System comprising the gasification of fossil fuels to process unconventional oil sources

a fossil fuel and oil processing technology, applied in gasification process details, gas purification by non-gaseous material condensation, inorganic chemistry, etc., can solve the problems of high cost of injecting steam, uneconomical cost of steam injection, and difficulty in small-scale economics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Plasma Gasification System Integrated with an IGCC

[0698]This example describes a plasma Gasification System integrated with an IGCC. The plasma Gasification System comprises a converter, solid residue conditioner, a GCS, and a gas storage or regulation system, integrated with use of a combined-cycle to produce electricity.

[0699]As shown in FIG. 119, coal 106 is combined with oxygen from an oxygen plant 105 in the converter 100 to produce syngas, which is mainly hydrogen and carbon monoxide. The syngas is then cooled in a heat recovery steam generator (HRSG) 120 and then cleaned by a gas cleanup process in a GCS which includes the steps of scrubbing the syngas in a scrubber 130, removing particulate matter and heavy metals from the syngas in a baghouse 140, and H2S removal in an H2S removal system 150. The cleaned or conditioned gas is then stored or regulated in a gas storage or regulation system 160 prior to being fed to a gas turbine 170 for the production of electricity.

Combined-...

example 2

Configurations of Gasifiers Suitable for Use

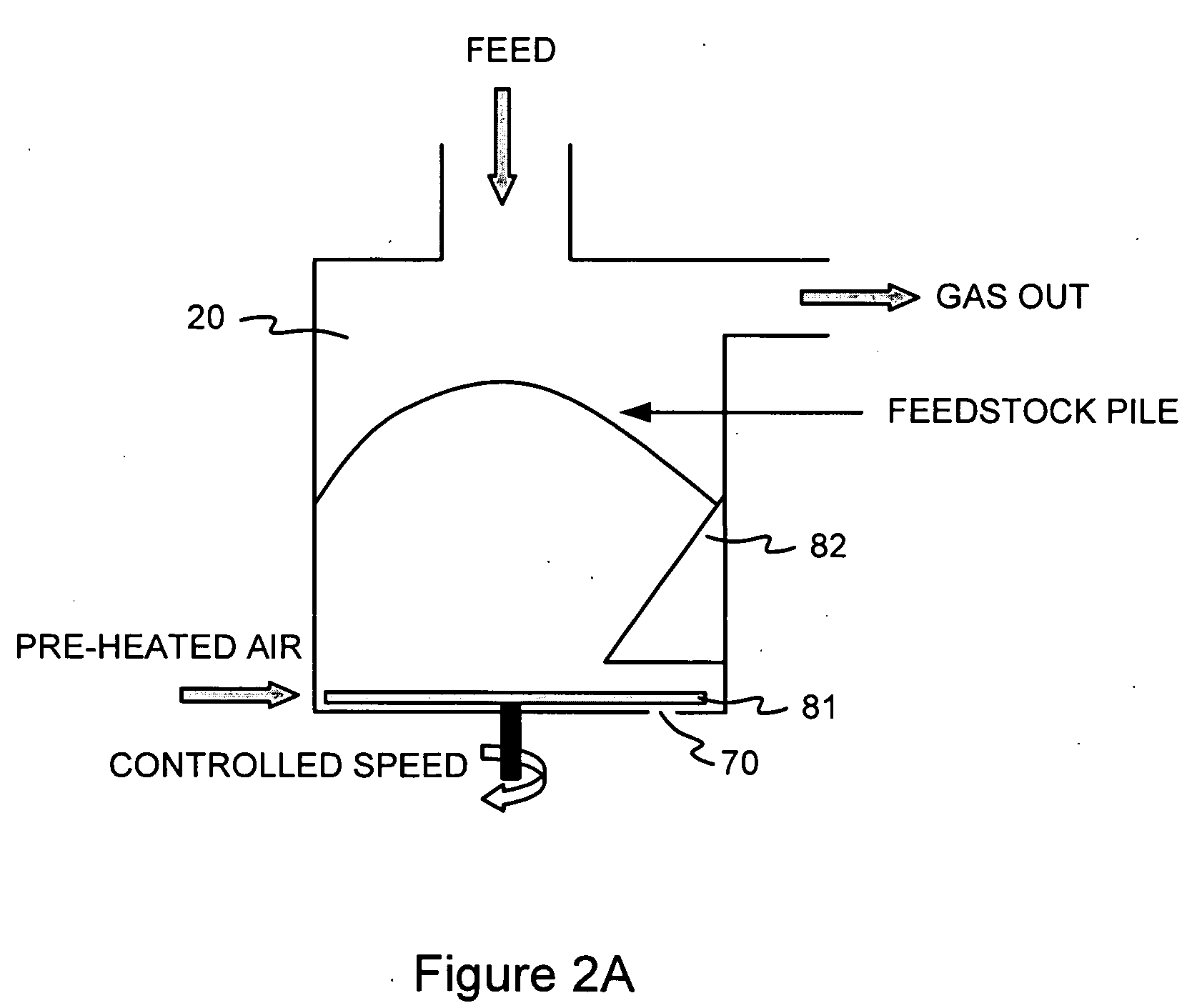

[0701]FIG. 121A to D depicts various examples of gasifiers that can be used in the system of the invention.

example 3

Design of a GCS for Use in the System of the Invention

[0702]FIG. 122 depicts an example of a GCS that is designed for use in tar sands applications. As shown in FIG. 122, gas from the gasifier is cooled, particulates are removed, as is heavy metal and H2S. The conditioned gas is then fed to a gas boiler for the production of steam.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com