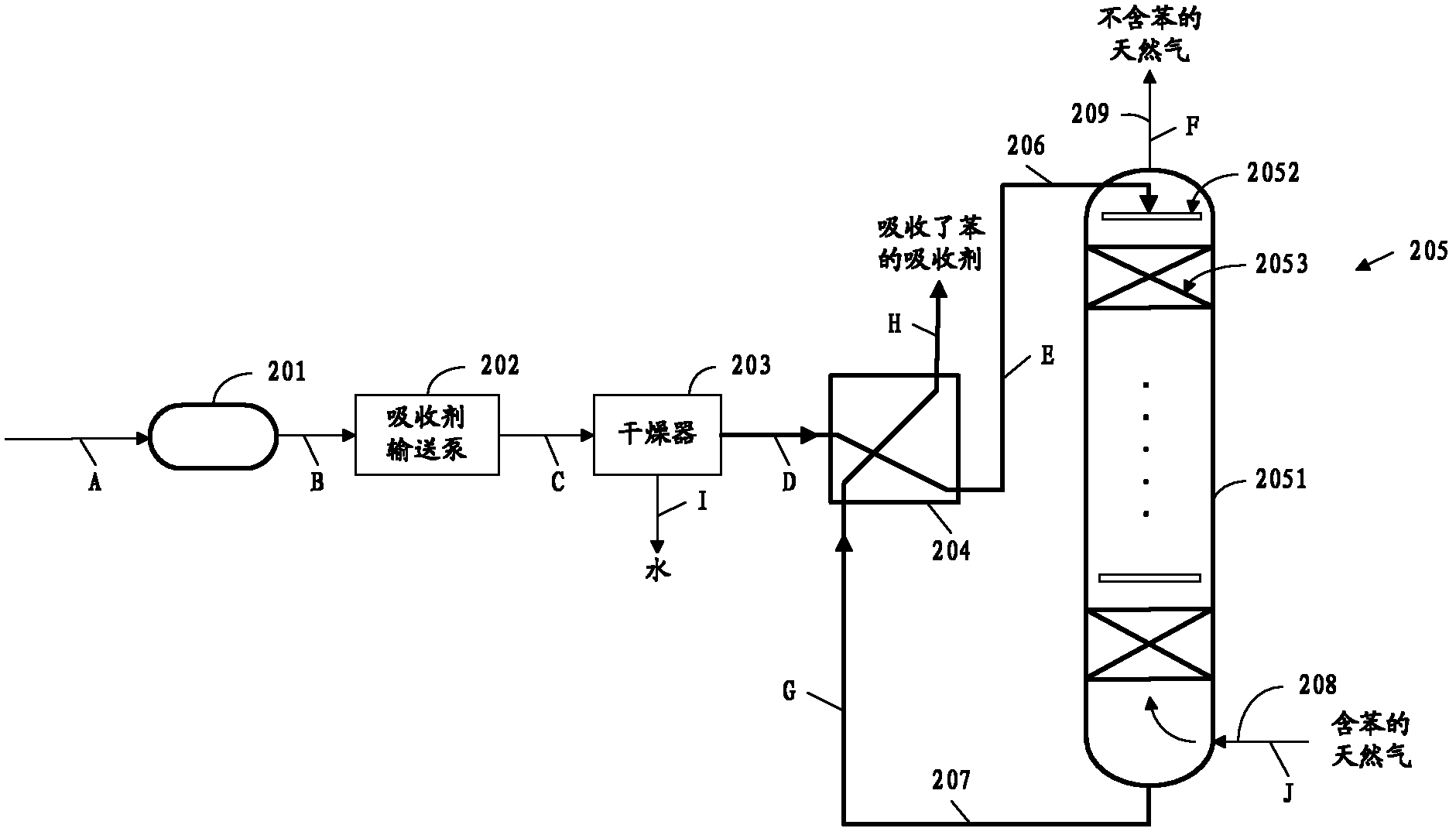

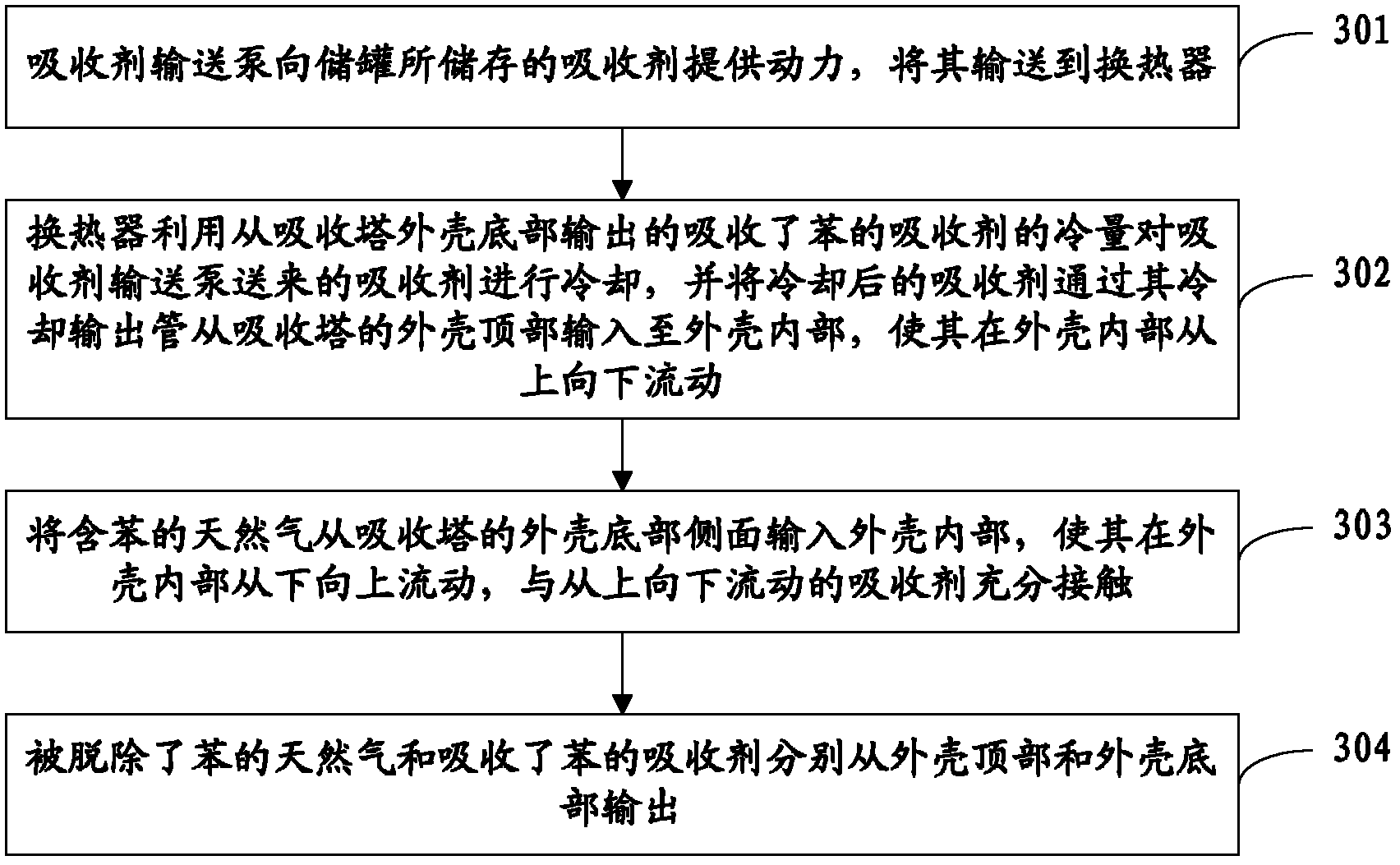

[0034] figure 2 It is a structural diagram of a system for removing benzene in natural gas proposed by the present invention. Such as figure 2As shown, the system includes: a storage tank 201 for storing absorbent; an absorbent delivery pump 202 connected to the storage tank 201 to provide power to the absorbent therein; an absorption tower 205; a bottom side of a housing 2051 connected to the absorption tower 205 to The natural gas input pipe 208 for inputting the benzene-containing natural gas into the shell 2051 and the natural gas output pipe 209 connected to the top of the shell 2051 to export the natural gas from which benzene has been removed; the heat exchanger 204 for cooling the absorbent input to the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com