Catalytic down-hole upgrading of heavy oil and oil sand bitumens

a technology of heavy oil and oil sand bitumen, applied in the direction of physical/chemical process catalysts, fluid removal, borehole/well accessories, etc., can solve the problems of difficult production and upgrading, the project of upgrading mostly does not provide a high degree of upgrading, and the reaction can be both destructive and non-destructiv

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

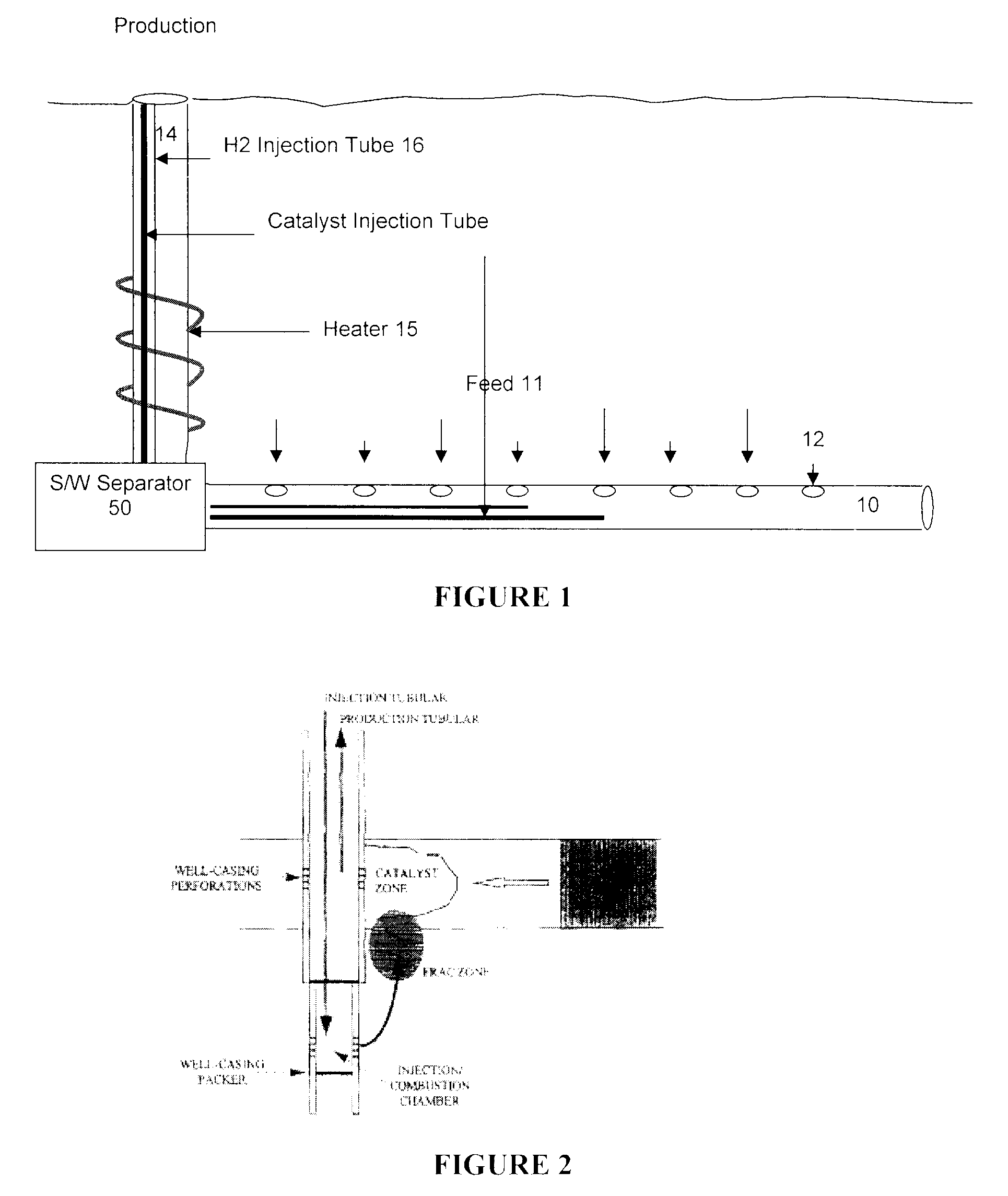

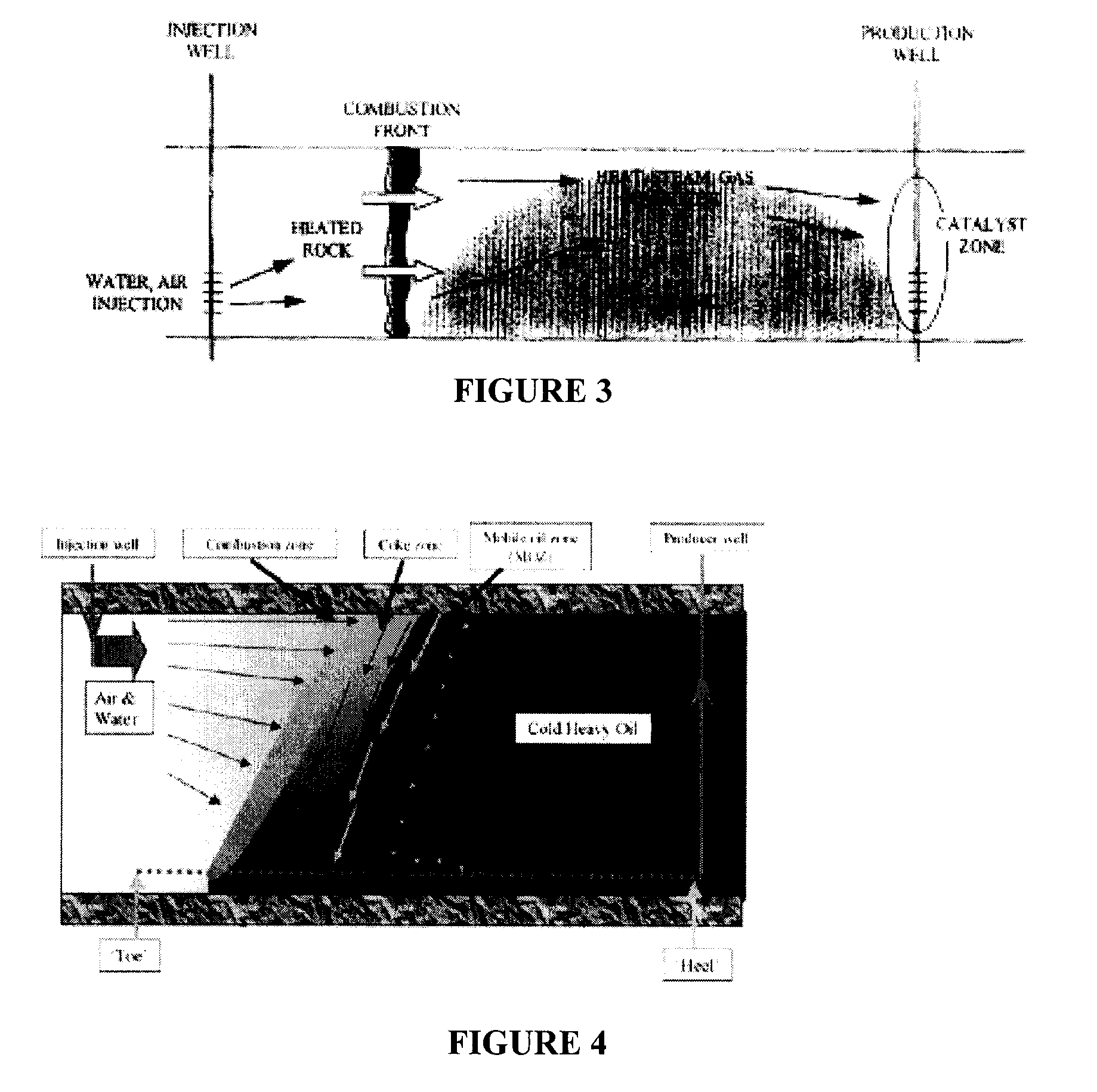

[0097]In accordance with the invention and with reference to the figures, systems and methods for upgrading hydrocarbons within a petroleum reservoir are described. In particular, the methods enable upgrading of heavy, extra heavy and shale oils and bitumen within a production well bore using selective downhole heating elements, hydrogen and catalyst injection so as to integrate exploitation with in-situ upgrading. The methods of the invention are particularly applicable to steam-assisted gravity drainage (SAGD) and vapor extraction (VAPEX), and cyclic steam stimulation (CSS) recovery methodologies.

[0098]In a preferred embodiment, as shown in FIG. 1, the invention provides a system for hydrocarbon upgrading in a well bore system having both horizontal and vertical sections. As discussed below, the methodologies of the invention may be applied to other EOR techniques including wells having only a single vertical section. As shown in FIG. 1, the horizontal section 10 serves to collect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com