Device for preparing styrene through dehydrating phenethyl alcohol as well as method

A technology of styrene and phenylethyl alcohol, which is applied in the field of styrene dehydration equipment, can solve the problems of local uneven mixing, long residence time, main reaction selectivity and conversion rate reduction, etc., so as to reduce the occurrence of side reactions, The effect of reducing equipment investment and reducing residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

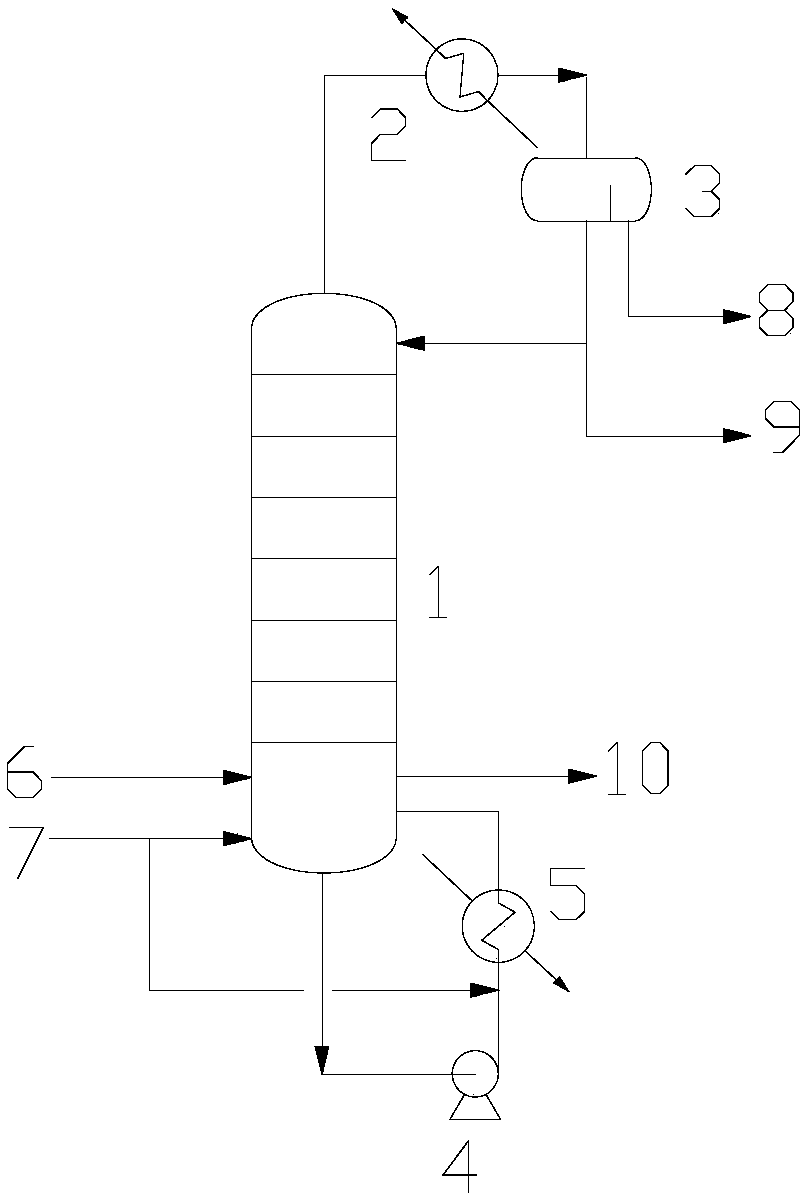

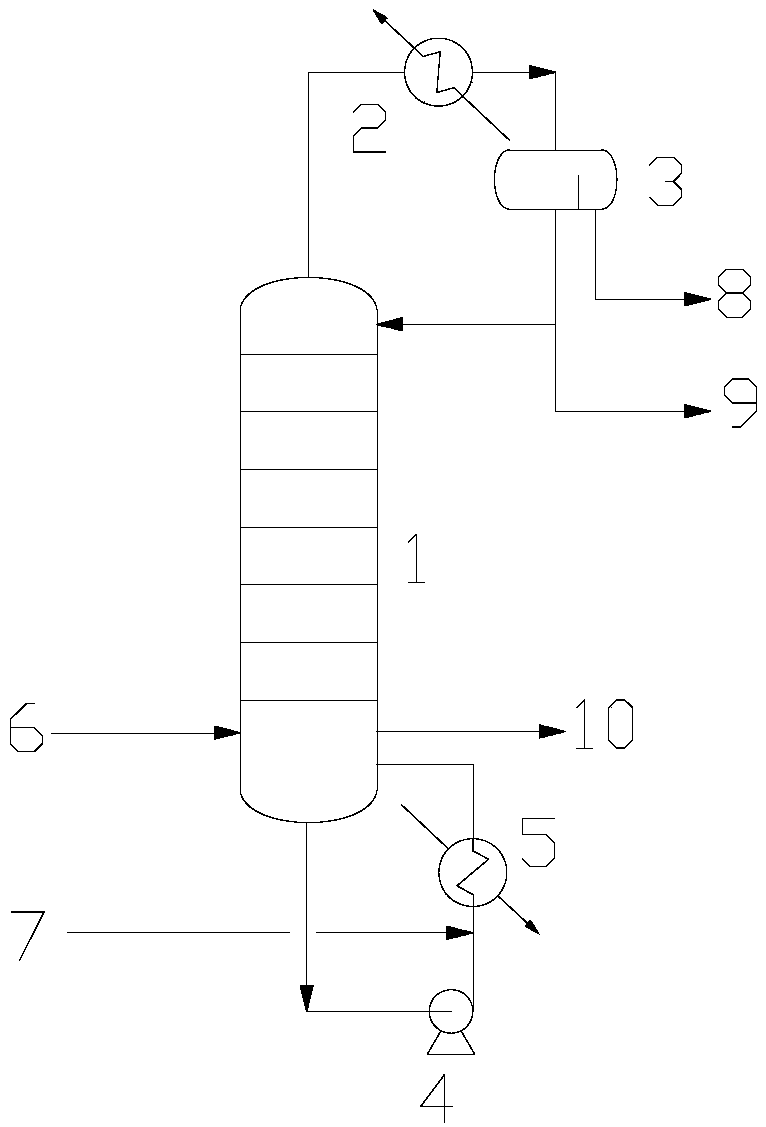

[0040] use as figure 2 The device for preparing styrene by dehydration of phenylethanol is shown to carry out the reaction of preparing styrene by dehydration of phenylethanol.

[0041] The device comprises: a dehydration tower 1, a dehydration tower condenser 2, a dehydration tower reflux tank 3, a dehydration tower recirculation pump 4, a dehydration tower reboiler 5; wherein, a catalyst feed line 6 is connected to the dehydration tower retort; Feed line 7 is connected to the inlet of dehydration tower reboiler 5; the top of dehydration tower 1 is connected to dehydration tower condenser 2 and dehydration tower reflux tank 3 in turn; dehydration tower reflux tank 3 is connected to dehydration tower 1; the bottom of dehydration tower 1 is connected to dehydration tower kettle circulation in turn Pump 4, dehydration tower reboiler 5; the outlet of dehydration tower reboiler 5 is connected to dehydration tower 1; wherein, the dehydration tower reboiler 5 is a shell-and-tube he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com